Gillette - AmCham Technology Committee

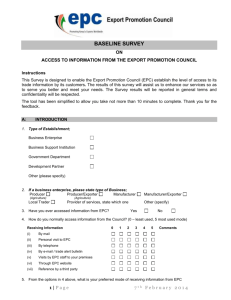

advertisement

Andrew S. Houlberg General Manager November 23, 2004 andrew_houlberg@gillette.com Agenda Company background Main message: RFID: An Enabling Technology for Maximizing Retail Availability Case study details Video of the project Summary & Next Steps Q&A Global Company with well known brands Sales worth US$9.3 Billion 60% of sales & profits originate outside U.S.A. Selling products in over 200 countries More than 30 manufacturing facilities worldwide …each day, more than a billion consumers choose our products In the shops: An Empty Shelf Is Often a Reality Everyone Suffers: Retailers, Consumers & Manufacturers High Velocity Items Suffer Even Higher Rates of Out-of-Stock, Varying by Hour Number of OOS Items – Top 2000 UPCs 18% 360 350 340 Number of OOS Items per Store 330 320 310 300 290 280 15% 270 260 250 Sat Sun Sun Mon Mon Tue Tue Wed Wed Thu Thu Fri Fri Sat 12pm 12am 12pm 12am 12pm 12am 12pm 12am 12pm 12am 12pm 12am 12pm 12am First the Brand Suffers, then the Store Consumer Reaction to Stockouts (%) Substitution 69% 50% 31% No Purchase / Change to Different Store 31% 50% 69% 1st Time 2nd Time 3rd Time Source: ECR Europe The Causes: Numerous and Often Unclear Store staff don’t know when shelves are empty Can’t find the product in the backroom to restock Book inventory records not accurate Supply chain shrinkage further corrupts the data Automatic replenishment programs compromised Store Shelf Store ‘Backroom’ Customer Distribution Center Transportation Manufacturer’s Warehouse Packaging Manufacturing Today’s Supply Chain are Functional Silos Goal: That Gillette Products be Available to Shoppers All the Time Main Message: Size of the Prize is Huge: US$1Billion Gillette is a $10 billion Company: At 10% Out of Stocks maximum today Cost the Company up to US$1 billion in lost sales Discounted by 50%, still worth US$500 million in new sales! RFID enabling technology could be the “Silver Bullet“ Create Electronic Product Codes (EPC) storing needed data For Manufacturer, Retailer & Consumer, New RFID Based EPC Offers Benefits Global Value Chain: Seamless Interaction & No Out-Of-Stocks Manufacturing Packaging Manufacturer’s Transportation Warehouse Tagged cases/pallets – Within Gillette’s '4 Walls' Customer Distribution Center Store Backroom Store Shelf Tagged cases/inner packs/pallets – Collaborate with Customer Unit level tagging How is Gillette Getting Ready? Organizational Structure Strategic Focus Pilot Testing & Learning Business Case Working with Retailers RFID & EPC Have CEO Support Gillette CEO Gillette Senior EPC Steering Committee Gillette EPC Implementation Team (Cross-Functional) Value Chain RFID IT Engineering MFG Marketing Customer/ Sales Corporate Communications Finance Legal EPC Implementation Team "Work Groups" Focus on Key Priorities Technology Hardware / Software Development System Integration EPC Standards Engineering Research "Strategic Roadmap" Business Case Development Implementation Strategy Strategy Process Process Mapping Change Process Development Sharing Key Learning's Strategic Partnerships Pilot Testing Implementation Customer Breakthrough Goal Research & Development Oct. 99 00 01 02 Tests & Pilots 03 04 Early Adopters Early Followers Breakthrough Zone Stretch Zone 05 06 07 08 09 Followers Predictable Zone 10 Auto-ID Center Launch Symposium Aggressive timetable set for limited early adoption at case and pallet level beginning in late 2004 and expanding in 2005 Manufacturers Ship Tagged Pallets/Inner Packs/ Cases to Retailer Distribution Centers What’s happening • Cases/inner packs are tagged by CPG manufacturers Benefits • Throughout the rest of the supply chain, each case/inner pack can be tracked and counted • Orders are shipped with 100% accuracy Shipping dock door MANUFACTURING PLANT OR DISTRIBUTION CENTER XPLANATiONS® BY XPLANE® Gillette Warehouse Pilot Goal Track 100% of all Venus cartridges (cases/pallets) within Gillette’s ‘4 Walls’ Prove the technology Develop a scaleable solution Validate the business case Video explanation Pilot Summary Cases had been RFID tagged & correctly scanned: 100% were successfully aggregated to pallets All were verified moving from Pack Center to DC to "exit points" Significant learning Process Technology Data capture and management Infrastructure Continuing to test, learn and expand Connecting with key customer (Wal-Mart) Designing the Value Chain of the Future with Electronic Product Coding (EPC) EPC Manufacturing Packaging EPC EPC Manufacturer’s Transportation Warehouse EPC Customer Distribution Center EPC Store Backroom Store Shelf EPC In Customer: “Tagged” Cases/Inner Packs Arrive at Store and Read, Real-Time, in Back Room Back room inventory EPC-tagged cases/inner packs are received and automatically reflected in system as backroom inventory. Backroom to sales floor POS system Receiving doors RETAIL STORE XPLANATiONS® BY XPLANE® Retailer: Real-Time POS Combined with Accurate Book Inventory Predicts OOS EPOS • 24 units sold from floor • 12 cases in backroom EPC INITIATE • Restock shelves • Re-order BACKROOM AND CHECKOUT XPLANATiONS® BY XPLANE® If RFID EPC Works: Benefits are Increased Sales & Profits As a retailer, Shoppers will be more satisfied, buy more products, and be more loyal if they find what they are looking for the first time ... .......results in more profits As a manufacturer or supplier, Retailers will buy more because they sell more, less urgent deliveries, and greater market share....... ......results in more profits EPC Adoption Timetable 'Best Guess' Expansion Early Adoption by Lead Retailers (More Retailers, Products & Locations) Becomes the Standard Case / Inner Pack / Pallet 2005-7 2008-12 2013+ Unit / Shelf 2007-9 2010-14 2015+ How Do We Recommend Getting Started? 1. Gain top management support 2. Understand your business case – create a vision 3. Map your current processes: physical, network, trading partners, etc. 4. Determine your plan: hardware, software, infrastructure, etc. 5. Assemble cross functional team 6. Begin pilot implementation 7. Measure and capture learning 8. Develop your change process and business case 9. "Launch & Learn” 10. Join Global Data Synchronization initiative and EPCglobal Join EPCglobal Visit site Understand their role Review benefits Vendor lists/contacts Business cases Other resources www.epcglobalinc.org Thank You!