R 1

advertisement

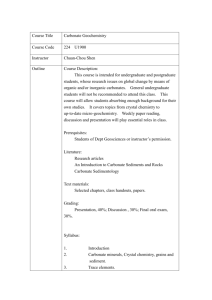

Nonisocyanate Polyurethanes Systems and Cyclic Carbonates Oleg L. Figovsky, D.Sc., Professor, Academician of European Academy of Sciences, Director R&D of Nanotech Industries, Inc. and INRC Polymate, Editor-in-chief of journals – ICMS (USA), SITA (Israel), Chairman of the UNESCO Chair "Green Chemistry" 1 Polyurethanes Polyurethanes (PUs) is a product of the addition polymerization reaction between diisocyanates and diols. The demand in PUs has continued to increase and it will attain in 2016 a production of 18 million tons (~US$66.4 bln) of which 75% are foam. The main environmental issue of PU materials concerns the use of isocyanate raw materials. In fact, these compounds are harmful for human and environment. MDI and TDI, the most widely used isocyanates in PU industry, are classified as CMR (Carcinogen, Mutagen and Reprotoxic): Merenyi S. REACH: regulation (EC) No 1907/2006: consolidated version (June 2012) with an introduction and future prospects regarding the area of Chemicals legislation. GRIN Verlag; 2012. 2 Among all methods of non-isocyanate synthesis of polyurethane, reaction of cyclic carbonate with amine is the most attractive. NIPU – Non-Isocyanate PolyUrethane HNIPU – Hybrid Non-Isocyanate PolyUrethane 3 Historical inventions in the field of NIPU – HNIPU Fundamentals for the practical application of NIPU on the basis of five-membered cyclic carbonates (1,3-dioxolan-2-ones) in coatings, sealants, adhesives, etc. were largely developed by L. Rappoport, O. Figovsky, V. Mikheev, V. Stroganov et al. in the 1970 – 1990’s Soviet Union patents: SU 351835, 1972 – Cyclic carbonate synthesis SU 359255, 1972 – Polyhydroxyurethanes SU 413824, 1983 – NIPU hardeners SU 422262, 1978 – Polycyclic carbonate polydiens SU 426493, 1978 – Polycyclic carbonate polydiens SU 441805, 1978 – acrylic cyclic carbonate SU 462478, 1975 – Dienehydroxyurethanes SU 671318, 1984 – Cyclic carbonate synthesis SU 707258, 1984 – Cyclic carbonate synthesis RU 970856, 1996 – Polydienehydroxyurethanes SU 1110783, 1984 – Cyclic carbonate synthesis SU 1126569, 1984 – Cyclic carbonate synthesis SU 529197, 1976 – Coating, sealant SU 563396, 1977 – Polymer concrete SU 628125, 1978 – Polymer concrete SU 630275, 1978 – Coating, sealant SU 659588, 1979 – Sealant SU 518506, 1976 – Urethanediols SU 812797, 1981 – Coating SU 903340, 1982 – Polymer concrete SU 908769, 1982 – Polymer concrete RU 1770324, 1992 – NIPU foam SU 1754747, 1992 – Coating SU 1754748, 1992 – Coating 4 Non-amine curing of hybrid oligomer compositions SU Patent 722206, Figovsky O.L. et al. Hybrid anticorrosion composition on the base of epoxy resin includes hydroxyphenyl ester of phosphoric acid (OEPA). OEPA is the reaction product of alkyl resorcinol fractions shale phenols with orthophosphoric acid. Hybrid composition cure at ambient temperatures (+5 - +35o C) 5 Reaction of cyclocarbonates with amines has long been used in the pharmaceutical: Preparation of hydroxyaromatic esters of substituted carbamic acids SU Patent 722082, Figovsky O.L. et al. by reaction of aromatic amines with arylen cyclic carbonates at temperatures 20-100o C R1-Ar[NHCOO-Ph(o-OH)(R)]m m = 1, 2, 3 R = H; -CH=CH-CH3; -OH; -C(CH3)3 R1 = -OH; -Cl; -COOC(CH3)-CH2-OOC-Ph-o-NH2 Ar = -Ph; naphtyl 6 Synthesis of cyclic carbonates A plausible mechanism for catalyzed synthesis of cyclic carbonates from epoxides and CO2 J Polymer Sci. Part A: Polymer Chemistry, 2013, V. 51, Issue 5, p. 1230-1242 7 Known role of Bu4NBr (TBAB) in cyclic carbonate synthesis Bimetallic aluminum(salen) complex 1: [(salen)Al]2O Angew. Chem. Int. Ed. 2009, 48, 2946-2948 8 Synthesis of cyclic carbonates from epoxides and CO2 at 1 atm and at ambient temperature: complex 1 is used in conjunction with TBAB rate = k [epoxide] [CO2] [1] [Bu4NBr]2 Eur. J. Inorg. Chem. 2007, 3323-3326 Angew. Chem. Int. Ed. 2009, 48, 2946-2948 9 Conversion of CO2 and epoxides into cyclic carbonates Multilayered covalently supported ionic liquid phase (mlc-SILP) materials synthesised by grafting different bis-vinylimidazolium salts on thiol-functionalised silica. Catal. Sci. Technol., 2014, 4, 6, 1598-1607 10 One-pot coupling reaction of CO2, propylene oxide (PO) and bisepoxides without the addition of external organic solvents by using a nanolamellar zinc-cobalt double metal cyanide complex (Zn–Co(III) DMCC) as the catalyst and cetyltrimethyl-ammonium bromide (CTAB) as the co-catalyst. RSC Adv., 2013, 3, 38, 17307-17313 11 Progress made in the use of ionic liquid catalysts and related systems for cycloaddition reactions of carbon dioxide with epoxides Catalysts range: from simple onium species including tetrabutylammonium bromide, functionalized and simple imidazolium ionic liquids, to a plethora of supported ionic liquid systems. A range of supports: alumina, silica, carbon nanotubes, magnetic nanoparticles, poly(ethyleneglycol), polystyrene, cellulose and chitosan have been used with a variety of ionic groups. Catal. Sci. Technol., 2014, 4, 6, 1513-1528 12 Alternative routes for the synthesis of cyclic carbonates (Green Chem., 2010, 12, 1514–1539) 1. Cyclic carbonate synthesis via oxidative addition of CO2 to olefins 2. Carboxylative cyclization of propargyl alcohol with CO2 13 3. Cyclic carbonate synthesis from CO2 and 1,2-diols 4. Electrochemical synthesis of cyclic carbonates 14 Versatile dehydration systems have been developed, which have drastically improved the yields of the target carbonates Catal. Sci. Technol., 2014, 4, 9, 2830-2845 15 Direct synthesis of propylene carbonate from CO2 and 1,2-propanediol in excellent yield (>99%) using a carboxylation/hydration cascade catalyst of CeO2 with 2-cyanopyridine ACS Catal., 2014, 4 (6), pp 1893–1896 16 Renewable Raw Materials Regimes of carbonization Raw materials: epoxidized fatty oils Ref. Catalyst T, oC Pg, atm t, hours Conversion, % 1 2 3 4 5 6 Tetrabutyl ammonium bromide (TBAB), 5 mol. % TBAB KI coupled with 18-crown-6 SnCl4 . 5H2O and TBAB, 3 mol. % TBAB TBAB (M = 322.4), 1-5 wt. % 94 100 98 65-90 63-100 50 63 TBAB 3.5% (or 3 mol.% halide per epoxy) and silica-supported 4-pyrrolidino-pyridinium iodide, SiO2–(I) 1 105 60 10 0-57 1 54 0; 10; 30 70 20-40 120 20 20-150 24 18 7 110 100 130 120 110-140 80 120 140 40, 70 and 100 1-200 8 1. J. Appl. Polym. Sci., 2004, 92 (2), 883-891; US Pat. 7045577, 2006. 2. Green Chem., 2005, 7 (12), 849-854; J. Agric. Food Chem., 2005, 53 (24), 9608-9614. 3. J. App. Polym. Sci., 2006, 102 (3), 2904-2914. 4. Catal Lett., 2008, 123 (3-4), 246-251; 5. J. Appl. Polym. Sci., 2008, 108 (6), 3867-3875. 6. J. Oleo Sci., 2007, 56 (12), 629-632. 7. Green Chem., 2012, 14, 2, 483-489. 8. Polym. Chem., 2012, 3, 2, 525-532. 17 Examples of cyclic carbonates Monocyclic carbonates Propylene carbonate Glycerine carbonate Propyl Carbonate Triethoxysilane Allyl Glycerol carbonate Glycerol carbonate methacrylate Phenoxycarbonyloxymethyl ethylene carbonate 18 Examples of cyclic carbonates Dicyclic carbonates Resorcinol Bis Carbonate Alkyl Bis Carbonate Bis Carbonate Terephtalate Polydimethyl Siloxane Bis Carbonate Cebacate Bis Carbonate PPO Bis Carbonate 19 Examples of cyclic carbonates Tricyclic and polycyclic carbonates Propoxylated glycerine tricyclic carbonate Trimethylolpropane tricyclic carbonate Diaminodiphenylmethane tetracyclic carbonate Aminophenol tricyclic carbonate 20 Examples of cyclic carbonates Polyaromatic polycyclic carbonates 21 Examples of cyclic carbonates Renewable plant-base raw materials Carbonated epoxidized unsaturated fatty acid triglyceride Vanillin Bis Carbonate Poly Isosorbide Bis Carbonate Limonene dicarbonate 22 Proprietary Chemistry of Nonisocyanate PU ★ NIPU networks are obtained through a reaction between polycyclic carbonate oligomers and aliphatic or cycloaliphatic polyamines with primary amino groups. This forms a crosslinked polymer with β-hydroxyurethane groups of different structure resulting in a polyhydroxyurethane polymer. ★ Since NIPU is obtained without using highly toxic isocyanates, the process of synthesis is relatively safe for both humans and environment in comparison to the production of the conventional polyurethanes. 23 β-Hydroxyurethane moieties of nonisocyanate polyurethanes: (a) with secondary hydroxyl groups; (b) with primary hydroxyl groups. 24 Stages of the hydroxyurethane formation process Dok. Phys. Chem., 2003, Vol. 393, Nos. 1–3, pp. 289–292. 25 Activation of the cyclic carbonate group in proton-donor medium Kinetic equation containing an uncatalysed and an autocatalysed reaction -d[c]/dt = kl[C][a]p + k2[c][a]q[OH ] [c] = concentration of cyclic carbonate [a] = concentration of amine [OH] = concentration of the product + initial concentration of OH p~q~2 k2 >> kl Polymer Bulletin, 1991, 27, 171-177. 26 Structures of the hydroxyurethane conformers and isomers Russian Chem. Bull., Int. Edition, 2012, Vol. 61, No. 3, pp. 518-527. 27 Alternative synthesis of NIPU (The Dow Chemical Company ) Recently a new isocyanate-free chemistry for the preparation of polyurethane materials at ambient temperatures from the reaction of polyaldehydes with carbamate functional polymers using an acid catalyst was proposed by Dow Chemical: US Patent 8,653,174, February 18, 2014; SSPC 2015. Isocyanate Free Polyurthane Coatings for Industrial Metal Applications 28 Alternative synthesis of NIPU (The Dow Chemical Company ) Preferably the polyaldehyde is prepared by hydroformylating process with hydrogen gas, carbon monoxide, and an olefin-containing starting compound. The polycarbamates are acrylic carbamate functional polymers with a molecular weight of ~15,000 in n-butyl acetate at ~70% solids by weight. Isocyanates and phosgene are used on the preliminary stages for preparation of the carbamate functional polymers. Blocking agents (alcohols) are used for regulation of pot life. As a result an additional allocation of water takes place. US Patent 8,653,174, February 18, 2014; SSPC 2015. Isocyanate Free Polyurthane Coatings for Industrial Metal Applications 29 NIPU is not sensitive to moisture in the surrounding environment. Hydroxyl groups formed at the β-carbon atom of the urethane moiety increase adhesion properties. Plurality of intra- and intermolecular hydrogen bonds as well as an absence of unstable biuret and allophanate units seem to be responsible for increased thermal stability and chemical resistance to nonpolar solvents. 30 Advantages of HNIPU HNIPU has superior properties in comparison to conventional polyurethanes (PU) High hydrolytic stability Reduced permeability 3-4 time less than conventional PU Superior abrasive and chemical resistance 30-50% better than conventional PU Excellent adhesiveness Safer and easer application Do not use the toxic isocyanate Wide spectrum of applications 31 Some recently achievements in chemistry and technology of NIPU (literature and patent data) 32 Five-membered cyclic carbonate polysiloxane compounds and amine-modified polysiloxane compounds (Japan) wherein A means in which R1 means an alkylene group which has from 1 to 12 carbon atoms and may be linked via an element of O, S or N and/or -(C2H4O)b-, R2 means a direct bond or an alkylene group having from 2 to 20 carbon atoms, R2 may be linked to an alicyclic group or aromatic group, b stands for a number of from 1 to 300, and a stands for a number of from 1 to 300. 33 The resulting polysiloxane-modified polyhydroxy polyurethane resins are very useful as a raw material for various molding materials, synthetic leather and artificial leather materials, fiber coating materials, surface treatment materials, thermal recording media, strippable materials, paints, and a binder for printing inks; and, when added in epoxy resins, as a raw material for various paints, adhesives, composite materials and sealants. US Patents: 8,975,420, 2015; 8,951,933, 2015; US Patent 8,703,648, 2014. 34 A novel cyclic carbonate monomer comprising a reaction product of (a) at least one divinylarene dioxide; and (b) carbon dioxide: The poly(hydroxyurethane) compositions made from Divinylbenzene Dicarbonate and polyamines forms a reactive intermediate that can be used for making, for example, a poly(hydroxyurethane) foam product having an approximate volume expansion of 10. US Patent Application 20140191156, DOW GLOBAL TECHNOLOGIES LLC 35 NIPU foams (France – Poland) The obtained foamed mixtures were heated at 80 C for 12 h and 120 C for 4 h. Apparent density of foam varies in the range 194-295 kg/m3. Tension strain is 0.005-0.009 % at 35 % elongation. European Polymer Journal, 2015, 66, 129–138 36 Synthesis of Terminal Bicarbonate Precursors from Plant Base Raw Materials 37 US Patent Application 20120259087 38 A method for preparing a compound comprising a β-hydroxy urethane unit or a γ-hydroxy-urethane unit, comprising reacting a compound A comprising a cyclocarbonate reactive unit with a compound B comprising an amino reactive unit (-NH2) in the presence of a catalyst, said method being characterized in that said catalyst comprises an organometallic complex and a cocatalyst selected from the group of Lewis bases, or salts of tetra-alkyl ammonium. US Patent Application 20140378648 39 Curing of epoxy resin compositions comprising cyclic carbonates using mixtures of amino hardeners and catalysts US Patent 8,586,653, 2013, US Patent 8,877,837, 2014. BASF 40 Water-dispersible, cyclocarbonate-functionalized vinyl copolymer binder, a process for the preparation of the binder, an aqueous dispersion containing the binder, a system comprising the binder, water and an (amine) curing agent and the use of the binder for the production of a hardened coating are proposed. It was surprisingly found that this binder, in which the emulsifier groups are incorporated in the polymer chain, gives stable aqueous dispersions having a solids content of up to a 30% by weight. US Patent 8,853,322, 2014 41 Method for preparing polyhydroxy-urethanes from amino compounds and compounds carrying carbonate functions, in particular cyclic carbonate functions. US Patent 8,017,719, 2011. Rhodia. 42 Plasticizer Mixture of Epoxidized Fatty Acid Glycerin Carbonate Ester and Epoxidized Fatty Acid Esters wherein R1 is an epoxidized C7-23 hydrocarbon chain, represented by wherein 1 ≤n ≤5 and 8 ≤ (m+3n+p+1) ≤ 23. US Patent Application 20150057397 43 2-oxo-1,3-dioxolane-4-carboxamides (I) in which R2 can be, inter alia, an n-valent radical (n>1) which is substituted with n-1 further 2oxo-1,3-dioxolane-4carboxamide groups of general formula (II), (I) (II) to processes for the preparation of these 2-oxo1,3-dioxolane-4-carboxamides, to processes for the preparation of the 2-oxo-1,3-dioxolane4-carboxylic acids of formula (III), which are suitable starting materials for the above processes, and to the use of said 2-oxo1,3-dioxolane-4-carboxamides for the preparation of (poly)hydroxyurethanes. US Patent Application 20150051365 44 HYBRID POLYURETHANE SPRAY FOAMS MADE WITH URETHANE PREPOLYMERS AND RHEOLOGY MODIFIERS It was disclosed hybrid spray foams that use a urethane reactant, a crosslinker, and an (optional) epoxy and/or acrylic resin, along with a blowing agent and rheology modifier to produce a quick-setting foam that remains in place until the foam forms and cures. In some other formulations it was used the NIPU adducts of cyclic carbonates and di- or polyamines, received from Polymate. Unfortunately, the use of rheology modifiers in practice increases the viscosity of the compositions and imparts to them a thixotropic property, which significantly limits the use of this method for spray foams. US Patent Application 20120183694 45 Elaborations of novel NIPU – HNIPU products and technologies HCTI – Polymate Cyclocarbonated Acrylic Oligomer It was developed NIPU paint on the base of cyclocarbonated acrylic oligomer cured by polyamines at 110-120 °C / 2-3 hours. Paint has high water and weather stabilities but unfortunately we need to use solvents for this composition. 46 Synthesis of polyaminofunctional hydroxyurethane oligomers and hybrid polymers formed therefrom (EP 1070733, 2001) Chemically resistant materials with high mechanical properties are provided by using adducts of primary diamines (with oligocyclocarbonate and epoxy compounds) and epoxy oligomers with ended epoxy groups (or mixture of epoxy oligomers and oligomercaptanes). + H2N-R2-NH2 → 47 Cyclocarbonate groups containing hydroxyamine oligomers from epoxycylclic carbonates (US 6,407,198, 2002) Chemically resistant materials with high mechanical properties are provided by using polycyclic carbonates of special structure. The polycyclic carbonates are prepared by the reaction of oligocyclic carbonates containing ended epoxy groups with primary aromatic diamine. 48 Hydroxyurethane-amine adducts as hardeners for epoxy resins at RT Scheme of hydroxyurethane modified amine adduct for curing of epoxy resins (US Patent Application 2010/0144966) 49 "HUMs" & "Uramines" • > "Hydroxy Urethane Modifiers" (HUMs) are the patented backbone technology of HNIPU and are formulated as part of curing agents under the name "Uramine" (Urethane Amines) • > Developed for epoxides to enhance their properties to the level of a polyurethane or better 50 Hydroxyalkyl urethane modifier (HUM) HUM is obtained as a result of a reaction between a primary amine and a cyclic carbonate compound at stoichiometric ratio, and can be represented by the formula: wherein R1 is a residue of the primary amine, R2 and R3 are the same or different and are selected from the group consisting of H, alkyl, hydroxyalkyl, and n satisfies the following condition: n ≥ 2 (US Patent 7,989,553, 2011). 51 Nano-structured non-isocyanate hybrid epoxyurethane polymer A novel non-isocyanate hybrid epoxyurethane composition contains alkoxysilane units. The composition is highly curable at low temperatures with forming of nanostructure under the influence of atmospheric moisture and the forming of active, specific hydroxyl groups. The cured composition has excellent strengthstress properties, adhesion to a variety of substrates, appearance, and resistance to weathering, abrasion, and solvents (US Patent 7,820,779 2010). 52 Radiation-curable biobased composition A radiation-curable composition comprising (meth)acrylic monomers and/or oligomers, photoinitiators, and a nonreactive composite additive, wherein the nonreactive composite additive comprises a) a biobased hydroxyurethane additive of formula (1): R1[−NH−COO−CR2H−CR3H(OH)]2 (1) wherein R1 is a residue of the biobased primary diamine, and R2 and R3 are the same or different and are selected from the group consisting of H, alkyl, and hydroxyalkyl; and b) a silane-based hydroxyurethane additive of formula (2): (R6)3-n(OR5)nSi−R4−NH−COO−CR2H−CR3H(OH) (2) wherein R2 and R3 are the same as stated above, R4 is generally an aliphatic group having from 1 to 6 carbon atoms, R5 and R6, independently, are hydrocarbon radicals containing from 1 to 20 carbon atoms and selected from the group consisting of aliphatic, cycloaliphatic, and aromatic groups or combinations thereof, and n is equal to 1, 2, or 3 (US Application 14/160,297, 2014). 53 Hybrid nonisocyanate polyurethane grafted polymers Recently Polymate Ltd. develops a new hybrid epoxy-amine hydroxyurethane network polymers with lengthy epoxy-amine chains and pendulous hydroxyurethane units (US Application 14/296,478, 2014). The cured linear hybrid epoxy-amine hydroxyurethane-grafted polymers by novel structure have a controlled number of cross-links and combine increased flexibility with well balanced physical-mechanical and physicalchemical properties of conventional epoxy-amine systems. In particular, new materials have tensile strength up to 12 MPa and elongation at break 70-275%. They may be used for various applications, for example, for manufacturing of synthetic/ artificial leather, soft monolithic floorings and flexible foam. 54 Topological structure of polymer chains The schematic structural formula of the novel polymer is the following: where E―R`―E is a residue of a diglycidyl ether, which reacted with amine hydrogens, E is a converted epoxy group, i.e., –CH2–CH(OH)–CH2–O–, N is a nitrogen atom, A is a residue of a di-primary amine, U(OH) is a hydroxyurethane group, i.e., –R1–NH–CO–O–CH(R2)–CH(OH)–R3, and =N―A―U(OH) is a residue of aminohydroxyurethane with the number of free amine hydrogen atoms equal 2. 55 Creating a controlled number of cross-links A schematic structural formula of the novel polymer with the directions of the possible cross-links (shown by arrows) is the following: , where is a residue of the polyfunctional epoxy resin, other designations being the same as above. Polyamines with a number of free amine hydrogen atoms more than 2 also may be used for cross-linking. 56 Some of perspective raw amines PPGs amine terminated di- and tri-amines with MW up to 5000 Bio-based polyamines – idealized chemical structures 57 HNIPU FLOORING APPLICATION: Indoor/Outdoor for Industrial & Commercial Buildings; Garages; Chemical Plants; Warehouses; Monolithic Flooring for Civil, Industrial and Military Engineering, Marine Apps, etc. PRODUCT NAME FLI4W FLI4W-FC FLI4W-LP FLI4W-B FLIO6W FLIO6S FLI3 SPECIFIC PROPERTY Increased chemical, wearing, light and humidity resistance plus high sanitary-hygeinic properties. Application temperature: 5068 ˚F (10-20 ˚C) Same as FLI4W but shorter curing time and pot life (10-30 minutes) Same as FLI4W but longer pot life (2-3 hours) Same as FLI4W but longer pot life (up to 4 hours) Higher light resistance. Application temperature: 50-68 ˚F (10-20 ˚C) Same as FLIO6W but increased "ultra" UV resistance Low application temperature: 36-77 ˚F (2-25 ˚C), fast curing, high sanitary-hygienic properties HNIPU PAINT APPLICATION: Indoor/Outdoor for Industrial & Commercial Buildings; Chemical Plants; Marine Apps; Protective Coatings Inside Pipes; Equipment for Liquid Fertilizer Delivery; Military Equip., etc. PRODUCT NAME SPECIFIC PROPERTY PI9W Paint for indoor light stable and chemical resistant applications. Application temperature: 50-68 ˚F (10-20 ˚C) PIO15W Increased light resistance and high decorative properties. Application temperature: 50-68 ˚F (10-20 ˚C) PIO15S Same as PIO15W but increased "ultra" UV resistance Comparative properties of coatings “cold curing” Charackteristics HNIPU Conventional epoxy Conventional PU 50-70 50-70 10-30 25-30 80-120 40-80 2 -1.4 51 -99 4 -5 Tensile strength, MPa Abrasion resistance (TABER, wheel CS17, 1000g), loss of mass, mg/1000 cycles Weatherability (QUVA testing, 1000 h)*: color change, ΔE gloss change, % *Data of Sherwin-Williams 59 HNIPU foam HNIPU foam is elaborated on the base of wide spectrum of hydroxyurethanes. Composition of polymeric matrix include up to 40 % renewable components. We have elaborated: - sealant one-component foam; - 2K sprayable foam insulation – rigid and semirigid; - pourable rigid and semirigid foam; - preliminary results on some types of soft and flexible foam 60 Non-isocyanate foam compositions related to hybrid systems on the basis of epoxy, hydroxyurethane, acrylic, cyclic carbonate, and amine raw materials in different combinations Foamable, photopolymerizable liquid acrylicbased compositions for sealing applications US Patent 6,960,619 B2, 2005. 61 Hybrid non-isocyanate foams and coatings on the basis of epoxies, acrylic epoxies, acrylic cyclocarbonates, acrylic hydroxyurethane oligomers, and bifunctional amines US Patent 7,232,877 B2, 2007. 62 Hybrid polyhydroxyurethane network on a base of vegetable oil Hybrid epoxy-hydroxyurethane compositions cross-linked at ambient temperatures were obtained on the base of renewable raw materials. Networks of hybrid polyhydroxyurethane were formed from carbonated-epoxidized soybean oil, without the use of isocyanate intermediates. Compositions can apply to the preparation of curable polymeric foam and other materials (coatings, sealants, adhesives). US Patent Application 2012/0208967. 63 Adaptation of hybrid nonisocyanate composition for sprayable foam application Provided is a method for the spray application of a nonisocyanate polymer foam composition. The method comprises the steps of supplying dosed quantities of the components of the nonisocyanate polymer composition to the mixing chamber, transferring the foamable nonisocyanate polymer composition to the intermediate chamber and continuously moving the composition through the intermediate chamber for providing conditions most optimal for the spray application onto the substrate. US Patent Application 2015/0024138. 64 Principles of creating compositions for polymer matrices Varying oligomer raw materials (epoxy, hydroxyurethane, acrylic, cyclic carbonate, and amine) in different combinations. Using the hydroxyurethane components as comprising the main chain, and as external dopants. Using the renewable plant-based raw materials. Blowing agents: No impact on ozone layer depletion, low Global Warming Impact (direct and indirect) 65 Blowing agents Code and Name Commercial Name Boiling point, Tb, oC Hydrofluorocarbons (HFCs) HFC-227ea FM-200, DuPont Fluoroproducts 1,1,1,2,3,3,3-Heptafluoropropane HFC-236fa SUVA® 236fa, DuPont Fluoroproducts 1,1,1,3,3,3-hexafluoropropane HFC-245fa Enovate® 3000, Honeywell 1,1,1,3,3-pentafluoropropane HFC-365mfc Forane® 365mfc, Arkema Inc.; 1,1,1,3,3-Pentafluorobutane Solkane® 365mfc, Solvay Fluorides, Inc. HFC-43-10mee Vertrel® XF, DuPont Fluoroproducts 1,1,1,2,2,3,4,5,5,5-Decafluoropentane HFC-1336mzz Formacel® 1100, DuPont Fluoroproducts 1,1,1,4,4,4-hexafluoro-2-butene Unsaturated hydrochlorofluorocarbon (HCFC) HCFC-1233zd(E) Solstice® LBA, Honeywell trans-3,3,3-trifluoro-1-chloropropene Hydrocarbons n-Pentane iso-Pentane Cyclopentane Chemical blowing agent Polymethylhydrogensiloxane Dow Corning 1107® Fluid, Dow Corning Corp. –16.5 –1.4 15.3 40.2 55 33 19 36 28 49 66 Preliminary testing of HNIPU sprayable foam in Graco 67 68 69 70 RIGID HNIPU FOAM Properties Standard Viscosity (Brookfield RVDV II, Spindle 29, 20 rpm) at 25ºC, cP Base “A” Base “B” “A” + “B” (3-5 sec after mixing) Pot life at: 25ºC (77 ºF), s VOC Gel time, s Touch dry, s Curing for transportation, min Appearance of rigid foam Compressive Properties of Rigid Cellular Plastics, 24 hours, kg/mm2 ASTM D2196 Apparent Density of Rigid Cellular Plastics, kg/m3 Thermal Resistance (R-value), hr•ft2•oF/BTU•in Rigid Foam Insulation ASTM D2369 2800 – 3200 3600-4100 ≤3700 8-10 Compliant 2-4 30-40 15-20 White ASTM D1621 0.02 – 0.04 ASTM D1622 30-40 C 518 4.5-5.0 71 Properties of preliminary flexible foam samples Example No. Properties PP-1-77 PP-1-82 PP-1-88 PP-1-90 Brief description Good foaming, not shrinkage flexible foam Temperature of curing, oC 40 80 80 70 Cream time, sec 30 10 20 15 Touch dry, min 20 5 30 15 Density, kg/m3 45 40 38 38 Tensile Strength, MPa 0.028 0.026 0.03 0.12 Elongation at break, % 60 60 70 70 Sustainable raw materials 20-40 % 72