Micromouse 296 Preliminary Design Review

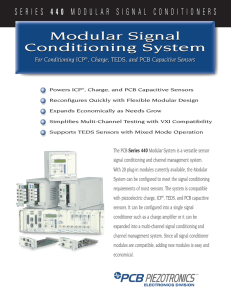

advertisement

Micromouse 296 Final Presentation Fall 2008 Group: Rabbitwagon The Team Richard Ordonez- Project Leader Bob Barfield- Software Manager Lance Lavarias- Mechanical Architect Micheal Pascual- Hardware Overview To create, a small autonomous robotic mouse that will: 1.Navigate it’s way safely to a central point of a maze 2.Map the maze 3.Find the shortest route from the start point to central point of the maze. Contest rules must be followed UH Micromouse Maze Initial Goals Build a light and fast mouse Implement top-down sensor technology Build an Intelligent mouse 1. Wall hugger 2. Follow flood fill algorithm 3. Map and solve maze FINISH Design Chassis Stepper Motors Top-down sensors Wall hugger with good tracking Block Diagram of system Chassis Design A good chassis design should have the the following features: 1.Made of robust material 2.Narrow enough to fit in a cell with plenty room for correction on either side. 3.Able to rotate 180 degree turns without hitting walls 4.Shouldn’t have problems riding over cracks Previous Semester Designs First Chassis Design Fossil Watch Box Too big for 18x18 cm cell Flimsy Aluminum Second Chassis Design Robust and light-weight Aluminum chassis Narrow-fit to easily maneuver in any cell Sled-shaped bottom to go over bumps Final Chassis Too Long Cut down sled For better fit in Cells. Chassis Components 1) Jameco Stepper Motors 2) Aluminum Wheels 3) 8 Metal Hydride Batteries Chassis Components layout Circuit Design Tower-like design Bottom level: 1. Top-down sensors 2. Voltage regulator Second Level: 1. Mosfets 2. Rabbit 3. Power First Level Graphical Representation of Sensor Design Ideal Sensor layout Actual graphical Sensor layout with two Protoboards Alignment Strategy •Sensors lay out is clock face •Crossed sensors give best alignment Actual Sensor Layout Bottom view Top View Major Sensor Problem All sensor connected 12 volts. (Red wires) DUMB! Reconnected to 5 volts (Yellow wires) SMART! Second Level 1. Rabbit Microcontroller 2 2. Power/Ground 4 3. Switch 4. Mosfets 3 1 Programming RabbitWagon Program Overview •Series of states •Used CoState functions in Dynamic C Strategy •Wander as right wall hugger while mapping •Flood fill to solve •Speed up stepper motors for timed run Summary Of Problems Chassis 1. Body too big 2. Sled too long (not able to rotate) Sensors 1. Burned out sensors due to too much voltage 2. Sensor board too close together 3. Too high Motor Circuit 1. Step sequence Rabbit microcontroller 1. Programming 2. DEAD Ports Code/Programming 1. Co-states Completed Goals Completed Hardware Got mouse to move Rabbit read sensors Tracking Improvements More compact with fewer wires Stability Side sensors Tracking Possibly use a pic microcontroller Lessons Learned •More scheduled meetings •More design time •More coders •Put everything possible in a socket •Use patch panel between controller and rest of mouse •Simulate mouse with breadboard/LEDs while developing software Gant Chart ANY QUESTIONS?