College of Business - Iowa State University Extension and Outreach

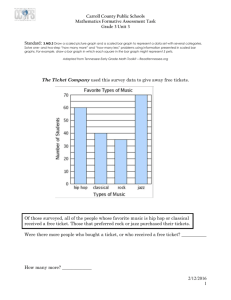

advertisement

The Impact of an Auditable Quality Management System in a Grain Elevator Application Iowa Grain Quality Initiative Advisory Committee Meeting: 1/12/07 Chad Laux Industrial and Agricultural Technology Program Dr. Charles Hurburgh, Jr. Major Professor Outline Farmer’s Cooperative Results of QMS in Quality Control FDA Bioterror Act FC Mock Recall Results Farmers Cooperative Company Northwest Iowa Company Over $400 million in sales 50 locations and growing 350+ employees Departments: Grain, Agronomy, Feed, Seed, Admin., Accounting Source: FC, 2006 Problem Statement With the adoption of QMS, how has it impacted Farmer’s Cooperative operations? What measurements would provide evidence so FC may proceed with other location implementations? Inquiry focused on company processes which directly affect grain preservation and handling Core Farmer’s Cooperative Co. Processes: ISO Defined Processes which transform the end product in ISO structure 7.2.1 Order Processing for Gain Shipments Shipping 7.4.3 Verification of Purchased Product Receiving 7.5.1 Control of Operations-Loading Order Shipping 7.5.1 Control of Operations-Release & Post Shipping Shipping 7.5.3 Identification and Tracking- Grain Identification and Tracking All 3 7.5.3 Identification and Tracking-Inspection and Grading Storage 7.5.5 Preservation of Grain-Handling and Preservation Storage 7.5.5 Preservation of Grain-Storage Areas Storage 7.5.5 Preservation of Grain-Bulk Grain Shipping Storage 8.2.4 In-process Inspections Storage 8.2.5 Final Inspection Storage 8.3.1 Control of Nonconforming Grain Shipping Statistical Process Control - Grain Grading Farmers Coop has been grading the same grain samples that were also graded by an official inspector – Matching the precision of the official inspectors Research Model & Hypothesis Grain quality for shipment is improved when QMS procedures are adopted FC/FGIS/customer comparisons of same sample: Corn Moisture - Content Instrument Factor Corn Damage - Visual Judgment Factor Smaller Difference is Better! Comparison of: QMS locations vs. non-QMS locations Locations before and after QMS implementation Moisture Content Absolute Mean Difference All Locations 0.5 FC-Official (% pts) 0.4 0.3 0.2 0.1 0.0 w/ SEM’s shown AIB ISO None n=218 n=279 n=15087 Moisture Content Absolute Mean Difference – Location 1 Before and After AIB/QSE Adoption 0.5 FC-Official (% pts) 0.4 0.3 0.2 0.1 0.0 w/ SEM’s shown After QSE n=218 Before QSE n=2924 Moisture Content Absolute Mean Difference – Location 2 Before and After QMS Adoption 0.5 FC-Official (% pts) 0.4 0.3 0.2 0.1 0.0 w/ SEM’s shown After N=279 Before QMS N=2864 Total Points % Damage Absolute Mean Difference All Locations 5 FC-Official (% pts) 4 3 2 1 0 w/ SEM’s shown AIB ISO n=79 n=110 None n=5303 Total Points % Damage Absolute Mean Difference– Location 1 Before and After AIB/QSE Adoption 5 FC-Official (% pts) 4 3 2 1 0 w/ SEM’s shown After QSE n=79 Before QSE n=1197 Total Points % Damage Absolute Mean Difference – Location 2 Before and After QMS Adoption 10 FC-Official (% pts) 8 6 4 2 0 w/ SEM’s shown After Before QMS n=110 n=1637 Conclusions QMS positively impacted FC operations through improved product quality of shipped grain. – Better resource management => Better quality control There was no difference in quality where the basis of determination was instrumentation. (moisture content) – Process control through calibration BPM is a suitable model of inquiry for research of ISO results in organizations How to Meet the FDA Bioterrorism Act: An Elevator Case Study of Tracking Commodity Grain Using ISO 9000 Bioterrorism Act of 2002 FDA Mandate of ‘one up-one down’ traceability by 6/06 (sliding scale based on size) Protection of food supply Legislation – Registration – Section 305 – Recordkeeping & maintenance – Title III, Section 306 – FDA expects documentation to be mode of traceability Produce information upon official investigation Unfunded mandate Note: Traceability a requirement of ISO certification Product Traceability Research Questions: Does a QMS facilitate traceability in commodity grain elevator operations? Does the traceability system meet FDA guidelines for traceability under the Bioterrorism Act? Methodology Traceability/safety training conducted at 21 QMS/non-QMS locations Mock recalls conducted at locations to measure of training effectiveness (ISO requirement) Devin Mogler (QMS Intern) conducted recalls per FC ISO Procedure for Recalling Commodity Grain Recall Summary Results Location Commodity Quantity (bu) Received Source Lot/code identifier Recipient Lot/code identifier Delivered Recall Time (hrs.) Location 1 Corn 282.14 6/19/2006 Producer 1 scale ticket External railroad 1 load order 6/30/2006 1.77 Location 2 Soybeans 284.00 6/23/2006 Producer 1 scale ticket To FC location 10 3 scale tickets 6/23/2006 3.07 Location 3 Corn 998.93 6/15/2006 Producer 1 scale ticket Still in storage 1 storage bin n/a 24.42 Location 4 Soybeans 282.67 6/16/2006 Producer 1 scale ticket Still in storage 1 storage bin n/a 1.95 Location 5 Corn 442.86 6/12/2006 Producer 1 scale ticket Still in storage 1 storage bin n/a 20.88 Location 6 Soybeans 199.00 6/26/2006 Producer 1 scale ticket To FC location 8 14 scale tickets 7/5/2006 Location 7 Corn 762.50 6/14/2006 Producer 1 scale ticket Still in storage 3 storage bins n/a 22.17 Location 8 Soybeans 12,070.00 7/5/2006 From FC location 6 14 scale tickets External railroad 1 load order 7/5/2006 17.25 Location 9 Soybeans 2,704.00 6/23/2006 From FC location 2 3 scale tickets Still in storage 1 storage bin n/a 14.68 Location 10 Corn 1,486.07 6/20/2006 Producer 1 scale ticket External railroad 1 load order 7/10/2006 1.90 Location 11 Corn 982.50 6/15/2006 Producer 1 scale ticket Still in storage 2 storage bins n/a 2.03 Location 12 Soybeans 500.67 6/14/2006 Producer 1 scale ticket External trucking 1 scale ticket 7/6/2006 1.70 Location 13 Corn 483.21 6/15/2006 Producer 1 scale ticket Still in storage 1 storage bin n/a 1.28 Location 14 Soybeans 867.33 6/13/2006 Producer 1 scale ticket To FC location 8 54 scale tickets 7/5/2006 7.60 Location 15 Corn 973.57 6/20/2006 Producer 1 scale ticket Unknown feed mill Unknown Unknown 2.33 Location 16 Corn 757.50 6/22/2006 External trucking 1 scale ticket Still in storage 1 storage bin n/a 2.72 Location 17 Corn 972.86 6/16/2006 External trucking 1 scale ticket To FC location 10 Unknown 7/3/2006 3.98 Location 18 Corn 989.64 6/16/2006 Producer 1 scale ticket To FC location 8 Unknown 7/6/2006 19.38 Location 19 Corn 188.93 6/29/2006 Producer 1 scale ticket To FC location 1 2 scale tickets 7/19/2006 19.63 Location 20 Corn 559.64 6/15/2006 Producer 1 scale ticket External trucking 4 scale tickets 6/16/2006 3.85 Location 21 Soybeans 273.00 6/14/2006 Producer 1 scale ticket To FC location 8 Unknown 6/29/2006 - 7/5/2006 3.02 20.18 Distribution of Recall Duration 7 Mock Recall Events (No.) 6 5 4 3 2 1 0 0 8 16 Time Duration of Mock Recalls (hrs.) 24 Discussion and Conclusions FC Mock Recall Audit Results 4. RESOURCES Audited FC results per FDA rules: 3. INPUTS 5. PERSONNEL 1. PROCESS 7. METHODS 1. Enter Process Name and Owner – QMS traceability is adequate to meet FDA mandate – Wide variation in duration of recalls – Wide variation in precision i.e. lot size 3. OUTPUTS 6. EFFECTIVENESS FC Procedure for Recalling Commodity Grain 2. Enter details of the actual output; this may be product or document, & should be linked to or used as a measure of effectiveness listed in (7) FC Mock Recall Summary Sheet (added page) Elevator Location Manager Duration Summary Report (added page) Process Audit Form results (this sheet) 3. Enter details of the actual input; this may be a document, materials, tooling, schedule, etc. FDA Bioterrorism Act Traceability Characteristics 4. List those resources used in the process, such as: machines, materials, equipment. FC QMS Form, Commodity Grain Recall Record FDA Bioterrorism Act of 2002 Checklist (note: results of study not on this recorded List of emails initiating recall events Form). Need a traceable record of results (not email or uncoded Excel spreadsheet). 5. List details of personnel involved, with required skills, criteria for competence, training requirements, etc. Quality Assurance Intern, Location Managers, 6. List details of methods, process controls, support processes & measurements taken, etc. Quality Manager, Management Trainee, Elevator 14, 17, 18, 19, 21. Unknown Precision at Operators Locations 15, 17, 18. Unknown Subsequent Necessary Depth not met at Locations User at Location 15. Timeframe not met at Location 4. Unknown finished bu quantities at all Locations. 7. List the measures to show process effectiveness, (such as: targets, results) FDA minimum requirements identifying immediate source, subsequent user, quantities, and duration (note: no trace back at any Locations) Recommendations Trace from back to front in next round of recalls Follow through on multi-site recalls Improve internal communication – reduce lag time Use older scale tickets in recalls – will test system more thoroughly Collect all sources in bin, railcar assignments – indicator of precision (index) Use controlled documents for recalls – ‘traceable’ documents required Launch CAR’s on failed recalls – close the loop Decide on lot sizes – operations issue Final Steps Impact of ISO on Quality and Quantity (Inventory mgmt.) on grain Key process with management measures on performance imbedded in QMS system: – 8.2.4 – Monitoring and measurement of product – 8.3 – Control of non-conforming product – 8.5.2 – Corrective and preventive action Final Defense and graduate by Aug. 2007