Ieper, added with Praestol650BC flocculants

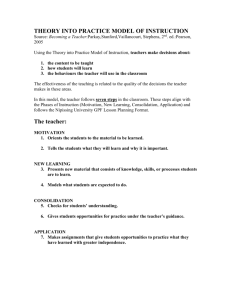

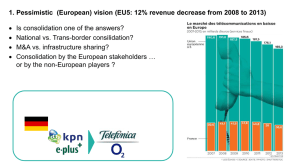

advertisement

Impact of flocculating agents on stress-strain behaviour of natural mineral sludges Luca Barbetti The author is involved in a scientific research project at the Laboratory of Geotechnics of Ghent University, funded by the Flemish Environmental 100Technology Platform (MIP). On this research project they are participating also several universities, research institutes, contractors, design offices and big industries as VITO, KUL, KHBO Oostende, LabMet, MWH, Rasenberg Milieu, DEC, Envisan, Ghent Dredging, WVRB, MOW- Maritieme Toegang, Gementelijk Havenbedrijf Antwerpen, Nyrstar and Tessenderloo Chemie. The aim of this research is to possibly modify the consolidation behaviour of dredged material of mineral origin, as well as to look after a possible stiffness increase of the slurries, by adding flocculants. MATERIALS AND METHODS This project aims at using additives to optimise the behaviour of sludge material. This optimization can be related to different aspects of the behaviour of the material as sedimentation, consolidation, final density, final shear strength, leachate production, stabilisation of organic and inorganic pollutants. Not all aspects will be completely compatible between each other. In most cases, in the industry, the main choice of a flocculants is based on optimizing sedimentation behaviour, this based on very rudimentary tests (shaking beaker test, sieve permeation test...). A correct optimization should be based on the full large strain consolidation behaviour. To reach this, we try to obtain large strain parameters (permeability and compressibility function) and shear and stiffness property for sludges that have been altered using different types of additives, in this case flocculants. The impact of the technique used to add flocculants is also important in the study of the consolidation behaviour. There were identified two kinds of possible mixing methods in-site those were try to simulate in laboratory scale: the “inline mixing” method of the flocculants with a sludge of initial relative low density (1.051.1 ton/m³) try to simulate the turbulent mixing that we can have in pipe-lines and dumping methods, and the “in-situ” mixing method of a flocculants with a sludge at a pre-consolidated stage (density of 1.2-1.3 ton/m³) try to simulate different kind of injection methods that we can have directly in a real sludge storage pond. Looking at the large number of tests to be performed and on the several type of soils and flocculants at disposal, it was chosen to focus on the most interesting sludge materials. The main part of the research has been done on the material from the Ieper-Ijzer canal, that presents the most difficulty to be consolidate and which has been adapted using the Praestol 650BC (cationic) flocculants. A whole range of tests has been performed on the reference material : Seepage Induced Consolidation cell test (SIC), CRS test, standard oedometer, big diameter oedometer, simple shear test,… The basic materials have also been characterised : grain size distribution, atterberg limits, chemical analysis of pollutants. PRELIMINARY RESULTS The most important tool during our research work was the SIC test. This test allows to determine the full compressibility and permeability functions simultaneously over a large range of stress. Unfortunately, the tests take quite a long time (6 to 8 weeks) which leads to disturbances in the measurements due to gas formation. A simple drawing of the test set-up is plotted here in figure 1, while some typical results from the first series of test are shown in figure 2 and 3. Tests performed till now showed that the modified materials show an increased of permeability, till quite high densities. It is also clear that the in situ mixing method has a larger impact than the in-line mixing. This is of course related to the procedure of the in situ mixing and the creation of the dual porosity structure. It is necessary to repeat these tests on samples which have been mixed with an Figure 1. Seepage induced consolidation test actual existing mixing technique on a setup – Laboratory of Geotechnics larger scale to confirm the results. To avoid some problems with the gas formation, it was decided to perform some faster oedometer compression tests. These have the disadvantage that they do not allow direct measurement of permeability, instead we get values for the consolidation coefficient, which is a direct indication of the velocity of consolidation (combining permeability and compressibility). To this extent, we have performed both small and larger scale oedometer tests. All results so far indicate that the values of the consolidation coefficient cv are indeed higher with the treated material (with slightly higher values for the in situ mixed material as compared to the in-line mixing situation) which shows the beneficial effect of the use of the flocculants. There were also encounter some less positive aspects, in situ mixing creates a dual porosity structure with lower shear strength at low stress levels. At higher stress levels, this effect is minimal. In-line mixing induces higher creep deformation at low stress levels. The relevant (long term) tests are still running, so it cannot be specified if this behaviour is limited only to low stress levels. Gas formation has a devastating impact on the long term behaviour of the material, leading to a decrease in permeability and therefore prolonging the consolidation time. In some cases, swell could be occurring due to the large volume of gas produced. Permeability curve I- no floc Compressibility curve 5 I- inline- 0,7% Pr650BC 5 I-in situ - 0,1% Pr650BC 4,5 I-in situ - 0,1% Pr650BC and sand 4,5 4 3,5 3 2,5 2 1,00E-08 I- no floc I- inline- 0,7% Pr650BC I-in situ - 0,1% Pr650BC 1,00E-09 1,00E-10 I-in situ - 0,1% Pr650BC and sand 4 void ratio INTRODUCTION Luca.Barbetti@UGent.be barbettiluca@libero.it void ratio www.ugent.be Supervisors: William F. Van Impe, Peter O. Van Impe Laboratory of Geotechnics 3,5 3 2,5 2 10 permeability (m/s) Figure 2. Permeability curve using the SIC test, test on sludge from Ijzer Canal - Ieper, added with Praestol650BC flocculants 100 eff stress (kPa) Figure 3. Compressibility curve using the SIC test, test on sludge from Ijzer Canal - Ieper, added with Praestol650BC flocculants CONCLUSION AND FUTURE WORKS The first series of results presented in this paper shows as SIC test equipment can be used in order to predict compressibility and hydraulic conductivity behaviour of soft soils. The results showed an improvement of the sludge treated with the cationic flocculants, improvement that can be related to an increase of permeability of 2-3 times for a large range of effective stress, between ~10 – 40 kPa. In our future research we will continue on the study of soft clayey mineral slurries, and try to understand if using additives have any impact on the consolidation of the slurry and on its permeability in function of effective stress and time. Variables of our studies will be: mixing methods of flocculants (in-line mixing at low initial density, mechanical and injection mixing at high initial density, low and high energy of mixing); type of flocculants (anionic, cationic and non-ionic, artificial and natural) and its efficiency in function of the storage time. Together with SIC tests other standard and non standard tests will be performed to determine shear strength development in presence of flocculants at different stress level; the stiffness of the consolidating soil behaviour will be studied, using bender elements. The samples used for the SIC tests will be also subjected to x-ray tomography analysis, it will be possible to have nondestructive 2D and 3D images of the consolidated sample, algorithms analysis to determine porosity, pore size distributions, particle sizes and orientation of the structure of the slurry in presence or not of flocculants. These analyses will help us to study the behaviour of the flocculants with the clay particles and clay structures, and to define the effect of the mixing method on the sludge, double porosity or homogeneous mixing of the slurry. Some large scale test have been also designed to have the possibility to compare the laboratory results with real case test. References (1) Been, K., Sills, G.C., 1981. Self weight consolidation of soft soils: an experimental and theoretical study. Geotechnique 31, (4) 519-535 (2) Gibson, R.E., England, G.L., Hussey, M.J.L., 1967. The theory of one dimensional consolidation of saturated clays: I. Finite nonlinear consolidation of thin homogeneous layers. Geotechnique 17 (3), 261–273. (3) Abu-Hejleh A.N., Znidarcic D., 1992. Consolidation characteristics determination for phosphatic clays- Volume 1-2-3, Publication No. 02-084 104 University of Colorado (4) Silva, W.S., De Azevedo, R.F., 2001. Hydraulic consolidation test: equipment description and testing analysis. University Federal of Vicosa, Department of Civil Engineering, Vicosa, Brazil (5) Znidarcic, D., Liu, J.C., 1989. Consolidation characteristics determination for dredged materials. Proc., 22nd Annual Dredging Seminar, Ctr. For dredged Studies. Texas A&M Univ., College Station, Tex, 45–65