mintek management - Parliamentary Monitoring Group

advertisement

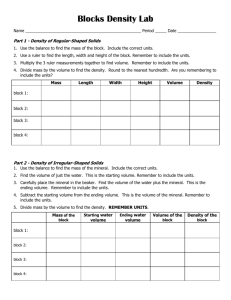

10th June 2003 Presentation to the Parliamentary Portfolio Committee Science & Technology By Dr Paul Jourdan Mintek Specialists in mineral and metallurgical technology Mintek: Adding value to our Natural Resources Exploration Mining, Resource Processing Refining Fabrication Mineral separation, Smelting, Leaching Mineral analysis, Special Alloys, Smallscale Mining, Jewellery, Enviromin, etc. Specialists in mineral and metallurgical technology FINANCIAL SUMMARY 2002/2003 R’k Income 207 960 Core funding Earmarked funding Own Income (incl. post-retirement fund interest) Expenditure 214 128 Staff Costs Overheads and Operating Expenditure Depreciation 121 408 85 226 7 494 Shortfall Forex losses (11:1 to 8:1) Avmin royalty Mindev investment Transformation Operating Shortfall Total 78 160 9 521 114 718 6 168 R2mn R3mn R5mn R1mn R6mn R17mn Specialists in mineral and metallurgical technology MINTEK INCOME 350,000 Core 300,000 Earmarked Non-state Total 200,000 150,000 100,000 50,000 2005/2006 2003/2004 2001/2002 1999/2000 1997/98 1995/96 1993/94 1991/92 1989/90 0 1987/88 Rands X 1000 250,000 Specialists in mineral and metallurgical technology MINTEK MANAGEMENT CHIEF EXECUTIVE OFFICER Technology Research Technology Commercialisation Business Services Corporate Relations Corporate Services Human Resources & Training Finance (Treasury) Pyrometallurgy Mineralogy Analytical Science High Temp. Technology Bioleaching Hydrometallurgy Minerals Processing Process Eng. Services (Mintek Exco) Physical Metallurgy Small Scale Mining Unit CEO (50%) Information & Publications Mindev COO Measurement & Control Engineering Support MESU HDSA PROJECTS (JVs) Specialists in mineral and metallurgical technology MINDEV CORPORATE STRUCTURE MINDEV BOARD (CHAIR – PP JOURDAN) MINTEK EXECUTIVE MANAGEMENT MINDEV CEO NA BARCZA (50%) PUBLIC OFFICER YUNUS OMAR SUBSIDIARY COMPANIES ATOLL Bateman Titaco Mindev 50% 50% TOLLSORT Mindev IMS Eng. SPH B&H 25% 25% 25% 25% MOGALE Mindev 30% PGR 30% Atoll 20% BEE 30% (10%DGE Trust) (Sebeso) MUSUKU Mindev Harmony BEE 40% 40% 20% (Laetoli) Specialists in mineral and metallurgical technology MINDEV SUBSIDIARIES • • • • Tollsort: with Mikrosort of Germany, to apply new optical sorting technology to improve recoveries in the southern African minerals industry; Musuku: with Harmony and BEE company, to beneficiate gold bullion into pure (99.99%) gold and into value-added intermediate products such as salts, wire, alloys, bars and high purity gold for electronics, using Mintek technologies. Musuku is the Venda word for gold. Mogale: with management, workers and BEE company, to treat Columbus stainless steel dusts to produce a valuable nickel alloy and to produce ferrochrome using Mintek’s new “Enviroplas” technology, but based on its early DC FeCr technology that was taken over by Samancor in 1993. Atoll: with Bateman (outsourcing some operations to BEE companies), was established prior to Mindev’s formation to provide toll processing services to the ferro-alloys industry to recover valuable alloys from slag dumps Specialists in mineral and metallurgical technology FEASIBILITY STUDIES INITIATED • A coastal Electrolytic Manganese Dioxide (EMD) plant based on SA’s abundant manganese ores. EMD is used in the manufacture of dry-cell batteries • A Hot Briquetted Iron (HBI) plant based on SA’s iron ore fines. HBI is used in steel making • A coastal ferro-nickel (FeNi) plant based on SA’s cheap electricity and imported laterite ores. FeNi is used in stainless steel production • A plant to recover platinum concentrate from chromite tailings dumps (the Platdumps project) Specialists in mineral and metallurgical technology BEE Business Partners • • • • • • PDI >51% HDSA Broad-based (equity) Tech expertise Finance (balance sheet) Biz expertise BEE dbase Advert BEE shortlist • • • • BEE Selection Core BEE partner in broad tech areas (eg DC plasma) Local BEE on discrete investment projects BEE R&D partners? BEE IP funding? BEE Financing BEE Partner Informal Other dbases Deposit? Specialists in mineral and metallurgical technology REGIONAL STUDIES Completed or underway • • • Mineral potential of the Gariep SDI of the Northern Cape • A scan of the aluminium downstream industry for the CDC (Coega) • A titanium cluster study in East London for ECDC in Eastern Cape • Mintek signed an historic MOU with the ECDC to develop eight mineral based projects in the Eastern Cape • Mintek is also in discussion with other provinces to help them develop mineral based projects (N.Prov & Limpopo) • Mintek is co-ordinating The Great African Rift Development Strategy (GARDS) on behalf of COHORT (committee of SA’s Science Councils) Mozambican part of the Beira Corridor and Zambezi SDI First phase of a mineral scan for the Nacala corridor in Mozambique, Malawi and Zambia Mineral Economics and Strategy Unit Specialists in mineral and metallurgical technology RESOURCE-BASED SUSTAINABLE DEVELOPMENT • • The RBSD thesis has been incorporated into the National R&D Strategy • The overall objective and aim of the RBSD project is to identify the critical factors and necessary conditions (i.e. “lessons”) required for a resource-based economy such as South Africa to make the transition to a high-tech industrialised state • Study trip to Sweden and Finland to build a research network Mining Inputs Cluster – Mintek has also been tasked with facilitating the development of a mineral processing inputs cluster (consumables, capital goods, services) – Mintek proceeded to initiate the resuscitation of the South African mining cluster and has received the commitment of various industry, government, science council, and organisational support for this endeavour • Defining the inputs cluster in terms of key product categories and the type of goods and services associated with them. • Putting together a database of leading South African and international firms associated with the domestic mining and mineral processing sector. • Funding proposal has been submitted to Fridge Mineral Economics and Strategy Unit Specialists in mineral and metallurgical technology 1. Beneficiation (RBI); 2. Resource Inputs: Capital Goods & Services expl. capital goods • geophysical • drilling • survey • etc. Exploration exploration services • GIS • analytical • data processing • financing • etc mining capital goods • drilling • cutting • hauling • hoisting, etc. Mining mining services • mine planning • consumables/spares • sub-contracting • financing • analytical, etc processing cap. goods • crushers/mills • hydromet plant • materials handling • furnaces, etc. Mineral Processing processing services • comminution • grinding media • chem/reagents • process control • analytical, etc knowledge-based resource-inputs industry Specialists in mineral and metallurgical technology RURAL DEVELOPMENT & POVERTY ALLEVIATION • Kgabane Project – The Kgabane Jewellery and Craft Project was initiated by the Ministry of Minerals and Energy to alleviate poverty and create jobs through the creation of a vibrant and inclusive jewellery industry and taking advantage of existing resources – The project was formally launched in October 2002 during the Mining Week, with a jewellery show. The launch celebrated the Kgabane – Harmony range, which was realised through its partnership with Harmony Gold – A Production and Training Unit has been set up and is operational. The unit is tasked with the creating a range of jewellery products that will be inspired by rural - indigenous craft designs and will utilise a range of materials ranging from natural fibres, beads, ceramics, precious and semi-precious metals and stones – Through the Kgabane Rural Development Jewellery Project, seven groups of crafts-women from rural and urban impoverished areas have been set up and are receiving training according to the unit standards qualification set with the Mining Qualifications Authority Mineral Economics and Strategy Unit Specialists in mineral and metallurgical technology ALEXKOR Audited profit from operations (30 June 2003), R millions 1999 2000 2001 2002 2003 -R69,8 -R36,8 -R31,7 R16,0 R32,0* * Estimated 30 June 2003 Highlights of Mintek’s management • • • • • (17 May 2001 - 16 November 2002) Eliminationof loss-making activities (mid-sea, closure of some plants) Expansion of profit-making activities (shallow marine) Implementation of tight cost control on all activities Repayment of R25m loan to BOE Creation of a permanent, empowered, Alexkor management team Specialists in mineral and metallurgical technology TECHNICAL HIGHLIGHTS GOLD • Developing local and international codes of best practice for cyanide use (Au CIP: health & safety and enviro) • Bioleach amenability tests on sulphide gold concentrates from SA, Zimbabwe, Tajikistan, Dominican Republic, Canada, Kazakhstan and Finland • Optimisation of gold circuits for clients around the globe • Project Autek, focussing on new industrial applications for gold, has been expanded rapidly (breakthrough on respirators) Specialists in mineral and metallurgical technology TECHNICAL HIGHLIGHTS (cont.) PLATINUM • Laboratory and pilot milling and flotation work has been conducted for Anglo American, Avmin, Lonmin, Cluff Resources and Aquarius South Africa • Interest has been expressed in the ConRoast process (smelting of dead-roasted sulphide concentrates in a DC arc furnace) by major platinum producers and new BEE entrants (Cr constraint, enviro) • New modules of MillStar, PlantStar, FrothStar have been developed for process control (40 sites in 15 countries) and Minstral EAF furnace control (80 sites in 10 countries) • Significant progress has been made on the development of alloys based on Pt-Al-Cr-Ru for high temperature applications (eg aeroengines with RR) Specialists in mineral and metallurgical technology TECHNICAL HIGHLIGHTS (cont.) FERROUS METALS • • Cluster computer (“LAN”) approach for furnace and slags modelling Various projects conducted using DC arc furnace (SS dusts, FeCr, FeMn, Ti-Fe) NON FERROUS METALS • • • • Testwork and process design on heap bioleaching of low-grade copper ores (Haib) Solvent extraction for recovery and upgrading of zinc Liquid Magnesium was produced at atmospheric pressure through Mintek’s new magnesium process Zincref- new Mintek Zn refining pilot column commissioned Specialists in mineral and metallurgical technology TECHNICAL HIGHLIGHTS (cont.) INDUSTRIAL MINERALS • • Batch jigging for the Fe and Mn industries has been conducted successfully Optical sorting has gained rapid attention in the mineral processing industry (PGM, limestone, dolomite) SMALL SCALE MINING • • • • Established a small scale mining division Involvement in rural development spans over 9 provinces Examples are: glass beads, diamond treatment facility, iGoli-process for gold recovery, ceramics incubator, etc. Specialists in mineral and metallurgical technology ALLOCATION OF CORE FUNDING • All core funds for 2003/2004 (R80,9m) allocated to specific activities • Allocation was achieved via an internal competitive mechanism similar to the Innovation Fund • Progress reports every 6 months Allocation as follows: Technical Innovation SMME SET/HRD Total R60,4m 74,7% R6,5m 8,0% R14,0m 17,3% R80,9m 100% Specialists in mineral and metallurgical technology PROJECTED TRANSFORMATION From Base Year 2000, to 2008 MANAGERS EXECUTIVE 16 14 12 10 8 6 4 2 0 16 14 12 10 8 6 4 2 0 2000 2003 2004 2006 2008 NON-DG DG 2000 2003 2004 2006 2008 NON-DG DG Specialists in mineral and metallurgical technology OUTREACH PROGRAMMES Specialists in mineral and metallurgical technology HUMAN RESOURCE DEVELOPMENT • 53 Undergraduate students – (81% of designated group) • 17 Postgraduate students – (71% of designated group) • 44 Technikon training students – (100% of designated group) • 7 Engineering-in-training students – (86% of designated group) • Supports the EduMap Programme – (65 core learners and 350 on the programme) • Adopted a school (Kwadeda) in Zola, Soweto • Science lab, ICT lab, >pass rate Specialists in mineral and metallurgical technology QUALITY, ENVIRONMENT & SAFETY • Achieved integration of Mintek’s quality, environmental and safety systems • Mintek certified on 8 August 2002 to be compliant with the ISO 9001:2000 international quality standard • Certification to the ISO14001 international environmental standard expected August 2003 • Awarded 3-star rating by NOSA for safety • Disabling Injury Frequency rate (DIFR) of 1,8 equivalent to 4star rating. Zero fatalities. Specialists in mineral and metallurgical technology SA Energy Map (gas, oil, coal) Selected Mintek Projects Pande;Temane pipeline (Sasol/CEF/ENH) Fe & Mn Fields Lily Pipeline (Petronet) Kudu Pipeline Ore Rail Molteno/Indwe Field A-K Field Pipeline Musuku sites Nqura HBI sites FeNi & SS site EMD sites Specialists in mineral and metallurgical technology SADC: Key Projects SDI’s R&D Projects Specialists in mineral and metallurgical technology Mintek “helping make resources catalyze sustainable development” Thank you, Ke a leboga, Enkosi Kanimambo, Dankie, Siyabonga www.mintek.co.za Specialists in mineral and metallurgical technology