MOD-8000 Process NMR Analyzer

advertisement

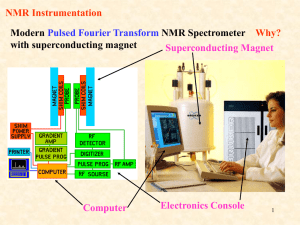

CEMTREX, INC. MODCON SYSTEMS LTD MOD 8000 Process MRS Analyzer 3rd Generation On-Line MRS Analyzers November 2012 The NMR Technology Fundamental Background Proton – Magnetic Moment (M) Hydrogen Atom (Proton) + M Proton is spinning Magnetic moment(M) generated Spins With no magnetic field, magnetic moments are random In Strong Magnetic Field (Bo), magnetic moments align along Bo Align and Precess Magnetic Moments Align and Precess at a Frequency wo wo is Proportional to size of Bo Bo = 1.4 Tesla wo = 60 MHz Magnetic Moment Precessing Spins can be described as a Bulk Magnetic Moment Mo* *Mo = Summation of Individual Magnetic Moments Radio Frequency Pulse RF Pulse turned on for 4-20 microseconds Generates a Second Magnetic Field B1 Re-Align to Second Magnetic Axis Magnetic Field B1 Causes Mo to Move and re-align to second Magnetic axis Re-Align to Original Magnetic Axis When RF Pulse ends protons relax and align to their original equilibrium position along Bo Axis A decay signal is generated : Free induction Decay Signal (FID) Fourier Transform F.F.T. Free Induction Decay(FID) Time domain signal NMR Spectrum Frequency domain The Technology :What is NMR? • Nuclear Magnetic Resonance - is an effect whereby magnetic nuclei in a magnetic field absorb and re-emit electromagnetic (EM) energy at a specific resonance frequency. The resonance frequency depends mainly on the strength of the magnetic field. • This physical phenomena can provides picture or spectra of the hydrocarbon structure, which enable to determine physical and chemical information. • A major benefit of this analyzer is the capability to provides continuous flow-through and accurate chemical and physical analysis of multiple components in dense and opaque materials. • Additional key advantage is a linear spectral response across a broad range which enables models to be extrapolated accurately. NMR technology does not have the continual model maintenance issue which caused by spectral changes seen with crude composition changes. Typical Hydrocarbon Spectrum Evolution of Process NMR Systems • First process NMR analyzer was introduced in the late nineties of the last century. • This analyzer was characterized by its high sensitivity towards temperature variations, which is its main drawback. • In spite of improvement made in previous generations, the magnets were typify by a low to medium homogeneity and of high susceptibility towards temperature fluctuations. The stability of the magnets homogeneity was affected by temperatures differences between process streams. • To achieve stable homogeneity of the magnetic field, temperature fluctuations must be isolated from influencing the magnet properties. • The re-design of the 3rd generation process NMR analyzers (hardware and software), resulted in a decreased temperature susceptibility. Allowable temperature deviations, without affecting the accuracy and reliability of the analytical measurements increased from ± 2C to ± 10C. It enables the NMR analyzer to be applied to any stream, notwithstanding the temperature differences between them. • The overall new design ensure successful application of this unique technology in refineries and chemical process industries. 1997- 1st Generation of Process NMR System – Magnet – 18mm bore size (medium homogeneity; high temperature susceptibility; inadequate repeatability) – 7 Electronic units (Shim controller; RF unit; PS unit; 19” rack PC; Heater controller; ADC PCB; Timing PCB) – Shim coils – manually wrap around coils ( inferior performance; inadequate repeatability) – Probe – Low Q (low SNR- Signal to Noise Ratio); defective temperature insulation – Software – DOS based software (awfully limited; no remote diagnostic; lacking major process requirements; imperfect signal processing algorithms; imperfect communication ability) – Huge overall foot print of the entire enclosure 2000- 2nd Generation of Process NMR System – Magnet – 24mm bore size (high homogeneity; high temperature susceptibility) – 6 Electronic units (Shim-Heater controller; RF unit; PS unit; 19” rack PC; ADC PCB; Timing PCB) – Shim Coils – manually wrap around coils ( inferior performance; inadequate repeatability) – Probe – Low Q (low SNR- Signal to Noise Ratio); imperfect temperature insulation – Software – Windows NT based software – Large overall foot print of the entire enclosure 2010- 3rd Generation of Process NMR System New magnet design – 30mm bore size • The amount of magnetic pieces that assemble the magnet reduced from 34 to 10. This contributed to major improvement in the mechanical structure and enhances the overall magnet stability. • Bore size of the magnet was increased to 30 mm, to allow better temperature insulation between the magnet and the process probe which improve temperature susceptibility. New concept of Process Probe • To minimize heat transfer between samples and the magnet, an entire ceramic pipe passes contactless throughout the entire system. • Temperature insulation increased to a large extent. It prevents temperature fluctuations in the sample stream to affect magnet stability. • Additionally, any welding between ceramic and stainless steel tubes is omitted. • Much better temperature insulation • Higher Q (better SNR) 2010- 3rd Generation of Process NMR System Shim Cassette •Previous applied manually wrapped shim coils were replaced by two single PCB boards assembled in the SHIM cassette. This serves four major functions: Standardize the actual location and shape of the shim coils. Additional thermal insulation between the magnet and the probe (replacing the Aluminum plate in the previous generations). Easy replacement of the SHIM cassette in case of malfunction. Elimination of cables and soldering of the shim coils which caused many failures in previous generations. State of the Art electronics (Only 3 units) • Magnet Unit includes integrated PCB for Shim & Heater Control along with Low Noise receiver pre-amplifier • Spectrometer Unit includes Digital RF & Acquisition Boards along with Power Supply • Panel mount touch screen PC ( ATEX certified) • Overall small foot-print 2010- 3rd Generation of Process NMR System Windows XP or 7 based Software • Includes new algorithm for standard and global Models • Fully automated process capacity • Extensive remote diagnostic capabilities Enclosure • The newly designed MOD 8000 - NMR process analyzer allowed to reduce the entire enclosure of the analyzer itself and the surrounding equipment, such as the sampling systems, air-conditioners etc. Summary- Old Generation Vs. New Generation Features Magnet Weight & Size Field strength Bore size Mechanical 2nd Generation 3rd Generation Advantages & Benefits Improvement in the mechanical structure and enhances the overall magnet stability. Better temperature insulation between magnet and the process probe. 170Kg; 35 x 45 x 40 cm 1.47 Tesla (60Mhz for H+) 24mm 34 pieces 170Kg; 40 x 40 x 45 cm 1.47 Tesla (60Mhz for H+) 30mm to 34mm 10 pieces Process Probe Dewar, Stainless steel brazed to Ceramic tube Plain Ceramic pipe Minimize heat transfer between samples and magnet. Better temperature insulation. Increased reliability and robustness. Higher Q (better SNR) Shim Coils 40 copper coils, manually warped and glued onto Aluminum plate. 2 PC boards contain 40 copper coils, fit together as a SHIM cassette Standardize location of the shim coils. Additional thermal insulation. Easy replacement of the SHIM cassette. Elimination of cables & soldering. Hardware 6 Electronic units Plenty of wiring & cables 3 Electronic units Minimal wiring Increased reliability. Overall small foot-print. Software Windows NT Windows XP or 7; New algorithm for standard Models. Fully automated process capacity. Extensive remote diagnostic capabilities. Temperature Susceptibility Environment Fluctuations between streams Must be within : ±1.5°C Should not exceed : ±2.5°C Must be within : ±3°C Should not exceed : ±10°C Enables the analyzer to be applied to any stream, notwithstanding the temperature differences between them. Simpler Sampling System. Why On Line Analyzer? • Enables real time adjustment of processing conditions • Increases product quality • Prevents the need for reprocessing • Reduces off-spec or borderline product • Reduces expensive laboratory analyses On-Line Analyzers Categories • Discrete Analyzers – Direct analyses of a physical property according to standardized methods, i.e. Density, Boiling Points, RVP, RON, MON… • Correlative Analyzers – Correlative analyzers are based on the correlation between spectral data and physical properties, i.e. NIR, RAMAN, IR and NMR spectrometry based process analyzers – Physical properties are calculated by means of chemo-metrics – Multi properties for each samples Principles of Chemo-metrics Calibration Phase Reference Spectra Reference Measurements mix# 0.25 0.2 0.15 0.25 0.1 0.2 0.05 0.15 0 0.1 0.2 -0.05 810 0.05 0.15 860 0.1 0.2 -0.1 0 -0.05 810 0.05 0.15 860 -0.15 0.25 0.25 910 -0.1 0 0.1 -0.15 -0.05 810 0.05 -0.1 0 -0.15 -0.05 960 1010 910 860 810 960 910 860 + 1060 1010 960 910 1060 1010 960 1060 1010 1060 HCl 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 0 1.178964 0.790395 1.090314 1.06258 0.852719 0.99566 0.873404 0.988138 0.849897 1.000474 1.102819 1.135659 0.799425 0.950737 Calibration Model HF 0 0.39912 0.442637 0.496751 0.543865 0.593886 0.634382 0.669103 0.721126 0.778561 0.81478 0.853354 0.893109 1.009638 0.958367 -0.1 -0.15 Measurement Phase Unknown Spectra Calibration Model 0.25 0.2 + 0.15 0.1 0.05 A1(t) A2(t) tote changeover new lot changeover 0.04 0.03 0.02 0.01 0.05 0 0 -0.05 -0.01 -0.1 -0.02 -0.15 -0.03 -0.04 -0.2 -0.05 -0.25 Wed 07/7 Fri 09/7 Sun 11/7 Tue 13/7 Thu 15/7 Sat 17/7 Mon 19/7 Wed 21/7 Fri 23/7 Sun 25/7 Tue 27/7 Thu 29/7 Sat 31/7 Mon 02/8 Wed 04/8 Fri 06/8 The Linear Modelling - Advantage • Fewer Data Points required to build model • Extrapolation for “out-of-range” feeds benefits : • Faster start up • Low maintenance 165 145 125 Predicted Flash (C) of model Distillates Flash Point 105 Global Model Unknown Sample 85 65 45 25 25 75 125 Actual Flash (C) Fields of Application for NMR Analyzers • • • • • • • • • Refineries Olefins plants Biotech Bio-Chemical Ag/Food R&D - Both Academia and Industrial Polymer Chemical Industries Pharmaceuticals Case Study - Crude Oil Distillation Properties Measurements by NMR • • • • • • • • • Cetane Index API Gravity Distillation Flash Point Cloud Point Sulfur Content Freeze point Octane (RON, MON) Specific gravity • • • • • Density Boiling Point / Range Naphthalene Content PIONA Pour Point • Applicable to all refinery streams (transparent dense, opaque) • Not influenced by hetero-atomic substances – not influenced by crude switching Case Study – Liquors Analysis • Case Study – Dairy Products Overlay of 4 Cream Cheese Products Water •15 •10 Saturated fat and protein Unsaturated fat region Carbohydrates and sugars •5 •0 • 20 • 40 • 60 • 80 • 100 • 120 • 140 Case Study – Food Oil Analysis Oils and fats are key elements in the taste, melting properties, shelf life, and appearance of foods 15 10 5 0 20 40 60 80 100 120 140 Arbitrary Y / Arbitrary X Overlay X-Zoom CURSOR File # 4 = OILINT0001 6/27/00 6:30 AM Res=None Foxboro NMR SPC File. Composite Spectra of 4 Oils (Olive, Sesame, Canola and Caesar Salad Dressing) Showing Differences Observed by NMR Thank You for Your Attention