Presentation

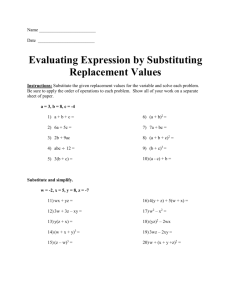

advertisement

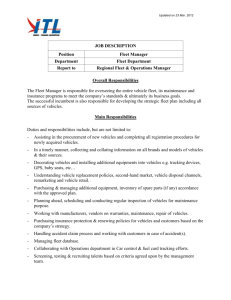

How to Get a Newer, Better Fleet Gary Hatfield Mercury Associates Why do fleets get too old? – – – – – Lack of replacement funding Inadequate replacement planning Lack of structured approach Poor data Failure or inability of fleet manager to communicate the problem to upper management and CFO © 2014 Mercury Associates Why is the timely replacement of vehicles important? – – – – – – – – – Getting a newer, better fleet Projecting a positive image Managing total costs of vehicle ownership Minimizing fleet maintenance costs Improving safety and technology Improving employee productivity Reducing fuel consumption and emissions Improving utilization of vehicles Reducing the need for spare vehicles © 2014 Mercury Associates Why aren’t vehicles replaced in a timely manner? – Choice of financing approach affects decisions: • Pay before you go versus pay as you go (purchase vs. lease) • Sunk cost versus ongoing depreciation – Focus on marginal M&R cost versus total cost – Lack of understanding of vehicle life-cycle costs and how to compute the ideal cycle – Lack of understanding of the magnitude and volatility of fleet replacement costs – Lack of understanding of the impact of vehicle age on vehicle performance © 2014 Mercury Associates How do we fix the problem? 1. Right-size and Right-type the fleet (VAM) 2. Optimize replacement cycles for each type of vehicle 3. Compute the cost difference between current and optimal replacement cycles 4. Use the cost savings to make the business case for sufficient capital funding 5. Develop a long-range capital-funding plan 6. Alternatively, lease instead of buy © 2014 Mercury Associates 1. Right-size and Right-Type the Fleet (VAM for Federal fleets) • GSA provides VAM guidance for eliminating unnecessary or non-essential vehicles from an agency's fleet inventory – FMR Bulletin B-30 • Ensure lifecycle cost-effectiveness (lease vs. own; optimized replacement cycles for owned) • VAM must address composition of light duty fleets (i.e., vehicle types and sizes) • Agencies must determine their optimal fleet inventory (including alternatively fueled vehicles) using the VAM and post on agency websites • Agencies must develop and submit fleet management plans annually for achieving their inventory targets © 2014 Mercury Associates Total Cost of Ownership – TCO: – Essential for determining optimum replacement cycle – Used for comparing buying vs. leasing – Aggregated total of all costs of owning and operating a vehicle over a given life span (lifecycle) – Includes all fixed and variable costs © 2014 Mercury Associates Depreciation Fuel Interest Insurance Maintenance License & Tax Source: ConsumerReports.org • Fixed Costs: – Depreciation = purchase price + upfitting cost – resale value – Taxes, insurance, license • Variable Costs – Fuel – Maintenance & repair – never include accident costs • TCO must include ALL costs! © 2014 Mercury Associates 2. Optimizing Vehicle Replacement Cycles – Reduces fleet cost – Makes business case for replacement funding – Usually results in a newer, safer, more fuel-efficient fleet – Establishes the lifecycle that minimizes Equivalent Annual Cost (EAC) – Specifies the year (age) vehicle should be sold © 2014 Mercury Associates Lifecycle Cost Analysis (Single-Axle Dump Truck) $25 Total Cost of Ownership Costs (000) $20 $15 Ideal Replacement $10 M&O Cost $5 Depreciation $1 2 3 4 5 6 7 8 9 10 11 12 Replacement Cycle (years) 11 © 2014 Mercury Associates Determining Cost Savings – Develop your Lifecycle Cost Analysis model (LCA - get help from your CFO office or fleet expert if needed) – Choose a class of vehicles with large population – the more the better – Gather all required data elements – Run the LCA model to determine optimal replacement age – Compare existing cycle EAC with optimum cycle EAC and compute annual cost savings – Multiply annual cost savings per vehicle x number of vehicles © 2014 Mercury Associates Optimizing a Replacement Cycle ORCA™ = Optimized Replacement Cycle Analysis Single-Axle Dump Truck Replacement Cycle Meter at replacement CAPITAL COST Total Residual Value Annual Depreciation Cumulative Depreciation OPERATING COSTS Annual M&R Cost Annual Fuel Cost Total Annual Operating Cost Cumulative Operating Cost TOTAL COST Annual Total Cost Cumulative Total Cost NPV of Cumulative Total Cost Equivalent Annual Cost 1 6,209 2 12,418 3 18,627 4 24,836 5 31,045 6 37,254 7 43,463 8 49,672 9 55,881 $ 114,750 $ 20,250 $ 20,250 $104,288 $ 10,463 $ 30,713 $93,094 $11,194 $41,906 $84,085 $ 9,009 $50,915 $75,972 $ 8,113 $59,028 $ 70,426 $ 5,546 $ 64,574 $ 66,091 $ 4,335 $ 68,909 $ 63,093 $ 2,998 $ 71,907 $ 59,855 $ 3,238 $ 75,145 $ $ $ $ 2,963 2,755 5,718 5,718 $ 4,164 $ 2,867 $ 7,031 $ 12,749 $ 5,145 $ 2,982 $ 8,127 $20,876 $ 6,028 $ 3,102 $ 9,131 $30,007 $ 6,863 $ 3,227 $10,090 $40,097 $ 7,671 $ 3,357 $ 11,028 $ 51,125 $ 8,466 $ 3,493 $ 11,959 $ 63,084 $ 9,258 $ 3,633 $ 12,892 $ 75,975 $ 10,053 $ 3,780 $ 13,833 $ 89,809 $ $ $ $ 25,968 25,968 24,499 25,234 $ $ $ $ $19,320 $62,782 $59,228 $20,939 $18,139 $80,921 $76,341 $20,538 $18,203 $99,125 $93,514 $20,419 $ 16,574 $115,699 $109,150 $ 20,149 $ 16,294 $131,993 $124,522 $ 19,987 $ 15,890 $147,883 $139,512 $ 19,874 $ 17,071 $164,954 $155,617 $ 19,986 17,493 43,462 41,002 21,428 What data elements are required? © 2014 Mercury Associates 13 3. Compute Cost Difference Between Current & Optimal Cycles Vehicle Type Hybrid-Electric Sedan 7 to 9-Passenger Van Patrol Car Investigative Sedan ½-Ton Pickup Truck ¾-Ton Pickup Truck Utility Truck Bucket Truck Dump Truck (165) Refuse Truck Ambulance Fire Pumper Truck Current Cycle (years) 4 15 8 11 12 16 20 17 20 9 Recommended Cycle (years) 4 8 6 7 5 6 10 9 8 4 4 16 2 9 EAC Under Current Cycle $ 4,053 $ 7,050 $ 9,701 $ 4,777 $ 6,821 $ 8,823 $ 16,265 $ 23,401 $ 26,731 $ 124,945 $ 27,944 $ 77,195 EAC Under Recommended Cycle $ 4,053 $ 5,379 $ 9,405 $ 4,214 $ 4,761 $ 5,989 $ 14,098 $ 17,947 $ 19,874 $ 79,672 $ 23,246 $ 48,344 Annual Per-Unit Savings $ $ 1,671 $ 296 $ 421 $ 2,060 $ 2,834 $ 2,167 $ 5,454 $ 6,857 $ 45,273 Annual FleetWide Savings $ $ 138,684 $ 510,648 $ 414,298 $ 688, 102 $ 2,324,056 $ 318.567 $ 414,530 $ 1,131,405 $ 5,794,962 $ 4,698 $ 28,851 $ 483,873 $ 3,289,031 Total Savings > $14.5 Million per Year! © 2014 Mercury Associates 14 4. Use $ Savings for Your Capital Funding Business Case © 2014 Mercury Associates Don’t be intimidated by the business case… Just show them the savings! 5. Develop Long Range Capital Funding Plan 1. Identify purchase prices (with inflation) for each type of asset 2. Project future replacement dates and costs for each asset 3. Calculate total fleet replacement costs for each future year 4. “Smooth” the plan by delaying or advancing the replacement of specific vehicles to reduce near-term peaks and valleys in fleet replacement costs © 2014 Mercury Associates Baseline Plan – Existing Fleet Gross Replacement Costs - Existing Fleet Size $300 $260 Million Backlog $250 (Millions) $200 $150 $100 $50 $0 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 Fiscal Year © 2014 Mercury Associates Baseline Plan – Right Sized Fleet Gross Replacement Costs $300 $250 $210 Million Backlog (Millions) $200 $150 $100 $50 $0 20102011201220132014201520162017201820192020202120222023202420252026202720282029 Fiscal Year © 2014 Mercury Associates Smoothed Plan Gross Replacement Costs – Smoothed $300 $250 (Millions) $200 $150 $125 Million Backlog $100 $50 $0 20102011201220132014201520162017201820192020202120222023202420252026202720282029 Fiscal Year Approximately $50M per year needed to sustain the fleet © 2014 Mercury Associates Comparison – Baseline vs. Smoothed Baseline v Smoothed Costs $300 $250 (Millions) $200 $150 $100 $50 $0 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 Fiscal Year Baseline Smoothed © 2014 Mercury Associates 18 How do we get more capital $ for fleet replacement? 1. Empirically identify optimal vehicle replacement cycles 2. Develop a plan that quantifies long-term fleet replacement costs 3. Identify total fleet costs under different levels of replacement spending 4. Work with the CFO to show potential savings with proper investment Every excess dollar spent on a fleet due to suboptimal replacement practices is a dollar that cannot be devoted to an agency’s primary mission! © 2014 Mercury Associates Summary – An old, costly fleet did not happen overnight and cannot be fixed quickly – Optimize replacement cycles – Develop long-term capital plan – Establish a 5-year plan for fleet renewal © 2014 Mercury Associates MERCURY ASSOCIATES, INC. “Specializing in the science of fleet management.” For more information, contact: Gary Hatfield Vice President, Federal Fleet Consulting ghatfield@mercury-assoc.com (941-685-6907) 24

![[STORY ARCHIVES IMAGE]](http://s3.studylib.net/store/data/007416224_1-64c2a7011f134ef436c8487d1d0c1ae2-300x300.png)