Production Flowchart

advertisement

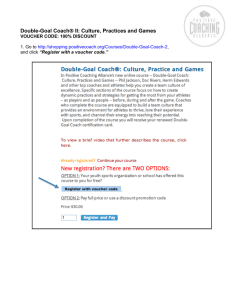

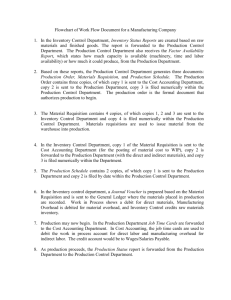

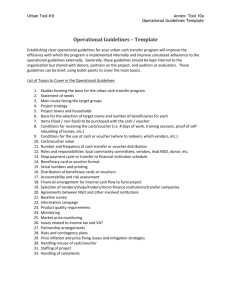

Production Cycle PRODUCTION FLOWCHART: PAGE 3 Kevin Ma Steven Radcliff Jie Chen Ernesto Pena Bryan Vien Narrative The company issues reports at the beginning of the period to check the status of raw materials, finished goods, and the capacity of the production lines. The production schedules are sent to the production department and the material requisitions were approved by the inventory control department; the production takes place. In the meantime, the production schedule is made. After the production is completed, a production status report is created and is sent to the production control department. The completed units are sent to the inventory control department. Narrative The cost accounting department receives purchase orders, job time cards, and material requisition forms and processes the financial data related to the job order. The journal vouchers are used to update the general ledger to post adjustments. The documents are sent to the management. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 1 Prior to any production, Inventory Control Department and Production Department each performs a routine procedure. Production Control Production Department Inventory Status Report Factor Availability Report Inventory Control Inventory Status Report Factor Availability Report Step 1 Production Control Production Department Inventory Status Report Factor Availability Report Inventory Control Inventory Status Report Factor Availability Report • Inventory Control Department performs a status check on the amount of raw materials and finished goods and then sends the report to Production Control Department. • This is to inform the Production Control Department the amount of available raw materials can go into production, and the amount of finished units can be used to fill customers orders. Step 1 Production Control Production Department Inventory Status Report Factor Availability Report Inventory Control Inventory Status Report Factor Availability Report • Production Department checks the production capacity and issues a Factor Availability Report and sends it to Production Control Department. Factor Availability Report – states the available production capacity. It contains how much resource such as labor, land, capital etc are available. • With these information, the Production Control Department can make plans to schedule productions, so all orders can be met in time. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 2 Production Control Production Department Production Order 1 Cost Accounting Production Order 1 2 Production Order 2 3 N Completed Production Order • Production Control Department issues production orders which authorize the unit production. a. A copy of the P.O. is sent to Cost Accounting Department. b. Another copy of the P.O. is sent to the Production Dept. which authorizes them to produce the order. c. The last copy of the P.O. is filed numerically in Production Control Department. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 3 Production Control Material Req. Production Department 1 Inventory Control Material Req. 2 Cost Accounting 1 2 3 3 4 N • Production Control issues material requisition. a. Production Control send 3 copies of the Material Requisition to inventory control. b. The 4th copy of the Material Requisition is filed numerically in Production Control. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 4 Production Control Production Department Inventory Control Material Req. Material Req. Cost Accounting 1 2 Material Req. 2 3 N • Inventory Control receives 3 copies of the Material Requisition from Production Control. a. 1 copy goes to Cost Accounting. b. Another goes to the Production Dept. along with the requested amount of raw materials. c. The last copy is filed numerically in Inventory Control to keep track of the inflows and outflows of raw materials 1 Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 5 Production Control Production Schedule 1 Production Department 2 Production Schedule 1 D • Production Control sends a copy of the Production Schedule to the Production Dept. This informs the Production Department the scheduled date of completion of that particular order. • The other copy of the Production Schedule is filed in Production Control by date. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 6 Inventory Control General Ledger Journal Voucher Journal Voucher • Inventory Control creates a Journal Voucher which contains information about the amount of material used in production. And this journal voucher is used to update the general ledger. Journal Voucher updates general ledger. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 7 Production Department Inventory Control Production Order 2 Production Order 2 Completed Production Order 2 • This is the actual production process. As the Production Department receives the production order, which is the approval of production from step (2), and the raw material required for production from step (4), the production takes place. • The material requisition form is attached to the production order form, and along with the finished production, they are sent to the Inventory Control Department. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 8 Inventory control Completed Production Order 2 Cost Accounting Completed Production Order 2 1. Inventory Control receives the Completed Production Order along with the Material Requisition from the Production Dept. (7) a. They post to the inventory records. Quantity produced Quantity of material used b. It is sent to Cost Accounting i. To summarize production ii. Record unit cost/total cost/quantity etc. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 9 Production Department Job Time Card Cost Accounting Job Time Card 1. The Production Dept. sends the Job Time Cards to Cost Accounting to calculate Labor Costs. a. Cost Accounting posts to WIP records. b. Direct Labor Cost c. Indirect Labor Cost Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 10 Production Control Production Department Production Status Production Status Production Control receives a Production Status Report from the Production Dept. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 11 Cost Accounting Post to WIP Records Production Order 1 Cost Accounting posts the Production Order to WIP records. The Production order was received from Inventory Control earlier in step (2). Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 12 Cost Accounting Post to WIP Records Material Req. 1 Cost Accounting posts the Material Requisition to WIP records. The Material Requisition was received from Inventory Control in step (4). Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 13 Cost Accounting Journal Voucher General Ledger Journal Voucher 1. Cost Accounting updates the General Ledger by using a Journal Voucher to record Conversion Costs = Direct Labor + Manufacturing Cost Overhead Cost Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 14 Cost Accounting Journal Voucher General Ledger Journal Voucher 1. Cost Accounting updates the General Ledger by using the Journal Voucher to record the Cost of Goods Manufactured. + + + = Direct Material used Direct Manufacturing Labor Manufacturing Overhead Costs Work in Process (beginning) Work in Process (ending) Cost of Goods Manufactured Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Step 15 Cost Accounting General Ledger Completed Production Order 2 M Management M Cost Accounting sends the Completed Production Order to Management. Production Flowchart Production Control Production Department Inventory Control Inventory Status Report Cost Accounting General Ledger Inventory Status Report 1 Factor Availability Report Raw Materials and Finished Goods Factor Availability Report 1 Production Order 2 3 2 11 Post to WIP records 1 Production Order 2 Production Order Materials Placed in Production 6 Journal Voucher Journal Voucher N Post to WIP records 4 1 Material Requisition 1 Material Requisition 2 2 3 4 2 Material Requisition 1 Material Requisition 3 12 7 3 N Conversion Costs 13 N Attach to completed Production Order 1 Production Schedule 2 Journal Voucher Journal Voucher 1 Production Schedule Post to WIP records 5 9 D Job T ime Cards Job T ime Cards Post to Inventory records 10 Production Status Sum m arize Production Production Status 2 2 5 14 Completed Production Order Completed Production Order Cost of Goods Manufactured 8 Journal Voucher Journal Voucher 2 Completed Production Order M Management M 15 Threats and Controls Threat – lack of management control during the process could cause under or over production Control – proper approval of production orders by involving management earlier on in the process(2) Control – periodic status reports to management Threats and Controls (cont) Threat – inaccurate inventory control, threat is this system only shows when raw material is being used, but it does not show when/how many completed units the company has on hand Control – inventory control department should update the general ledger by sending a journal voucher after production has been completed Control – use RFID technology to keep track of inventory Control – do a periodic physical inventory counts Control – move tickets should be used to document subsequent movement of inventory. Threats and Controls (cont) Threat – employees cheating on how many hours they actually worked Control – computerized time card system that automatically records and tightened management control procedures Control – install camera’s to monitor that employees are where they say they were Control – have manager responsible for time card accuracy from their specific department Threats and Controls (cont) Threat – time conflicts might occur between different production lines without a proper production schedule when planning production orders. Control – make the production schedule right after the production order. THANK YOU FOR YOUR TIME!