The Channel Tunnel (Chunnel) Project Case Study

advertisement

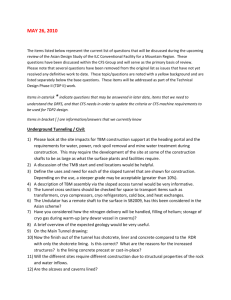

Background 0 An underground tunnel connecting England and France. 0 The largest privately funded project ever undertaken. 0 Bankers underwriting the funding for the project. Project Proposal 0 A 32-mile (51.5 km) double-rail tunnel 0 Will accommodate through-trains & special car-and- truck-carrying shuttle trains. 0 Their bid was US$5.5 billion. 0 The country with the highest standard would prevail. New Technology 0 New technology being used. 0 State-of-the-art laser and computer tech. 0 The Chunnel project was completed but it was late and over budget. 0 The new technology required significant modifications during the project due to unexpected conditions and changes required by various parties. Phases for the Project 0 1-Inception-Historical background, overall objectives, political climate, and pre-feasibility studies. 0 2-Development-Overall planning, feasibility studies, financing, and conceptual design. 0 3-Implementation-Detail design, construction, installation, testing, and commissioning. 0 4-Closeout-Reflection on overall performance, settlement of claims, financial status, and post-project evaluation. Inception Phase 0 The ideas was to create a fixed transportation link between England and France. 0 This would create a spur of economic development. 0 Improve trade using the new alternative high-speed transportation. Ground Rules & Time Line 0 1974- Initial tunnel ideas gather but abandoned. 0 1978-British & French discussions resumed. 0 1983-Frensh & British banks & contractors propose tunnel scheme. 0 1984 British and French agree to common safety, environmental, and security concerns. Ground Rules & Time Line 0 1985-French & British governments ask for fixed-link proposals. 0 1986 The project was awarded to Channel Tunnel Group/FranceManche a.k.a. Eurotunnel and declared owner of 55-year concession for the link. Ground Rules & Time Line 0 1987 the “Concession Contract” was awarded to Channel Tunnel Group/FranceMache (CTG/FM) bid for US$5.5 billion and ended on Dec. 15, 1994 with a fully operational station. 0 The project was 19 months late and had a cost overrun of some US$3 billion (total construction cost of US$7.1 billion). 0 On 1 December 1990, Englishman Graham Fagg and Frenchman Phillippe Cozette broke through the service tunnel with the media watching. The Implementation Phase 0 Not agreeing in details resulted in eventual delays and cost overruns. 0 Warning signs of rolling stock had not yet been designed (vehicle and freight cars). 0 No contingency was set aside to cover “unknown unknonws” (Ventilation system). 0 The specifications for British rolling stock and French rolling stock were not the same. The Implementation Phase 0 With costs out of control, fixed-priced contract were awarded to contractors in order to have any chance of winning the bid and not risk losing the bid to next lowest bidder. 0 Contractors assumed an optimistic case, and since underground construction is rife with changed conditions. Early Problems 0 No air-conditioning was included costing US$200 million more. 0 The Intergovernmental Commission (IGC) approved designs that weren’t within the original concession agreement. 0 Thus indicating possible problems with initiation and planning. Early Problems 0 The lack of defined scope makes resource planning, cost estimating, and budgeting difficult. 0 Return on Investment (R.O.I.) assumptions made in the planning stages may not prove accurate. Leaving a trail of unhappy investors and stakeholders. Early Problems 0 From US$5.5 Billion to US$7.1 Billion 0 Ongoing safety requirements changes sought by ICG continued to create negative impact. 0 Not enough was understood to limit the impact of known and unknown risks. 0 Contractual errors were made in the estimates and risk allocation method, costing additional US$2.25 billion. Early Problems 0 Passenger doors be widened from 600mm to 700mm. Cost increase from US$9 million to US$7O million. 0 Objectives of a project need to be identified and communicated clearly from the beginning. This was the largest and most damaging failure of both governments. Early Problems 0 By not having the real goals, objectives, and scope defined early, and by not implementation a contract method that directly linked the rewards to contractors at all levels of the procurement chain to those objectives. 0 The project was essentially run by bankers. Finances 0 The Chunnel project had to be financed through private sources without government aid or loan guarantees. 0 The government was prohibited from regulating prices except in monopolies. 0 Financing was pursed via equity and loan capital markets. Finances 0 Most shareholders seeking equity interest were mostly in France and eventually Britain. 0 206 banks world wide participated with the loan. 0 The refinancing had to be pursued, should negative variances in time and cost estimates occur. Success From a Project Management Perspective 0 Contracts are a critical part of the procurement management process. 0 Contracts define the scope of work, cost, timeline and rules of engagement. 0 Risk planning and mitigation needs to be ongoing part of each project. 0 The hope is that most material risk are identified, quantified, and prioritized early enough so that an effective risk response strategy can be establish. Success From a Project Management Perspective 0 3 tunnels total North, South, and Service. 0 46 contractors were hired. 0 The tunneling itself was finished 3 months ahead of schedule. 0 Each team member has a responsibility for quality. 0 Quality requirements were mostly defined up-front, quality planning, quality assurance, and quality control. Success From a Project Management Perspective 0 Team work was necessary to complete this project. 0 It was estimated that 15,000 workers were employed on the project. 0 From a P.O.V. quality management was a success. The Development Phase 0 Consisted of detailed planning, communication, agreements, and government approvals. 0 A large part of the struggles were do to inflexibility of some characteristics of the project, and cross-cultural exchange between 2 countries. The Development Phase 0 A scope creep played a large part in the substantial increase from its initial cost estimates, and its completion behind schedule. 0 The scope was not fully assessed and the proper precautions to prevent scope creep weren’t put in place. 0 The project team were able to understand the complexity and were able to use previous research on the soil, but in the end, the lack of continued focus on the scope resulted in the frustrations of trying to do too much. Closeout 0 The completion of the project was rushed to allow operations to begin before the entire effort was completed. 0 The tunnel was actually completed. 0 Teamwork and communication were broken down into several key areas. Financial Issues during Closing 0 Focused on minimizing their losses, refused to accept negotiated arrangements for settling some of the key contracts disputes. 0 International Chamber of Commerce was involved with helping the various competing sides to bargaining table in an attempt to resolve key portions. From a Management P.O.V. 0 Even with a high-level design and respective rough- order-of-magnitude estimates were appropriate. 0 In 1996 the American Society of Civil Engineers identified the tunnel as one of the Seven Wonders of the Modern World. Rating Scale: 5-Excellent, 4-Very Good, 3-good, 2-poor, 1-Very Poor Project Management Area Scope Management Time Management Quality Management Human Resource Management Communication Management Risk Management Procurement Management Integration Management Implementation Phase 3 1 3 5 2 4 3 2