Pumps and Actuators - Department of Agricultural and Biological

TSM363 Fluid Power

Systems

Pumps and Actuators

Tony Grift

Dept. of Agricultural & Biological Engineering

University of Illinois

1

Agenda

• Units, Pumps, Pressure Relief Valve

• Cylinders

• Double acting/ Single acting

• Single rod, Double rod

• Cylinder construction

• Pressure, Flow, Work and Power in cylinders

• Pressure, Flow, Torque and Power in pump/motors

• Volumetric and Torque efficiency of pump/motors

• Pump implementations

2

Hydraulic Units (SI)

Pascal

Newton

Watt

1 Bar

10

5

N m

2

10

5

Pascal

Pressure p

N m

2

Flow

Area q

Force F

Work

A

W

m m s

3

Power

Torque

P ow

T

Nm s

Displaceme nt D

m

3 rad

3

Control can take place in various ways. Power is pressure times flow rate

• Pressure control

• Pressure relief valve

• Pressure reducing valve (regulator)

• Pressure compensation: Only provide the pressure needed to move the load(s). In idle reduce energy loss by providing a open center condition

• Pressure compensated pump. Make the pressure independent of the flow required to move the load at a preset speed. Deal with multiple cylinders that need to move simultaneously

• Flow control

• Throttle (needle valve, very crude, Orifice equation applies)

• Pressure compensated Flow Control Valve: Assure a preset flow rate independent of the pressure drop across the valve

• Pressure and Flow control

• Load sensing systems: combine pressure and flow control to reduce energy losses

4

Choice of pump depends on these factors

• Application

• Max and working Pressure and Flow rate requirements

• Constant rate / Variable rate

• Pump efficiency

• Leakage

• Noise level

• Contamination sensitivity

• Price

5

Pump ‘family tree’

6

Video 8: Power units (3:26)

• Power supply unit

• Converts Mechanical energy into hydraulic energy

• Hydraulic Fluid is conditioned (cooled, cleaned)

• Components

• Drive motor

• Safety valve

• Oil reservoir

• Pump

• External Gear pump function (constant delivery)

• Where teeth unmesh, volume increases, oil enters

• Where teeth mesh, volume decreases, oil leaves

• Pressure only builds when there is a resistance (load)

• Safety valve needed to prevent failure when cylinder stalls

• Pressure Relief Valve diverts flow back to tank when cylinders are stalled

• Reservoir

• Cools oil

• Cleans oil from suspended particles, water and air which takes time (Capacity)

• Filters trap impurities

• 70% of all malfunctions are due to impurities

7

Mechanical Torque in a pump/motor

• In case of a motor shaft, the Work can be found by multiplying a force through a distance. Suppose we assume a force at a distance . The total work per radian of the shaft is now equal to

W

MECH

F * r

F r r

1 Radian

8

Mechanical Power in a pump/motor

• The power is now equal to this value divided by the time per radian.

• If the shaft is turning at

rad s

• Since for Power we have to divide the Work by time, this leads to:

Pow

MECH

W t

F

1

* r

*

T

*

Pow

MECH

Nm s

* T

rad s

*

9

q

q

Pow

HYD

p * q

10

Pump/Motor flow is proportional to the speed of rotation and the displacement per revolution

Pump displacement is a volume per angular displacement (radian).

Assuming the volumetric efficiency is 1.0 (no leakage) q

D *

More realistic, with Volumetric Efficiency (why in numerator?) q

D *

*

V

, 0

V

1

11

Torque Required to drive a pump is proportional to

Pressure

Pow

HYD q

D *

p * q

Pow

HYD

p * D *

Pow

HYD

Pow

MECH

p

T

*

*

D

*

T

p *

Constant

(No losses here)

More realistic, with Torque Efficiency (why in the denominator?)

T

p * D

T

, 0

T

1

12

Power Efficiency of Pumps

From before:

T

p * D

T q

D *

*

V

q

*

V

And

Pow

MECH

* T

Power Efficiency: Without loss

Pow

MECH

* T

q

D *

V

*

p * D

T

q *

p

V

*

T

Efficiencies

13

Data sheet Eaton MHT vane pump

14

A Pressure Relief Valve (PRV) provides overload protection

• In the symbol there are

• Main pressure lines (solid)

• Sense lines (dashed)

• Spring return

• Adjust arrow

• Direction arrow

• Pressure and Tank connections

15

Some questions about a PRV

• Is this valve normal open or normal closed

• Closed / open, think of a door

• Where is the pressure sensed, upstream or downstream and why ?

• What is the pressure at the tank port ?

• Why is a PRV adjustable ?

16

Cylinders

17

Video 9: Hydraulic actuators (6:58)

• Cylinders convert hydraulic energy into linear motion

• Motors generate rotary motion

• Single acting cylinder: One working port

• Can do work in only one direction (extension)

• External force retracts the cylinder

• No perfect seal, over time oil passes on to unpressurized side: need for drain

• Good for high load single lift (scissor platform)

• Return stroke through gravity or spring return

• Plunger (ram) cylinders: Cap end only, very powerful and stiff

• Double acting cylinder: Two working ports

• Pressure advances and retracts the cylinder: push and pull

• Cylinder retracts faster than it extends due to different areas of cap end and rod end side

18

Video 9: Hydraulic actuators (6:58) cont.

• Example: ratio of cap and rod end side area is

2:1.

• Assume

• During extension rod end pressure =0

• During retraction cap end pressure =0

p

N

m

2

* A m

2

A

CAP

F

F

EXT

RET

2*

*

A

ROD

CAP

ROD

F

EXT

A

CAP

A

ROD

* F

RET

2* F

RET

19

Video 9: Hydraulic actuators (6:58) cont.

• Example: ratio of cap and rod end side area is 2:1.

v

s

q

m

3

s

2

v v

A

CAP

EXT

RET

2 *

A q

A

CAP q

A

ROD

ROD

v

EXT

*

A

ROD * v

RET

A

CAP

1

2

* v

RET v m

P

Nm s

• Linear Power:

Pow

Watt

*

20

Hydraulic Cylinder

21

Cylinder construction

1 2 3

7

4 5 6

8 9 10 11 12

22

13

1 2 3

7

4 5 6

8 9

1. Tie rod

2. Rod end head

3. Rod end port

4. Piston seals pressure)

5. Cap end head

6. Cap end port

7. Rod bearing

8. Rod wiper

9. Rod seal

10. Barrel

11. Piston rod

12. Piston

13. Static seal

10 11 12 13

( keeps cylinder assembly together )

( mounting point )

( fluid entrance/exit point )

( dynamic, seals cap end from rod end

( mounting point)

( fluid entrance/exit point )

( lateral support of the rod )

( keeps dirt out )

(dynamic, seals fluid from environment )

( cylinder )

( mechanical force output )

( pressure to force converter )

( seals fluid from environment ) 23

Cylinders are perfect for linear motion

• Single rod (most common)

• Dual rod (power steering)

24

Telescopic cylinder

25

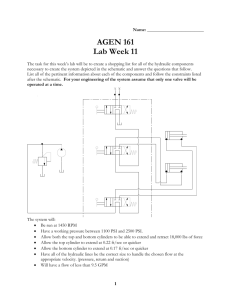

Basic Circuit with Double Acting Cylinder

Pressure gage

Overload

Protection

Reservoir Pump

Actuator

Electric Motor

26

Question: Can the cylinder be moved ?

1) Cylinder:

•

Double acting, differential area

2) Fluid is incompressible

3) Rod and cap end connected

Check in FluidSim

27

Hydraulic Work (rod end pressure = 0) q

C s

F p

C

A

C

A

R p

R

W p

R

F * s

0 p

C

* A

C

* s

28

Differential area cylinder: Flow and displacement q

C q

R s

F

R

F

C

F p

C

A

C

A

R p

R q

C q

R

A

C s

A t t

R s

A

C

A

R v v

q

C

A

C

q

R

A

R

29

Differential area cylinder: Force equilibrium q

C q

R s

F

R

F

C

F p

C

A

C

A

R p

R

F

p A

F

C

p

F

R

30

Differential area cylinder: Work q

C s q

R

F

R

F

C p

C

A

C

A

R p

R

W

Fs

s

p

C

A

C

p

R

A

R

p

R

0

F

31

Differential area cylinder: Power q

C s q

R

F

R

F

C

F p

C

A

C

A

R p

R

W

Fs

s

p

C

A

C

p

R

A

R

Pow

W t

F s t

p

C

A

C s

p

R

A

R s

p

C q

C

p

R q

R q

C q

R

32

Dual rod cylinder: Power q

C s

F

R q

R

F

F

C p

C

A

C

A

R p

R

W

Fs

s

p

C

A

C

p

R

A

C

Pow

W t

F s t

p

C

A t

C s

p

R

A t

C q

C q

C s

q

C

C

p p

R

33

q

q q

C

q s

F

R

F

C q

R p

C

A

C p

R

A

R

Pow

q *

p

F

34

Question: Will the cylinder extend ?

Check in FluidSim

35

Video 5: Pressure transmission (0:53)

• Pressure intensification in hydraulic systems:

• Differential area cylinders cause this effect p

F

F

ROD

F

CAP

CAP

p p

F

CAP

ROD

ROD

*

*

A

A

CAP

ROD

p

CAP

* A

CAP

p

ROD

*

Check in FluidSim

A

ROD

p

ROD

A

CAP

A

ROD p

CAP

36

Question in ‘Customary Units’

• Given

• PRV Setting 15 MPa

• pump displacement of 10.54 cm 3 /rev

• the speed of the pump is 1800 rpm

• Required

• Torque needed to drive the pump

• Power needed to drive the pump

• Neglect friction

37

Answer in ‘Customary Units’ p

PRV

15 MPa

15 E 6

N m

2

D

10 .

54

cm

3 rev

*

1

2

rev rad

1

*

10

6

m

3 cm

3

1 .

6775 E

6

m

3 rad

T

1800

rev min

D * p

PRV

* 2

rad rev

*

1

60

min s

188.495

rad s

1 .

6775 E

6

m

3 rad

* 15 E 6

N m

2

25.163

Pow

T *

25.163

* 188.495

rad s

4743

Nm s

38

Question in ‘Customary Units’

• Given

• PRV Setting

• pump displacement of

• the speed of the pump

• Required

• Torque needed to drive the pump

• Power needed to drive the pump .

• Neglect friction

39

Answer in SI Units

T

MECH

Pow

MECH

D

*

T p

PRV

*

40

Types of Pumps and Motors

• External Gear

• Internal Gear

• Vane

• Axial Piston

• Radial Piston

41

External Gear pump

• Poorly sealing

• Low flow rates

• Low pressures

• Fixed displacement

• Low cost

42

Internal Gear pump

• Poorly sealing

• Low flow rates

• Medium pressures

• Fixed displacement

• Medium cost

43

Vane pump

• Medium sealing

• Higher pressures

• Inexpensive

• Fixed or variable flow rate

44

Axial piston pump with swash plate. In this case the swash plate angle is variable, which results in a variable delivery pump

• Excellent sealing

• High pressures

• Relatively simple design

• Variable flow rate

• No need for valves

• Expensive

45

Axial piston pump with swash plate. In this case the swash plate angle is constant, which results in a constant delivery pump

• Here fixed flow rate

46

Radial piston pump with variable rate through changing eccentricity between shaft and ‘pintle’

• Excellent sealing

• High pressures

• Relatively expensive

• Variable flow rate

• Valves are needed

• Complex design

47

Radial piston pump with variable rate through changing eccentricity between shaft and ‘pintle’

• Excellent sealing

• High pressures

• Relatively expensive

• Variable flow rate

48

External Gear

Fixed Displacement

49

Pump ‘family tree’

50

TSM363 Fluid Power

Systems

Pumps and Actuators

The End

Dept. of Agricultural & Biological Engineering

University of Illinois

51