Kraft Foods Template - Dubai International Food Safety Conference

advertisement

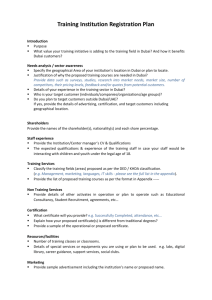

Shelf-Life of Pre-packaged Food Products An Industry Perspective Dr. Ahmet Anbarci Scientific & Regulatory Affairs Kraft Foods CEEMA Region Dubai International Food Safety Conference 24-26 February, 2009 Agenda • Kraft Foods in short • Shelf-life – Definition, Dimensions • Shelf-life Kraft Foods RD&Q functions • Establishing and Managing Shelf-life • Testing, Principles, Parameters • Selected Aspects, Examples • Discussion DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 2 Kraft Foods Overview, 2008 DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 3 Kraft Foods Overview, 2008 Worldwide headquarters in Northfield, Illinois, U.S. Sales in more than 155 Countries Operations in 70 Countries With approximately 100,000 employees, more than 180 manufacturing and processing facilities 11 global or geographic Research and Development Centers around the world DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 4 One of Best Brand Portfolios in Food & Beverage Industry 9 Brands over $1 billion annual revenue 50+ Brands over $100 million 40+ Brands over 100 years old DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 5 Eastern Europe, Middle East & Africa Region Fast Facts Region headquarters: Vienna, Austria Key markets in the region: Bulgaria, Egypt, Romania, Russia, South Africa, Turkey, Ukraine and the Gulf Cooperation Council, as well as other Middle East & Africa Markets Some key region brands: Kraft cheeses; Tang powdered beverages; Alpen Gold, Karuna, Korona and Milka chocolates; Estrella and Cipso salted snacks; Rasco biscuits; Carte Noire, Jacobs, Maxwell House and Nova Brasilia coffees. DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 6 Kingdom of Saudi Arabia: - Production Facility – Biscuits - Employees: 138 (23% Saudi) - Brands: Oreo, Ritz and Belvita Kraft Foods in GCC Kingdom of Bahrain: - Production Facility - (Tang and Cheese) - Employees: 287 (17% Bahraini) - Brands: Tang, Kraft Cheese United Arab Emirates: - MEA Regional Office - Employees: 130 - Lead Brands Marketed in GCC: DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 7 Shelf-life, definition, dimensions Shelf-Life is the time between manufacture and possible latest consumption, wherein the characteristics of a food product are considered to remain acceptable with following dimensions and aspects: products must be safe quality must remain acceptable nutritional value needs to be maintained commercial stability to be assured - self-speaking, un-debated, un-compromised; HACCP ------------------------------------------------------------------------------------------ consumer accepted quality; vital to gain consumers and maintain their loyalty - prime aspect for food; maintain claims on products - package integrity, look; key for customers and at point of sale DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 8 Packaged food over shelf-life DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 9 Shelf-life Food Research, Development & Quality (Kraft Foods RD&Q) Kraft Foods RD&Q is the owner of shelf-life and has the responsibility, expertise and the infrastructure for establishing products’ shelf-life. Category Expertise + Geographic Proximity + Functional Excellence • Coffee • Banbury, UK • Quality and Safety • Refreshment Beverages • Tarrytown, NY • Scientific Affairs • Grocery • East Hanover, NJ • Regulatory • Biscuits and Cakes • Munich, Germany • Nutrition • Confectionery • Glenview, IL • Research • Savory Snacks • Madison, WI • Chemistry • Cheese/Dairy • Battle Creek, MI • Microbiology • Convenient Meals • Melbourne, Australia • Sensory / Consumer Insight • Curitiba, Brazil • Packaging • Intellectual Property/ Patents DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 10 Our RD&Q centre in Munich has the geographic responsibility for West, Central, East Europe, Middle East and Africa Global Glenview, IL East Hanover, NJ Tarrytown, NY Banbury, UK Munich, Germany Functions in Munich Product Dev Process Dev Packaging Microbiology & Food Safety Quality Chemistry Sensory Regulatory Scientific Affairs Nutrition Geographic / Local Madison, Battle Creek, Melbourne, Curitiba and 50 other smaller centers Munich – Geographic Scope West, Central, East Europe, Middle East and Africa Munich – Product Role Cheese/Dairy, Convenient Meals, Refreshment Beverages, Grocery, Chocolate Confectionery, Savory Snacks, (Quality & Safety for Coffee) DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 11 Same principles around the Globe Kraft Product Safety & Quality Assurance Guiding Principles • Product Safety/Public Health is our uncompromised priority. • Food Safety is pre competitive. • Food Safety is based on sound science and correct risk assessment. • HACCP and our ISO based QCMS (Quality Chain Management System) are central to our business process. • Kraft applies common Food Safety & Quality Standards globally. In addition we believe in: • a systems and process driven approach • a strong upstream focus with major supplier collaboration • covering each and every component in the business Value Chain. DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 12 Quality Chain Management System Shelf-life evaluation and management is an essential part of successful food quality management. Ideally, shelf-life is an integral part of an overall Quality Management System through the entire value chain. • Kraft Foods worldwide approach to the systematic management of product Safety and Quality is called the Quality Chain Management System (QCMS). • QCMS is a complete embodiment of the ISO 9001 quality system model enhanced to include the product Safety and Quality requirements of Kraft Foods worldwide food businesses. • QCMS defines the requirements throughout the process of design, procurement, manufacture, distribution and customer/consumer product usage and relations. Kraft Foods’ procedure on “shelf-life evaluation” is a fundamental part of QCMS and has to be applied by all relevant employees around the world. Objective: “All Kraft Food businesses shall have a process in place for establishing and managing the shelf-life of all products.” Scope: “Shelf-life evaluation applies globally to all KF businesses and categories. Key elements are parameters, procedures, storage conditions, shelf-life management and modification of shelf-life.” DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 13 Food Value Chain DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 14 Shelf-life, definition, dimensions Shelf-Life is the time between manufacture and possible latest consumption, wherein the characteristics of a food product are considered to remain acceptable with following dimensions and aspects: products must be safe quality must remain acceptable nutritional value needs to be maintained commercial stability to be assured - self-speaking, un-debated, un-compromised; HACCP ------------------------------------------------------------------------------------ consumer defined quality; vital to gain consumers and maintain their loyalty - prime aspect for food; maintain claims on products - package integrity, look; key for customers and at point of sale DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 15 RD&Q functions involved RD&Q is responsible for the “design” and establishing shelf-life; Category Product Development Groups lead, relevant RD&Q functions as listed below support the process. Other parties along value chain consulted as required, e.g. Manufacturing. products must be safe - Quality /Safety Chemistry Microbiology Toxicology Packaging nutritional value to be maintained - Scientific Affairs Regulatory Nutrition Chemistry Packaging quality must remain acceptable Insight - Quality /Safety Regulatory Chemistry Microbiology Sensory / Consumer - Packaging commercial stability to be assured - Quality /Safety - Regulatory - Packaging DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 16 Testing Shelf-life testing is a vital part of new product development. Existing products are re-evaluated, if an extension of shelf-life is targeted or any changes are considered. Re-evaluation may also be triggered by consumer complaints or quality issues. Close to reality conditions pursued - Full shelf-life testing and beyond Representative samples Representative storage conditions Consumer relevant sensory testing Consumer research, if required Testing protocols - Sampling Testing conditions Testing period Schedule, intervals Attributes, parameters Methods Record keeping DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 17 Testing – parameters, questions to be considered Product Safety and Robustness are uncompromised and checked and verified for the intended use and foreseeable misuse of products. risk of pathogens ? risk of toxins ? allergens ? Shelf-Life beyond safety: Many parameters and a high number of possible combinations for industrially packaged food lead to a wide range of possible shelf-life’s. product category, type, nature ? micro-stability, risk of spoilage ? chemical reactions ? physical changes ? organoleptic, sensory, consumer ? packaging integrity and protection ? transport and storage conditions ? consumer behaviour, usage ? DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 18 Shelf-life – Regulated limits? Considering the complexity inherent to shelf-life, i.e. many parameters, their interaction, possible combinations (vs. the time we have in this forum), only some selected aspects/examples will follow. DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 19 Aspects/Examples: Basics for micro risks STATIONARY LOG DEATH LAG Microbiological Growth Time of LAG phase determines maximum shelf life possible. LAG phase can vary depending on other parameters and can be extended by improved sanitation, processing, storage conditions, preservatives, modified atmosphere or some emerging technology. DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 20 Aspects/Examples: Consumer Relevant Shelf-life Testing Key elements: 1. Representative Sampling - Final testing with plant products only (pilot products only for pre-assessment) - Freezing samples (= freezing the time) - If products cannot be frozen, multiple lots testing (assess impact of lots’ variability) 2. Representative Storage Conditions - All along the Value Chain (transport, warehouses, consumer households) - Close to reality simulation (consider varying conditions, best / worst case scenarios) 3. Test plan/methods relevant to product, market, potential consumers alienation - Internal sensory testing (people without project involvement, descriptive) - Quantitative descriptive analysis (trained panel) - Consumer acceptance testing (consumer liking, judgemental) DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 21 Shelf-life of food products Internal Sensory Testing • At least three of the same participants at each tasting, involving people without project background. • Focus should be descriptive, not judgement. After documenting the descriptive differences, judgement about the expected seriosity of deviations may be necessary. • Representative control product needs to be used as a reference. • Project leaders organize the taste sessions, sample storage and ensure right participants at each session. Consumer Sensory group provides the test procedure and analysis forms. • Project leaders own next steps as agreed by team DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 22 Shelf-life of food products Quantitative Descriptive Analysis (QDA) • A tool to test in an objective manner, whether sensory changes are perceivable. • Generally recommended, when significant changes are expected / predicted over shelf-life. • In case of changes that are not necessarily negative: Perceivability and relevance of changes need to be tested with consumers, to determine effects on consumer acceptability. • Key acceptance drivers are known from earlier consumer tests can be used to judge the differences observed in QDA and the shelf life. DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 23 Shelf-life, Consumer testing Consumer Acceptance Testing • For key products, and for critical cases, consumer acceptance testing is recommended. • Multiproduct Central Location Test of samples at different stages in shelf life, before, at, and after end of shelf life at stake. • Absolute safety of samples to be ensured via thorough micro testing. • Test should be run with target consumers in the target countries. Participants need to be unaware of the test background. DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 24 Aspects/Examples: Cheese and many parameters Same category, different types, processing, storage conditions, packaging, … => Shelf-life’s in a range of few to 18 months. 12 months 18 months DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 25 Aspects/Examples: Packaging materials Substrate OTR (cc/m2/24hrs) WVTR (g/m2/24hrs) Light Barrier Strength Foil 0 0 100% Low Aluminum laminate <1 <1 100% Medium Polyester (PET) 90 40 <5% Medium Metallised PET (met-PET) 0.5 <1 >95% Medium PVdC coated PET 6 14 <5% Medium Biaxially Oriented Polyprop. 1900 6 <5% Medium PVdC Coated BOPP 10 5 <5% Medium Metallised BOPP (met-BOPP) 100 1.5 >95% Medium Biaxially Oriented Nylon (OPA) 45 260 <5% Medium PVdC Coated OPA 6 7 <5% Medium Glass Jar 0 0 <5% High PP Rigid <1-200 <1-100 <5% High Tetrapak/Combibloc 0 0 100% Medium 3 Piece Metal Can 0 0 100% High DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 26 Aspects/Examples: Packaging with the right protection High protection and other factors help to achieve a long shelf-life: Glass Jar Processed Cheese in a glass jar with a proven shelf-life of 12 months. Metal can PET container Composite can Plastic container Aluminium laminate Metalised laminate DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 27 Shelf-life: Regulated limits? Considering the complexity of shelf-life, limits set for shelf-life of packaged foods would either be overcomplicated (wide array, needs regular updating) or a weak compromise, most likely at category minimum. Risks and disadvantages for all appear to outweigh any advantages. Consumers and all stakeholders along the value chain benefit from safe and high-quality products with tested and proven shelf-life. While the added safety, quality and value through regulated shelf-life limits is open to discussion, some risks and disadvantages are certain for industrial, packaged food: - Avoidable costs, economic penalty, if the limits set are too conservative, , i.e. at the category minimum (lowest common denominator) - Risk of low quality products to consumers, if the limits set are too broad - Risk of missing new aspects, development or scientific progress - Low incentive, low motivation for industry to innovate or apply the “new” DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 28 Shelf-life: Regulated limits? Conclusions: The food industry should perform due-diligence to judge, test and establish the shelf-life for each single product they manufacture, regardless how strict or wide the limits set by regulations may be. Food companies in general have to have their products’ data and expertise and to know about the nature, details and limits of their products. Shelf-life limits set for packaged food are open to abuse and do not appear to add value, safety or quality of especially packaged food. Shelf-life limits may be an unnecessary hurdle, especially for long tested products with a good record in country of origin or in other markets. DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 29 Shelf-life of food products Thank you! DIFSC, Dubai, 24 – 26 February, 2009 / Dr Ahmet Anbarci - 30