MicroPEM Procurement

advertisement

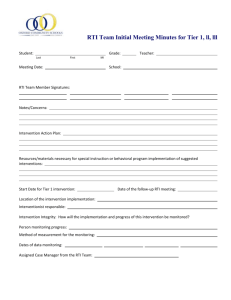

FINAL - October 26,2012 1 RTI MicroPEM v3.2 Build II Procurement Instructions and Functional/Performance Design Specifications 1. PREFACE The Engineering Technology Unit at RTI International has completed a series of key validation tests of the current v3.2 MicroPEM™ single channel personal exposure sensor/sampler. The expectations based on the previously set specification have been confirmed to be acceptable for domestic lower concentration settings (validation data from the on-going RTI CHATS program), and in cookstove exposure settings (validation data from the RTI Sri Lanka study, recently completed in September, 2012). Key findings from both types of extended period deployments in personal (older children in the CHATS; adult cooks in the Sri Lanka effort) and indoor setting show a robust ability to handle both low and high concentrations without adversely affecting performance, and an ability to be deployed by modestly trained staff and still obtain valid sample and data capture rates easily exceeding 98%. The single most important functionality issue resolved for the Build 1 units is associated with computer communications (uploading and downloading data) has been development of enhanced device drivers to facilitate communications with both Windows XP and 7 operating systems. Somewhat surprisingly, connectivity issues across the myriad of computer platforms (and upgrade levels) caused far more problem during the past year than all other issues combined. The inability of MicroPEMs to simply "talk" to the user's computer platform is a GO/NO-GO link that is crucial to all operations. Some other minor issues corrected with software upgrades during the past year included correcting the way data are parsed to the data file when the system cycling mode is utilized, minimizing the allowable range of laser cycle times to minimize self-heating wavelength shifts, and modifying the information provided in the .csv data download header files to allow more automated data review and summarization. After a series of RTI investments to streamline and miniaturize the design, and correct functionality problems with both the on-board firmware, and supporting Docking Station Software1 were completed, an initial build of 200 MicroPEMs was conducted in July, 2011, "selling" units at a nominal $2,000 each. The success of the units from that initial Build I in field US and international cookstove study trials has prompted a number of requests for RTI to build additional units in a Build II. These additional units would be essentially the v3.2 design and would have the identical performance as characteristics as the Build I units, but now enabled by a system ON-OFF cycling timer option which allows parsing the available 40 hours of battery life across periods as long as 168 hours (1 week). A minor design change was increasing the range of the filter pressure drop sensor from 0 to 5 inches of water to 1 to 10 inches to facilitate recording of higher loading events during strong source exposure studies such as indoor cooking scenarios. A series of performance papers documenting the MicroPEM are in preparation. Thus, the Engineering Technology Unit at RTI has again proposed allowing organizations outside of RTI to "purchase" limited quantities of the v3.2 MicroPEM™ as part of a . Build II effort. It is likely that RTI will consider building as many as 200 units in this second build, and it is not clear at the moment how many of these 200 will be retained internally for RTI studies. In order to help RTI recover investment costs, we are encouraging external organizations to consider partnering with RTI scientists in conducting exposure studies that use these MicroPEMs. A continued over-arching objective of the sale process is to both foster greater potential partnering opportunities between external research organizations and RTI, as well as continued assistance in help validate and improve the technology for the long term by sharing data and experiences. 1 following the support from the NIEHS primary technology development grant (U01-ES016093) FINAL - October 26,2012 2 2. PROCESS 2.1 General - Those interested in "purchasing" v3.2 MicroPEM™ units from Build II are asked to consider whether the SPECIFICATIONS in Section 5 will meet their needs (only a high level summary of specifications is included here. Please contact Dr. Rodes (contact information to follow) if additional technical or design questions are not answered here. The purchase price per unit has been nominally set (as of 7/1/11) at $2,000.00, which includes: 1 filter cassette, your choice of impactor cutpoints (select either PM2.5 or PM10), the supporting Docking Station software on CD, an AC adapter and cable, a 3’ USB to mini-USB connector cable to link the unit to a MicroSoft (XP or Windows 7 operating system2) computer) and an electronic copy of the SOP. The sell price does not include: a) additional weighed or unweighed filters (1 supplied) @ $7 or filter cassettes @ $7 (only 1 supplied), b) flow check adapter cap ($85) and low pressure drop HEPA zero filter ($40), c) spare and interchangeable inlet impactor sets and cutpoints (currently only PM2.5 and PM10 sizing are available ($50 per set). The table in Section 6 provides costs of some items. Contact RTI for of costs. The adapter cap, zeroing filter, and spare impactor set are strongly recommended options. A low pressure drop flow calibration referee such as the AC or battery powered TSI 4100 mass flowmeter unit is very easy to use in the field and recommended rather than bubble flow meters3,; please order directly from TSI4. Th e cost of shipping is also not included in the purchase price. The real-time sensor will not be pre-calibrated (see below) against specified challenge aerosol to provide individual calibration slopes, unless requested separately - contact RTI for cost. Complete analytical support services for the MicroPEM Teflon filter can be provided at RTI (contact Dr. Thornburg) if you don't have access to laboratory analytical services with sufficient detection limits for 0.5 lpm sample collections (see Table 2). Orders will be shipped within the US via FedEx 2-day, and a nominal shipping charge of $15 should be added to the order. Contact RTI for foreign shipping costs. 2.2 Ordering Format - Order paperwork should be provided to Ms. Marcia Langan (contact information below) in standard short form purchase order format referencing RTI’s Standard Terms and Conditions (Section 7). The unit price without extras is $2,000 (US) which essentially reflects our cost for build units across the first two build cycles. Please include funds for the other components requested in the same order to simplify paperwork. Questions on the procurement process should be directed to Ms. Langan. In order to meet the requested deadline, RTI needs an email Letter of Intent to Ms. Langan to purchase (including number of units and 2012 need-by date) by 11/15/12 if at all possible, and requires a signed purchase order referencing RTI’s standard terms and conditions no later than 11/31/12 in order to cover the cost of ordered components prior to assembly. Receipt of a purchase order after that date may result in cancellation of the order, as scheduling is very tight for this effort. 3. ADDITIONAL MATERIALS 3.1 Calibration Pre-Set - All MicroPEMs will includeEach MicroPEM nephelometer will have a nominal pre-set slope of 3.0, which is based on refereed average MicroPEM responses to ISO fine test dust, and verified against a transfer standard referee TSI DustTrak that has been factory calibrated at TSI gravimetrically against fine ISO test dust. For domestic US studies, ISO fine test dust calibration is a reasonable challenge representing scatter responses to background ambient particles. The most 2 currently only XP and W7 drivers are available for the MicroPEM. While some success has been observed with Apple computers having Windows emulation software, those applications are not yet encouraged until better drivers are developed. Contact RTI if you have special connectivity questions. 3 elevated humidity in bubble flow exhaust can bias the flow setpoint. 4 all prices in US$ FINAL - October 26,2012 3 accurate approach is to obtain a parallel filter collection with gravimetrically -defined collections along with each nephelometer data file. Then, normalize the nephelometer average response to make it match each filter collection. This is especially true for strong source scenarios where the nephelometer response might not mimic ambient US aerosol - such as for biomass smoke during cookstove studies., As noted previously, a dynamic collocated chamber calibration can be conducted at RTI with specific challenge aerosol to more accurate pre-set the nephelometer response, but this service has a separate cost. For more extensive calibrations – contact Dr. Thornburg for additional information. NOTE: Applications of the MicroPEM and the collection of samples and data are strictly under the control of the user, and RTI accepts no liability (actual or implied) in the way the data are utilized or applied. 3.2 Warranty - All units and software are expected to function as described and will be replaced or fixed by RTI within the first 90 days if the unit fails due to component failures or assembly problems. User damage (dropping, mis-installed batteries, tampering with electronics) will be repaired at user expense. Please call or email either Dr. Thornburg or Dr. Rodes for advice before returning a unit. While these units are reasonably rugged and should function well within study cohort applications, they do not meet MilSpecs so treat them accordingly. For problems after 90 days, please contact RTI. 4. CONTACT INFORMATION 4.1 MicroPEM™ Technical Questions and Design Issue Contacts: Dr. Charles Rodes Engineering Technology Unit RTI International Building 11-409 3040 E. Cornwallis Road Research Triangle Park, NC 27709 ph. 919-541-6749; fax. 919-541-6936 email: charlesr@rti.org Dr. Jonathan Thornburg Engineering Technology Unit RTI International Building 113949 E. Cornwallis Road Research Triangle Park, NC 27709 ph. 919-541- ; fax 919-541-6935 email: jwt@rti.org 4.2 MicroPEM™ Procurement and/or Order Submittal Questions Contact: Ms. Marcia Langan Office of Research Contracts RTI International Herbert 150 3040 E. Cornwallis Road Research Triangle Park, NC 27709 ph. 919-990-8339; fax. 919-485-5569 email: mlangan@rti.org FINAL - October 26,2012 4 5. SUMMARY SPECIFICATIONS 5.1 General - The MicroPEM technology provides exposure data at the personal level in a very lowburden package that can worn by individuals to significantly enhance studies of public and occupational health. The National Research Council (NRC, 20045) strongly supports the application of personal exposure monitors to characterize exposure levels and patterns for correlation with acute- and chronicscale health effects. But personal exposure sampling can be burdensome, and periods when the monitor is not worn according to protocol must be identified to maximize data representativeness (Rodes et al., 2010). The v3.2 MicroPEM™ is designed to minimize the majority of key aspects of exposure misclassification bias, thereby meeting NRC goals. The current v3.2 MicroPEM provides for the first time fully representative personal exposure characterizations simultaneously defining both the integrated exposure (filter based) as well as the patterns of exposure in real-time in a wearable low burden package weighing less than 240 grams. Selectable U. S. EPA particle cutpoint definitions of PM2.5 or PM10 relate the collected data to targeted respiratory system deposition zones (deep lun or thoracic, respectively), allowing health-based associations to be studied against adverse disease outcomes. On board collection of quality control data and accelerometric motion levels allows straightforward validation of both wearing compliance for the collected samples and data, as well as enablish estimates of ventilation and potential dose following the methodology of Rodes et al. (2012)6. 5.2 Data Quality Indicators (DQO’s) – Four primary data quality objectives (accuracy, precision, completeness, and representativeness) and three physical system attributes (burden level, response range and operating time) define the major performance characteristics of the MicroPEM v3.2 necessary to minimize exposure misclassification bias - all meeting or exceeding the requirements for the CDC/CHATS program. A journal article summarizing the design process under the NIEHS developmental grant is currently in preparation, and will include the data and documentation for the specifications to follow. That publication will be provided when available. DQO's include: 5 National Research Council (2004), Research Priorities for Airborne Particulate Matter, NAS, Washington, DC 6 7 Accuracy: The comparability of MicroPEM PM and accelerometer data to a known "referee" standard define its accuracy. Using EPA PM sampling criteria, acceptable MicroPEM accuracy is obtained if the inlet cutpoint D50 is within 0.5 m (for either PM2.5 or PM10)7 and the calibration slope from collocated field sampling is within ±15% and the intercept is within ±10% of the standard. The accelerometry standard is the downward 1.0 G value when at rest. "Predicting adult pulmonary ventilation volume and wearing complianceby on-board accelerometry during personal level exposure assessments", Atmospheric Environment, Volume 57, September 2012, Pages 126-137, C.E. Rodes, S.N. Chillrud, W.L. Haskell, S.S. Intille, F. Albinali, M.E. Rosenberge Cutpoint accuracy in lab calibrations have been conducted for both PM2.5 and PM10 verifying the +/-0.5 micron accuracy, and a summary publication documenting performance will be released in November, 2012. Collocated precision testing data is currently being summarized from two field studies and is expected to readily support the +/-15% target in either domestic or cookstove studies.. FINAL - October 26,2012 8 5 Precision: A target variability of +/- 15% in collocated measurements over a nominal concentration range (see Range) Completeness: The reliability (e.g., minimum valid data capture rate) of the MicroPEM should exceed 95%. Proper instrument performance determines completeness. Instrument performance is defined as pump flow rate, sampling period, data logging frequency, etc. meeting user specifications. Recent 2012 field experience by RTI, has produced 97% and 98% MicroPEM filter and data capture rates for personal mode deployments in a US residential, and Sri Lankan cookstove setting, respectively. Representativeness: Data collected at the personal level will be representative of a person’s breathing zone exposure if the unit is worn nominally within 30 cm of the oral/nasal cavity8. That means a wearability design (vest for example, if a front chest pocket is not utilized) must be devised and the person must be willing to carry/wear the MicroPEM according to study protocols. Burden: The v3.2 fully operational (with 3 AA cells) weighs less than 240g, is extremely low burden and small enough to easily fit in an adults or child's shirt pocket – see Figure 1), has an extremely low noise level due in part to the low flowrate, and also due to a very innovative noise damping system, necessary for devices worn in the breathing zone and close to the ears. Clothing without pockets will still require the user to identify a suitable breathing zone wearing (attachment) arrangement. Maximum size, weight, noise, and other instrument characteristic targets are becoming apparent for adults and children that serve as go/no-go limits for the CHATS and future studies, including: weight: <240g, noise level at 30 cm of <3 dBA added to the background level. RTI is currently investigating a range of wearing possibilities - contact Dr. Thornburg for additional information. Concentration Response Range: Real-time concentration data collected must be representative of a person’s likely exposures in typical residential settings, but allowing for occasional strong source excursions (e.g. from passive SHS exposure) setting a nominal response range for realtime sensing from nominally 5 to 10,000 g/m3. Currently, the upper limit is capped at approximately 10,000 g/m3 limit (dependent on the type of aerosol) to retain reasonable detection limit capability at the low end for domestic residential exposure studies. The very low face velocity at the nominal 0.5 lpm flowrate thru the 25mm OD, 3 micron porosity Teflo filter allows substantial loadings (up to 200 micrograms) before filter blinding has been observed (at 10 inches of water). Note that sampling at 0.5 lpm sets detection limits that can be achieved only if a controlled weighing process is utilized that achieves a precision of <1 microgram for domestic studies and <5 micrograms for cookstove studies (see Table 2). Contact Dr. Rodes or Dr. Thornburg for additional information. Operating Time (on batteries): A nominal 36 to 40 hour continuous period of operation with a single set of 3 AA alkaline batteries is expected, with a nominal nephelometer laser duty cycle setting of 20% (2s ON out of each 10s) and the system pump operating at 100% duty cycle. Entire system cycling to allow this battery life range to be extended to represent periods of up per Rodes and Thornburg, 2005. FINAL - October 26,2012 6 to 168 hours (1 week) are facilitated by system cycling (presetting ON and OFF periods, in seconds). A supplemental battery pack (adding weight and bulk) can be connected externally to increase the operating time for indoor sampling, or alternatively, the MicroPEM can be connected to an optional 120 vac adapter for continuous sampling (up to the pressure drop limit of the collection filter). 5.3 Other Specifications - The table below summarize v3.2 design features incorporated. The subsequent Figure 1 shows case open and closed views of the v3.2, and b) a v3.2 MicroPEM deployed in the (chest) shirt pocket of a 10 year old boy to illustrate the relative size. Tables 1A and 1B provide a more detailed list of key specifications determined from lab and field testing. Note that a weatherproof version is currently not available nor an omni-directional inlet (planned but not initiated). The current micro-electronics are fully capable of adding both a GPS chip set, and a communications (e.g. Bluetooth) module for wireless linkage operations. Also, an on-board display is purposely not included for (blind) cohort setting sampling, but an add-on display is being considered for the next version. Dr. Rodes will continue to lead future MicroPEM™ design innovation efforts and additional feature enhancements possible from software changes are under consideration. Table 2 provides the expected limits of detection that occur at various environmental concentration levels. A relatively clean filter processing environment is strongly recommended to avoid blank contamination confounding, as well as utilizing a computer controlled 7-place microbalance to routinely obtain robust precisions. Table 3 provides a more detailed list of the currently allowable ON and OFF time cycling options. RTI is successfully using cycle times of 30S ON and 100s OFF to study exposure impacts on asthmatic children in the Gulf (US) states. This cyclying enables 168 hr sampling periods on a set of batteries. RTI used a shorter cycle (30s ON and 30s OFF) to study cookstove exposures in Kenya, to enable 48 hour sampling periods and observed no filter overloadings. Software modifications are under consideration to broaden the range of allowable cycle times. Note also that RTI was pleased to learn that the MicroPEM exposure monitor was one of the recipients of the RandD magazine RD100 Awards for the best technoligies of 2012. http://www.rdmag.com/articles/2012/06/2012-r-d-100-award-winners http://www.rdmag.com/award-winners/2012/08/personal-pollutant-monitor FINAL - October 26,2012 7 Table 1A. Design specifications incorporated into v3.2a (adult size) MicroPEM. Category System Aerosol Sizing Filter Nephelometer Accelerometer 9 Feature Flows of 0.4 or 0.5 Lpm (less collected at lower flow) Integrated (filter) and real-time data (nephelometer) collected simultaneously Self-deployable directly to the participant or by minimally trained study personnel Programmable start/stop times Personal, indoor, outdoor versions Collection, storage, download of QC data 16 MB onboard memory 8 MHz processor Weight less than 240 g Outdoor platforms, custom vests, and wearing protocols Weatherproof enclosures and omni-directional inlet for outdoor application Max Dimensions, inches (LxDxH) = 2.6 x 1.6 x 5.0 PM2.5 and PM10 inlets to size all aerosol reaching filter Dual sequential oiled frit impactor stages to minimize particle bounce Pressure drop less than 1 inch H2O across clean system. Maximum pressure drop across system is 5 inches H2O. 25 mm Teflo, 3 micro porosity10; nominally equivalent to the EPA FRM Teflo Low face filter velocity and very laminar flow within the sensing volume to minimize internal losses 10 mm filter exposed area to focus collection while minimizing face velocity 5 to 10,000 g/m3 dynamic range Detect 5 g/m3 change Controllable laser cycling timing Laser diode source at 785 nm RH monitoring and storage RH correction factor applied via DS software 3-axis accelerometer (Okidata) 9 Achieved Yes Yes Yes Yes Yes Yes Yes; from 4 MB v2.7 Yes Yes Yes Not yet; but planned Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes operation at 0.4 lpm is possible to reduce noise levels even further, but a proportional loss of mass collection to the filter is observed, and the inlet cutpoints shift upward slightly (by ~4%). 10 The MicroPEM flow system was designed to have extremely low pressure drop to maximize the operational period for a set of batteries. Filters other than the Pall Teflo with these specifications have not yet been shown to be completely functional in the MicroPEM. FINAL - October 26,2012 8 Table 1B. Additional design specifications for incorporation into v3.2a MicroPEM. Category Power Mgmt Flow Control Sensors Feature Flexible on/off cycling to allow operation for extended periods representing up to 168 hours on 3 AA batteries Power from internal AA, external C/D battery, or AC power sources On/off laser cycling to control the real-time data collection rate and additionally extend battery life Coin cell internal battery backup (CR2032) Simple battery changing Micro-processor budgets power Volumetric flow control for aerodynamic sizing Inlet/filter blockage and overloading detection (up to 10") Temperature and relative humidity monitoring and storage High sensitivity scattering signal diode photodiode Achieved Yes; upgraded from the v2.7 software Yes Yes Yes Yes Yes Yes Yes Yes Yes Communications Standard: mini-USB connector for cable Display - red and green signaling LEDs; no on-board display; a real-time display currently requires an attached laptop Yes On-board mini-display being planned Timing Yes Three modes: 1) manual - start/stop from external pushbuttons; cumulative 2) timed duration – start from pushbutton; unit auto stops > for self-deploying option with user start and all other operations automatic [note: this timing option is being modified in the DS software]. 3) clock timed – start and stop times with data & time 4) system cycling - setable ON and OFF-cycle intervals to parse 40 operating hours for periods up to 168 hrs FINAL - October 26,2012 9 Table 2. Minimum recommended MicroPEM™ filter collections (g in blue) for selected integration period - air concentration combinations at a sampling rate of 0.5 lpm. Collections >1 g but <10 g during domestic residential sampling can still be quantified, but will result in poorer precision (less than 3 times the measurement quantitation limit for gravimetric analysis). Cookstove studies typically have average concentrations exceeding 100 g/m3 such that weighing precision issues are minimal. Blank contamination biases during domestic studies that are >3 g obviously must be avoided and a "clean" processing environment is strongly recommended. It is recommended that filters be kept in Filter Keepers11 rather than plastic petri dishes since blank contaminations from new/unused dishes have been observed. Mean PM2.5 or PM10 Air Concentration, g/m3 Integration period, minutes 5 15 25 50 100 150 250 60 (1 hour) <1 <1 <1 1.5 3.0 4.5 7.5 240 <1 1.8 3.0 6.0 12.0 18.0 30.0 480 1.2 3.6 6.0 12.0 24.0 36.0 60.0 1,440 (24 hrs) 2,400 (40 hrs) 3.6 6.0 10.8 18.0 12.0 30.0 36.0 60.0 72.0 120 108 180 180 300 2,880 (2 days) 7.2 21.6 36.0 72.0 144 216 360 4,320 10.8 32.4 72.0 108 216 324 540 5,760 14.4 43.2 108 144 288 432 720 7,200 18.0 54.0 144 180 360 540 900 8,640 21.6 64.8 180 216 432 648 1,080 10,080 (1 week) 25.2 75.6 216 252 504 758 1,260 Table 3. System Cycling (ON/OFF) Times – The entire system can be cycled ON and OFF to extend the nominal 40 hour battery pack life to 168 hours or longer. The ON and OFF periods are set in the Launch screen, with the following possible settings: MicroPEM v3.2 System Cycling Options ON time, s 20 30 60 11 0 (always ON) X X X 30 40 X 60 X 90 100 X 120 X X X OFF time possibilities, s 150 160 180 210 X X X X 240 300 360 420 480 540 X X X X X X http://www.omegaspec.com/downloads/PB469_Filter-Keeper_Storage_and_Archiving_System.pdf FINAL - October 26,2012 Figure 1. Version 3.2 MicroPEM with case closed, open, and worn in the pocket of an 11 year old boy. 10 FINAL - October 26,2012 11 6. Partial MicroPEM Component Price list Item Description 1. single-channel v3.2 units PM2.5 complete (includes USB cable and AC adapter) Cost, ea., $US comments $2,000 2. HEPA zero filter $40 3. flow adapter cap $85 5. spare PM2.5 inlet assemblies $50 Only one size is included with MicroPEMTM purchase (specify) 6. spare PM10 inlet assemblies $50 Only one size is included with MicroPEMTM purchase (specify) 7. spare filter cassettes $7 8. cassette release tool $85 8. Pall 25mm OD, 3 m porosity Teflo filters; not pre-weighed $8 9. RTI Docking Station software, with Windows XP and 7 driver files Included in MicroPEMTM purchase 10. MicroPEM™ v3.2 Operational SOP, with screenshots supplement Included in MicroPEMTM purchase 11. Battery set: Three (3) alkaline AA batteries & one CR2032 coin cell Included in MicroPEMTM purchase One is included in MicroPEMTM purchase 12. Spare 3 foot USB cable $7 One is included in MicroPEMTM purchase 13. Spare AC adapter $13 One is included in MicroPEMTM purchase Contact: Marcia Langan RTI International 3040 E. Cornwallis Rd. Research Triangle Park, NC 27709 919-990-8339 (office) mlangan@rti.org FINAL - October 26,2012 7. RTI Terms and Conditions 12 FINAL - October 26,2012 13