See more - Milk Solidation

advertisement

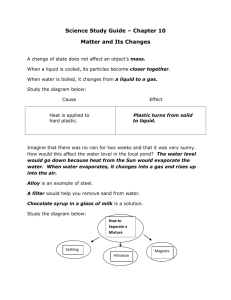

INTRODUCTION: Nowadays, the population in our country is increasing and mostly of the society are the children. We could not say that they are all safe especially when they are playing. We could not say all of the things they touch are harmless. We also cannot say that all the toys they are using are safe. in this situation, our group manage to find a good investigatory project for this school year. We’re going to make materials such as toys, accessories and other things that people may use. We decide to turn milk into plastic. As we all know, some plastic nowadays are not allowed to use anymore, so why not turn milk into plastic, plus, it is harmless and totally safe. We found this experiment that can turn milk into plastic by making it curdle. In this project, we’re going to discover if our product will lessen the danger of a high chemical-made plastic. OBJECTIVES: 1. To know if turning milk into plastic can lessen the dangers in plastic materials. 2. To find out how safe is the product. 3. To know the right safety precautions of this experiment. STATEMENT OF THE PROBLEM: Can this product will be more harmless than other plastic and if it is more eco-friendly than the other products. SIGNIFICANCE OF THE STUDY: This study gives importance of using alternative products that is safer and non-toxic and more eco-friendly than the other products. SCOPE AND LIMITATIONS: This study is about turning milk into plastic. In this study, we are going to prove that the components in our product is less toxic and less harmful compared to usual products we usually buy. This product can be alternative products that we have; it is less toxic and less harmful especially for children. HYPOTHESIS: If we can produce plastic made up of milk and vinegar, can it be also effective to promote more harmless and more eco-friendly plastic materials especially for children. DEFINITION OF TERMS: a. Early-Lactation – secretion or formation of milk by the mammary glands b. Colostrum – the thin yellowish fluid secreted by the mammary glands at the time of parturition that is rich in antibodies and minerals, and precedes the production of true milk. c. Curdling – The process of forming semisolid lumps in a liquid. d. Coagulate - change to a solid or semisolid state e. Formaldehyde - an organic compound with the formula CH2O or HCHO. It is the simplest aldehyde, hence its systematic name methanol. The common name of the substance comes from its similarity and relation to formic acid f. Polymer – a chemical compound or mixture of compounds formed by polymerization and consisting essentially of repeating structural units. REVIEW OF RELATED LITERATURE: We combined milk and vinegar in making a harmless plastic. The vinegar is acidic that when you combine it with the milk there is a curdling process happening. When you add the vinegar with the milk, the vinegar separates the water and protein found in the milk due to the vinegar’s acidity. The protein found in the milk is also called cottage cheese or paneer. This product maybe used such as toys, accessories etc. but this plastic is less toxic and less harmful because there is no other chemicals combined with this only the dried curds after the milk and vinegar were combined. MATERIALS: 1. Measuring cup 2. Stirring spoon 3. Milk (fat free, skimmed) 4. Plain vinegar 5. Pan or bowl 6. Cloth towel 7. Heating source 8. Drying place 9. Formaldehyde (optional) 10. Dyes (optional) PROCEDURES: 1. Measure a cup of non-fat milk into a pan to experiment with and warm it until it is simmering; stir to avoid scorching; allow a little foaming around the edges. 2. Pour in one tablespoon of vinegar using measuring spoon, stir and wait for the reaction. 3. Add foil strips or other decorative material to the batch while stirring it. 4. Add dye, for streaking it in the wet casein plastic or can dye surface later. 5. Cool it carefully to be comfortable to the touch; avoid touching or splashing the material or container while it is hot. 6. Strain slowly to separate the coagulated, curdled milk out of the liquid, using a colander. Strain the liquid twice or more if needed. 7. Place the soggy casein onto paper or smooth kitchen towel. 8. Fold towel and blot excess liquid. Squeeze gently. 9. Unfold, unwrap and place the curd on an appropriate paper or wax paper and place it to dry. 10. Shape it by drying in some kind of form, such as bottle cap, for the basic shape or dry it in sheets, rod form or in other forms. 11. Harden the plastic, (optional) when dry by immersing it in formaldehyde and re-drying it. This is a porous material it goes more than surface than surface deep. IMPLICATION: In making our own plastic, it is crumbly and fragile and the contents are perfectly safe for consumers compared to usual plastics that are being used because plastics are manufactured from petroleum. This brings a host of issues like destruction of habitat, extraction of crude oil, security issues from the volatile countries where oil is produced, processing of crude oil, chemical manipulation into various types of plastics. The manufacture involves many chemicals, many of which have not been sufficiently tested for their toxicological impact on humans or animals. There are also certain plastics that are durable materials. Thus, they are hard to eliminate once used and create tremendous waste, While some common plastics can be recycled. In our product, it is perfectly safe and non toxic because each casein molecule is a monomer and chain of casein monomers is a polymer. The polymer can be scooped up and molded. CONCLUSION AND RECOMMENDATION: The whole experiment was a success. We successfully turned milk into a plastic. We have proven that it is less toxic and less harmful compared to any other usual plastics. In this experiment we knew that there will be separation of water and curds in the milk if we put some vinegar. We also knew that the curds can be molded and turned into a plastic without any other chemicals mixed to it, just only the curds and let it dry Materials used milk was poured to the pan one cup of milk one tablespoon of vinegar The milk is simmering we added the food coloring stir until molds are formed and strain to separate the coagulated, curdled milk out of the liquid until it gets hard. We recommend that consumers should stop using the usual plastic that we have and instead use this less toxic and less harmless. This product would be good especially for children. We also recommend that people should try this experiment so they can prove it on their own when they have thoughts about it. ABSTRACT Our investigatory project tackles about turning milk into plastic. Plastic is a polymeric material that has the capability of being molded or shaped, usually by the application of heat and pressure. This property of plasticity, often found in combination with other special properties such as low density, low electrical conductivity, transparency, and toughness, allows plastics to be made into a great variety of products. Our group discussed that it would be better if we do an alternative material for plastic but using different materials that are more harmless and more eco-friendly to the society since several of us are avoiding plastics for the environment’s sake. We gathered information about Plastic, and we used certain alternatives materials to make our own plastic and how will it become more eco-friendly. MILK SOLIDATION 9-St. James Angelica Cruz Colleen Tubungan Francelle Tuaño Paolo Parreñas Francis Bustamante