Integrated Management Team

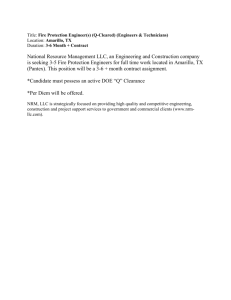

advertisement

Technology Solutions Group PADS Provisioning Effort Kick OFF File Location: Presenter: Paul Paolillo 1pm-3pm January 12, 2012 QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-1 Technology Solutions Group Contents • Welcome to the Kick off • Introductions • Program Description Overview SOW Schedule • PADS Provisioning IPT Structure Defined • PADS Provisioning Explained • Roles and Responsibilities • Charters Integrated Management Team Systems Engineering Hardware Engineering Logistics Engineering Product Assurance - CM - DM - Quality QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group What is PADS? (Precision Airdrop System) • Overall, PADS uses Global Positioning System (GPS) technology that permits Air Force aircrews to literally steer and fly a cargo pallet to the desired location, increasing the margin of safety for the aircrews. They can also land the cargo in a way that keeps the troops from having to scatter over a wide area and potentially making them vulnerable to hostile fire, when retrieving needed supplies. PSI has been working on the PADS system with the US Air Force and US Army since 1999. • http://www.spacewar.com/reports/Qinetiq_Subsidiarys_Precision_Airdrop_System_Used_By_USAF_In_Afghanistan_999.html QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Precision Airdrop System | PADS™ High-Res Atmospheric Forecast Model Airborne sensor, comms, and processing system for precision aerial delivery from high altitude QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 4733-4 Technology Solutions Group PADS Simulates all Airdrop Components 2,000 Meters MSL 2,500 Meters MSL QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 4733-5 Technology Solutions Group PADs Provisioning Product Team (IPT) Structure QNA TSG QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Contract: Statement of Work SUPPLIES/SERVICES QUANTITY 1 UNIT Each UNIT PRICE $1,453,675.77 Production Technical Data Package FFP Contractor shall provide a Level 3 Production Technical Data Package (TDP) to the Government, which includes applicable parts list, detail and assembly drawings, schematics, interface control data, diagrams, performance characteristics, critical manufacturing limits and details of new materials and processes and any other information necessary to enable a competent manufacturer to produce and maintain quality control for the JPADS BLK 4 UHF-DRS and GPS-RTS. The contractor shall provide all data, to include data that is currently claimed as contractor intellectual property, as Government Purpose Rights consistent with that prescribed in DFARS 252.227-7013 and/or DFARS 252.227-7014. Additionally, any data rights provided to the Government shall be documented consistent with that prescribed in DFARS 252.227-7017. In the event that the Government does not agree with any data rights position proposed by the Contractor, the Government may require substantiation of said data rights position by following the procedure prescribed in DFARS 252.227-7019 and/or DFARS 252.227-7037. Delivery Schedule/Cost/Deliverable 31 Dec 2011 $143,367.58 Guidance Conference 31 Mar 2012 $436,102.73 Long Lead Item List 31 Jul 2012 $290,735.15 Provisioning Conference 31 Aug 2012 $145,367.58 Submission of SDFP/LMI 31 Oct 2012 $145,367.58 Submission of PTD 30 Nov 2012 $218,051.37 Spares Conference 20 Dec 2012 $72,683.79 PTD/SDFP/LMI Deliveries QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group SOW: Attachments Attachments: AFMC Form 718 – Provisioning Performance Schedule CDRL A017 – Logistics Management Information (LMI) Data Products(S) CDRL A018 – Supplemental Data for Provisioning (SDFP) CDRL A019 – Logistics Management Information (LMI) Summaries QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Key Points of Contact Contracting Officer Name: Anne Hellman Organization/Office Symbol: DITCO/PL8322 Phone No.: 628-229-9596 E-Mail Address: Anne.Hellman@disa.mil Contract Specialist Name: Danette Wesselmann Organization/Office Symbol: DITCO/PL8322 Phone No.: 618-229-9273 E-Mail Address: Danette.Wesselmann@disa.mil Customer/COR Point of Contact Name: Kristin Dole-Mitchell Organization/Office Symbol: 951ELSG/OC(JPADS) Phone No.: 781-225-9317 E-Mail Address: Kristin.Dole-Mitchell@hanscom.af.mil Contractor Point of Contact Contractor Legal Business Name: Planning Systems Inc DUNS: 072651391 CAGE CODE: 1K736 Contractor POC: Quinn Smith E-Mail Address: qsmith@plansys.com Phone Number: 703-480-0749 QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Risks 1. Start date slippage beyond 1 October 2011 will result in a high level of risk in achieving the goal of an accelerated nine (09) month delivery schedule for this effort. 2. QNA TSG is concerned with rejection rates of stock listing data submissions. To mitigate this risk, we will develop a random sample selection of data early in the effort for review and comment by the Government. 3. An unforeseen elongated contract definition period. 4. QNA TSG believes that not having an updated Provisioning Guidance Conference may affect the critical path for completion of this effort in a manner that could impact the ability of the Air Force to utilize the PTD data for input into the logistics system. 5. QNA TSG understands the requirements as set forth in the CDRLs and SOWs. We reserve the right to equitable adjustment to our price and schedule based on additional requirements that may arise from the Provisioning Guidance Conference, Provisioning Conference, or other formally communicated requirements that may arise during the period of performance of this effort. 6. That the Legacy Drawings are in a non-combatable format, and may need to be re-created in a new tool. QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-10 Technology Solutions Group PADS Provisioning IPT Structure Company Name: sdsdsd(Air force) Quinn Smith (QNA TSG) Paul Paolillo (PM) Systems Bob Holmes (CAM) SE Role (TBD) Drafting Fran Rush (CAM) Drafting/Eng (TBD) Logistics Michelle Sullivan (CAM) Sr. Provisioner (TBD) Deanna Dysert Steve Spongberg Tom Karol Ed Humbarger Product Assurance Fran Rush (CAM) CM Role (TBD) DM Role (TBD) Mike Waxman Hardware Bob Holme (CAM) Wheaton(ME) Pratt (EE) QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Integrated Management Team Integrated Product Team (IPT) Charter Membership, Roles, Responsibilities, and Work Products QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Integrated Management Team IPT Charter Charter The charter of the Integrated Management Team IPT is to transform customer’s needs, expectations, and constraints into provisioned product solutions and support those product solutions throughout the product’s development lifecycle. The IMT IPT is an overarching IPT primarily concerned with management and oversight of PADS Provisioning program execution. QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Integrated Management Team IPT Work Products Integrated Baseline Reviews Program Issue Resolution IPT Management and Conflict Resolution Risk Assessment and Mitigation Cost and Schedule Control Workload Management Life Cycle/Total Ownership Cost Analysis QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Integrated Management Team IPT Roles & Responsibilities Roles: IPT Lead Responsible for technical quality, cost and schedule performance for all activity within the Integrated Management Team IPT. Overarching responsibility for Hardware, Systems Engineering, Product Assurance, and Logistics Serves as the primary customer interface. Applies risk and opportunity management throughout the product contract cycle. Identifies and establishes any corrective actions necessary to ensure IPT objectives are achieved. Coordinates IPT staffing requirements with the Skillset Directors. Supports the metrics coordinator(s) in the collection and reporting of metrics as they pertain to working group activity for the program. IPT Member Fully understand the scope and impact of technical, cost, and schedule issues confronting the team, so that they can communicate, to the other team members, the impact those issues have with respect to their particular area of expertise. QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Integrated Management Team IPT Roles & Responsibilities Responsibilities of IPT: Cost account management Contracts Finance Planning (IMS) Subcontracts Management Sourcing Support CAIV activities as required QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Integrated Management Team IPT Membership List QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Integrated Management Team IPT Integrated Management Team IPT Authority/Accountability Authority/Accountability Cost, Schedule and Technical Performance authority and accountability is held by the Integrated Management Team Control Account Manager (CAM). Integrated Management Team IPT Metrics IPT Metrics EV lite Cost & Schedule, IMS Critical Path, Stop light charts (Hardware/deliveries) Workload burn down for key functional areas as needed (Requirements, part research, drawing and Provisioning Card creation etc.). Also, overall technical performance authority and accountability is held by the Integrated Management Team Control Account Manager (CAM). QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Engineering Integrated Product Team (IPT) Charter Membership, Roles, Responsibilities, and Work Products QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Systems Engineering IPT Charter Charter The charter of the Engineering IPT is to transform customer’s needs, expectations, and constraints into product solutions and support those product solutions throughout the product’s development lifecycle. QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Systems Engineering IPT Work Products Requirements Database Systems Documentation Example: Technical Data Package Supporting research for Provisioning CARDs Supporting research for Drawing creation Requirements Traceability Matrix Drafting Drawing modifications, update and creation As needed or requested Trade Studies White Papers Review Delivery Packages QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Engineering IPT Roles & Responsibilities Roles: IPT Lead Responsible for technical quality, cost and schedule performance for all engineering activity within a IPT. Serves as the primary customer technical interface for the respective IPT product. Serves as IPT Control Account Manager (CAM). Applies risk and opportunity management throughout the product life cycle. Identifies and establishes any corrective actions necessary to ensure IPT objectives are achieved. Technical process discipline within the IPT. Coordinates IPT staffing requirements with the Program Office, Skillset Manager, and Chief Technology Officer. Supports the metrics coordinator(s) in the collection and reporting of technical metrics as they pertain to IPT activity. IPT Member Fully understands the scope and impact of technical, cost, and schedule issues confronting the team, so that they can communicate, to the other team members, the impact those issues have with respect to their particular area of expertise. QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Engineering IPT Roles & Responsibilities Responsibilities of IPT: Accept top-level requirements and allocate to subsystems Systems Integration, assessments of derivation of lower-level requirements, systems design decisions, and compliance with top-level requirements Manage and approve allocation of system-level functions to subsystems and components Lead and approve design trade studies Oversee engineering analysis in support of subsystem, component, hardware and software design Review Verification Requirements, Risk Assessment and Mitigation and Traceability of Requirements As needed update and review applicable sections of technical operations and functionality within the IDE customer database environment Support CAIV activities as required QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Engineering IPT Engineering IPT Authority/Accountability Authority/Accountability Cost, Schedule and Technical Performance authority and accountability is held by the Systems Engineering Control Account Manager (CAM). Systems Engineering IPT Metrics IPT Metrics are such things as: EV Cost & Schedule, IMS Critical Path, Stop light charts (Hardware/deliveries) Workload burn down for key functional areas as needed (Requirements, PADS research of development, etc.). Also, overall technical performance authority and accountability is held by the Integrated Management Team Control Account Manager (CAM). QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Hardware Engineering Integrated Product Team (IPT) Charter Membership, Roles, Responsibilities, and Work Products QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Hardware Engineering IPT Charter Charter The charter of the Hardware Engineering IPT is to provide engineering support to provision the PADS design (electrical and mechanical) that directly implements all system and hardware requirements, helps understand the hardware architecture so that flexibly supports future expansion while ensuring reliability, maintainability, and long term support throughout the contract life-cycle. QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Hardware Engineering IPT Work Products The PADS hardware design Technical Data Package Detail Drawings Assembly Drawings Specification Control Drawings Vendor Item Drawings Peer Review Packages of Drawings and Provisioning Cards QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Hardware Engineering IPT Roles & Responsibilities Roles: IPT Lead Responsible for technical quality, cost and schedule performance for all engineering activity within a IPT. Serves as the primary customer technical interface for the respective IPT product. Applies risk and opportunity management throughout the product life cycle. Serves as IPT Control Account Manager (CAM). Identifies and establishes any corrective actions necessary to ensure IPT objectives are achieved. Technical process discipline within the IPT. Coordinates IPT staffing requirements with the Chief Technology Officer. Supports the metrics coordinator(s) in the collection and reporting of metrics as they pertain to IPT activity. Also responsible understanding the metrics data and for making prudent technical management decisions based on the data. IPT Member Fully understand the scope and impact of technical, cost, and schedule issues confronting the team, so that they can communicate, to the other team members, the impact those issues have with respect to their particular area of expertise. QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Hardware Engineering IPT Roles & Responsibilities Responsibilities of IPT: Direct implementation of allocated hardware requirements Integration of mechanical and electrical design elements Participate in program and technical reviews Manage hardware design including schedule and approvals Review and resolve program problem reports Support CAIV Activities as required QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Hardware Engineering IPT Hardware Engineering IPT Authority/Accountability Authority/Accountability Cost, Schedule and Technical Performance authority and accountability is held by the Hardware Engineering Control Account Manager (CAM). Hardware Engineering IPT Metrics IPT Metrics are such things as: EV Cost & Schedule, IMS Critical Path, Stop light charts (Hardware/deliveries) Workload burn down for key functional areas as needed (Requirements, Software Development, etc.). Also, overall technical performance authority and accountability is held by the Integrated Management Team Control Account Manager (CAM). QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Provisioning Overview Michelle L. Sullivan QinetiQ NA ILS Manager JANUARY 2012 QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-31 Technology Solutions Group Topics What is Provisioning? Where Provisioning Fits in ILS The Provisioning Process Provisioning Schedule Provisioning Technical Data (PTD) JPADS Path Forward QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-32 Technology Solutions Group What is Provisioning? • Provisioning is the process of identifying and obtaining the initial stock of spare parts required to support fielded equipment. • Part of the provisioning process is to obtain National Stock Numbers (NSN’s) for spare parts. Having an NSN allows the field to purchase the items through the DoD Requisitioning System. Additionally, it allows the DoD item manager to properly forecast requirements for the items and ensure items are stocked. • NSN assignment is accomplished by generating provisioning lists containing Provisioning Technical Data (PTD). This data identifies the parts of an item of equipment and their application within the overall system. • QNA’s role is to provide provisioning technical data regarding the items so they may obtain a National Stock Number (NSN). QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-33 Technology Solutions Group The ILS Equation Integrated Logistics Support (ILS) is the process that facilitates the development and integration of all of the logistics support elements to acquire, test, field, and support a weapons system 10 ILS Elements Design Influence Technical Data Maintenance Planning Manpower and Personnel Supply Support Training and Training Support Computer Resources Support Facilities Packaging, Handling, Storage and Transportation Maintain Operational Readiness at system fielding and throughout the systems lifecycle Provisioning is part of Supply Support QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-34 Technology Solutions Group Integrated Logistics Support – Supply Support Objective: Identify, plan, resource and implement management actions to acquire and support the product required to sustain the operation and maintenance of the system to ensure the product is available when needed. Description: Consists of all management actions, procedures, and techniques necessary to determine requirements to acquire, catalog, receive, store, transfer, issue, and dispose of spares, repair parts, and supplies. Process includes provisioning for initial support as well as acquiring, distributing, and replenishing inventories. Having the right items, in the right place, at the right time QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-35 Technology Solutions Group Provisioning Process Engineering Drawings Maintenance Task Analysis (MTA) Data Helpful Definitions Prepare Initial Provisioning List Obtain Application Information Research Parts Information Application Data Cataloging Data Provisioning Parts List (PPL): The PPL is a complete listing of all the parts that make up an item of equipment. This list is prepared by the contractor (us!) and submitted to the Government at or before the provisioning conference (not to be confused with the Provisioning Guidance Conference). Prepare Detailed Provisioning List Review/Verify List (may require rework) Submit List for NSN Screening Prepare Final Provisioning List Provisioning Screening: Screening of provisioning lists to identify parts that have already been assigned NSN’s. Provisioning Submittal: Provisioning Lists are submitted to the Government for review prior to each conference Submit Provisioning Technical Data to Government QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-36 Technology Solutions Group Common Provisioning Schedule Contract Award Provisioning Guidance Conference Long Lead Time Items Provisioning Conference DLIS screening* *The Defense Logistics Information Service (DLIS) is responsible for screening provisioning lists for existing NSN’s Submission of PTD Provisioning Conference Submission of Post Conference List QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-37 Technology Solutions Group Provisioning Technical Data (PTD) • PTD is any data submitted to the Government as part of the provisioning Process • There are several different types of PTD. The data reflected in them is generally the same. The difference in the lists is the type of items for which they are prepared and the intended use of the lists. • Per the contract, QNA will be submitting a Provisioning Parts List (PPL) for items associated with JPAD’s. Provisioning Parts List (PPL): The PPL is a complete listing of all the parts that make up an item of equipment. This list is prepared by the contractor (us!) and submitted to the Government at or before the provisioning conference (not to be confused with the Provisioning Guidance Conference). Additionally, some of our items will be considered Common Bulk Items (CBI’s) and will fall under a CBI list. QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-38 Technology Solutions Group Data elements on the PPL • PPL be divided into two categories Cataloging Data: describes the part without regard to its usage (Ex. Item Name, NSN, Unit of Issue, etc.) Application Data: data that relates to the specific application of the part being reported on the provisioning list (Ex. Quantity per assembly, maintenance task distribution, etc). Application data can be different for each use of a part in a system and tell how a part is used. • PPL is generating using engineering drawings as a basis for data. • Some elements will be provided by the Government at the Provisioning Guidance Conference • Data elements commonly required: •Provisioning List Item Sequence Number (PLISN) •Manufacturer’s Part Number •Commercial and Government Entity Code (CAGE) •Source, Maintenance, and Recovery Code (SMR) •National Stock Number (NSN) •Quantity per End Item (QPEI) •Recommended Quantity •Production Lead Time (PLT) •Unit of Issue (UI) •Item Name QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-39 Technology Solutions Group PTD 80 Card Column Format QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-40 Technology Solutions Group Sample 80CC Provisioning Parts List ABF888A0001XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX-------ABF888A0001 3023312345-65 XXXXXXXXXXXXXXXXXX2X RADAR SYSTEM -XXA ABF888A0001----XXXXXXXXXXXXXXXXX------------XXXXXXXXXXXX-----XXXXXXXXXXXXXXXXXXB ABF888A0001-XXXXX-XXXXXXXXXXXXXXXXXXXX---------------XXXXXXXXXXXXXXXXXXXXXXXXXXC ABF888A0001-XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX--------------------XXD ABF888A0001-XXXXXXXXXXXXXX---------------XXX---------------------------XX----XXE ABF888A0001----------------XXXXXXXXXXXXXXXXXXXXXX--XXXXX-XXXXXXXXXXXX--------XXF ABF888A0001------------------------------------------------------------------XXG ABF888A0001---------------------XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX--XXXXXXXXXXXXH ABF888A0001------------------XXXXXXXXXXX-------------------------------------XXJ ABF888A0001---------------XX-------------------------------------------------XXL QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-41 Technology Solutions Group Path Forward Near Term: •Provisioning Guidance Conference (to be scheduled in January 2012) •Development and Review of Engineering Drawings •Development of Data Entry Forms •Provisioning Parts Lists Data Research •Training of personnel on Data Entry •Data Entry Long Term: •Data QA for content and formatting •Data Submittal (Initial) •Review and Revision of Data (from initial submittal) •Data Submittal (Final) QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-42 Technology Solutions Group Program Schedule QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com Technology Solutions Group Comments or Questions? QinetiQ North America Operations LLC Proprietary © QinetiQ North America Operations LLC 2009 www.QinetiQ-NA.com 0000-44

![Your_Solutions_LLC_-_New_Business3[1]](http://s2.studylib.net/store/data/005544494_1-444a738d95c4d66d28ef7ef4e25c86f0-300x300.png)