Team 4 Final Report

advertisement

AAE 451 Aircraft Design

Final Report

Team 4

Sean Bhise

Kyle Brite

Philip Catania

Thomas Horan

Timothy Ma

Jason Wirth

Code of Ethics

Taken from the Purdue University Handbook, Student Code of Honor:

“The purpose of the Purdue University academic community is to search for truth and to

endeavor to communicate with each other. Self-discipline and a sense of social obligation within

each individual are necessary for the fulfillment of these goals. It is the responsibility of all

Purdue students to live by this code, not out of fear of the consequences of its violation, but out

of personal self-respect. As human beings we are obliged to conduct ourselves with high

integrity. As members of the civil community we have to conduct ourselves as responsible

citizens in accordance with the rules and regulations governing all residents of the state of

Indiana and of the local community. As members of the Purdue University community, we have

the responsibility to observe all University regulations.

To foster a climate of trust and high standards of academic achievement, Purdue University

is committed to cultivating academic integrity and expects students to exhibit the highest

standards of honor in their scholastic endeavors. Academic integrity is essential to the success of

Purdue University’s mission. As members of the academic community, our foremost interest is

toward achieving noble educational goals and our foremost responsibility is to ensure that

academic honesty prevails.”

The members of Team 4 agree with and uphold to the above Code of Ethics and maintain

that the information contained within this report is original unless otherwise referenced.

i

Table of Contents

1. Executive Summary .............................................................................................................. 1

2. Aircraft Introduction ............................................................................................................ 2

3. Mission Requirements, Concept Selection, Initial Sizing .................................................. 3

- Jason Wirth; Sean Bhise; Philip Catania

3.1. Mission Requirements ..................................................................................................... 3

3.2. Concept Selection ............................................................................................................ 3

3.3. Initial Weight Estimation ................................................................................................. 4

3.4. Constraint Diagrams ........................................................................................................ 5

4. Structures and Weights ........................................................................................................ 6

- Timothy Ma

4.1. Introduction...................................................................................................................... 6

4.2. Material Properties........................................................................................................... 6

4.3. Weight Determination ..................................................................................................... 7

4.4. Geometric Layout of Wing Structure .............................................................................. 8

4.5. Analysis of Wing Loads .................................................................................................. 8

4.6. Landing Gear Configuration ............................................................................................ 9

5. Aerodynamics ........................................................................................................................ 10

- Thomas Horan; Sean Bhise

5.1. Introduction...................................................................................................................... 10

5.2. Lift Production ................................................................................................................. 11

5.3. Drag Minimization........................................................................................................... 12

5.4. Wing Design .................................................................................................................... 13

5.5. Stability ............................................................................................................................ 13

6. Propulsion .............................................................................................................................. 14

- Philip Catania

6.1. Introduction...................................................................................................................... 14

6.2. Propeller Selection ........................................................................................................... 14

6.3. Motor/Gearbox Selection................................................................................................. 16

6.4. Speed Controller Selection .............................................................................................. 17

6.5. Battery Selection .............................................................................................................. 17

7. Dynamics and Controls ........................................................................................................ 18

- Jason Wirth

7.1. Introduction...................................................................................................................... 18

7.2. Tail Surface Sizing .......................................................................................................... 18

7.3. Control Surface Sizing ..................................................................................................... 21

7.4. Roll Mode Approximation ............................................................................................... 21

7.5. Gain Selection .................................................................................................................. 21

7.6. Flight Characteristics ....................................................................................................... 22

ii

8. Economics .............................................................................................................................. 23

- Kyle Brite

9. References .............................................................................................................................. 25

APPENDIX A – Initial Sizing and Concept Selection ............................................................. 26

APPENDIX B – Structures and Weights .................................................................................. 33

APPENDIX C – Aerodynamics ................................................................................................. 37

APPENDIX D – Propulsion ....................................................................................................... 48

APPENDIX E – Dynamics and Controls .................................................................................. 58

APPENDIX F – Economics / Project Management ................................................................. 81

iii

1. Executive Summary

The purpose for this project is to design, build, and successfully fly an aircraft within the

confines of the Purdue Armory. This project is intended to demonstrate to Dr. Andrisani that an

interdisciplinary team of senior-level aeronautical engineering students can successfully design

an aircraft that meets all mission requirements. There are several mission requirements that must

be met for this aircraft to be considered successful. The aircraft must navigate through several

phases of flight before ultimately pitching up into a hover maneuver.

A roll rate gyro will be employed for this project to successfully maintain the hover. This

gyro will assist the pilot in maintaining a steady roll angle while allowing him to keep the

aircraft in a nose up configuration within the confines of the Purdue Armory. Team 4’s aircraft

uses an approximation of the roll mode to determine a nominal gain for the rate gyro..

The philosophy behind Team 4’s aircraft is a simple to build, easy to repair aircraft. The

aircraft that has been designed uses a large rectangular wing with a NACA 6412 airfoil in order

to minimize stall and cruise speed. The optimum cruise speed for our aircraft is 19.5 ft/s, which

allows an experienced pilot more than enough time to turn and avoid any obstacles inside of the

Armory. Since this aircraft is being flown indoors, a considerable amount of the design reflects

those considerations. Team 4 feels that our large, slow flying aircraft will be more controllable

in an indoor environment than a smaller and faster aircraft.

Another mission requirement for this aircraft is to be built on an operating budget of

$150. After careful evaluation and consideration, Team 4 found this to be insufficient for the

mission that the aircraft is required to perform. With an eye on costs, Team 4’s entire parts

budget was kept under $200. As this aircraft is potentially being marketed to a teenage audience,

the marketability of the aircraft is another concern. With this in mind, Team 4’s aircraft will use

a bright and bold paint scheme to increase possible sales.

The aircraft that Team 4 designed is anticipated to meet all mission requirements. The

construction will be simple and easily repairable to prevent extended periods of downtime in the

event of a crash. The aircraft is designed to be sufficiently maneuverable to be able to perform

aerobatic maneuvers without significant effort by the pilot.

1

2. Aircraft Description

Figure 1 - Aircraft 3-View

Wing Span

Wing Area

Wing Chord

Aspect Ratio

Dihedral

Fuselage Length

Aircraft Weight

Horizontal Tail Area

Vertical Tail Area

4.8

4.8

1

4.8

3

3.75

1.94

1.75

0.35

ft

ft2

ft

o

ft

lb

ft2

ft2

Propellor Size

Motor Power

Battery Cell Type

Battery Cell Number

Battery Power

Battery Voltage

Gearbox Ratio

Feedback Controller Axis

Gear Type

13 x 6.5

150 W

Lithium Polymer

1x3

1320 mAh

11.1 V

2.5:1

roll

taildragger

Table 1 - Aircraft Specifications

2

3. Mission Requirements, Concept Selection, and Initial Sizing

3.1 Mission Requirements

There are several mission requirements that the aircraft must meet. Per the Request For

Proposal (RFP), the aircraft must be able to be flown within the confines of the Purdue Armory.

It must also be robust to crashes and be easy to fly. It must meet all Level IA military flying

qualities. The aircraft must be built for less than $150. During takeoff, the total ground roll

must not exceed 10 feet. During the climb stage, the aircraft must perform a 45° banked turn. It

must then loiter for a period of three minutes while maintaining a stall speed of no greater than

15 ft/s. The aircraft must then perform a pitch up maneuver and maintain a ±20° roll angle while

in a hover for a period of two minutes. To assist the pilot during this maneuver, a roll rate

feedback gyro will be used to assist in aileron control. Finally the aircraft must be demonstrated

to land safely.

3.2 Concept Selection

After considering the requirements set forth in the RFP, all team members were asked to

come up with an initial conceptual design for an aircraft capable of completing all aspects of the

mission. Three designs were then chosen by the team as finalists. These three designs included

a conventional single-engine aircraft, a twin-engine aircraft, and a single-engine design with a

dual-boom fuselage with integrated vertical tails that resembled a “double extruded plus-sign”.

Three-view drawings of these designs can be seen in Appendix A.

The next step in determining the final concept was using Pugh’s Method to compare

pertinent design variables and qualities. Concept 1, which was the conventional single-engine

aircraft, was chosen as the baseline because it is the most common design of the three. Concepts

2 and 3 were then compared with Concept 1 in each of the areas shown in Table , and even

though Concept 3, the “double plus-sign”, shows a final value of +2, a decision was made that

the complexity was not weighted heavily enough and would not be worth the benefits gained in

other areas. This ended up ruling out both Concepts 2 and 3, leaving Concept 1, with some

appropriate modifications, as the design of choice for Team 4.

3

Design 1 Design 2 Design 3

Wing Area

Roll Control

Aspect Ratio

Cost

Weight

Cruise Speed

Stall Speed

Durability

Complexity

Repairability

+

S

S

+

S

+

S

S

2

4

4

+

S

S

S

+

+

+

S

4

2

4

Table 2 - Pugh's Method Comparison of Three Final Conceptual Designs

3.3 Initial Weight Estimation

To initially estimate the weight of this aircraft, a historical approach was employed.

Team 4 used a database of 10 commercial radio controlled (R/C) aircraft and found a linear

relationship between required battery weight and total weight for the aircraft. The table and

resulting plot are located in Appendix A. However this trend line only gives data for historical

r/c aircraft which may not have the same mission requirements as those given in the RFP. To

determine an accurate estimation of the battery weight required for the mission given for this

project, MATLAB code was used to analyze each phase of the flight. Detailed analysis for the

estimation of battery fraction necessary for each flight phase is located in Appendix A.

4

Weight estimation using historical weight data

0.8

Historical data

Estimated weight

0.7

W-We and Wb+Wp~lbf

0.6

0.5

0.4

0.3

0.2

Estimated aircraft weight is 1.8623 pounds.

Estimated battery weight is 0.20854 pounds.

0.1

0

Payload weight is 0.25 pounds.

0

0.5

1

1.5

Weight~lbf

2

2.5

3

Figure 2 - Aircraft Weight Estimation

3.4 Constraint Diagram

The constraint diagram shown below allowed us to pick a feasible design point for the

aircraft. The condition that constrained the aircraft the most was the hover condition which can

be seen on the graph as the horizontal lines. The loiter and cruise phases of the mission had no

effect on picking a feasible design point. As our simulations showed the CLmax = 1.66 for the

NACA 6412 airfoil, the design point was chosen to be at a CLmax = 1.61 in order to have a small

buffer area. The stall constraints can be seen as the vertical lines in the graph. The results from

choosing this design point yielded a wing loading of 0.405 lb/ft2 and power loading of 15 lbf/hp

at Vstall = 15 ft/s.

5

Constraint Diagram

30

25

Power loading (lbf/hp)

20

Hover

Constraint

15

Design

Point

CLmax : 1.60 1.61 1.62

10

5

0

0.39

0.395

0.4

0.405

0.41

0.415

Wing loading lbf/ft 2

Figure 3. Plot of Constraint Diagram

4. Structures and Weights

4.1. Introduction

Within the mission specifications, the requirements that set parameters for the structural

aspect of the aircraft are that it must be robust to crashes, lightweight, easy to construct, and

inexpensive. Preliminary research on various model R/C aircraft, specifically in the Park Flyer

aircraft category, was done to enhance the understanding of the weights and typical structures

that should be expected. After collecting the data, the aircraft could be designed with an

approximate weight and model in mind. Considering the requirements for the mission, extruded

polystyrene (EPS) foam will be a major material used to compose the main structural member of

our aircraft. Compiling the historical knowledge of model aircraft, researching different design

philosophies, and performing different structural analyses, the structure of the aircraft can be

designed.

4.2. Material Properties

The material properties chosen for the aircraft needed to be lightweight, durable, easily

workable in construction, and relatively inexpensive. The main materials of the aircraft are

extruded polystyrene (EPS) foam, aluminum, and film covering. The properties of the main

materials used in the aircraft are summarized below in Table 3.

6

Material Properties

EPS Foam

1.8

Aluminum

0.098

Corregated Plastic

14.02

MonoKote

0.0021

lb/ft^3

lb/ft^3

lb/ft^3

oz/in^2

Table 3 - Moments and Products of Inertia

Most aircraft in the Park Flyer category of R/C aircraft are constructed out of foam,

heavily influencing the design to be composed of foam. Since the wing is the primary structure

of our aircraft and is approximately a third of the weight, using EPS foam will help assist with

weight concerns. The qualities that EPS foam possess that it is rigid, lightweight, easily shaped

into the needed airfoil contour, and inexpensive. A film covering will be used as a wing skin to

assist in keeping the rigidity and shape of the wing and also to help prevent punctures, dents, and

scrapes in the EPS foam. The aluminum will be mainly used in the aircraft for the fuselage and

ribs for the fairing. An aluminum square tube for the fuselage will provide a strong foundation

for all the other aircraft structures to attach to. The thin sheet aluminum will be used to construct

the ribs for the fairing and wing connectors (images of these can be seen in Appendix B). The

aluminum fairing ribs, which holds all the necessary and vital propulsion and control

components, and EPS foam covering will provide a sturdy structure to house and protect the

parts during flight conditions and during a rough landing or crash. The horizontal and vertical

tails will be constructed from corrugated plastic. Images of the horizontal and vertical tail can be

seen in Figure 24 and Figure 25 in Appendix B.

4.3. Weight Determination

An analysis was done to approximate the weight of the aircraft for use in preliminary

calculations and design. The approximation was based on historical data of other commercially

sold R/C aircraft in production today. In determining the center of gravity (CG) location, a

tabular listing of weights and location of all parts of the aircraft was used and is provided below

inTable 4 . The weights are calculated using volume and material density properties or from

research done on commercial websites. To calculate the actual CG location, equation 1 in

Appendix B was used.

7

Location from

Propeller (in)

0.00

0.50

1.13

8.00

8.00

12.00

12.00

13.00

11.00

12.00

22.50

42.50

40.00

Propeller

Motor

Gear box

Speed Controller

Batteries

Wing

Fairing

Servos (4)

Receiver

Rate Gyro

Fuselage

Vertical Stablizer

Horizontal Stablizer

Weight (lb)

0.04

0.14

0.13

0.04

0.13

0.60

0.17

0.08

0.06

0.06

0.37

0.02

0.14

Table 4 - Tabular Listing of Weights and Locations of Aircraft Parts

The aircraft weight is 1.94 pounds and the CG location of the aircraft is 14.17 inches

from the nose. The CATIA computer drafting program was used in calculating the moments and

products of inertias of the aircraft, which are listed in Table .

Moments of Inertia

Products of Inertia

2

Ixy

0 slug*ft2

3

Ixz

0 slug*ft

4

Iyz

0 slug*ft

Ixx

0.038 slug*ft

Iyy

0.044 slug*ft

Izz

0.081 slug*ft

3

4

Table 5 - Products and Moments of Inertias

4.4. Geometric Layout of Wing Structure

The primary geometry for the wing will be solid EPS foam using a film covering as a

wing skin. No other wing structures such as spars, stringers, or ribs are needed. As the aircraft is

lightweight and rigid, it will not see excessive loads that will warrant extra wing structures. The

wing will have a span of 4.8 feet and a chord length of 1 foot. It will be shaped into a NACA

6412 airfoil using a hot-wire CNC machine. In order to help with stability and control, the wing

will also have dihedral of 3 degrees.

4.5. Analysis of Wing Loads

From calculations done by other sections of the team and using equations 7-9, a V-n

diagram was created (Figure 4). The V-n diagram represents load factor versus velocity. The

FAA has defined the range of load factor for aerobatic aircraft from -3 to 6 g’s. From the

maximum lift curve, at the load of 6 g’s the velocity is approximately 35 ft/s. The wing load is

modeled using an elliptical load distribution approximation (Equation 8) and can also be seen in

Figure 8, both in appendix B. From that, to calculate the maximum root bending moment, a

8

maximum load of 6 g’s was used to determine lift (Equation 8 in appendix B) and calculating the

distance to the centroid of a quarter ellipse (Equation 7 in appendix B) where the load is

assumed. This gives a moment of 5.91 ft-lbs (Appendix B, equation 4). Using Equation 9 in

appendix B, the bending stress is 19.4 psi. Although this number seems high, loads of this

magnitude are not expected to be experienced by the aircraft. Furthermore, the calculations did

not take into account the film covering, which will help with the bending moments and stresses

of the entire wing. From these calculations, it directed the structural development of the aircraft.

V-n Diagram

8

6

Load Factor (g)

4

2

0

-2

-4

0

5

10

15

20

25

Velocity (ft/s)

30

35

40

Figure 4 - V-n Diagram

4.6. Landing Gear Configuration

The design strategy for the landing gear is to survive multiple landings, especially ones

which are rough and unplanned. The landing gear design is referenced from Raymer as seen

from in Figure 5.

9

Figure 5 - Taildragger Landing Gear Diagram from Raymer

The tail-down angle should be between 10-15˚ with the gear in the static position and

aircraft is modeled with a 12.5˚ angle. The CG should fall between 16˚-25˚ back from the

vertically measured main wheel location and the aircraft is designed with a 21˚ placement. If the

CG is too far forward, the aircraft will nose over and if it is too far back it will groundloop. The

main wheels must be laterally separated beyond 25˚ off the CG to prevent the aircraft from

overturning and the aircraft has a 35˚ separation. Also, a one inch clearance from the ground to

the propeller is added in to prevent a prop-strike when the tail begins to lift during takeoff. The

tail wheel will also be steerable as it is directly connected to the rudder.

5. Aerodynamics

5.1 Introduction

The mission requirements for our aircraft dictated the final design every step of the way.

Of the given requirements in the RFP, those with aerodynamic consideration are:

-

Slow flight with Vstall ≤ 15 ft/s

Short takeoff ability with takeoff ground roll ≤ 10 ft

Climbing right-angle following takeoff with γmin ≥ 45˚

Aircraft must be easily controlled and able to fly within the Purdue Armory

From these considerations, several specific design areas must be addressed. The main areas of

concern are the lift production, drag minimization, and the stability & control characteristics.

These design areas, combined with the requirements as stated above, will drive the design and

subsequent performance of the aircraft. The overall number of constraints will be minimized as

best possible in order to leave a wide design area.

During the initial sizing analysis, it became very apparent that the stall speed requirement

was going to require a high CLmax in order to be able to perform at such low speeds and still have

control over the aircraft. So while the design needs to be able to produce a large amount of lift,

drag needs to be minimized in order to curtail weight and power expenditures with the

10

propulsion system. This will, in turn, reduce the overall aircraft weight, another very important

aspect of the design.

As this aircraft is being designed to be marketed and sold to teenagers, it must exhibit

good flight characteristics as well. Several aspects of the final design were specifically included

to maximize aircraft handling, and as a result, they have a direct aerodynamic response.

5.2 Lift Production

The center of lift production lies in the airfoil selection. By selecting the proper airfoil

given the aircraft’s mission, lift will be maximized while drag is subsequently reduced. It will

also allow the design to meet the requirements of a 15 ft/s stall speed, in addition to being able to

achieve flight after a fairly short ground roll. As a result of those two requirements, airfoil

selection was driven mainly by the Cl max, which would as a result, dictate the size and weight of

our wing. Before any airfoil analysis could be performed, the aircraft’s operating conditions

were studied. A Reynolds number (Re) for the flight conditions of 119,000 was calculated using

atmospheric conditions, aircraft operating speed, and wing chord length (Equation 13). After

calculation and subsequent research, it was determined that our aircraft would be operating in the

low Reynolds number regime (generally described as Re < 800,000).

Operating in the low Reynolds number regime introduces its own set of design

challenges. Namely, the flow tends to want to resist the transition to turbulent flow and remain

laminar. As the aircraft will have a relatively low operating velocity, there tends to be a

relatively adverse pressure gradient at the boundary of the airfoil surface and the air. The

resulting interaction tends to lead to a less “full” velocity profile, as compared to one from a

turbulent boundary layer. This can cause flow separation, which will cause a loss of lift and a

sharp increase of drag.

In the pursuit to find the optimal airfoil, several avenues were investigated. The airfoils

of several aircraft with similar missions were considered, in addition to experimental high-lift

airfoils (some with a Cl max purported to be over 2.0). From the large field of potential airfoils,

two airfoils were selected for further analysis: the NACA 6412 and the Selig & Donovan 7062

(as shown in Figure 6). The driving factor for the airfoil selection came down to lift production

and ease of construction. Some of the higher-lift airfoils require manufacturing tolerances

greater then what our building abilities allow, and as a result, were removed from consideration.

After generating airfoil data in XFOIL, a panel-based flow simulation program, we then

analyzed the lift curve plot and the drag polar (Figure 7) for those two airfoils.

Figure 6 - Airfoil Candidates

11

1.8000

0.3

1.6000

0.25

1.4000

1.2000

0.2

Cl

Cd

1.0000

0.15

0.8000

0.6000

0.1

0.4000

0.05

0.2000

0.0000

-10.000

-5.000

0

0.000

5.000

10.000

15.000

20.000

25.000

0.0000

0.5000

alpha (degrees)

NACA 6412

1.0000

1.5000

2.0000

Cl

SD 7062

NACA 6412

SD 7062

Figure 7 - Airfoil Candidates Lift Curve & Drag Polar

The NACA 6412 was selected for its good lift characteristics and low drag response at high

angles of attack. From the constraint diagram, a total wing area of 4.8 ft2 is required using this

airfoil.

From the beginning, the largest area of concern has been the aircraft’s ability to meet the

stall speed constraint. Computer models of this scenario are difficult to create and produce

questionable results at best, mainly due to the flow separation. Therefore, Raymer’s method for

predicting wing lift coefficient was used (Raymer, “Aircraft Design”).

5.3 Drag Minimization

The elimination of drag was a facet of the design from the beginning stages. Although

we are unable to do the fine-tuned drag optimization using CFD codes and wind tunnels as used

in industry, we still tried to model the drag characteristics of the aircraft as best as possible.

Every aspect of the flight profile is influenced in some way by the drag produced by the aircraft.

The aircraft drag was calculated from Nicolai:

𝐶𝐷 = 𝐶𝐷𝑚𝑖𝑛 + (𝐾 + 𝐾 ′ )(𝐶𝐿 − 𝐶𝐿𝑚𝑖𝑛 )2

Equation 1

Where the total drag is a sum of the parasite drag (𝐶𝐷𝑚𝑖𝑛 ) and the drag produced by lift.

The parasite drag is a result of the whole aircraft body, and is equal to the sum of all the wetted

surface areas, multiplied by the coefficient of skin friction and form factors for each piece of

geometry on the aircraft. The skin friction is based upon the Re, which is derived from the

aircraft flight conditions. Due to a majority of the aircraft sitting in the slipstream from the

propeller, all airflow over the aircraft surfaces was assumed to be turbulent. In order to decrease

its own parasite drag contribution, the cylindrical size and shape of the fuselage was optimized as

part of a trade study (see Appendix C.4). The wing tips will also be optimized accordingly as

well during the build.

12

The wing was designed in such a way as to ensure elliptical span-wise lift distribution, in

order to minimize induced drag. In order to account for any non-elliptical results, an Oswald’s

efficiency factor was calculated as well (Equation 14). Using the equation, an e = .9073 was

calculated, higher than the historical average for small, high-wing aircraft, but in line with values

produced by other teams in the design class.

As the aircraft flies, its trim condition is always changing due to differing flight

characteristics. Therefore, the produced drag is always changing as well, from the downwash

produced by the horizontal tail countering the pitching moment of the wing. Taking this into

account during our pitch stability analysis, a MATLAB script was used to generate the whole

aircraft drag polar (Figure 28).

5.4 Wing Design

Once a required wing area was generated, the wing design was started. The aspect ratio

was calculated to find the best possible compromise between induced drag and the wing root

bending moment. An aspect ratio of 4.8 was chosen. As a result of our required wing area, this

sets the wing chord at a constant 1 foot, due to our wing being untapered. Although wing taper

does produce a more elliptical lift distribution, analysis indicated that it was unnecessary due to

our wing size.

5.5 Stability

The aircraft has been designed to be stable and capable of handling aerobatic-type

maneuvers. The most important task that was taken into account when designing the aircraft was

the hover condition that had to be met. In order to remain stable in the hover, the aircraft has

large ailerons which will allow for more control since they will be in the prop wash.

In order to meet a minimum static margin of 10-20% MAC for our aircraft, the

aerodynamic center must be behind the CG. In order to meet these conditions, our wing was

placed 6 inches aft of the nose of the aircraft in order to move the aerodynamic center towards

the back of the aircraft. The aircraft also features a larger horizontal tail area of 1.75ft2 for this

same reason. The size of the horizontal tail was determined by a Class II sizing analysis which

will be further discussed in the Dynamics and Controls section. Using Equation 30 located in the

appendix for aerodynamic center, our static margin was calculated to be 14% of the mean

aerodynamic chord (MAC).

The CG of the aircraft was determined to be at 32% MAC as described in the Structures

section of the report. Using this CG, the trim conditions for the aircraft were able to be

determined using the trim diagram shown in Figure 8. The elevator deflection angle at αstall = 11°

is -7° with a deflection range from -1° to -7° and a horizontal tail angle of incidence = 0°. The

aircraft will be able to trim at stall since we will be able to achieve a CL = 0.98 with the CLmax of

the aircraft equal to 0.92. The CLmax determination of the aircraft was explained earlier in the

section.

13

Figure 8 - Aircraft Trim Diagram

6. Propulsion

6.1

Introduction

The mission specification set out several important parameters that had to be met while

determining the components of the propulsion system for the aircraft, primarily the restriction to

using a battery-powered electric motor. This limited the propulsion system to a propeller,

electric motor and gearbox, speed controller, and batteries. Another major constraint that had to

be taken into account was that the aircraft had to be able to transition out of straight and level

flight after 3 minutes into a hover and hold there for 2 minutes before landing. The hover phase

of the flight ended up being the major contributor in determining the power required for the

mission.

The first parameter to be decided upon before the next steps of the analysis was that of a

cruise velocity. This was determined from the provided constraint of a maximum stall speed of

15 ft/s. The assumption was made to use this limiting case of 15 ft/s when calculating a cruise

speed. Cruise speed was then taken to be 130% of the stall speed, resulting in a cruise speed of

19.5 ft/s.

6.2

Propeller Selection

All of the propeller analysis for this project was done using two provided MATLAB

scripts, both of which are provided in Appendix D. The first uses Goldstein’s method of

propeller design to determine advance ratio and the thrust and power coefficients for a given

14

propeller geometry, which in this case was assumed to be that of a Clark Y airfoil because of its

common use in propellers for small model aircraft. The second script uses parameters such as

cruise speed, aircraft weight, and airfoil geometry to step through the entire propulsion system

and determine power and other requirements for each component. After the aerodynamics team

selected the airfoil shape of the main wing, the necessary parameters were input into the two

scripts. Over 50 different propeller diameter and pitch combinations, with diameters ranging

from 6 inches to 14 inches and pitches ranging from 3 inches to 14 inches, were analyzed to

determine efficiency, power required, RPM, and endurance. An equation calculating power

required for the hover phase had to be determined and then inserted into

Main_System_Design.m, since it was initially optimized for cruising flight and not hover. The

equation used to determine the power required during the hover phase was the disc loading

equation derived in helicopter theory. It is listed as Equation 2 below.

𝑊

𝐷 2

𝑃𝐻𝑃 =

𝑤ℎ𝑒𝑟𝑒 𝐴 = 𝜋 ( )

2

2𝜌𝐴

550 ∗ 𝜂𝑃 √ 𝑊

Equation 2

Endurance (min)

Once this was done, the propellers all had to be run through the scripts again to get a

more accurate power requirement and therefore a more accurate sizing of all of the components

of the propulsion system. After compiling all of the data, it was seen that a larger diameter and a

smaller pitch both led to increased endurance, allowing for a smaller battery to be selected.

Hover Endurance vs. Propeller

Diameter for P/D = 0.5

8

7

6

5

4

3

2

1

0

7

9

11

13

Propeller Diameter (in)

15

Figure 9 - Hover Endurance vs. Propeller Pitch for 13 in. Propeller

15

Endurance (min)

Hover Endurance vs. Pitch for 13 in.

Propeller

6.35

6.30

6.25

6.20

6.15

6.10

6.05

6.00

5.95

5.90

5

7

9

11

13

15

Propeller Pitch (in)

Figure 10 - Hover Endurance vs. Propeller Pitch for P/D = 0.5

Two final factors had to be taken into account, the first being the fact that a larger

propeller would provide a larger area of prop wash flowing over the ailerons, which would assist

the pilot in keeping the roll angle of the aircraft steady during hover. The second factor was that

most motors in the power range required for the aircraft could not physically handle some of the

larger propellers considered for this mission. This second fact, coupled with a recommendation

from Sean Henady, one of the test pilots, to strictly follow the propeller size range limitations

listed for the motor, caused some of the larger propeller options to be discarded. The size

limitations also factored in to the motor selection, which will be discussed below.

All of these factors together led the propulsion team to choose a 13”x6” APC Sport

Propeller; however, after a discussion with the pilots, it was determined that the chosen propeller

was too heavy, since it had been made for gas-powered aircraft. After a search online, a

13”x6.5” APC Thin Electric propeller was chosen for Team 4’s aircraft since it was the closest

geometry to the original chosen propeller.

6.3

Motor and Gearbox Selection

The next step in the design process for the propulsion system was to step backwards from

the propeller through the gearbox and motor. Using the selected propeller motor data provided

in a subroutine of Main_System_Design.m, along with the calculated input power to the

propeller, the power, voltage, and current required to the motor were calculated, effectively

providing minimum values that must be met when choosing a motor and gearbox. These values

were 0.143 hp, 7.8V, and 17.7A. For the chosen propeller size of 13”x6.5”,

Main_System_Design.m calculated the optimal gear ratio to be 2.1:1; however, the most

common gear ratio in that range was 2.5:1, which yielded the same input power of .143 hp, while

decreasing the current to 15.3A and increasing voltage to 9V.

16

Because of the limited number of motors available and the propeller size range

limitations previously mentioned, Team 4 chose to utilize a 150W (0.201 hp) motor, even though

only 106W (0.143 hp) is necessary for hover according to the results of Main_System_Design.m.

This is due mostly to the fact that the 110W motors cannot physically handle a propeller large

enough to produce a satisfactory amount of prop wash over the ailerons, which would result in

an inability to damp out the roll rate created by the motor during hover. 110W motors would

also not produce enough extra thrust to accommodate additional construction weight or give the

pilots the extra maneuverability they had asked for.

The other pertinent parameter to be mentioned at this point is the thrust generated by this

setup. With the chosen 13”x6.5” propeller, this propulsion setup generates roughly 4.5 lbf of

thrust, which produces a thrust-to-weight ratio of approximately 2.3 at full power, which is well

above the pilot recommendation of a thrust-to-weight ratio of approximately 1.3. This was

calculated with Error! Reference source not found. aboveusing maximum output power of the

motor, propeller area and propeller efficiency. Solving for weight yielded the maximum weight

that this motor-propeller combination could hold in a hover, which is equivalent to the maximum

thrust produced. The weight estimate of the aircraft does not take into account the extra weight

that will be present in the form of adhesive, wiring, the motor mount, and other small elements of

the aircraft not considered as part of the weight thus far. By estimating that up to an additional

0.5 lbf of weight, per the test pilots’ suggestion, will be added, the thrust-to-weight ratio drops to

1.8.

The final choice for the motor is the Himax HC2812-0850 150W Electric Brushless

Outrunner Motor, and the final gearbox choice is the Electrifly GD-600 Electric Flight Gear

Drive 2.5:1.

6.4

Speed Controller Selection

One of the values in the output from Main_System_Design.m was the input current to the

motor, which in this case is 17.7A. The smallest electric speed controller that could be found

that could handle at least 17.7A was a 25A speed controller. The one chosen for this aircraft was

the Castle Phoenix 25 ESC because it was sold in a bundle with the motor that was chosen to

power the aircraft and therefore was guaranteed to be able to safely handle the current

requirements of this motor and was provided free of charge by the test pilots themselves.

6.5

Battery Selection

After running Main_System_Design.m for the chosen propeller size and cruise speed,

several battery properties were given in the output, including the voltage required and the

endurance. This endurance value assumed that the aircraft was hovering for the entire mission,

which was a limiting case for this analysis since the hover phase uses more energy than any other

phase of the mission. Main_System_Design.m was also run assuming that the aircraft would be

cruising the entire time instead of hovering in order to determine the energy necessary to cruise,

17

since that would be the phase of the mission in which the aircraft would be spending the most

time.

The given battery data included in one of the subroutines assumed that the plane would

be powered by an n x m array of lithium polymer battery packs of a given voltage and energy,

where n is determined by the energy required and m is determined by the voltage required. The

voltage and energy values were varied using different common sizes of battery pack. After

running Main_System_Design.m, the required voltage was output as 9V. The two battery pack

options given were a 1x1 array, yielding 6.3 minutes of endurance in hover or 32 minutes in

cruise, and a 2x1 array, yielding 12.6 minutes of endurance in hover or 64 minutes in cruise. It

was decided that the energy required for 6.3 minutes of endurance in hover would be more than

adequate to complete the entire mission since the energy required for hover was roughly a factor

of five higher than the energy required for the same time in cruising flight. Therefore, the 2

minutes of hover would still leave roughly 68% of the battery life for all other mission phases,

allowing for 18 extra minutes of cruise after the loiter and hover phases of the mission were

completed. After comparing multiple batteries online at www.towerhobbies.com and

www.rctoys.com, decision was made to purchase the Thunder Power RC Pro Lite 1320mAh

11.1V 3 Cell Li Poly 3S battery pack. This provided the necessary energy and voltage and

stayed under the maximum current allowed by the speed controller.

7. Dynamics and Controls

7.1 Introduction

7.1.1 Stability Requirements

There are several dynamics and controls requirements for this aircraft. Of primary

concern is to ensure that the aircraft is stable in all relevant flight modes while also meeting

control anticipation parameter requirements. This is done first by ensuring that the aircraft has a

large enough static margin to ensure stability. The derivation of the static margin is found in

section 5.5. In addition to this, the aircraft must meet all Level IA flying qualities for military

and civilian aircraft as defined in Roskam. Specific information regarding these flight modes is

located in section 7.6. Team 4’s aircraft is found to meet all requirements for Level IA flight.

7.1.2 Dynamic Approximation

Another requirement that must be fulfilled is to correctly model the dynamic properties of

the aircraft. Per the RFP, the aircraft must be able to hold itself in a hover while maintaining a

±20˚ roll angle. A pilot would have a difficult time of being able to control the roll while the

aircraft is in the hover configuration so a roll rate gyro is installed on the aircraft to assist the

pilot in maintaining roll angle. A nominal gain is chosen and set on the rate gyro before the

aircraft takes off. The gain is selected by using a roll mode approximation for the hover as found

in section 7.4.

7.2 Tail Surface Sizing

7.2.1 Class I

Class I sizing for the horizontal and vertical tails of the aircraft is done by using a method

as described in Raymer. This method uses the tail volume coefficient in conjunction with the

moment arm from the wing to the horizontal or vertical tail as well as the surface size of the tail.

18

To determine a sizing estimate typical values for horizontal tail volume coefficient ch (and cv for

the vertical tail) were found in the table below:

Aircraft Type

Sailplane

Homebuilt

GA Single Engine

GA Twin Engine

Jet Trainer

Military Cargo

Jet Transport

Horizontal

Ch

0.50

0.50

0.70

0.80

0.70

1.00

1.00

Vertical

Cv

0.02

0.04

0.04

0.07

0.06

0.08

0.09

Table 6 – Historical Tail Volume Coefficients

Using the results from the tail volume coefficient method values were obtained for the

horizontal and vertical tail sizing. The horizontal tail size obtained is Sh = 1.2 ft2 and the vertical

tail size is Sv = 0.35 ft2. These values are used as initial starting points for the Class II X-Plot

sizing.

7.2.2 Class II

The method used to refine the horizontal and vertical tail sizes of the aircraft is done

through an analytical method described in Roskam Part II. This method provides a significantly

more accurate method to approximate the tail size of an aircraft because it uses parameters

directly from the aircraft being designed to ensure proper stability. The horizontal tail is resized

using an X-Plot that plots the aircraft’s aerodynamic center and center of gravity against the

horizontal tail size. The plot is found below:

19

X-Plot

1.5

Xcg

Xac

1.4

Xcg and Xac bar

1.3

1.2

1.1

1

0.9

0.8

1

1.2

1.4

1.6

1.8

2

2.2

Horizontal Tail Size Sh (ft2)

Figure 11 - X-Plot for Horizontal Tail Sizing

The important aircraft parameter derived from this plot is that the aircraft’s static margin

is determined by taking the difference between the aircraft aerodynamic center and center of

gravity. This plot shows that it is necessary to have a tail of at least Sh = 1.18 ft2 to maintain a

positive static margin. Historical data from Raymer suggests that the static margin must be in

the range of 10-25% for sufficient aircraft stability. This plot shows that the original Class I

sizing estimate for tail size was insufficient due to instability. A revised tail size is determined to

be Sh = 1.75 ft2 which yields a static margin of 14% for the aircraft.

The vertical tail is also resized by using a separate X-Plot as also determined by Roskam.

The weathercock stability derivative, 𝐶𝑛𝛽 , is plotted against vertical tail size. According to

Roskam this derivative must be larger than 0.001 deg-1 to ensure weathercock stability. The

resulting plot is found below:

-3

1.8

X-Plot for Directional Stability

x 10

1.6

Cn,beta (deg -1)

1.4

1.2

1

0.8

0.6

0.4

0.2

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

Sv (ft2)

Figure 12 - X-Plot for Directional Stability

20

Figure 12shows that a vertical tail size of at least Sv = 0.28 ft2 must be chosen to ensure

weathercock stability. From this it is determined that the Class I sizing data is accurate for the

vertical tail and thus a final size of Sv = 0.35 ft2 is chosen.

7.3 Control Surface Sizing

Control surfaces for this aircraft are sized primarily according to historical data. Using

data from twenty general aviation single engine and light trainer models control surface sizing

ratios were determined for the elevator and rudder. The ailerons were sized according to

Roskam who suggests at least a ratio of 13% for full-span ailerons. Due to the additional aileron

control required during the hover phase of the aircraft’s flight, a value of 15% has been chosen to

ensure the ailerons are of sufficient size. A table with the results from this Class I sizing

estimate is found below.

Control

Surface

Aileron

Elevator

Rudder

Ratio

(Scs/S)

0.15

0.48

0.42

Value

(ft2)

1.1

0.83

0.13

Table 7 – Historical Control Surface Ratios

7.4 Roll Mode Approximation

The primary flight mode that must be modeled for this aircraft is the roll mode. This

mode is typically associated with the bank angle of the aircraft and important so that if perturbed

the aircraft will counter the perturbation in a time period Tr and return to trim conditions. For

this project the roll mode is of special importance because of the unique hover condition imposed

onto the design by the RFP. Since a roll rate feedback gyro will be used to help control the roll

angle it is important to accurately model the roll mode so that a nominal gain can be selected.

Using Roskam, the transfer function for the roll mode is found to be:

𝑳𝜹𝒂

𝝓(𝒔)

𝟕𝟑. 𝟑

= 𝟐

= 𝟐

𝜹𝒂 (𝒔) 𝒔 + (𝑳𝜹𝒂 𝑲 − 𝑳𝒑 )𝒔 𝒔 + (𝟕𝟑. 𝟑𝑲 − 𝟐. 𝟒𝟔)𝒔

Equation 3

This transfer function shows that the input is an impulsive aileron deflection by the pilot

and the output is a roll angle φ. The values for 𝑳𝜹𝒂 and 𝑳𝒑 are determined by using the Flat Earth

code provided by Dr. Andrisani. Specific values and calculations for these rolling moments can

be found in Appendix E. The results are shown in the equation above. The idea behind using a

roll rate feedback gyro is to reduce the roll mode time constant to stop the aircraft from rolling

during the hover.

7.5 Gain Selection

Using the approximation for the roll mode found in section 7.4, a Simulink model was

built to demonstrate the simulated flying qualities of the aircraft. This model is detailed below:

21

Figure 13 – Simulink Model of the Roll Mode Approximation

This model shows how the feedback control system works on the aircraft. An initial

aileron deflection is given to the aircraft which translates that into a roll rate. From equation (1)

the rate gyro moves the closed loop pole further negative, making the system more stable. This

roll rate is then turned into a roll angle via an integrator and output to the user. A root locus of

both the open- and closed-loop transfer functions can be found in Appendix E of this report. The

nominal gain selected for the rate gyro is 1.3 deg/deg/sec. This gain is chosen because for the

hover condition a nominal gain of 5 deg/deg/sec is necessary to reduce the roll mode time

constant to under 0.01 seconds. However, historical calibration data for the rate gyro shows that

the maximum absolute gain that can be set is 1.3 deg/deg/sec. Thus the largest possible value for

the gain is chosen. It should be noted that even though the rate gyro cannot achieve the nominal

gain calculated, the aircraft should still perform within requirements during the hover.

7.6 Flight Characteristics

There are several military and civilian flight requirements that must be met for this

aircraft. Per the RFP the aircraft designed must meet all Level I flying qualities. This means that

all requirements for flight modes must be met with the utmost precision. The aircraft has its

flying qualities modeled for a category A flight phase. This is a non-terminal flight phase

typically involving aerobatic or high maneuverability. The aircraft is also modeled as a Class

IV aircraft. This is the typical class for aerobatic and fighter aircraft. The combination of all

three of these requirements ensures that the aircraft built will meet the strictest flight qualities

and be able to perform well indoors under the control of an experienced pilot. A table of flight

characteristics is found below. Relevant calculations for these numbers can be found in

Appendix E.

22

Flight Mode

Level IA

Level IIA

Team 4

Meets

Level IA?

Short Period

0.35 ≤ ζsp ≤ 1.30

0.25 ≤ ζsp ≤ 2.00

ζsp = 0.84

x

Phugoid

ζph ≥ 0.04

ζph ≥ 0

ζph = 0.125

x

Dutch Roll

ζdr ≥ 0.19

ζdrωn,dr ≥ 0.35

ωn,dr ≥ 1.0

ζdr ≥ 0.02

ζdrωn,dr ≥ 0.05

ωn,dr ≥ 0.4

ζdr = 0.44

ζdrωn,dr = 2.01

ωn,dr = 4.57

x

Roll

Tr ≤ 1.0s

Tr ≤ 1.4s

Tr = 0.01s

x

Table 8 – Required Flight Qualities

In the table above the short period and phugoid flight modes both represent longitudinal

stability modes for the aircraft. The dutch roll and roll modes represent lateral stability. While

all of these modes are important the two most important for this project are the roll and short

period modes. The phugoid mode has the longest frequency of all the modes and as the aircraft

will be flown indoors it will not ever fly in a straight line long enough for this mode to be

significant. The roll mode ensures that if the aircraft is banked at an angle φ that it will return to

a trim condition after a certain time period Tr. This is important for this design because of the

hover roll angle requirement. The short period mode is also important because the aircraft

should return to a steady-state value when the aircraft is perturbed in the pitch axis over a short

distance. From the table above it is clear that the designed aircraft meets all Level IA flying

qualities and is stable for flight.

The other flight characteristic requirement that must be met for this project is to meet all

control anticipation parameter, or CAP, requirements. Using the master’s thesis prepared by

Mark Jacobs, he postulates that remotely controlled aircraft must have a CAP of at least 5.92 to

ensure stability. To determine the CAP of the aircraft, a MATLAB script provided by Mr.

Jacobs is used. From the code, the CAP of the designed aircraft is 18.02, clearly sufficient for

stability.

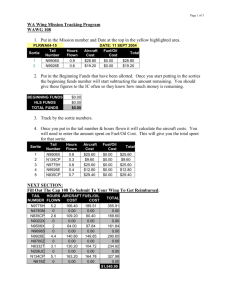

8. Economics

Aircraft cost plays a major role in every design. If an aircraft design exceeds its budget,

the number of customers who purchase the aircraft may be reduced. The budget intended for this

semester was $150. Components to be included into the budget were materials for the airframe,

the propulsion system, and control servos. Specifically excluded from the budget were radio

equipment (transmitter, receiver, rate gyro, and speed controller), which is provided by the

course instructor.

To determine the full cost of our airplane, the number of man-hours and a list of

construction costs were made. Using timesheets for each individual team member, an estimation

of total man-hours was made for the entire semester. The total number of estimated man-hours

devoted to the design, build, and test of the aircraft came to 1353 hours. Each man-hour was

determined to have the value of $100.00, which translates into $135,300.00 for the cost of the

total man-hours. The breakdown and distribution of time, for the team is below and the team

members, is outlined in Appendix F.

23

Team Hours Per Week

200

Hours

150

100

50

0

1

2

3

4

5

6

7

8

9

10 11 12 13 14

Week

Figure 14 - Team Hours per Week Plot

The parts acquisition list in Appendix F shows a total cost of $197.12 for all parts,

bringing the total cost to be $135,497.12 for the entire aircraft design.

24

9. References

Brandt, Steven, et al. Introduction to Aeronautics: A Design Perspective. Reston: American

Institute of Aeronautics and Astronautics, 2004.

Nicolai, Leland M. “Estimating R/C Model Aerodynamics and Performance,” June 2002.

Raymer, Daniel P. Aircraft Design: A Conceptual Approach. Reston: American Institute of

Aeronautics and Astronautics, 2006.

Roskam, Jan. Airplane Design. Ottawa: Roskam Aviation and Engineering Corporation, 1985.

Roskam, Jan. Airplane Flight Dynamics and Automated Flight Controls. Ottawa: Roskam

Aviation and Engineering Corporation, 1995.

U.S. Military Specification MIL-F-8785C. “Flying Qualities of Piloted Airplanes,” November

1980.

25

APPENDIX A – Initial Sizing and Concept Selection

A.1 – Concept Selections

Figure 15 - Concept 1

26

Figure 16 - Concept 2

27

Figure 17 - Concept 3

A.2 – Weight Estimation

28

The following plot shows the relationship between battery weight and total weight of a

given r/c aircraft. The list of aircraft was compiled using specifications freely available on the

internet. This relationship gives a linear relationship between aircraft weight and battery size

required. It was used to give a rough estimate for the approximate battery size required for Team

4’s aircraft.

Battery Weight Vs. Total Weight

(Historical)

Battery Weight (lbf)

0.500

y = 0.2433x + 0.0065

R² = 0.7999

0.400

0.300

0.200

0.100

0.000

0.000

0.500

1.000

1.500

2.000

Total Weight (lbf)

Figure 18 - Historical Data for Battery and Total Aircraft Weight

RC AIRCRAFT

Mustang P-51D

Cessna 182

Decathlon

Edge 540T v.2

Aerobat

Gee Bee 3D

Super Cub Speed 400

Soareasy

Extra 330L

Fundango

Cessna 172

WING SPAN

(in)

30.0

38.5

38.5

36.6

38.0

30.3

46.5

42.5

38.0

35.0

44.0

LENGTH

(in)

24.0

29.0

29.0

33.1

30.5

29.5

29.0

31.8

33.0

30.0

33.0

TOTAL WEIGHT

(lb)

0.833

1.313

1.375

1.250

1.063

0.825

1.313

1.625

1.375

1.000

1.625

BATTERY

li-poly 7.4 volt 2 cell with balanced port

7 cell 8.4v 1000 mah nihm

8 cell 9.6v 1000 mah nihm

3 cell li-poly 1800 mah

11.1v li poly 1250 mah

2 cell 7.4v 1800mah

6 Cell 1100 X-Cell Sport NiMH Pack

8 Cell 1100 mAh Folded NiMH Pack w/Connector

11.1v li-poly 3 cell 1500 mah

8C 700 AA NiCd Flat Pack (GPMP0200)

3 cell 11.1V 1200mah Li-Poly

BATTERY WEIGHT

(lb)

0.192

0.362

0.397

0.309

0.249

0.223

0.281

0.375

0.265

0.400

0.250

Figure 19 - Historical Data for R/C Aircraft

MATLAB script weight_3.m:

% FILE: Weight_3.m

% Preliminary weight estimator for electric powereed aircraft

% Revised 9/5/06

disp(' '); disp('>>>>>>>>>Start here <<<<<<<<<'); disp(' ')

LoverDmax=12

% for fixed gear GA aircraft (Skyhawk) (See Raymer p.

22)

LoverD=.866*LoverDmax % for loiter (See Raymer p. 22)

Vloiter=40

% ft/sec, Estimated loiter speed

ETAmotor=0.75

29

ETAprop= 0.60

%RHOb=72900

% battery energy density for NiCad joule per pound

%RHOb=9.25E+04 % battery energy density for NiMH joule per pound

RHOb=2.39E+05 % battery energy density for Lithium polymer joule per pound

disp('Battery energy density for NiCad batteries, joules per pound')

EnduranceMIN=7

Wpayload=1 % payload weight pounds

EnduranceSEC=EnduranceMIN*60

TimeLoiterStraight=EnduranceSEC/2

% Loiter time in straight flight (sec)

TimeLoiterTurn=EnduranceSEC/2

% Loiter time in turning flight (sec)

g=32.17 % acceleration of gravity ft/sec^2

% For loiter in straight flight

WlsperW=Vloiter*1.356*TimeLoiterStraight/(ETAmotor*ETAprop*RHOb*LoverD)

% For loiter in turning flight

R=50 % Turn radius at loiter from mission spec.

phi=atan(Vloiter*Vloiter/(R*g)) % bank angle in the turn (rad)

WltperW=Vloiter*1.356*TimeLoiterTurn/(ETAmotor*ETAprop*RHOb*LoverD*cos(phi))

% For climbing flight

gamma=20/57.3 % climb angle (rad)

TimeClimb=12/(Vloiter*sin(gamma)) % time to climb to 12 feet

WclimbperW=Vloiter*1.356*TimeClimb*(cos(gamma)/LoverD+sin(gamma))/(ETAmotor*E

TAprop*RHOb)

% For Takeoff

disp('From integration of eoms at takeoff, assume that the battery')

disp(' weight fraction is .002.')

WtoperW=.002

% For warm-up assume takeoff times aree about 3 sec and

% warm-up times are about 30 seconds.

disp('Assume that the warmup weight fraction is 10 times the ')

disp(' takeoff weight fraction.')

WwarmperW=10*WtoperW

% Assemble the complete battery weight fraction.

WbperW=WlsperW+WltperW+WclimbperW+WtoperW+WwarmperW

Weight=0:1:10; %weight in pounds

echo on

WminusWe=.2103*Weight+.1243; % formula for historical data (pounds)

echo off

disp('Your weight estimate will only be as good at that historical data

represented in the equation above')

Wbattery=WbperW*Weight;

WbplusWpay=Wbattery+Wpayload;

30

plot(Weight,WminusWe,Weight,WbplusWpay)

xlabel('Weight~lbf')

ylabel('W-We and Wb+Wp~lbf')

% Determination of aircraft weight

delta=WminusWe-WbplusWpay;

% YI = INTERP1(X,Y,XI)

Waircraft=interp1(delta,Weight,0)

y=.2103*Waircraft+.1243;

string1=['Estimated aircraft weight is ',num2str(Waircraft),' pounds.']

text2(.25,.2,['

',string1])

title('Weight estimation using historical weight data')

legend('Historical data','Estimated weight')

hold on; plot(Waircraft,y,'o'); hold off

Wb=WbperW*Waircraft

string2=['Estimated battery weight is ',num2str(Wb),' pounds.']

text2(.25,.15,['

',string2])

string2=['Payload weight is ',num2str(Wpayload),' pounds.']

text2(.25,.1,['

',string2])

This code was used to determine the battery weight fractions necessary for each section

of the flight. Below is a table of hand-calculated values which confirm what weight3.m outputs.

Flight

Section

%

Battery

Endurance

Required

(m:s)

Energy

Required (J)

ETO

1.0%

0:02

149

EWU

7.5%

0:30

1120

ECL

0.4%

0:02

64

ELF

7.1%

3:00

1005

EHV

84%

2:00

12349

EB

100

5:34

27580

Table 2 - Energy Required per Flight Phase

31

Constraint Diagram

300

Power loading (lbf/hp)

250

200

150

100

50

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Wing loading lbf/ft2

Figure 20 - Constraint Diagram

This is a zoomed out version of Team 4’s constraint diagram as found in section 3.4 of

the main report. It provides an overall view of the constraints on the aircraft as per this project.

This is simply for reference as it does not provide a detailed view of the design space. That plot

can be found in section 3.4 of the main report.

32

APPENDIX B – Structures and Weights

𝑥̅𝑐𝑔𝑎 =

𝛴𝑚𝑖 𝑟𝑖

𝛴𝑚𝑖

Equation 4

𝑞(𝑦) =

4𝑆

2𝑦 2

√1 − ( )

𝑏𝜋

𝑏

Equation 5

𝐿 =𝑛 ×𝑊

Equation 6

𝑥̅ =

4𝑎

3𝜋

Equation 7

𝑀 =𝑑 ×𝐿

Equation 8

𝜎=

𝑀𝑦

𝐼𝑥

Equation 9

𝑉𝑒𝑞𝑢𝑖𝑣𝑎𝑙𝑒𝑛𝑡 = √𝜌⁄𝜌𝑠𝑙 𝑉𝑎𝑐𝑡𝑢𝑎𝑙

Equation 10

𝐿=

1

𝜌𝐶𝐿𝑚𝑎𝑥 𝑠𝑉𝑒2

2

𝑛=

𝐿

𝑊

Equation 11

Equation 12

33

Elliptical Load Distribution

1.2

Wing Load (lb/ft)

1

0.8

0.6

0.4

0.2

0

0

0.5

1

1.5

2

Distance from Centerline of Aircraft (ft)

2.5

Figure 21 – Elliptical Load Distribution

Figure 22 – Wing Connector Rib

34

Figure 23 – Fairing Rib

Figure 24 – Vertical Tail

35

Figure 25 – Horizontal Tail

36

APPENDIX C – Aerodynamics

C.1 - Reynolds Number

𝜌 = .00226 𝑠𝑙𝑢𝑔/𝑓𝑡 2

𝑈 = 19.5

𝑓𝑡

𝑠

𝑐 = 1 𝑓𝑡

𝜇 = 3.72 ∙ 10−7 𝑠𝑙𝑢𝑔/(𝑓𝑡 ∙ 𝑠)

𝑅𝑒 =

𝜌𝑈𝑐

≈ 119,000

𝜇

Equation 13

C.2 - Drag Computation

𝐴𝑅 = 4.8

𝐶𝑓𝑒 = 0.0055

𝑆𝑤𝑒𝑡 = 10.59 𝑓𝑡 2

𝑆 = 4.8 𝑓𝑡 2

𝑒 = 1.78(1 − 0.045𝐴𝑅 0.68 ) − 0.64 = 0.9073

Equation 14

𝐶𝐷0 = 𝐶𝑓𝑒

𝑆𝑤𝑒𝑡

= 0.0144

𝑆

Equation 15

𝐶𝐿𝑚𝑖𝑛 ≈ 𝐶𝑙𝑚𝑖𝑛 = 0.2149

Equation 16

𝐾=

1

= 0.0731

𝜋𝐴𝑅𝑒

Equation 17

𝐾 ′ = 0.0137

Individual Component Minimum Aircraft Drag Calculation

37

-

Fuselage

Fuselage Fineness Ratio : 𝐹𝑅 =

𝑓𝑢𝑠𝑒𝑙𝑎𝑔𝑒 𝑙𝑒𝑛𝑔𝑡ℎ

1 𝑓𝑡

=

=4

𝑓𝑢𝑠𝑒𝑙𝑎𝑔𝑒 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 . 25 𝑓𝑡

Equation 18

Fuselage 𝐶𝐷𝑚𝑖𝑛 = (1 +

60

+ .0025 ∙ 𝐹𝑅) 𝐶𝐷0 = 0.0280

(𝐹𝑅)3

Equation 19

-

Wing

𝑡

𝐿 = 1.2 as maximum location is ≥ 0.3𝑐

𝑐

𝑡

= 0.12

𝑐

𝑅 = 1.05 for low-speed, unswept wing

𝑡

𝑡 4

Wing 𝐶𝐷𝑚𝑖𝑛 = [1 + 𝐿 ( ) + 100 ( ) ] 𝑅 ∙ 𝐶𝐷0 = 0.0176

𝑐

𝑐

Equation 20

-

Horizontal Tail

𝑡

= .01, 𝑅 = 1.05, 𝐿 = 1.2

𝑐

𝑡

𝑡 4

Horizontal Tail 𝐶𝐷𝑚𝑖𝑛 = [1 + 𝐿 ( ) + 100 ( ) ] 𝑅 ∙ 𝐶𝐷0 = 0.0153

𝑐

𝑐

Equation 21

-

Vertical Tail

𝑡

= .01, 𝑅 = 1.05, 𝐿 = 1.2

𝑐

𝑡

𝑡 4

Vertical Tail 𝐶𝐷𝑚𝑖𝑛 = [1 + 𝐿 ( ) + 100 ( ) ] 𝑅 ∙ 𝐶𝐷0 = 0.0153

𝑐

𝑐

Equation 22

-

Tail boom

Tail Boom 𝐶𝐷𝑚𝑖𝑛 = 1.05 ∙ 𝐶𝐷0 = 0.0151

Equation 23

-

Whole Aircraft

𝐶𝐷𝑚𝑖𝑛 = 𝐶𝐷𝑚𝑖𝑛

+ 𝐶𝐷𝑚𝑖𝑛

𝑓𝑢𝑠𝑒𝑙𝑎𝑔𝑒

𝑤𝑖𝑛𝑔

+ 𝐶𝐷𝑚𝑖𝑛

𝐻−𝑇𝑎𝑖𝑙

+ 𝐶𝐷𝑚𝑖𝑛

𝑉−𝑇𝑎𝑖𝑙

+ 𝐶𝐷𝑚𝑖𝑛

𝑇𝑎𝑖𝑙 𝐵𝑜𝑜𝑚

= 0.0913

Equation 24

Whole Aircraft Drag Equation

38

2

𝐶𝐷 = 𝐶𝐷𝑚𝑖𝑛 + (𝐾 + 𝐾 ′ )(𝐶𝐿 − 𝐶𝐿𝑚𝑖𝑛 ) = 0.0913 + (0.0731 + 0.0137)(𝐶𝐿 − 0.2149)2

Equation 25

C.3 - Lift & Moment Calculations

Lift and moment values were calculated using the FlatEarth.m code (inputs and outputs

cited in the Dynamics & Controls appendix). From the inputs, the FlatEarth program produced

the following mathematical models:

𝐶𝐿 = 𝐶𝐿0 + 𝐶𝐿𝛼 𝛼 + 𝐶𝐿𝛿𝑒 𝛿𝑒 = 0.2471 + 3.525𝛼 + 0.9613𝛿𝑒

Equation 26

𝐶𝑀 = 𝐶𝑀0 + 𝐶𝑀𝛼 𝛼 + 𝐶𝑀𝛿𝑒 𝛿𝑒 = −0.07567 − 0.489𝛼 − 1.667𝛿𝑒

Equation 27

The above lift and drag models were used to generate the lift and drag polars in sections 5 and 6

of this appendix.

C.4 - Fuselage Sizing Trade Study

Objective

The primary objective of this trade study is to analyze the relationship between the aspect

ratio, fuselage size, and the minimum drag of our aircraft design. Aspect ratio has been a bit of

an issue for everyone in the class, as essentially every aspect of the aircraft is driven by its

selection. However, due to practicality, as not all aircraft are as sleek as one may like, fuselage

size is a significant issue as well. Necessary flight electronics need to be stored, easily accessible

to certain areas of the aircraft, as well as protected. But bulky fuselages “tarnish” the

aerodynamic beauty of an aircraft. That is the tradeoff that has to be made. The proper design of

fuselages is something that will follow an aerospace engineer for the rest of their career. Real

world examples are everywhere: case in point, the Lockheed Martin F-22 Raptor. The F-22 is

the king of the sky, and it requires some extremely specialized equipment in order to hold its

throne there. However, there is a major maintenance issue whenever an internal component

breaks, as in some cases whole sections of the aircraft have to be completely disassembled in

order to replace a tiny part (I experienced this problem firsthand when I had the opportunity to

work with an Air Force maintenance unit on the F-22. Needless to say, there was some animosity

between the on-site engineers and the maintainers). Early on in our design process, we wanted

the aircraft to be easily repairable, and in order to accomplish that, every component of the

aircraft has to be accessed when the user wants to access it; there is no point in marketing a r/c

aircraft that requires complete disassembly in order to flip a switch.

39

Procedure

The code that was developed by our group for our aerodynamic lift and drag calculations

was modified to suit this trade study. Given some specifications of our aircraft, such as

component sizes, airfoil data, and operating conditions, the script outputs several values and

plots. The important data that was utilized is the CDmin values for the fuselage and the entire

aircraft, the CD vs. α plot, and the CD vs. CL plot. Earlier in our design process, we chose a half

cylinder to be our fairing cover for the fuselage. It is slung underneath the wing. A range of

aspect ratios, from 2 to 8, were inputted, and the radius of the fuselage was varied from 0.5

inches up to 2.0 inches. The outputted data was analyzed, and from this, our group will select

the proper fuselage radius in order to minimize drag as based upon our selected aspect ratio.

Results

An initial design point was selected for the total CDmin of the entire aircraft. We wanted

to keep our total drag estimate to be as close to 500 counts as possible, ± 10 counts. As of when

this trade study was performed, our working aspect ratio is 3.88. Before we actually went and

selected a fuselage radius, we first analyzed the data to look for trends. One large trend that was

discovered is that there is the change in the CDmin is not linear as aspect ratio and fuselage radius

is varied; it is closer to a quadratic approximation. This is illustrated in the CDmin vs alpha plot

below (figure 1). As a result, we immediately discovered that the radius had to be large, no

matter what aspect ratio was chosen. The aircraft drag builds quickly as the aspect ratio is

minimized, and the CDmin of the fuselage becomes a larger percentage of the total aircraft CDmin

as a result.

40

Radius of

AR

Fuselage

2

3

3.88

4

5

6

7

8

2

3

3.88

4

5

6

7

8

2

3

3.88

4

5

6

7

8

0.5

1

1.5

CDmin

CDmin

Fuselage

0.0297

0.0809

0.0198

0.0591

0.0153

0.0492

0.0148

0.0482

0.0119

0.0417

0.0099

0.0373

0.0085

0.0342

0.0074

0.0319

0.031

0.0822

0.0207

0.06

0.016

0.0499

0.0155

0.0489

0.0124

0.0422

0.0103

0.0378

0.0089

0.0346

0.0078

0.0322

0.0331

0.0843

0.0221

0.0614

0.0171

0.051

0.0166

0.0499

0.0132

0.0431

0.011

0.0385

0.0095

0.0352

0.0083

0.0328

Radius of

AR

Fuselage

2

2.5

3

2

3

3.88

4

5

6

7

8

2

3

3.88

4

5

6

7

8

2

3

3.88

4

5

6

7

8

CDmin

CDmin

Fuselage

0.0376

0.0888

0.0251

0.0644

0.0194

0.0533

0.0188

0.0522

0.0151

0.0449

0.0125

0.04

0.0108

0.0365

0.0083

0.0328

0.0453

0.0965

0.0302

0.0695

0.0233

0.0573

0.0226

0.056

0.0181

0.0479

0.0151

0.0425

0.0129

0.0387

0.0113

0.0358

0.0567

0.1079

0.0378

0.0771

0.0292

0.0632

0.0284

0.0617

0.0227

0.0525

0.0189

0.0464

0.0162

0.042

0.0142

0.0387

Table 3 - CDmin Results

From all this, for our current aspect ratio of 3.88, the optimized fuselage radius is 1.5

inches. Though the CDmin is at the edge of our limits for aircraft drag, any smaller and there are

going to be serious storage issues based upon the purported size of our electronic components.

The fuselage CDmin may be a bit large, but it is at the lower end of the CDmin values for all of the

fuselages radii, no matter the aspect ratio. As a result of this trade study, the new fuselage radius

was added to our final model.

CDmin

CDmin vs AR

0.105

0.095

0.085

0.075

0.065

0.055

0.045

0.035

0.025

2

3

4

5

6

7

8

AR

r = 0.5

r = 1.0

r = 1.5

r = 2.0

r = 2.5

r = 3.0

Figure 26 - CDmin vs. AR for entire aircraft

41

CDmin Fuselage vs AR

0.065

0.055

CDmin

0.045

0.035

0.025

0.015

0.005

2

3

4

5

6

7

8

AR

r = 0.5

r = 1.0

r = 1.5

r = 2.0

r = 2.5

r = 3.0

Figure 27 - CDmin vs. AR for fuselage

42

C.5 - Aircraft drag polar

CD vs CL - Team 4

0.24

0.22

0.2

0.18

C

D

0.16

0.14

e =-20o

0.12

e =-10o

0.1

e =0o

0.08

e =5o

0.06

e =10o

0.04

-0.5

0

0.5

1

1.5

2

CL

Figure 28 - Aircraft Drag Polar

C.6 - Aircraft lift versus α

CL vs - Team 4

2

1.5

L

1

C

e =-20o

e =-10o

0.5

e =0o

e =5o

0

e =10o

-0.5

-5

0

5

10

15

20

25

(degrees)

Figure 29 - Airfoil Lift Curve

43

C.7 - Aircraft Center of Gravity Computation

Weight

(lb)

Location from

Propeller (in)

0.00

0.50

1.13

8.00

8.00

12.00

12.00

13.00

11.00

12.00

22.50

42.50

40.00

Propeller

Motor

Gear box

Speed Controller

Batteries

Wing

Fairing

Servos (4)

Receiver

Rate Gyro

Fuselage

Vertical Stablizer

Horizontal Stablizer

0.04

0.14

0.13

0.04

0.13

0.60

0.17

0.08

0.06

0.06

0.37

0.02

0.14

Table 4 - Tabular Listing of Aircraft Equipment

Total Weight (lb)

Center of Gravity (in)

Aerodynamic Center (in)

Static Margin

1.94

14.17

15.92

0.14

Table 5 - Total Aircraft Weight and Static Margin

Static Margin Computation

Equation 28

𝐶𝐺 =

∑ 𝑟𝑖 𝑚𝑖

∑ 𝑚𝑖

Equation 29

𝑆𝑀 = 𝑥̅𝐴𝐶 − 𝑥̅𝐶𝐺

Equation 30

44

C.8 - Aircraft Trim Diagram code

% Aircraft trim diagram

clear all

%close all