Batch Quantity Tradeoffs

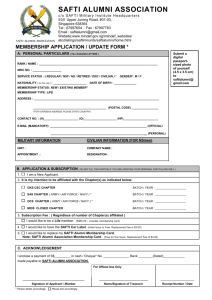

advertisement

Calculate Economic Order Quantity Intermediate Cost Analysis and Management © 2011 1 What do you think? Corporal O’Reilly, the supply clerk, knows that it costs the Army money to generate a purchase order. To save money he proposes ordering the five years’ worth of ammunition at once. © 2011 2 Terminal Learning Objective • Action: Calculate Economic Order Quantity for Various Situations • Condition: You are training to become an ACE with access to ICAM course handouts, readings, and spreadsheet tools and awareness of Operational Environment (OE)/Contemporary Operational Environment (COE) variables and actors • Standard: With at least 80% accuracy: • Describe the concept of economic order quantity • Identify the key variables in the EOQ calculation © 2011 3 Batch Quantity Concepts • Certain costs are fixed on a per-batch basis • Setting up machinery to run a particular product • Purchasing cost • Training cost • We call these “Batch Costs” • More units in a batch means lower batch cost per unit $Batch Cost Batch cost per unit = #Units in batch © 2011 4 Batch Cost Assumptions • Annual demand for units produced in batches is known • Every batch is the same size • i.e. same quantity of units produced © 2011 5 Batch Costs • Batch Cost = Batch Cost per Unit * # Units Demanded -or- $Batch Cost * #Units Demanded #Units in batch © 2011 6 Batch Costs • Another way of thinking of Batch costs is: # of Batches * Cost per Batch -or#Units Demanded * Batch $Cost #Units in Batch © 2011 7 Batch Costs • The full equation is: # Units Demanded ∗ Batch $ Cost # Units in Batch • First divide # units demanded by # units in batch to get # of batches, then multiply by Batch $ Cost © 2011 8 Batch Costs • The full equation is: # Units Demanded ∗ Batch $ Cost # Units in Batch • First divide # units demanded by # units in batch to get # of batches, then multiply by Batch $ Cost © 2011 9 Batch Costs • The full equation is: # Units Demanded ∗ Batch $ Cost # Units in Batch • Or, first divide Batch $ Cost by # Units in batch to get Batch cost per unit, then multiply by # units demanded © 2011 10 Batch Costs • The full equation is: # Units Demanded ∗ Batch $ Cost # Units in Batch • Or, first divide Batch $ Cost by # Units in batch to get Batch cost per unit, then multiply by # units demanded © 2011 11 Batch Costs • Regardless of how you look at it: • More units in a batch mean fewer batches • Fewer batches mean lower Batch costs © 2011 12 Learning Check • How does batch cost per unit change as batch size increases? • What are the key assumptions in batch quantity tradeoffs? © 2011 13 Batch Cost Example • Purchasing supplies is a common example of a Batch cost • Each purchase order issued costs the organization $250 • Demand for supplies is 200 units © 2011 14 Batch Cost Example • How much is purchasing cost if a separate purchase order is issued for each unit of supplies? 200 purchase orders * $250/ purchase order = $50,000 • How much is purchasing cost if all 200 units are purchased using a single purchase order? 1 purchase order * $250/ purchase order = $250 © 2011 15 Batch Cost Example • How much is purchasing cost if a separate purchase order is issued for each unit of supplies? $250 200 purchase orders * = $50,000 purchase order • How much is purchasing cost if all 200 units are purchased using a single purchase order? 1 purchase order * $250/ purchase order = $250 © 2011 16 Batch Cost Example • How much is purchasing cost if a separate purchase order is issued for each unit of supplies? $250 200 purchase orders * = $50,000 purchase order • How much is purchasing cost if all 200 units are purchased using a single purchase order? $250 1 purchase order * = $250 purchase order © 2011 17 Graph of Purchasing Cost Purchasing Cost $ 5000 4500 4000 3500 3000 2500 2000 1500 1000 500 0 5000 When quantity per purchase order is 10, twenty purchase orders are issued and purchasing cost is $5000 When quantity per purchase order is 100, two purchase orders are issued and purchasing cost is $500 500 0 10 50 100 150 X-Axis = Number of units per purchase order or batch As number of units per PO or batch increases, purchasing cost decreases © 2011 200 18 Questions to Consider • Using only this information for your decision, how many units should be ordered per purchase order? • Similarly, what savings might be achieved by training all of the soldiers needed for a particular task in one large group? • What else should be considered? © 2011 19 Learning Check • How would you describe the graph of batch cost? © 2011 20 Batch Quantity Concepts • Certain costs increase as quantity per purchase order increases • Inventory ties up cash and must be stored and maintained • Spoilage and obsolescence can occur • Time value of money – cash paid now is worth more than cash paid later • “Just in Time” ordering minimizes these “Holding Costs” © 2011 21 Questions to Consider • What might be the “holding costs” involved with training all of the soldiers required for a particular task in one large group or “batch”? © 2011 22 Holding Cost Assumptions • Annual Holding Cost is linear or variable on a per-unit basis • Units produced or purchased in batches are consumed or sold uniformly throughout the period © 2011 23 Holding Costs • Holding cost = $Holding Cost/Unit * Avg. #Units in Inventory • Average #Units in Inventory = #Units per Purchase Order/2 • Assumes Inventory is consumed uniformly throughout the year © 2011 24 Graph of Inventory Assumption 50 Units produced or 60.00 purchased per batch Inventory Level 50.00 40.00 30.00 20.00 10.00 0.00 X axis represents time © 2011 25 Graph of Inventory Assumption 60.00 Inventory Level 50.00 40.00 30.00 25.00 20.00 10.00 0.00 Units Consumed or Sold uniformly until all Inventory is gone © 2011 26 Graph of Inventory Assumption 60.00 Inventory Level 50.00 Average Inventory is 50/2 or 25 Units 40.00 30.00 25.00 Average Inventory 20.00 10.00 0.00 X axis represents time © 2011 27 Learning Check • What are the underlying assumptions related to holding costs? • How is average inventory calculated? © 2011 28 Holding Cost Example • Annual holding cost for supplies is $50 per unit • What is holding cost if each unit of supplies is purchased on its own purchase order? • Average inventory = 1 unit/2 or ½ unit • ½ unit * $50/unit = $25 • What is holding cost if all 200 units of supplies are purchased on one purchase order? • Average inventory = 200 units/ 2 or 100 units • 100 units * $50/unit = $5,000 © 2011 29 Holding Cost Example • Annual holding cost for supplies is $50 per unit • What is holding cost if each unit of supplies is purchased on its own purchase order? • Average inventory = 1 unit/2 or ½ unit • ½ unit * $50/unit = $25 • What is holding cost if all 200 units of supplies are purchased on one purchase order? • Average inventory = 200 units/ 2 or 100 units • 100 units * $50/unit = $5,000 © 2011 30 Holding Cost Example • Annual holding cost for supplies is $50 per unit • What is holding cost if each unit of supplies is purchased on its own purchase order? • Average inventory = 1 unit/2 or ½ unit • ½ unit * $50/unit = $25 • What is holding cost if all 200 units of supplies are purchased on one purchase order? • Average inventory = 200 units/ 2 or 100 units • 100 units * $50/unit = $5,000 © 2011 31 Graph of Holding Cost Holding Cost $ 5000 4500 4000 3500 3000 2500 2000 1500 1000 500 0 When quantity per purchase order is 10 Average Inventory = 5 and holding cost is $250 When quantity per purchase order is 100 Average Inventory = 50 and purchasing cost is $2,500 1 50 100 150 X-Axis = Number of units per purchase order As number of units per purchase order increases, holding cost increases © 2011 200 32 Learning Check • How does holding cost change as batch quantity changes? • How is holding cost represented on the graph? © 2011 33 Optimizing Order Quantity • Total Costs Related to Order Quantity = Purchasing Cost + Holding Cost • What is Total Cost when Quantity per order is 10 units? 5000 + 250 = 5250 • What is Total Cost when Quantity per order is 100 units? 500 + 2500 = 3000 © 2011 34 Optimizing Order Quantity • Total Costs Related to Order Quantity = Purchasing Cost + Holding Cost • What is Total Cost when Quantity per order is 10 units? 5000 + 250 = 5250 • What is Total Cost when Quantity per order is 100 units? 500 + 2500 = 3000 © 2011 35 Optimizing Order Quantity • Total Costs Related to Order Quantity = Purchasing Cost + Holding Cost • What is Total Cost when Quantity per order is 10 units? 5000 + 250 = 5250 • What is Total Cost when Quantity per order is 100 units? 500 + 2500 = 3000 © 2011 36 Graph of Total Costs 5000 4500 Total Cost is minimized where Purchasing Cost = Holding Cost 4000 3500 3000 Purchasing Cost 2500 Holding Costs 2000 Total Cost 1500 1000 500 0 0 50 ≈45 100 150 200 X-Axis = Order quantity in units © 2011 37 Optimizing Order Quantity • Total Cost is minimized at the order quantity where Holding Cost = Purchasing Cost • Computation of this “Indifference Point” requires calculus beyond the scope of this course © 2011 38 Optimizing Order Quantity • The relationship is well-documented and is captured in the “Economic Order Quantity” (EOQ) Formula: 2dp EOQ = h d = Demand in units p = cost per Purchase Order h = Holding cost per unit © 2011 39 Calculating EOQ • Demand is 200 units • Purchasing Cost is $250 per Order • Holding Cost is $50 per Unit 2dp EOQ = h 2(200)(250) EOQ = = approx. 45 units 50 © 2011 40 Practical Exercise © 2011 41 Batch Quantity Spreadsheet Enter batch cost, holding cost, and demand into the spreadsheet to generate the graph of total cost © 2011 42 Practical Exercise © 2011 43