RBoR15

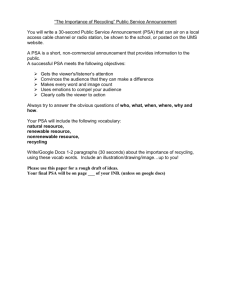

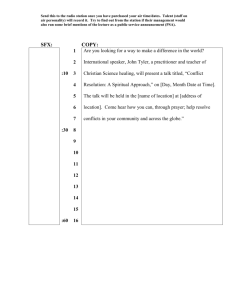

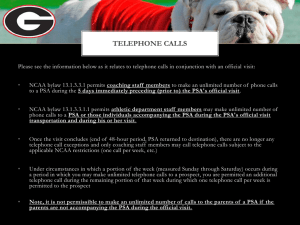

advertisement