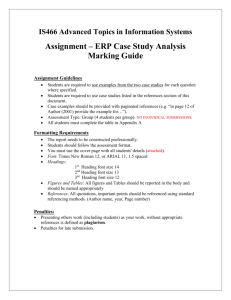

An Introduction to Enterprise Systems

advertisement

Enterprise Resource Planning (ERP) 정석화 Department of Computer Information Systems College of Business Eastern Michigan University 1 Agenda • • • • • • What is ERP? Why ERP? ERP Vendors SAP R/3 & Modules ERP Trends Questions/Answers 2 ERP • A collection of software systems that help to manage business processes for an entire organization • Designed to integrate all information processing support for an entire organization 3 Organization • A group of people engaged in purposeful activity over extended time • A tool used to coordinate in order to obtain Value for organizational goals 4 How an Organization Creates Value INPUTS PROCESS ENVIRONMENT OUTPUTS 5 Business Process • Work activities across time and place, with a beginning, an end, and clearly identified inputs and outputs (Davenport, 1993) • Has sequence, purpose, interaction 6 Example – ERP HR Module HR processes PAYROLL BENEFITS RECRUITING TRAINING IT resources payroll programs, personnel files, health plan documents, recruiting, Servers & networks, etc. 7 Theme of ERP • Reflects assumptions about the way companies operate • Provides the integration of all the information flowing through a company i.e., – Financial/accounting information – HR information – Customer information 8 An Organization with ERP • A process-oriented organization • Data at the core of the enterprise • ERP as a major part of the enterprise architecture 9 Differences between Function & Process Function Process Focus on “What” Focus on “How” Vertical Horizontal Static Dynamic Task-centered Customer-oriented Individual/Specialist Team/Generalist Parochial Holistic 10 Cross-functional Processes MARKETING R&D PRODUCTION Product development needs analysis component design research product test market test product release process design equipment design production start new product prototype competitor analysis market research i.e., Product Development 11 Support: Infrastructure, HR, R&D, Procurement Primary: Inbound Outbound Marketing Operations Service logistics logistics & Sales Profit Margin ERP for Organizational Value Chain − Stream of activities − Applies to both products and services 12 Business Process Reengineering (BPR) An organization fundamentally and radically redesigns its business process to achieve dramatic improvement − From the restructuring of an organization − To the redesigning of individual processes 13 BPR Example - Loan processing Desk-to-desk approach credit reporting Origination of loan prequalification document generation application processing credit analysis & underwriting approval & closing Servicing of loan payment processing escrow management customer service collections & foreclosures Follow-up processing valuation & risk analysis transfer to secondary mkt 14 BPR example - Loan processing Team approach Loan origination team Field rep laptop Regional production center Loan servicing team 15 ERP Strategic Issues • Compelling reasons - efficiencies • Organization change - better than current • Strategic advantage - gaining an advantage 16 ERP Tactical Issues • Functional /Cross-functional integration • Supply chain integration • Decision support 17 Operational Issues – ERP Implementation • Configuration – Methodology & Processes • Plan vanilla to start • Populating the data with integrity • Modifications made • Cut over or Phased rollout • Add-ons 18 ERP Benefits – Eli Lilly SAP R/3 Implementation Process Improvements − Eliminate redundant transactions − More efficient staff and succession planning IT − Reduced support costs − Reduced infrastructure costs Strategic Direction − Improved resource allocation − More flexible organization − Better future decision making Highlights: • 45 global sites • Implementation by 2002 – delayed to 2004 • Single client, servers in Indianapolis • Approx. 70 person implementation – now over 100 involved 19 ERP Vendors Over 100 vendors globally 5 major vendors – Lawson – JDEdwards – Oracle – PeopleSoft – SAP Healthcare Internet Database HRM originally German, pioneer of ERP 20 ERP Market (META Group, 2003) $15B globally in 2002 and growing at 12%-15% annually Satisfied at least 75% of the overall business application requirements Mission-critical functionality ERP regarded as core IT investments 21 Key Findings about ERP Market Mature and concentrated The five vendors - more than 80% of the investment ERP purchases - 10+ year commitments Vendor size does not guarantee high performance, and the smaller ones perform to the leaders for specific criteria Vendors must be compared to that of bestof-breed vendors (e.g., Siebel for CRM, i2 for SCM) 22 SAP R/3 Overview 23 About SAP AG from www.sap.com Founded in W. Germany in 1972 World's largest enterprise software and thirdlargest software supplier SAP R/3 - Collaborative business solutions for all types of industries 12 million users, 88,700 installations, and over 1,500 partners $7.5B revenue in 2004, More than 32,000 employees in over 50 countries 24 Partial SAP Client List Spacenet What is an R/3 System? Database Server Application Server Presentation Server R SAP AG 26 SD FI Sales & Distribution Financial Accounting MM CO Materials Mgmt. Controlling PP Production Planning R/3 SM Service Management AM Fixed Assets Mgmt. EC Enterprise Controlling Integrated Solution Logical Architecture QM Quality Management PS Project System PM WF Plant Maintenance Workflow HR IS Human Resources Industry Solutions 27 Client Highest hierarchical level in an SAP system A complete database with all the tables necessary for an integrated system Master records per client 28 Organizational Elements • Structures that represent the and/or organizational views of an enterprise • Company structure based on business processes • A framework that supports all business activities 29 Master Data Centrally and available to all applications and all authorized users In the database over an extended period of time 30 Transactions • Application programs that execute business processes • Whenever a transaction is executed, a document is created • The document contains all of the relevant information from the master data and organizational elements 31 Financial Accounting (FI) & Controlling (CO) Modules 32 FI and CO Comparison FI CO Legal or external reporting Reports by accounts Balance Sheet Income Statement Internal management reporting Reports by cost centers and cost elements Cost Center Reports 33 FI/CO Organizational Structures Client Company Chart of Accounts Company Code Business Area 34 Company Consolidated financial statements are created at the company level A company can include one or more company codes All company codes must use the same chart of accounts and fiscal year 35 Chart of Accounts The chart of accounts contains: − A complete listing of G/L accounts in FI − Cost and revenue elements in CO Each company code is assigned to one chart of accounts 36 General Ledger Accounts • Every account to be posted in FI must be defined as a G/L account master record • Each G/L account master record contains information that specifies the function of that account − e.g., balance sheet vs. P&L account 37 Materials Management (MM) Module 38 Procurement Process Purchase Order Purchase Requisition Demand Vendor Accounts Payable Goods Receipt & Inventory Mgmt. 39 Organizational Elements for the Procurement Process • • • • • • Client Company Code Plant Storage Location Purchasing Organization Purchasing Group 40 Company Code A company code represents an independent accounting unit Balance sheets and Profit/Loss statements, required by law, are created at the company code level 41 Plant A plant is an organizational unit within a company to produces goods, renders services, or distributes goods A plant can be one of the following types of locations: − Manufacturing facility − Warehouse distribution center − Regional sales office − Corporate headquarters 42 Storage Location An organizational unit for the differentiation of material stocks within a plant 43 Purchasing Organization and Groups • Groups can be a further division of purchasing responsibility and/or structure • Centralized or Decentralized • Hybrid - multiple organizations buy for multiple plants 44 Vendor Master • For processing business transactions and corresponding with vendors • Shared between the accounting and purchasing departments • Data is grouped into three categories: − General data − Accounting data − Purchasing data 45 Production Planning & Execution (PP) Module 46 Material Requirements Planning (MRP) A set of techniques utilizing – Bills of materials (BOM) – Inventory data – Master production schedule for material requirements A time-phased planning tool for quantity and capacity by a given – Day – Week – Month 47 Master Data - BOM BOMs are created as relationships between one parent material and one or more sub-component materials. i.e., uniform pants shirt hat emblem - 2 cover box 48 Production Process Schedule/Release Goods Issue Order Settlement Shop Floor Goods Receipt 49 Scheduling Techniques Forward scheduling − Starts when the order is received − Results in completion before the due date Backward scheduling − The last operation on the routing is scheduled first − Previous operations are scheduled back from the last one 50 Sales and Distribution (SD) Module 51 Organizational Unit 3000 MSI US Company Sales Area: Sales Organization 1000 4000 MSI German Canada yy Sales Area: Sales Organization 3000 US 12 Distribution Channel Division Plant 1000 4000 Germany Canada 12 Distribution Channel Resale s 02 90 Motorcycles Accessories 3000 3400 New York Seattle Division Plant Company Resale 02 90 Motorcycles Accessories 1000 4000 1400 4100 Hamburg Montreal Stuttgart Toronto 52 SD Master Data • Customer - Sale organization − Various relationship − Customer account (i.e, credit, invoice payment) • Material - Plant − Sales status, Material type, etc. • Pricing − A technique for prices to be executed in the order 53 SD Processes O rd e r M a n a g e m e n t: B u s in e s s P ro c e s s e s in C O M C y c le SSaale less O Ord rdeerr PPro rocceessssin ingg In Invveennto tory ry SSoouurc rcin ingg PPre re-S -Saale less AAcctiv tivitie itiess In v o ic e DDeeliv liveery ry PPaayym meenntt BBillin illingg R SAP AG 54 Human Resources (HR) Management Module 55 SAP HR Processes Recruitment Cost Planning & Reporting Hiring Employee Self-Service Travel Planning Payroll Administration Compensation & Benefits Course Credit Training and Personnel Development Managing Work Time 56 HR Integration Logistics Financial Accounting Controlling Sales and Distribution SAP HR Workflow 64 ERP Trends 1. Further integration of suppliers & customers 2. Focus on ERP system flexibility 3. Mass customization • Standard interfaces across chain 65 Extended ERP Upward Integration (i.e., EIS) Backward Integration (i.e., SCM) ERP Forward Integration (i.e, CRM) 66 ERP Motivations • Original ERP Design - Internal • Supply chain relationships requirements − Improved interactions & communications − Opportunities with suppliers & customers • Manufacturers surveyed had supply chain extensions to ERP • More planned to have extensions • Open systems for supply chains 67 ERP Vendor Response • mySAP.com - open, collaborative system for SAP & non-SAP software • SAP APO - forecasting, scheduling, other logistics activities • PeopleSoft - enterprise performance management • JDEdwards - planning & execution • Oracle’s 11i - Planning & Scheduling 68 69 Questions/Answers or email me at schung1@emich.edu 70