Tom Wilhelm, Consultant

advertisement

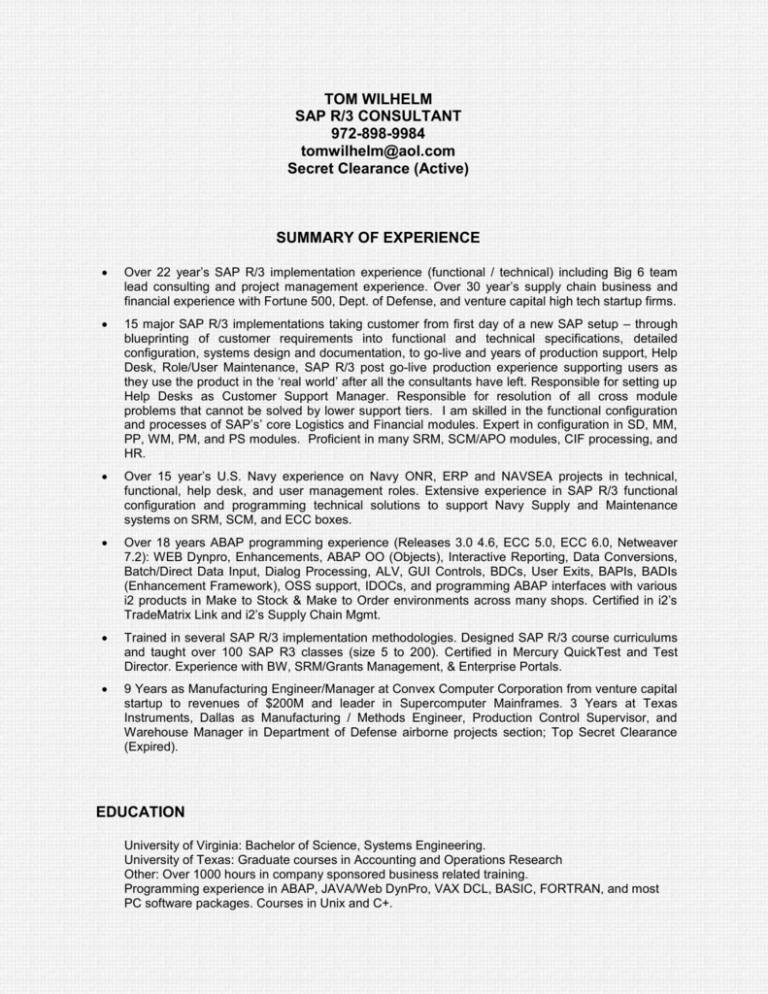

TOM WILHELM SAP R/3 CONSULTANT 972-898-9984 tomwilhelm@aol.com Secret Clearance (Active) SUMMARY OF EXPERIENCE Over 22 year’s SAP R/3 implementation experience (functional / technical) including Big 6 team lead consulting and project management experience. Over 30 year’s supply chain business and financial experience with Fortune 500, Dept. of Defense, and venture capital high tech startup firms. 15 major SAP R/3 implementations taking customer from first day of a new SAP setup – through blueprinting of customer requirements into functional and technical specifications, detailed configuration, systems design and documentation, to go-live and years of production support, Help Desk, Role/User Maintenance, SAP R/3 post go-live production experience supporting users as they use the product in the ‘real world’ after all the consultants have left. Responsible for setting up Help Desks as Customer Support Manager. Responsible for resolution of all cross module problems that cannot be solved by lower support tiers. I am skilled in the functional configuration and processes of SAP’s’ core Logistics and Financial modules. Expert in configuration in SD, MM, PP, WM, PM, and PS modules. Proficient in many SRM, SCM/APO modules, CIF processing, and HR. Over 15 year’s U.S. Navy experience on Navy ONR, ERP and NAVSEA projects in technical, functional, help desk, and user management roles. Extensive experience in SAP R/3 functional configuration and programming technical solutions to support Navy Supply and Maintenance systems on SRM, SCM, and ECC boxes. Over 18 years ABAP programming experience (Releases 3.0 4.6, ECC 5.0, ECC 6.0, Netweaver 7.2): WEB Dynpro, Enhancements, ABAP OO (Objects), Interactive Reporting, Data Conversions, Batch/Direct Data Input, Dialog Processing, ALV, GUI Controls, BDCs, User Exits, BAPIs, BADIs (Enhancement Framework), OSS support, IDOCs, and programming ABAP interfaces with various i2 products in Make to Stock & Make to Order environments across many shops. Certified in i2’s TradeMatrix Link and i2’s Supply Chain Mgmt. Trained in several SAP R/3 implementation methodologies. Designed SAP R/3 course curriculums and taught over 100 SAP R3 classes (size 5 to 200). Certified in Mercury QuickTest and Test Director. Experience with BW, SRM/Grants Management, & Enterprise Portals. 9 Years as Manufacturing Engineer/Manager at Convex Computer Corporation from venture capital startup to revenues of $200M and leader in Supercomputer Mainframes. 3 Years at Texas Instruments, Dallas as Manufacturing / Methods Engineer, Production Control Supervisor, and Warehouse Manager in Department of Defense airborne projects section; Top Secret Clearance (Expired). EDUCATION University of Virginia: Bachelor of Science, Systems Engineering. University of Texas: Graduate courses in Accounting and Operations Research Other: Over 1000 hours in company sponsored business related training. Programming experience in ABAP, JAVA/Web DynPro, VAX DCL, BASIC, FORTRAN, and most PC software packages. Courses in Unix and C+. DETAILED BUSINESS EXPERIENCE SPECIFIC SAP R3 PROJECTS Department of Navy / Office of Naval Research (Dallas, TX / Arlington, VA) Oct 2013 - Present SAP R/3 SRM (Netweaver 7.2) ABAP Developer Senior RICE consultant responsible for coding interfaces between ECC / SRM boxes. Coded custom WEB Dynpro components as well as ABAP enhancements for SAP objects RFx/Responses, Shopping Carts, and Purchase Orders. Supported existing SMARTFORM & Workflow objects. Extensive configuration and functional experience in SRM. Department of Navy / Navy ERP (Dallas, TX / Annapolis, MD) April 2006 – Oct 2013 SAP R/3 ECC Developer Senior ABAP RICE consultant responsible for coding custom screens, programs, interfaces (IDOCS), and enhancements (user exits/BADIs/Enhancement Spots), ALV, with focus on configuration of SD, MM, SCM/APO (Global ATP) modules in releases ECC 5.0/6.0. Overall 12 years in the functional/technical design, documentation, testing, and training for DOD processes and interfaces (DLMS, DAASC, DLA, NITA, NALCOMIS, Outfitting, Sourcing, Repair, MTIS, STARS, MRIL, etc.). Department of Navy / NEMAIS (Norfolk, Va.) Dec 2002 – April 2006 SAP R/3 Technical / Functional Lead for the US Navy’s NEMAIS ERP project for regional ship maintenance centers across 6 plants. Cross functional consultant ultimately responsible for configuration of FI, CO, FM, SD, PP, PM, PS, MM, and HR modules. All development issues, test defects, and production trouble tickets that cannot be solved by lower support tiers come directly to me for resolution. Also directly responsible for the specification and coding of over 50 ABAP modifications made to core SAP code to address security gaps in the IS-PS solution. These modifications have been approved by SAP to be implemented in their solution provided to the Navy. Customer Service Manager to set up the Help Desk Team and initiate their processes as Navy moved from Implementation to Production Support. Enterprise Portals Team Lead implementing a successful pilot for NAVSEA. Hands on experience developing screens using Web DynPro & Java. Lennox International (Dallas, TX) Jun 2002 – Dec 2002 SAP R/3 Project Manager Responsible for SAP R/3 production IT support (PP/MM/SD configuration and ABAP) for all of Lennox’s manufacturing operations. I was Project Manager for major SAP implementation supervising teams across three plants for Armstrong subsidiary using Value ASAP methodology. Responsible for all project planning, budgeting, and overall SAP scope and integration. Received certification in Lean Manufacturing techniques from University of Tennessee. Some experience in APO and BW. Department of Navy (Norfolk, VA) Apr 2001 – May 2002 SAP R/3 Lead Program Consultant “Consultant of Last Resort” handed the most difficult problems. Principal duties focused on the configuration & integration of the PM, PP, PS, FI, CO, FM, and MM modules to support the maintenance of US Navy ships and submarines. Basis security architect for setting up user profiles & authorization objects to secure naval sensitive data. Wrote ABAP data load programs for material master, inventory balances, PM orders & plans, PS networks, and custom dialogs certifying Time and Attendance for HR team. From April 2001 to Jan 2002, was principal ABAP programmer for i2’s development team to code first two-way interfaces to become part of i2’s standard ROI product. Lucent Technologies (Various Plants) Mar 1997 – Mar 2001 Matamoras, Mexico (Startup to Go-Live) Monterrey, Mexico (Startup to Configuration complete – Plant sold before Go-Live) Dallas, Texas (Startup to Go-Live + Post Implementation Support) SAP R/3 PP/MM Team Lead (W/ ABAP) – Lead consultant for installation of PP/MM modules at 3 plants for the world’s leading manufacturer of telecommunication equipment using SAP’s ASAP methodology. Led efforts for project planning, configuration of all PP/MM modules, manufacturing process re-engineering into SAP, user training, data mapping & conversion, all unit / integration testing, and ABAP programming (BDCs, interactive reporting, OSS support, Data Dictionary custom tables, and ‘bolt-on’ code for SD, PP, MM, & QM teams). I was responsible for design, coding, testing, and maintenance of ABAP interfaces between SAP R/3 - i2’s Demand Planner and SAP R3 - legacy systems (AMAPS). Member of SD team supporting SD and Variant Configurator. EDS, Inc. – (Plano, TX) Oct 1998 - Nov 1998 SAP R/3 PM Team Lead at a world's leading supplier of IT consulting services that completed a proof-of-concept project on Release 4.0. Designed PM configuration and process flows to support customer requirements. Toro, Inc. – (Riverside, CA) Dec 1996 – Mar 1997 SAP R/3 PP/MM Team Lead consultant responsible for all configuration, business process modeling, and team training from Start-up to Configuration Complete for high-volume plant for a world’s leading manufacturer of products and services for outdoor care. Experience interfacing with QM and SD. Toro, Inc. – (Minneapolis, MN) Feb 1996 – Dec 1996 SAP R/3 PP/MM Team Lead consultant responsible for installation of SAP R/3 at a light manufacturing and assembly plant. Responsible for team management of Product Development, Planning, Production Execution, & Materials Management Tracks. Led efforts for project planning, configuration, process re-engineering, training, data conversion, reporting, unit and integration testing, and ABAP ‘bolt-on’ solutions. Experience interfacing with QM and SD and in the configuration of WM. PRICE WATERHOUSE - SAP R/3 Senior Manager Aug 1994 - Jan 1996 Hitachi Semiconductor – (Dallas, TX) Nov 1995 – Jan 1996 SAP R/3 Project Manager starting an implementation of SAP R3 FI, CO, SD, MM, WM, QM, PP & HR modules for the semiconductor division of a international corporation with revenues over $85 billion. Responsible for presales support, project proposals and planning, staffing, budget and coordinating activities with management of other client divisions implementing SAP. Compaq Computer Co. – (Houston, TX) Aug 1994 – Oct 1995 SAP R/3 PP Team Lead responsible for analysis and design of manufacturing modules for the worldwide SAP R/3 implementation from ASK MANMAN for international manufacturer of computer equipment (revenues over $10 billion). Responsible for re-engineering sales and operation's processes to streamline corporate supply chain using SAP R3, i2 and custom software solutions. Established project plans, led all SAP R3 configuration of production environment, and conducted training classes for PP modules. Experience in configuration of WM and MM. SAP R/3 ABAP Lead for team of programmers charged with developing interface specifications, code, and test plans for all conversions from custom / standard SAP tables into I2 Rhythm shop floor scheduling package. Positioned process workflows to allow ease of transition as SAP functionality increases to assume roles of current and proposed software solutions. CONVEX COMPUTER CO. – Richardson, TX Mar 1985 - Jul 1994 Jul 1993 - Jun 1994 SAP R/3 PP Team Lead I managed a team of 8 users in the first SAP R/3 golive in U.S. Responsible for project design and schedule, team management, modeling of PP processes, reports, data conversion, re-engineering of manufacturing operation's workflows to support Sales & Distribution and Material Management modules, and setup & administration of PP user training courses. Convex was the first SAP customer in U.S. to go live on R/3. We received beta software and I worked directly with German developers to identify functionality required for proper implementation in first R/3 releases. Advisor to SAP customers implementing R/3 and worked with third-party vendors interfacing with SAP. Project manager for implementation CADENCE Material Planning Package Activities included evaluation and selection of vendor packages, envisioning new material planning model and restructuring of business processes to create better teamwork between functional areas resulting in $1.5M to $2M / year in productivity gains and inventory reductions. Manufacturing Project Manager Responsible for Convex's 3rd generation of computers and largest program to date with annual revenue over $90M. Interface with all levels of management in all departments. Directed activities between engineering, manufacturing, sales, field service, and key vendors to setup all manufacturing processes to take project into production. Manufacturing leader in changeover from department/hierarchical philosophy to cross functional team approach and member of Convex's first self managed team. Voted Starcruiser by peers (week-long expense paid cruise vacation for 2 with top management to recognize top performers outside of Sales). Purchasing Buyer Extensive travel to vendors for contract negotiations and to setup a partnership to revamp scheduling, delivery, and repair to a JIT environment. Managed project to re-engineer purchasing processes for vendor discrepant material where I developed a custom coded solution to streamline and automate return material. This led to an additional project to design / automate a new purchasing analysis system used by end users in manufacturing, accounting, and management today. New Products Manager Responsible for setup of company's first New Products and Special Systems Group. Manufacturing project manager for introduction of C2-Convex's 2nd generation of computers and all peripheral projects in this period, as well as specific solutions addressing customer / market needs. Setup of processes and teams to coordinate a new product's move from engineering into production for manufacturing, field service, purchasing, marketing, and sales departments. Setup first corporate wide ASK MAXCIM training program. Runner-up in StarCruiser performance recognition program. Operations Manager Manufacturing "do-everything" role in startup company to put first processes in place for Materials Planning, Inventory and Production Control, Warehouse, WIP Accounting, Process Methods, Document Control, and Field Service. Setup department for Sales/Manufacturing interface to develop revenue plan and schedule assembly/test. Managed project to re-engineer all manufacturing processes from kit-pull system to JIT KANBAN 'flowline'. TEXAS INSTRUMENTS - Dallas, TX Jul 1982 - Mar 1985 Manufacturing Engineer and Production Control/Warehouse Manager. Supervisor of 10-15 production control dispatchers responsible for scheduling final system assembly and test lines for Top Secret DOD projects. Responsible for routings, MRP, and shop floor control of systems, metal fab, cable, circuit boards, and optics through various TI shops in 4 cities. Warehouse manager over all project’s material kitting operations. Close customer interface for pricing/quotes on upgrades and repair charges. Manufacturing trainer in TI's integration of personal computer to manufacturing personnel at Forest Lane, Dallas site. Coordinator for interviewing and reviewing college recruits.