PRODUCTION AND OPERATIONS MANAGEMENT

advertisement

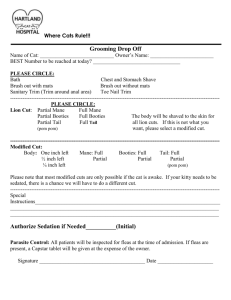

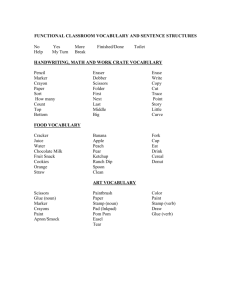

PRODUCTION AND OPERATIONS MANAGEMENT Ch. 6: Design of Goods and Services POM - J. Galván 1 Learning Objectives How should products/services be designed systematically? POM - J. Galván 2 Humor in Product Design As the customer wanted it. As Marketing interpreted it. © 1984-1994 T/Maker Co. As Operations made it. © 1984-1994 T/Maker Co. As Engineering designed it. © 1984-1994 T/Maker Co. © 1984-1994 T/Maker Co. POM - J. Galván 3 What is a Product? Need-satisfying offering of an organization • Example P&G does not sell laundry detergent P&G sells the benefit of clean clothes Customers buy satisfaction, not parts May be a good or a service POM - J. Galván 4 Product Strategy Options • Product differentiation • Low cost • Rapid response POM - J. Galván 5 Generation of New Product Opportunities Economic change Sociological and demographic change Technological change Political/legal change Changes in • market practice • professional standards • suppliers and distributors POM - J. Galván 6 Product Components Product Brand (Name) Physical Good Product Idea Features Quality Level POM - J. Galván Package Service (Warranty) 7 Product Life Cycle Introduction Growth Maturity Decline POM - J. Galván 8 Product Life Cycle Introduction Fine tuning • research • product development • process modification and enhancement • supplier development POM - J. Galván 9 Product Life Cycle Growth Product design begins to stabilize Effective forecasting of capacity becomes necessary Adding or enhancing capacity may be necessary POM - J. Galván 10 Product Life Cycle Maturity Competitors now established High volume, innovative production may be needed Improved cost control, reduction in options, paring down of product line POM - J. Galván 11 Product Life Cycle Decline Unless product makes a special contribution, must plan to terminate offering POM - J. Galván 12 Product Life Cycle, Sales, Cost, and Profit Sales, Cost & Profit . Cost of Development & Manufacture Sales Revenue Net Revenue Loss Time Introduction Growth Maturity POM - J. Galván Decline 13 Percent of Sales From New Product 50% 40% Industry Leader Top Third 30% 20% Middle Third 10% Bottom Third 0% Position of Firm in Its Industry POM - J. Galván 14 Products in Various Stages of Life Cycle Sales Introduction Growth Maturity Roller Blades Jet Ski Decline Boeing 727 Virtual Reality Time POM - J. Galván 15 Few Successes Number 2000 Ideas 1750 Design review, Testing, Introduction Market requirement 1500 1000 1000 Functional specification 500 500 0 Product specification 100 25 Development Stage POM - J. Galván 16 Product Development Stages Idea generation Assessment of firm’s ability to carry out Customer Requirements Functional Specification Scope of design for Product Specifications manufacturability and value engineering Design Review teams Test Market of product Introduction to Market Scope development team Evaluation POM - J. Galván 17 Idea Generation Stage Provides basis for entry into market Sources of ideas • Market need (60-80%); engineering & operations (20%); technology; competitors; inventions; employees Follows from marketing strategy • Identifies, defines, & selects best market opportunities POM - J. Galván 18 Customer Requirements Stage ¨ Identifies & positions key product benefits ¨ Stated in core benefits proposition (CBP) ¨ Example: Long lasting with more power (Sears’ Die Hard Battery) House of Quality ¨ Identifies detailed list of product attributes desired by customer Customer ¨ Focus groups or Requirements 1-on-1 interviews POM - J. Galván Product Characteristics 19 Functional Specification Stage Defines product in terms of how the product would meet desired attributes Identifies product’s engineering characteristics • Example: printer noise (dB) Prioritizes engineering characteristics House of Quality May rate product compared to competitors’ Product Characteristics Customer Requirements POM - J. Galván 20 Product Specification Stage Determines how product will be made Gives product’s physical specifications • Example: Dimensions, material etc. Defined by engineering House of Quality drawing Done often on computer Component Computer-Aided Design (CAD) Specifications • Product Characteristics POM - J. Galván 21 Manufacturability and Value Engineering Benefits: • reduced complexity of products • additional standardization of products • improved functional aspects of product • improved job design and job safety • improved maintainability of the product • robust design POM - J. Galván 22 Issues for Product Development Robust design • Product is designed so that small variations in production or assembly do not adversely affect the product Time-based competition • Product life cycles are becoming shorter Modular design • Products designed in easily segmented components Computer-aided design • Designing products at a computer terminal or work station Value analysis • Seeks improvements leading either to a better product or a product which can be more economically produced Product-by-value analysis • Lists products in descending order of their individual dollar contribution to the firm POM - J. Galván 23 Product Documents Engineering drawing • Shows dimensions, tolerances, & materials • Shows codes for Group Technology Bill of Material • Lists components, quantities & where used • Shows product structure POM - J. Galván 24 What documents are needed for production? Depends on the production technology/machinery available Adapted to the manufacturing process implemented What, who, when, how should be done with our machines POM - J. Galván 25 Gate Valve POM - J. Galván 26 “Exploded” Drawing of the Gate Valve POM - J. Galván 27 Engineering Drawing of the Gate Valve Provide part specifications and dimensions in sufficient detail for manufacturing POM - J. Galván 28 Parts List of the Gate Valve The parts list provides a listing of the component parts of a product. In addition to make or buy decisions, a parts list includes part number, part name, number of parts per product, and drawing references POM - J. Galván 29 Bill of Materials for the Gate Valve Bill of materials is also referred to as a structured parts list since it includes all of the information typically included in the parts list, as well as information concerning the structure of the product. POM - J. Galván 30 Make-or-Buy Decisions Decide whether or not you want (or need) to produce an item May be able to purchase the item as a “standard item” from another manufacturer POM - J. Galván 31 Group Technology Characteristics Parts grouped into families • Uses coding system • Similar, more standardized parts Describes processing & physical characteristics Part families produced in manufacturing cells • Mini-assembly lines POM - J. Galván 32 Group Technology Code Example 4mm x 45° chamfer 80mm 60mm Round Rod Product Code: 1 5 3 1 112mm Part function (round rod) Material (steel) Max. length (50 < L < 150) Primary machine (lathe) POM - J. Galván 33 Group Technology Benefits Improved product design Reduced purchases Reduced work-in-process inventory Improved routing & machine loading Reduced setup & production times Simplified production planning & control POM - J. Galván 34 Production Documents Assembly Drawings Assembly chart Route sheet Work order POM - J. Galván 35 Assembly Drawing Shows exploded view of product Head Neck Handle POM - J. Galván End Cap 36 Assembly Chart 1 Tuna Fish SA1 2 3 Tuna Assy A1 Sandwich Mayonaise FG Bread A2 POM - J. Galván 37 Assembly Chart I It is an analog model of the assembly process. Circles with a single link denote basic components, circles with several links denote assembly operations/subassemblies, and squares represent inspection operations. POM - J. Galván 38 Assembly Chart II POM - J. Galván 39 Route Sheet Lists all operations R o u te S h e e t fo r B ra c k e t Sequence M a c h in e O p e ra tio n 1 Shear # 3 2 Shear # 3 3 D rill p re s s B ra k e p re s s S h e a r to le n g th Shear 45° c o rn e rs D rill b o th h o le s Bend 90° 4 POM - J. Galván S e tu p T im e 5 O p e ra tio n T im e /U n it .0 3 0 8 .0 5 0 15 3 .0 0 0 10 .0 2 5 40 Information Gathering Information about process : - Route sheet (equipment and operation times) - Precedence Diagram (prerequisite assembly steps before new assembly step) - Operation process chart (processing operations, assembly operations, and inspections) Route Sheet for one Component of the Gate Valve Route sheet summarizes whether a part will be purchased or produced, how the production of a part will be achieved, what equipment will be used, and how long it take to perform each operation. POM - J. Galván 42 Precedence Diagram for Assembling the Gate Valve A precedence diagram establishes the prerequisite assembly steps that must be completed before performing a given assembly step. POM - J. Galván 43 Operations Process Chart By superimposing the route sheets and the assembly chart, a chart results that gives an overview of the flow within the facility. This chart is the operations process chart. POM - J. Galván 44 Work Order Authorizes producing a given item, usually to a schedule © 1984-1994 T/Maker Co. POM - J. Galván 45 Engineering Change Notice (ECN) A correction or modification of an engineering drawing or bill of material POM - J. Galván 46 Configuration Management A system by which a product’s planned and changing components are accurately identified and for which control and accountability of change are maintained POM - J. Galván 47 Application of Decision Trees to Product Design Particularly useful when there are a series of decisions and outcomes which lead to other decisions and outcomes. Considerations: • Include all possible alternatives and states of nature - including “doing nothing” • Enter payoffs at end of branch • Approach determining expected values by “pruning” tree POM - J. Galván 48 Transition to Production First issue: knowing when to move to production! Second: must view product development as evolutionary, not responsibility of single individual/department Third: expect to need a trial production period to work the bugs out Fourth: recognize that responsibility must also transition POM - J. Galván 49 Documents in the design of services Are they needed? Whenever rules must be applied in many different sites (e.g. Mcdonald’s) Whenever procedures must be followed to fullfil requirements POM - J. Galván 50 McDonald’s manuals POM - J. Galván 51 McDonald’s manuals POM - J. Galván 52 What do you need to implement this reception message? POM - J. Galván 53