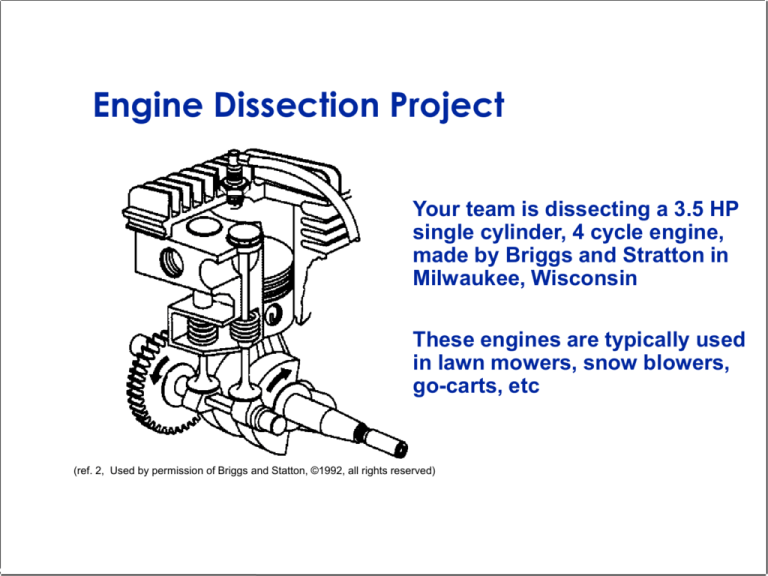

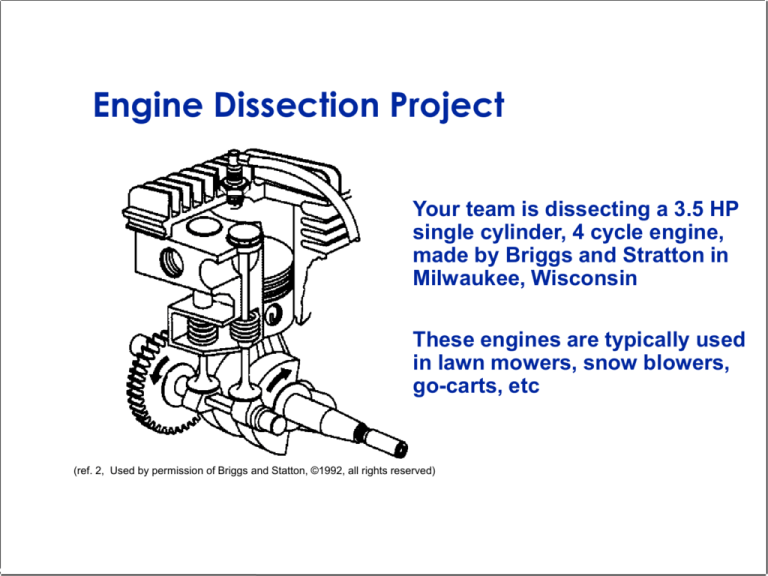

Engine Dissection Project

Your team is dissecting a 3.5 HP

single cylinder, 4 cycle engine,

made by Briggs and Stratton in

Milwaukee, Wisconsin

These engines are typically used

in lawn mowers, snow blowers,

go-carts, etc

(ref. 2, Used by permission of Briggs and Statton, ©1992, all rights reserved)

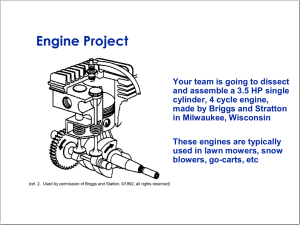

Engine Dissection Project

Start engine.

Disassemble engine.

Review parts and functions – Ask questions!

Reassemble engine.

Re-start engine.

Write individual report on how engine works.

4 Cycle Process

1

Intake Valve

Intake

Manifold

Cylinder

2

Exhaust Valve

Exhaust

Manifold

3

4

Spark

Plug

Piston

Connecting

Rod

Intake Stroke

Intake valve opens,

admitting fuel and air.

Exhaust valve closed

for most of stroke

Crank

Crankcase

Compression Stroke

Both valves closed,

Fuel/air mixture is

compressed by rising

piston. Spark ignites

mixture near end of

stroke.

Power Stroke

Fuel-air mixture burns,

increasing temperature

and pressure, expansion

of combustion gases

drives piston down. Both

valves closed - exhaust

valve opens near end

of stroke

Exhaust Stroke

Exhaust valve open,

exhaust products are

displaced from cylinder.

Intake valve opens

near end of stroke.

1. Intake

2. Compression

3. Power

4. Exhaust

Reciprocating to rotary motion

The pistons & crankshaft

Image from:

http://www.eng.iastate.edu/explorer/topics/car/engine.htm

Piston, crankshaft,

& fly wheel

Image from:

www.web-masters.com/ gms/crank_p.html

Piston

Image from:

www.rbracing-rsr.com/ 113orca.htm

darryl.hudson.home.mindspring.com/

ww.eng.iastate.edu/explorer/topics/car/engine.htm

Crankshaft

Image from :

toyotaperformance.com/crankshaft_kits.htm

Several common types of car engine arrangement

Image from :

Automotive mechanics, 8th ed. By William H. Crouse

4 cylinder in-line

6 cylinder in-line

V-6

V-8

Flat-4 engine

Flat-6 engine

Power strokes in 2 crankshaft rotations

Why you need flywheel

Image from :

Automotive mechanics, 8th ed. By William H. Crouse

4 cylinder

6 cylinder

Output

torque

8 cylinder

Output

torque

time

Output

torque

time

time

rocker

Valve Mechanisms:

How you get the

valve

right timing

push rod

Image from :

Automotive mechanics, 8th ed. By William H. Crouse

piston

valve lifter

camshaft

cam

crankshaft

Timing marks

Lubrication

Image from :

Automotive mechanics, 8th ed. By William H. Crouse

Venturi-type Carburetor

The carburetor of our engine

Choke

Throttle

Venturi

Higher Pressure

Outside Engine

Fuel

How do engines work?

How does the engine complete these Primary Functions?

Hint

Get started?

Suck in fuel?

Suck in air?

Mix air and fuel?

Compress the mixture?

Ignite the mixture (at the right time)?

Make the combusting gases do work?

Make the work available to somebody?

Exhaust the gases?

Shut off?

Think about the parts and processes involved for each.

How do engines work?

How does the engine complete these Secondary Functions?

Hint

Stay lubricated?

Operate the valves at the right time?

Smooth out the power pulses?

Store the fuel?

Keep cool?

Make it easy to start?

Think about the parts and processes involved for each.

Some variations:

Fuel Injection

(electronic, multi-port)

Monitored Engine

Operating Conditions:

Manifold Pressure

Engine Speed

Air Temperature

Coolant Temperature

Acceleration

COMPUTER

TRIGGER

INJECTOR DRIVE UNIT

Pressure Regulator

Fuel

Filter

50 psi typical

Injectors

FUEL TANK

Fuel

Pump

More variations:

OHC( overhead camshaft):

DOHC, SOHC……

Rocker

Valve spring

Valve

Valve lifter

Camshaft

Piston

Image from :

Automotive mechanics, 8th ed. By William H. Crouse

Connecting

rod

Crankshaft

More variations:

VTEC( Variable valve timing and lift electronic control)

2 Stroke Process (for comparison)

Compression

(ports closed)

Air Taken Into

Crankcase

Combustion

(ports closed)

Exhaust

(intake port closed)

Air compressed in crankcase

Scavenging

and Intake

(ports open)

Wankel Rotary Engine

•Smoother

•Engine is continuously moving in one direction

rather than changing direction like in piston

engines.

•Slower

•Main moving parts move slower which increase

the reliability of the engine.

•Fewer Moving Parts

•The rotary engine consists of three main moving

parts while a piston engine contains at least 40

moving parts.

•Challenges

•Passing the US Emissions tests.

•Manufacturing costs are higher.

•Consumes more fuel.

This presentation created by former ENGR 100 students Sam Henry, Thomas Munsey, Grayson Deitering, Daniel Munro