Chapter 2 - Industrial and Systems Engineering

advertisement

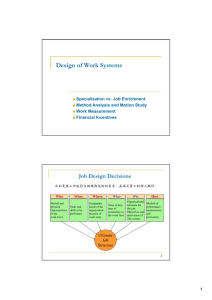

Chapter 2 Problem Solving Tools for Methods Engineering Our Text Book Website: http://highered.mcgraw-hill.com/sites/0072468246/ Outline for today A short history of Human Factors and Ergonomics, Methods Engineering/Work Design Example of Methods Engineering Discussion of in-class exercise, Approaches for both physical and “thinking” tasks, A Short History of Human Factors and Ergonomics Year Event 1760 Perronet makes time studies 1820 Charles W. Babbage makes time studies 1832 Charles W. Babbage publishes On the Economy of Machinery and Manufactures 1881 Frederick W. Taylor begins his time study work 1901 Gantt develops the task and bonus wage system 1910 Gilbreth publishes Motion Study 1933 First Ph.D. granted in the United State in the field of industrial engineering from Cornell University 1949 The Ergonomics Research Society (The Ergonomics Society) founded United Kingdom 1957 The Human Factors and Ergonomics Society is founded United States 1970 Congress passes the OSHAct, Occupational Safety and Health Administration 1981 NIOSH lifting guidelines are first introduced 1990 Americans with Disabiities Act (ADA) is passed by Congress 1995 ANSI Z-365 Standard for Control of Work-Related Cumulative Trauma Disorders 2006 50th Anniversary of the Human Factors and Ergonomics Society Methods Engineering Technique for: – Increasing production per unit of time. Example: increasing the number of customers that can be handled per cashier by installing bar code readers. – Decreasing cost per unit output. Example: decreasing total cost of each cell phone by reducing the number of parts and thus the labor hours required for assembly. It is critical to look at impact on whole system. Methods Engineering Focuses Primarily on improving productivity though (re)design of: Organizational structure Motivation: Incentives/rewards Work Process Work operations Tools (Products) Work environment Methods Engineering Often used synonymously with: – Corporate re-engineering – Work design – Operation analysis Big picture level Detail level The difference between these terms in the level of detail. Methods Engineering Select project I.D. product or service experiencing difficulties. Get and present data Study situation, take measurements to determine where difficulties really lie, Analyze the data: Figure out which of many problems are most critical Develop ideal method(s) Identify alternative approaches which may address most critical problems. Present and install method at the work site Develop a job analysis To insure operators are adequately selected, trained, rewarded, etc. Establish time standards Establish fair and equitable standards for work performance. Follow up the method Take measurements to determine if changes really did improve situation as predicted. Example: Mission Planning and control for the Mars Exploration Rover Researchers introduced automated planning tool, MAPGEN Tool had to fit with users’ existing way of thinking about plans, Introduction of new tools caused the planning process to change, Product and processes were evolved together, over time. Many methods can be used in many stages of the design process A typical spiral design process Prototype Testing Requirements Gathering Final Performance Evaluation or Comparison Design Specification Design Review Problem Solving Tools for Methods Engineering: help to identify what the most important problem is Observational tools: – Site walk-thrus – Observation and interviews of workers and managers – Ethnographic studies Problem Solving Tools for Methods Engineering (Ch. 2.1) Exploratory tools – Pareto Analysis (Vilfredo Pareto) – Fish Diagrams (from Japan, 60’s) – Gantt and PERT charts (40’s wartime). Pareto Analysis Items of interest are identified (e.g. types of product flaws that result in scrapped parts, time spent on each activity required to manufacture a product or perform a service. Items are measured on a common scale (such as frequency total cost, total time, etc.) Items are ordered in descending order 0.00 Reasons Had home or family Extended college Wanted to take a lighter Trying to get into a major Completed a double major Enjoyed college and Trying to prepare for Wanted to work additional 1.50 Couldn't get courses I 2.00 Wanted to take a lighter 2.31 Had to work more hrs to 2.50 Changed majors after Importance of Reason (1 - 4) Example of a Pareto Chart Reasons for Delay in Graduation, All Colleges and Departments, University of Minnesota, 2005 4.00 3.50 3.00 2.11 1.75 1.72 1.66 1.55 1.47 1.47 1.41 1.32 1.25 1.18 1.00 0.50 Example 2 Pareto chart: worker time study Plymouth Cashier 2-2-06 Barista operations (milk) 3.1% Cutomer interaction 3.0% Personal 1.4% Interaction with staff 4.1% Cashier functions Equipment maintenance Cleaning 6.1% Watch door Back to kitchen Cleaning Back to kitchen 7.9% Cashier functions 48.1% Watch door 13.1% Equipment maintenance 13.3% Interaction with staff Barista operations (milk) Cutomer interaction Personal Example of a Fish Diagram Fish Diagrams Cause and effect diagrams Effect is a problem = “fish head” Causes = “fish bones” Typical causes: – – – – – – Environment Methods Materials Administrative Machine Human Gantt Charts Activities shown as bars with: – Anticipated start times – Anticipated completion times – Actual start and completion times Use a vertical line to show current time May use color codes to show various things: – – – – Completed activities (grey) On going activities, on schedule (green) Overdue activities (red) Almost over due activities (yellow) Example of a GANTT chart PERT Charts: Program Review and Evaluation Technique Project networks Like Gannt charts, PERT charts show activities, start and end times Also show variation in activity durations: optimistic, average, pessimistic, Show dependencies between activities, Can identify a critical path (longest path) that constrains minimum completion time of whole project, Analyze how “crashing” activities can shorten duration of whole project. Example of a PERT chart Problem Solving Tools (cont.) Recording and Analysis tools: – Operation Process Chart – Flow process chart – Flow diagram – Worker and Machine Process Charts – Gang Process charts – Synchronous servicing Operation Process Charts Chronological sequence of operations Show operations as a flow chart though the worksite. Show the types of operations: – Operation – Transport – Inspection – Delay – Storage – Decision Operation Process Chart: Manufacture of a telephone stand Flow Process Chart More detail than Operation Process Chart: Not usually used for entire assemblies, Used for just one component (or operator) Add in information on: – Operation duration (time to complete) – Distance traveled (for transport operations) Good for showing savings of a new method. Flow Process Chart Preparation of direct mail advertizing Flow Diagram Show layout of work area Show the flow of work through that area Show congestion areas, crossing worker paths, total travel. Identify how layout can be redesigned to reduce travel, motion, collisions, etc. Store materials near where they are used. Increase efficiency and safety. Flow diagram A revised and more efficient flow diagram Worker and Machine Process Chart Show one worker, many processes Identify idle time for each, Reorganize operations to reduce idle time. Identify how many machines worker can manage Gang Process Charts Show one machine, many workers, Identify idle time for each, Re-arrange tasks between workers to reduce idle time. Synchronous and Random Servicing Synchronous servicing: operations (usually done by machine) take a predictable amount of time, so the operator(s) “servicing” actions can be synchronized with the machines’ cycle times. Random servicing (Asynchronous): operation occurrences happen with some unpredictability: e.g. machine breakages, field service calls, etc. Synchronous Servicing The number of Machines an operator Can be assigned: n ≤ l + m l+w Where: n = number of machines operator handles l = total operator loading and unloading time m = total machine running time w = worker time between machines. Example Should n be 3 or 4? Figure out how much it costs per unit of production if: – 3 machines are assigned to each worker – 4 machines are assigned to each worker Choose the assignment that is least expensive. Random Servicing This method applies when you have one person handling several machines (or things) that: – Do not run for a set length of time, – Need servicing at irregular intervals Examples: – Machine repair: machines break at random times. – Call center, calls come in at random times. Random Servicing: Approach The proportion of time, p, that a machine is up or down can be estimated through a time study (Chapter 9) or a work sampling study (Chapter 14) q=1- p P = the probability that m out of n total machines are down is: P (m of n) = n! x pm qn-m m! (n – m)! Random Servicing: Example Suppose at a call service center you have one phone operator to answer: – n = 4 phone lines – p = 0.10 = probability that a phone line is in use is. – q = 1 – p = 0.9 = the probability that a given phone line is unused, e.g. no one on the line. “In use” means that a caller may be either: – waiting on the line, or – speaking with the phone operator. If calls come into the center at random, what is the probability that there will be exactly three phone lines in use? (e.g. One caller speaking with the operator, two callers waiting). Random Servicing: Example 4! x (.10 ) (.94) = .66 0! (4 – 0)! One caller 4! x (.11 ) (.93 ) = .29 1! (4 – 1)! Two callers 4! x (.12 ) (.92) = .05 2! (4 – 2)! Three callers 4! x (.13 ) (.91) = .0036 3! (4 – 3)! Four callers 4! x (.14 ) (.90) = .0001 4! (4 – 4)! No callers Random Servicing: Example In other words, in this situation: Probability of exactly n calls 66 % of the time, the sales assistant has no calls; 1 0.9 0.8 29 % of the time, exactly one call; 5 % of the time, exactly two calls, e.g. the assistant helps one customer while one customer waits, 0.7 Probability 0.6561 0.6 0.5 0.4 0.2916 0.3 Less than a half a percent of the time (0.36 %), exactly three calls: one customer is being helped while two customers listen to Musak. The probability that all 4 lines are in use at once is almost non-existent. 0.2 0.0486 0.1 0.0036 0.0001 3 4 0 0 1 2 Num ber of calls Coffee Shop Study No studies had been done previously at this company to assess current efficiency Goal: to identify any way possible of improving productivity, Initial request: do a time study at 3 very different stores, improve productivity of coffee making process. Corporate goal: customer should be in and out within 3 minutes, “door-to-door”. Observational tools Site walk-thrus: look at layout, tools equipment, how they are used. Interviews of workers and managers to identify what they view as problems, Ethnographic studies: observe work in detail as a “fly on the wall” as it normally occurs in its normal setting, possibly over a long period of time. Good for observing interactions between workers. Time and/or motion studies: to learn detail about what people do and how long it takes. Job Worksite Analysis Guide Check list of items to think about/examine while touring jobsite: – – – – – – How do parts/products flow in and out? What kinds of motion are involved? Are any tools being used? Were there awkward motions? Is worker fatigued? Stressed? Is there decision making? Time and Motion studies In a time study: Often applied to large or small tasks, – Work is observed Work is broken into “elements” – Each element is timed, – The process is reengineered to be faster, safer, less error-prone, etc. In a motion study: Often applied to fine-grained continuous motions, – Motions are observed in performing a task, Motions are be divided into “therbligs” – The process is reengineered by: eliminating unnecessary motions, re-sequencing motions. The two are often combined. Tools for Time and Motion Studies Tools can be simple and low cost: – Stop watch, – Pen and paper, – Maybe a video camera. The task determines if it is necessary. The technique is low-tech, but can still result in major cost savings! How did your group speed up your assembly process? Use multiple packers, Use two hands, Lay-out pieces in advance in order of assembly, Orient each object in correct position in advance, Sequence objects to be easier to pack, Fewer objects = less material handing = time savings! What about thinking tasks? Time and motion studies apply to physical aspects of the task and physical objects. What about the psychological aspects of a task? How can one study “thought work” and apply factors to improve the work of people who do: driving, design, planning, management, and decision making? Additional Approaches: Time and “thought” studies Protocol Studies – Have the person talk out loud as they solve a problem E.g. create a design or manufacturing plan, or solve an algebraic problem – Record everything said and done on audio and video tape, or written notes Ethnographic Studies – Observe in the workplace where people are doing tasks Nuclear power plant Cockpit of airplane NASA control center (for Mars Explorations) – Record what is said and done (video or written notes) – Analyze Example of a Protocol Study Protocol means “record” Need 2 volunteers – Experimenter – Subject Tools: – Normal tools used for task, often pencil and paper in an office setting, – Experimenter needs pencil and paper (or other recording equipment: tape recorder, video). A thinking task Common themes in Human Factors approaches Observation of human activities in performance of tasks, Re-engineer many aspects of the task (tools, process, etc.) to improve effectiveness: The tools and techniques are often simple but powerful! In-Class Exercise Each group will be given a set of objects to assemble into a box. The items will be varied in: – shape – size, – flexibility, In-Class Exercise Figure out how to fit all the objects in the box – Decide what actions constitute “therbligs” or “elements” – Develop and record a procedure (in terms of therbligs) Figure out how to do it fast – – – – Time your procedure (minutes, seconds) Did your “therblig” descriptions change? Did your procedure descriptions change? Did other things change? Rules of Exercise Take all objects out and set them separately on desk. Fit all objects in the box so that you can close the lid all the way. No squashing or damaging objects. You may wish to assign different roles to the people on your team: packer, time keeper, process recorder, observer, etc. You will get several minutes to practice, then we will have a competition. Exercise (continued) Each group please report: – Your best time to complete the task – Your therbligs – Your procedure (sequence of therbligs) – What you did to improve your time? (did you develop new therbligs? New sequence? Other?) What Observational tools were used in Coffee Shop Study? Interviews with employees Site walk-thru Time studies of operations for three types of store setups and three job roles (4 hours observation each): – Cashier – Superglue – Barista Other measurements (had to design measurement methods appropriate for context): – At what rate do customers enter? – How long does it take an individual customer to go door to pick-up? Site walk-thru: Customer Area Tightly constrained workspace: Hard to find a safe place from which to observe! Projects Which Exploratory Tools did we Use in the Coffee Shop Study? Other types of charts: rate of customer arrival: when are the busy times? Comparison of total customer wait times at different stores, Comparison of customer volume at different stores, Plymouth: Customer Arrival Rates 50 44 42 37 40 37 29 30 20 23 19 16 10 Tim e Interval 10 :0 010 :3 0 9: 30 -1 0: 00 9: 00 -9 :3 0 8: 30 -9 :0 0 8: 00 -8 :3 0 7: 30 -8 :0 0 7: 00 -7 :3 0 0 6: 30 -7 :0 0 Number of Cutsomers 2-2-06, 6:30 AM - 10:30 AM Average total customer wait time with minimum and maximum wait times Total wait time (min) All stores (each bar aggregated over 1 or more days) 0:21 0:20 0:19 0:18 0:17 0:16 0:15 0:14 0:13 0:12 0:11 0:10 0:09 0:08 0:07 0:06 0:05 0:04 0:03 0:02 0:01 0:00 0:03:44 Chanhassen 2/9/06 Volume 0:02:59 0:02:39 high Plymouth (3 day ave.) Store and days high Mounds View (2 day ave) medium Chanhassen (Super Automatic) Thu 2/9/06 Total wait time frequency sample size, 84 Frequency (no. of customers experienceing this wait) 50 45 40 35 30 27 25 22 20 20 15 8 10 4 3 5 0 0 0 0 0 0 0 0 0 0 -1 1 -2 2 -3 3 -4 4 -5 5 -6 -7 -8 -9 6 7 8 Time (Minutes) 10 -11 -12 -13 -14 -15 9 10 11 12 13 14 0 Difficult Part: How do you translate this exploratory data into ideas of what to do? What does this say about where the problems might lie? How do I know if the what the data shows is good or bad? Is the most costly item a “problem” or a necessary part of the process?