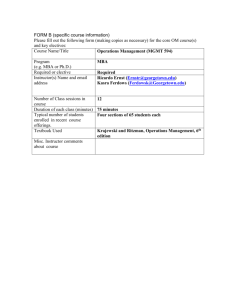

MBA 801 notes

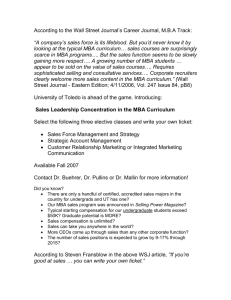

advertisement