script - Systems Thinking, Lean and Kanban

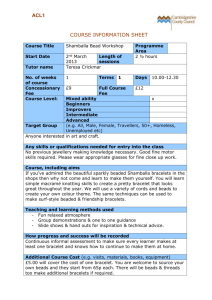

advertisement

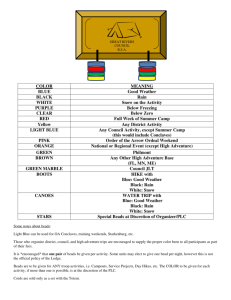

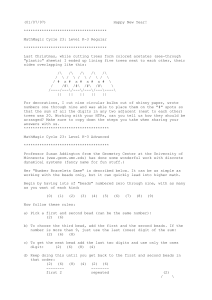

The Red Bead Experiment Project Manager text is in yellow Product Owner text is in purple Instructions are in green Preparation Put the motivation posters and vacancies on the walls 2 clipboards and pens for the inspectors Red bead kit, plastic bucket and tray on a table up the front PC and projector Excel spreadsheet with worker data, SPC chart and Burndown chart Handouts – red bead lessons document, Deming 14 points – hand out at the end Instructor 1 is the Project Manager Instructor 2 is the Product Owner 1 The Experiment Filling the positions We need 6 willing workers, who would like to apply for the job? This is an equal opportunities company We believe in high quality. We need good people. We now need 2 junior inspectors. Observant and able to count is important. Who would like to apply? Next we need a chief inspector. Someone who is able to inspect others Has a loud voice so they can announce the results and is trustworthy. Who would like to apply? We now need a customer. The chief inspector will review the work output with the customer. Pre-arrange with the customer to act like an irate customer when he gets different colored beads, etc. We need a recorder. Someone who will record the names of the team and their performance. Ask the recorder to enter the names of the workers into the spreadsheet and show the burndown chart. 2 Once the positions are filled You are not allowed to stand together – no collusion between employees Workers near the beads Inspectors on the other side and stand next to each other Chief inspector stand behind them, looking over their shoulders to inspect their work. Bunch the 6 workers up to the left of the stage Pair the junior inspectors together. Give them their clip boards and pens. Place the customer and chief inspector to the far right of the stage. Ask the recorder to sit out the front with the computer The recorder will update the spreadsheet with the errors from each of the workers which will total for each iteration. They will also show the burn down of white beads. Those of you in the audience can observe. We will discuss the experiment at the end. The F Test It may look like the inspection department is over staffed. BUT Inspection is a vital and difficult task. Without accurate data how can the customer be protected and the workers be judged? Run the F Test with the audience and the inspectors. 3 Training the workers We have been given a order by the customer to make white beads I need you all to do your best every day. Giving me 100% Pay close attention!!! We will explain the job Explaining the job Material comes in. In the form of red and white beads. The job is to make white beads, the customer wont pay for red. Is that clear? White beads not red beads A strict rigid procedure is defined in order to avoid variation. We have standardized the work. We are ISO certified, implemented ITIL and we achieved CMMI level 5. Clearly with such well defined procedures, accreditation, and training, then any variation will be the workers fault. Explaining the job I have successfully delivered many projects before. The work standard is 50 items of production per worker per iteration. In order to meet this quota, I will provide you with a paddle with 50 depressions in it. Each worker will take turns drawing a sample of 50 from the sampling device for each iteration. 4 Mixing Before each worker performs their job the material will be mixed. Take the wooden box of beads, poor them into the small container, from the corner, with a distance of no more than 8cm Tip all beads from the box to the bucket You understand gravity? Don’t tilt the box or shake it – gravity will do the work Tips the material back into the wooden box again, from the corner. Distance of no more than 8cm Tip all beads from the bucket to the box The material is now mixed. 5 Making units of work You will then produce 50 beads We have work standards here – 50 per worker – 300 per iteration. You have a paddle that will take 50 beads You take the paddle, place at the front of the box, holding exactly a 44 degree angle. Gently but firmly push the paddle into the beads, decreasing the angle as near as horizontal as the paddle will go. Take great care! Are you watching??? All 50 depressions will be covered in beads. Now raise the paddle to 44 degrees, then retaining that angle draw out the beads. There may be some surplus beads, gently shake them off into the box – not on the floor! Remove the paddle at exactly 44 degrees, failure to do so will result in some beads on the floor. Material is expensive. Having demonstrated then show the paddle to the workers. Note the white beads I have deliberately selected some red beads so you know what not to produce 6 Inspection Once a sample is drawn its ready for inspection Carry it to the inspector Walk over to the inspectors Inspector number 1 will count the red beads, and record the number Then inspector number 2 will do the same This high quality company has 2 levels of inspection They will independently write down the number of red beads they counted – in silence. Their job is to count defective items. It should be easy to count. If the workers are doing their jobs there should be a low number of red beads – if at all! Chief inspector They show their numbers to the chief inspector. Ask them to do this The chief inspector will compare the counts If the two numbers are the same, then the chief inspector in a LOUD VOICE calls out the number Then says DISMISSED Its very easy to miscount – remember the F test. 7 If the numbers are incorrect then the chief inspector will announce INSPECTION FAILED – RECOUNT I don’t expect a recount as you wouldn’t have applied for the job if you couldn’t count. The chief inspector will then show the output from the worker to the customer Once it has passed inspection the recorder will record the information on a data sheet. This will generate a burndown chart for white beads produced Ask the recorded to flick to the burndown chart Once you hear DISMISSED the beads are returned to the sampling device by the worker. Then mixed by the next worker and another sample is drawn Words of encouragement I will be managing by results. We are here to make money! But as you are new to the job then you are allowed to have up to 5 defective units for the first calibration iteration. Remember - the future of your jobs depends on your performance There is a lot of competition for your jobs The first iteration will be our calibration. There will be no talking, back chat or questions, you know what to do. There is a tried an trusted procedure in place. Every week may be your last on the job – if you don’t perform you will be fired Good luck! 8 Obviously the percent defective is a constant 20% but the actual percentage will vary with each sample due to sampling error and this is where the spoof begins. As the experiment is carried out over the four days the instructor uses the results of the samples to make his points. The exact order that the instructor will make the points will be dependent on the actual data develops in the experiment. However, after 24 samples you will have enough high and low readings along with increasing and decreasing trends to make all the points. 9 Start the experiment First iteration - calibration This is the first iteration – our calibration iteration First worker, would you please make our first batch of white beads. First worker draws the first sample Watch for wrong angle, too jerky, too fast, too slow, not inserted far enough, tipping the paddle, shaking it up and down instead of side to side. Remember what I told you. We have a well defined process for doing the work. 8cm! No need to be all day about it! And back again! Quick leaner! Take a glance at the paddle before if goes to the inspector to prepare your response. Carry work to inspector number 1 Inspect and record the number in silence Shows inspector 1 Then show inspector number 2 Inspect and record the number in silence Shows inspector 2 Chief inspector responsible for the count Check they are correct. Announce the count And say dismissed. 10 Chief inspector announces that we have x red beads – dismissed. Chief inspector show the output to the customer And then shows it to the customer who reacts accordingly. The product owner can then use the number announced to attach more blame to the worker Red defects, you know they are the worst kind and most costly to repair. A reduction in red beads is an improvement, an increase is the opposite, the same number is consistency (good or bad). Watch out for trends either per worker or per iteration. 11 Reactions First worker <name> I've told you that the customer will only accept white beads, red beads are not acceptable. Did you mix the material and hold the box completely flat like I told you? Did you hold the sampling paddle at precisely 44 degrees? Well you must not have been paying attention! Next worker (2) <name> can you please make us a batch of white beads? Remember all that I've told you. Repeat the appropriate instructions again Follow instructions! If the next sample is better Well <name> that is better than <name> BUT you must not have been paying attention either. If the next sample is worse Awful! You cant have been paying attention Next worker (3) Let me repeat the instructions once again. repeat the appropriate instructions <name> its your turn to follow the process Remember that the customer will only accept white beads. 12 Reactions for individuals Whilst sampling Don’t shake the box when pouring! Don’t shake the paddle! Follow instructions! Whilst agitating the beads – no more! If they stand in the wrong place is this where you belong? Get over here! Wrong angle no gymnastics! Excellent technique 8cm not 10cm! If the target of 5 or less is met If <name> can get down to x then anybody can do the same. Its perfectly obvious Follow procedure and anyone can do it! If a high number is found What happened? Disastrous! Should we stop the line to find out what happened? An improvement Now you are taking the job seriously. That’s what we need improvement! 13 A high performing worker One of our best workers. 14 A good first iteration You were all trying hard and wanting to make a good impression You have listened and learnt the process BUT Your job is to make white beads not red ones There seems to be a misunderstanding on what your job is. A bad first iteration I thought the job and the procedure was explained clearly? Your job is to make white beads not red ones There seems to be a misunderstanding on what your job is. Look at the burndown Ask the recorder to flick between the grid and the iteration burndown How are we going to deliver with production levels like that? 15 Before second iteration The calibration iteration is now over You are now fully trained and understand the process. No more than 5 red beads is acceptable If you produce more than 5 red beads it will be recorded and go on your record All you have to do is follow procedure We have a merit system here for performance A better second iteration Obviously you have learned by experience. BUT Your job is to make white beads not red ones Why don’t you understand? A worse second iteration You are getting complacent after your first weeks results. Costs are overrunning revenue thus far Try for better results or we may get shut down Your job is to make white beads not red ones Why don’t you understand? Look at the burndown Ask the recorder to flick between the grid and the iteration burndown Terrible! Don’t you realize what I have committed to the customer? 16 Third iteration appraisals and stretch target There seems to be a misunderstanding about what the job is Its to make white beads, not red ones Your yield is slow Variation is incomprehensible You are trained and procedures are rigid There should be no variation There will be appraisals at the end of this iteration based on the performance of the last 3 iterations. Incentives Anyone who can get 2 defects or less will get a £1 0 is acceptable, as is 1 We reward good performance We penalize bad performance Lay the money out on the table If the team only makes 12 defects then we will have pizza and beer evening! 17 Third iteration good results Call out the total iterations numbers This was to be expected due to appraisals looming Now we are seeing improvement BUT Is it good enough to keep us in our jobs? It wasn’t good enough for pizza and beer! Third iteration worse results Call out the total days numbers Were you all nervous about your appraisals? I cant understand why you aren’t improving. Whats wrong with you? Did you forget about the £1? Did you forget you could have had pizza and beer? Look at the burndown Ask the recorder to flick between the grid and the iteration burndown Our customer is not going to be happy with this Benjamin, can you make the team work harder Are they spending too much time surfing and chatting? 18 Merits and probation Recorder can you add up the numbers to determine the 3 best Highlight them on the spreadsheet Call out the names of the 3 best Ask them to group together I explained we have a merit system here Talk to the best 3 workers You have received a merit We should all congratulate them Round of applause The worst 3 workers are now on probation Try for better results Any day may be your last day on this job 19 Performance Appraisals There seems to be some difficulty in understanding the job No more that 5 red beads – no one has come close it it! The procedures are clear We have awards for our standards BUT Costs are overrunning revenue Management are watching the numbers We are going to conduct appraisals Conduct the appraisals 20 Appraising Someone who improved <name>, you started off bad and then improved slightly. You have got to do better. Someone up and down <name> you started off bad, then you improved, then you fell off the wagon again, and then improved again. You need to pay closer attention to your work and gain more consistency. Someone who was really poor at the beginning <name> you started off terrible and then you finally caught on. You have the same problem as <name>, you need more consistency. Best employee <name> your the best employee in the department, but you still have room for improvement. You could be the first employee to earn the zero defects button that the manager talked about at the employee meeting. Needs to improve – worst worker 1 <name> your performance needs to improve. Your overall rating was good. You can do better if you stop all that talking I warned you about. Distracted – worst worker 2 <name> you need to pay attention to your work. You started off good and something must have distracted you. I think it was all the talking with Worker <name>. 21 Prior to Forth iteration - sacking worst workers I have been informed that unless we show substantial improvement, they are going to cancel the project. As I explained at the outset, your jobs are based upon your own performance. Your performance has been miserable. I came through with a fantastic suggestion to save the project Instead of closing the project down, we are going to keep it going with our 3 best workers. Those with a real “can do attitude” We are going to sack the worst 3 workers. We cant afford to make so many defective products. Sack the worst 3 workers. Shake each one by hand and thank them for being such willing workers You did your best, pick up your pay as you go by the window Ask them to sit back down. 22 Best workers The remaining workers will do double shifts We have to keep up production There is no doubt that this will work Nothing can go wrong using our best workers Productivity will improve! Forth iteration after first sample Cant understand it We should be seeing better performance Forth iteration – first shift good results This was to be expected by retaining the best workers My idea to keep the best workers was correct The worst workers were holding us back They didn’t have the right attitude Forth iteration – first shift worse results You have all become complacent about keeping your jobs There is nothing wrong with my idea to keep the best workers The worst workers were holding us back You dont have the right attitude After the first shift ask the first person to do their second shift After the forth iteration 23 What happened? I was looking for improvement, meeting the target by keeping the best 3 workers BUT we costs are still overrunning revenue Look at the burndown Ask the recorder to flick between the grid and the iteration burndown We aren’t going to meet our deadlines How am I going to explain your poor performance to the customer? Closing the project down Management have decided we are going to have to close the project down. Shake each one by hand and thank them for being such willing workers You did your best This goes on your record Pick up your pay as you go by the window Ask them to sit back down. 24 Intimidation <name> - I need to talk to you. Didn't you hear me when I gave all these people instructions on how to make white beads? What were you doing at the time, dreaming? I thought you said you wanted a job. We bring you here, give you clear instructions, show you how to make white beads and you still don't do it. What's the matter with you? Now I'm telling you people, you all better start paying attention or I'll have to fire all of you. <name> - it's your turn. 25 Praise and Comparison Worker draws a sample and it comes out at a few colored beads. Now that's much better. <name> you are catching on. <name> got the same instructions as the rest of you and he is now beginning to master the process. He was almost twice as good as <name> We are going in the right direction now. <name> you especially need to watch <name> and see how he did it. In fact, the rest of you should all watch <name> and see how he does it. <name>, it is your turn. 26 Banners and Slogans <name> draws a sample and it turns out to be HIGH. Now all of you listen up. We have firm quality standards at this factory. Didn't you read the quality banners on the wall? See that poster on the wall over there Quality is critical to our survival as a company and you know what that means for all our jobs. This company has to get the silver star quality award. It is crucial to our success in the market place. 27 Improvement <name> please show us how it's done. <name > draws and sample and it come out to be lower than the last person. The project manager then walks over and talks to the chief inspector. ker <name>, here is a prime example of quality improvement. You see once I pointed out to everyone that we are really serious about people started to improve. While today wasn't the best I'm sure we'll do better tomorrow. (while walking over to the best worker) Worker <name>, excellent job. Keep up the good work. 28 Blame HIGH NUMBER of beads drawn The project manager is very upset that things are going bad after he has told management that things were improving. He then goes over to the chief inspector and discusses the problem with him. Walk over to the inspector I'm really upset. These people don't care. Here you give them a good job and show that it is possible to improve and what do they do, ignore you and make life easy for themselves. I think these two are spending too much time talking to one another and not paying attention to their job. I think that I'll warn both of them about their performance and tell them if I catch them talking again that I'll have to discipline them. 29 Performance and trends The product owner and project manager should now take on the role of explaining the results to the audience. The focus can now be on the graph and the noting of the various trends. The same praise and blame is offered for the trends. An evaluation of the trends for each iteration and an overall comparison of each of the workers may be appropriate at this point, as you try to present the results with the best possible explanation. They would make special note that he sacked the 3 worst workers. 30 Lessons Learned form the Red Bead Experiment) This experiment may appear “stupidly simple” BUT many profound messages will have emerged as you watched. The objective of the bead factory is to make white beads. The customer will not accept anything but white beads, all red beads are defective. The red beads themselves represent defects in an organization's business processes. They represent a faulty machine or tool, a bad engineering design, a defective part, a procedural flaw, an unreasonable change request, ... all the things that can and do go wrong with a process. Supervisors and management control the number of red bead in the processes that are given to the workers. Separate into groups to hold a retrospective on what lessons can be learnt. Can the workers, inspectors, recorder and customer divide yourself up amongst the groups. We will take 10 mins in groups and we can then discuss the findings. Think about what are the red beads in your company. See separate lessons learnt document Using the 14 point slide as a reference and discuss Ask each to present and discuss with the audience their observations. Then hand out the lessons learnt etc If asked there are 4000 beads, 800 red and 3200 white 31 Statistical process control chart The chart represents a stable system. We can predict that another 4, 8, 12 iterations would show the same variation. Planning requires prediction, sometimes you have a good basis for prediction, sometimes none. Here we have something to help us plan with. Dr Shewhart showed us when to look for special cause and when not to. A special cause is anything that is not built into the system. Common cause is anything that is. Charting the results of common causes you can establish the upper and lower limits of the system and predict in the near future what its going to do. Would you have halted the line at a high number? In the red bead experiment nothing special happened They poured the beads and scoped them up. The inspectors counted red beads and the recorder wrote them down, happened every time. Nothing else happened. Whatever caused one worker to scope up a high number of red beads and another to get a low number must be in the system. Its part of the variation that already exists. To treat variation as common causes as something special you will wind up tampering with the system, and making it worse! The lesson is that variation exists in any process. There are common and special causes for it. We have to learn to tell which is which. If we can then we can understand the system. The control limits tell you the variation of the system If all points are within the UCL and LCL then we have a stable system. This is good news, as we arent going to be surprised and can predict the future. 32 With a stable system we can predict with a high degree of belief limits of variation in the near future. Not too far in the future as the environment may change. In the near future you would expect the variation to stay in these limits. We can plan based on the average. That future workers using the paddle will extract somewhere between LCL and UCL red beads. AND the workers cant change it. Which is why you cant rate the workers based on what the system does. You are instead rating the system. Ranking the people is pointless. The top 3 this time might be the bottom 3 next time. What was best in the past is no help to us at all, as the system was causing the variation. Different workers respond in different ways on different days, its all part of the system. In the experiment the system was at fault. There was no attempt to modify the system, change the materials etc You have a customer for white beeds maybe you can find one for red beads. We did everything wrong, work standards, too much inspection. The only thing we did right was to keep the inspectors separate. This gives us independent opinions. The management has to do the looking, the worker cant. Management was blaming the willing workers instead of improving the system. When you rate people you are really rating the system. People work within the system. It’s the management job to work on the sytem. 33 Its their job to improve the incoming material. Costs are not causes, costs come from causes. We need to work on the causes. Western management is great at managing failures, too late. You need to work on the causes. In business today management looks at the red beads and worries about them, but they dont look at the system that made the red beads. In summary, this demonstration can be a lot of fun while still making a number of dramatic points. The use of participants keeps people involved and active. If you get involved and act out the roles, the class will do likewise. The more the instructor customizes the experiment to the class the better it will be received. Use phrases that are common to the work place. Finally, the power of the experiment is only limited to the creativity of the instructor. 34