The Wal-Mart RFID Vision

advertisement

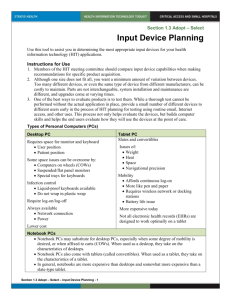

EIS Final Project RFID Technology A Comparative Study of E-ZPass and Wal-Mart Jose Malpartida, Sebastian Martinez Matias Moral, Avraj Sandhu, Phillip Wittwer 1. Technology overview RFID, or radio frequency identification, is a technology that allows for communication between two devices by means of radio waves. Thus neither a direct line of sight, nor a physical connection is needed. The first device is a reader or antenna, the second is a so called tag. Readers are more complex and expensive devices, whereas the tags are meant to be cheap and produced in high numbers. Tags can be very simple, for example they could transmit a short id code, similar to a bar code, that is powered by an electromagnetic field. Else, they can be more complex: they could be written to, perform calculations for authentication like a pay-tv chipcard, and contain a power source to increase range. Depending on the application, a major share of effort needs to also be put into an operations infrastructure acting on the data received by the antennas, for example time tracking of employees or billing for payment solutions. History The technology was first developed for military aircraft in the 1950s and 60s to allow identification of friendly planes, as the pure radar signature did not answer this question. The first patents for a RFID tag used to unlock a door touch less were awarded in 1973. In the 1980s first applications for toll collection, as discussed in this article, were developed. With ongoing miniaturization ongoing and decaying prices, in particular for tags, more and more potential applications were thought out. There was a major buzz around RFID in the late 90s and early 2000s, as it was envisaged to have a RFID tag on every coke bottle and a reader on every fridge, so the fridge would know how much is left and could order new goods automatically. Potential industries: The versatile features of RFID tags lend the technology to use in a variety of different industries: 1. Toll booth payments: RFID tags are a naturally good fit for this industry. Traditional toll booths require a person to be staffed at all times. In addition, the process can be inefficient since traffic slows down to make payments. Finally, drivers have to deal with the hassle of cash and receipts. Systems like E-ZPass install transponders with RFID tags in cars that are connected to pre-paid accounts. The car can drive through toll booths with RFID scanners without stopping. The RFID technology has been used very effectively here. 2. Retail: RFID tags can be used for retail environments like electronic stores or big box retailers in multiple ways. Suppliers can ship products to retailers with RFID tags either at the individual unit or collective (e.g. pallet) level to identify the contents of the package. This has several advantages for the retailer. Firstly, retailers can detect the contents of multiple packages at a time by simply passing them through a scanner (as compared to the manual process required with bar codes). In addition, retailers can use RFID scanners on shelves to track stock-outs on store shelves in real time to refine optimal inventory levels. Finally, RFID scanners can provide touchless, seamless checkout at retailers. 3. Smartcards: Smartcards are cards with embedded RFID chips that have been used in a variety of different applications ranging from ID cards for offices or colleges to passes for public transportation (e.g. Oystercard for the London Underground). The touchless nature of RFIDs makes them very useful for these purposes as people can simply wave their card near the scanner instead of having to swipe it physically through a reader. 4. Healthcare: The healthcare industry has enthusiastically embraced both active and passive RFID technology. Active technology is used to scan frequently moved or high impact items, while passive technology is used for lower-cost items that don’t need to be tracked as well. The Mayo Clinic reduced its error rate from 9% to 0.05% by deploying RFID technology. 5. Military: RFID tags have been widely used in the military, especially in the U.S. because of their usage in tracking military equipment ranging from packs of ammunition to tanks. Given the high cost of these items and the importance of being able to accurately track them to avoid losing them to the enemy, RFID tags provide a more accurate way to track items. Nonetheless, there are some security issues that have caused concerns about their implementation, e.g. enemies being able to read RFIDs on the guns of soldiers in the field to detect their positions. 6. Manufacturing: RFIDs can be used very effectively in supply chain environments such as car manufacturing. In a car manufacturing factory, several different models might be manufactured at the same time. So, each car can be fitted with an RFID tag that uniquely identifies its model and types of features that need to be installed. So when the car reaches the painting stations, the painting machine reads the RFID tag to figure out that the car needs to be painted red. 7. Animal identification: RFID tags can be clipped on animals like cows for multiple uses ranging from identification (to be able to identify healthy cows from the ones infected with mad-cow disease) to feed tracking (being able to track how long a cow has spent at the feeding trough). Challenges in implementation The difficulty of implementing an RFID based system depends on a variety of factors: Price of the infrastructure (readers and tags) compared to asset value, new processes and backend IT systems needed, number of players involved in the ecosystem and employee inertia in accepting new processes. In general, the more complex a system needs to be before any value can be created, the more challenging implementation will be. In this paper we will look at two industries: Toll collection with the example of E-ZPass, where RFID has been successfully implemented and retail by the example of Wal-Mart, where implementation has been attempted twice, and has not yet taken off. 2. E-ZPass E-ZPass History E-ZPass is an electronic toll collection system widely used in states along the east coast of the U.S. First introduced in the late 90s, it is now very widely used along toll roads. The E-ZPass system was introduced to make the process of collecting tolls more efficient from the highway’s perspective, and more convenient from the driver’s perspective. The E-ZPass system makes very effective use of the touch-less nature of RFIDs. How it works: The driver pays a one-time fee of $20 to $30 (depending on the state) and EZPass delivers a transponder that is attached to the windshield of your car. The driver loads his prepaid account with a certain amount of money. The transponder contains an RFID tag that connects the driver’s individual pre-paid E-ZPass account. Now instead of driving through a regular toll lane, the driver drives through a special E-ZPass lane that contains an RFID scanner. When the driver drives through the toll booth the scanner detects the driver’s E-ZPass RFID and automatically deducts the toll amount. Advantages for the driver: 1. Speed: Drivers don’t have to stop at the toll lane and traffic moves much quicker through the designated E-ZPass lanes. 2. Convenience: Drivers don’t have to deal with cash, coins, or receipts. All they need to do is make sure their pre-paid account has enough money. 3. Discounts: The E-ZPass system at different times has offered different types of discounts, ranging from carpooling discounts, green emission discounts, and resident discounts. Advantages for highways 1. Less congestion: E-ZPass toll booths ensure that car traffic moves smoothly, thus reducing the bottleneck effect of toll booths on highways. 2. Less manual labor: E-ZPass is an automated system that does not require the large amount of manual labor that toll booths usually need. 3. Efficient detection: The E-ZPass booths have cameras for capturing number plates of toll offenders. All these advantages are made possible by the following attributes of RFIDs: 1. Cost: RFID tags are cheap enough to not be a major cost in the transponder unit. 2. Touch-less: RFID technology allows touch-less scanning of tags by a scanner a few feet away. Ecosystem map: The E-ZPass ecosystem consists of 5 players: E-ZPass themselves, the highway authorities sponsoring it, politicians influencing these, technology providers and drivers using the system. Politicians Drivers Highway authorities E-Z Pass Technolog y provider Value prism: In the late 80s, when implementation of electronic toll collection systems was first discussed, the political will was to phase-out toll collection completely, which would have cost the highway authorities not just a revenue stream, but also a part of their ‘raison d’etre’. In an effort to make toll collection more convenient for drivers and thus more acceptable, seven highway authorities located in three states founded E-ZPass to create one system that could be used by all drivers in that area and would allow for quicker adoption as compared to a solution just backed by one authority. These circumstances led to the highway authorities driving the ecosystem and supporting E-ZPass. The authorities were also in a position to easily outfit existing toll collection booths with the required technology, signs and lanes, as they are the operators of these. All technology, including RFID tags and readers as well as the operational aspects were coordinated by E-ZPass. Drivers either buy into the E-ZPass system or continue to use the regular toll lines and thus interact directly with the highway authorities. As in the Wal-Mart example, technology providers are not the driving force in this ecosystem. However, they profited from the success and the fact that units had to be switched earlier than expected due to battery lifetime issues. Drivers were brought onboard by offering discounted fares, which offset the investment into the RFID device. Furthermore, they benefited from the faster process. Usage did not decline later on, as monthly fares were introduced. Today, drivers benefit even more as they do not have to slow down in special express lanes. E-ZPass itself was tightly run by the highway agencies, thus involved to get the system to life with the backing of the highway authorities. Politicians are interested in keeping drivers happy, as they represent a majority of the voters. Participant Drivers Costs One-off purchase of device Politicians No removal of toll collection Highway agencies Massive investments into infrastructure Change from employing toll collectors to technicians Coordinate across different states and agencies Lower revenues due to decreased fares Coordinate among 7 agencies in 3 states Full exposure to political and technical risks E-ZPass Benefits Faster drive through toll collect stations Lower toll fees Making process easier for drivers Secure ‘raison d’etre’ with investment Collect higher fees from violators Reduce number of employees Less clogging of highways Balance Positive Positive Positive Create business Neutral model with potential for future growth Information on customer accounts Technology providers Exposure to political risks Investments into infrastructure Usage statistics Reference use for RFID technology Big deal Positive Price vs. Convenience comparison: Toll booths Price E-ZPass Convenience E-ZPass is more convenient than traditional toll booths for drivers. Drivers don’t have to deal with cash, coins or receipts. Also, they don’t have to stop for the toll booths, thus improving the overall speed of their journey. In addition, E-ZPass offers discounts to drivers for several reasons – from general discounts to green emission discounts, to resident discounts. Although the cost of the system is a one-time fee of $20 to $30, the fee can be easily recuperated if the driver uses E-ZPass enough. So, overall, E-ZPass performs better than traditional toll booths for drivers in terms of both convenience and price. Use of RFID technology: Overall, the use of RFID technology in E-ZPass transponders was very successful. Even though RFID tags were more expensive in the late 90s when E-ZPass was first introduced, the tag itself made up a very small part of the overall cost of the transponder. Because of this, a more expensive tag only meant a difference of a few cents, and the cost could easily be passed down to the user. The critical feature of the E-ZPass system design was that each car only needed a single RFID tag. As we will see in future sections, this is a stark difference as compared to Wal-Mart which wants to implement RFID tags on every individual product, in which case a difference of a few cents in the cost of a tag has a major impact. Summary of RFID tags for E-ZPass: The main reason for E-ZPass succeeded was the will and power of the highway authorities, as their buy-in was assured right from day 1. The technology, although a critical enabler, was not the key driving force. Thus, the majority of the investments could be taken on by the authorities who were also taking the risk and benefiting from the ecosystem. In addition, E-ZPass provided benefits for all the players involved, thus making it a win-win proposition across the board. 3. Wal-Mart Background: The Wal-Mart RFID Vision Wal-Mart has always held innovation as a critical part of their competitive strategy. From the push it made to the adoption of the barcode standard in the retail industry to the introduction of the Retail Link system, the world’s largest retailer has always demonstrated a drive to invest in the new technologies that would enable its growth and provide them with an operational advantage in the market. As a part of that vision, Wal-Mart was the first big player in retail to explore the benefits that RFID can create in their supply chain. In this paper, we will explore the vision that Wal-Mart had for the application of the technology and why it failed to materialize. Potential benefits of RFID Technology for the Retail Industry An extensive list of benefits can be found, when you start thinking about the potential benefits that RFID can bring to the retail industry. Although Wal-Mart clearly understands the full potential of the technology (with state of the art functionalities), the following paragraphs try to illustrate a realistic view of the benefits that Wal-Mart was pursuing with its first attempt to implement RFID in 2003. - Prevention of stock outs. By having online information about inventory levels at shelf, stock outs can be dramatically reduced. In this initial attempt, Wal-Mart was not thinking about having individual tags for every SKU. Instead, they requested supplier to introduce tags at a case level. With tags at this level, Wal-Mart was going to develop an in-store process to monitor inventory on shelves by tracking cases that moves from the back store, into the store, and by case boxes that were destroyed once SKUs were placed on shelves. - Optimize shelf space usage. With more detailed information in a shelf level, Wal-Mart could reduce inventory levels (buffers) they need to have on shelf to prevent stock outs. However, the most important benefit for Wal-Mart consists in the opportunity of having more shelf space in stores to offer new products. Given the cost of shelf space, and its direct relationship with sales, this benefit can have a huge impact in the store performance - Improve customer shopping experience. Less stock outs in stores clearly impacts the shopping experience by eliminating the need of buying alternative products when the one you are looking for is not available. However, it is important to mention, that in this first attempt Wal-Mart was not considering eliminating the need of scanning products at checkouts (tags were not going to be placed at an SKU level), which could have had a considerable impact in the customer experience. - Save handling time in receiving and stocking orders in stores. Tags at a case level also impacts the time it takes to receive and process orders from the suppliers. Having the possibility of automatically scan products and incorporate them on the systems when being unloaded from the truck and moved into the store, can have an important impact in productivity in the back room of stores. - Save handling time and labor in distribution centers. With the same reasoning showed in the previous point, productivity can be also increased at distribution centers where handling times and labor costs are key variables to measure the performance of this type of facilities. - Reduce theft, both from employees and customers. This was another of the key benefits Wal-Mart was trying to address in the first attempt. Although, items were not going to be tagged at a SKU level, having better information in terms of location of products (split vs back room and store) will make it easier to track unauthorized out flows of products and identify the sources of the problem. At Distribution Centers, the impact will be even bigger, since products are handled in cases, and cases are tracked with tags. Total inventory levels will be online and adjusted constantly, and therefore it would be easier to track differences on time to address the problem. - Gather better data on promotion and placement effectiveness of different locations in the store. By having online information of shelf inventory levels and tracking the speed products are selling, Wal-Mart can measure product performance in different places within the store. This data is relevant both for the retailer and the consumer goods company since it provides quantitative information of the results of specific promotions and the impact that locations within the store has on sales. Whether Wal-Mart would like to share or not this information is another issue, but it could clearly be used by Wal-Mart to negotiate with its suppliers. The last paragraphs tried to present the benefits Wal-Mart was envisioning in its first attempt to implement RFID on its operations. Hopefully, many of the benefits mentioned would contribute to boost sales, one of the biggest objectives of this initiative. However a full implementation of the technology can bring additional benefits, i.e., RFID tags on every product, and it is relevant to understand them since they might explain and justify the constant efforts Wal-Mart has made in the last years to implement this technology. - Elimination of waiting times – With the full implementation, there will be no need to wait in lines in stores any more. An implementation at a SKU level can let Wal-Mart eliminate waiting times at checkouts. A cart full of tagged products can be automatically scanned and consumers will just need to swipe credit cards to pay for the orders. A further step, the inclusion of tags on the credit card could also eliminate the need of swiping cards at checkouts reducing times even more. - Save labor at check outs – Given the last benefit mentioned, there is also an important saving for Wal-Mart associated with the considerably reduction of labor at checkouts. - Considerable reduction of theft at all levels. Having information of all SKUs gives Wal-Mart the change to monitor all product flows and notice when products are leaving the facilities with no authorization. Moreover, if tags are embedded in the product packaging, stealing products clearly becomes harder. - Implementation of cross selling - When imaging the full potential of the technology, Wal-Mart was also thinking about spot advertising and targeted promotions to consumers when they are shopping in the stores. Let imagine for a second that Wal-Mart can identify what consumers have on their carts. With a very simple use of database marketing, WalMart can suggest to consumers products that they may be interested in given what it is on their carts. In other words, Wal-Mart might be able to replicate what Amazon is currently doing in its webpage when it suggests what other products consumer usually buys after buying on particular product. This benefit can have an incredible impact in sales. Timeline of Wal-Mart RFID Program Wal-Mart has launched various efforts since early 2003 to mandate the adoption of RFID in its supply chain. Attached is a timeline of the events that took place from the on-set of the initial mandate, to a modified attempt in 2007 (Sourced from Supply Chain Digest). Among all of these events, we highlighted what we thought were critical momentum shifters in the long term viability of the plans: June 2003: Wal-Mart’s then CIO Linda Dillman announces the start of the retailer’s EPC compliance program at a meeting of the VICS organization, saying Wal-Mart would ask its top 100 suppliers to begin tagging pallets and cases starting in January 2005. August 2003: Wal-Mart says it will require all of its suppliers to put RFID tags carrying Electronic Product Codes on pallets and cases by the end of 2006. "We have asked our 100 top suppliers to have product on pallets employing RFID chips and in cases with RFID chips. By 2006, we will roll it out with all suppliers," Wal-Mart spokesman Tom Williams says. November 2003: Wal-Mart brings the “top 100 suppliers” into Bentonville to learn more details of its RFID program, qualifying its previous announcement by saying the initial requirement will be for the first 100 to tag pallets and cases being shipped to three Texas distribution centers (DCs) in January 2005. April 2004: Wal-Mart begins its RFID trial by receiving cases and pallets of product with EPC tags at a single distribution center in Sanger, TX as part of a test being conducted with eight suppliers. The tagged goods are to track goods to the back of seven Wal-Mart stores in Texas served by the DC. The first eight suppliers, which each tagged just a small number of SKUs, were Gillette, Hewlett-Packard, Johnson & Johnson, Kimberly-Clark, Kraft Foods, Nestlé Purina PetCare, Procter & Gamble, and Unilever. June 2004: Wal-Mart meets with its top 100 and "next 200" suppliers in Bentonville to lay out its RFID tagging requirements and timeline. Suppliers are told that by June 2005, RFID systems will be operating in up to six of its distribution centers and 250 stores. WalMart further says that it expects to be using EPC technology in up to 13 distribution centers and 600 Wal-Mart and Sam's Club stores by the end of 2005. Deadline for the “next 200 suppliers” to start tagging cases and pallets is set for January 2006, though what shipments to what DCs is not clear. October 2004: Wal-Mart says it plans to start shipping RFID-tagged cases and pallets to a Sam's Club store in Plano, Texas very soon, starting the division’s RFID program. January 2005: Many, but not all, of the “top 100” start shipping some tagged products to three Wal-Mart DCs in Texas. March 2005: CIO Linda Dillman says Wal-Mart is on track to support RFID capability in 600 stores and 12 distribution centers by the end of the year. October 2005: Wal-Mart says that by the end of this month, it will have installed radio frequency identification systems in more than 500 stores and five distribution centers. October 2005: Wal-Mart says it expects the next wave of 300 suppliers (making 600 total) to start shipping tagged cases and pallets by January 2007. October 2005: A Wal-Mart sponsored report from the University of Arkansas’ Information Technology Research Institute, a part of the Sam Walton College of Business, releases a report based on its preliminary study of the impact of RFID on reducing retail out-of-stocks (OOS). The researchers conclude that RFID reduced OOS at store level by 16% over non-RFID based stores. January 2006: Wal-Mart says it is piloting a program with a few suppliers and EPCGlobal to generate advance ship notices for supplier shipments based on RFID reads. January 2006: Supposed deadline for the “next 200 suppliers” to begin sending some tagged product to some DCs, though relatively few do in any meaningful way. March 2006: Wal-Mart says it is working on two “proof of concept” pilots for using sensors along with RFID tags to track produce and environmental temperatures as the products move along the supply chain. April 2006: Wal-Mart says it will phase out the use of Gen 1 tags by in favor of Gen 2 by mid-year, saying it will no longer accept the use of Gen 1 tags on the cases and pallets it receives from its suppliers after June 30. April 2006: Linda Dillman leaves as CIO to take an executive role in Human Resources. Rollin Ford, previously head of supply chain and logistics, becomes CIO. Ford subsequently takes a much lower profile approach to RFID. September, 2006: Wal-Mart announces that by January 31, 2007, another 500 of Wal-Mart's 3,900 stores will have RFID readers installed. If it happened, that would bring the total of RFIDenabled Wal-Mart stores up to 1,000. February 2007: The Wall Street Journal runs an article entitled "Wal-Mart's RadioTracked Inventory Hits Static." The article says, "Wal-Mart Stores Inc.'s next leap forward in ultra-efficient distribution is showing signs of fizzling," given a lack of internal progress in rolling out the technology and a lack of value for suppliers. Rollin Ford writes rebuttal letter to the WSJ, and Wal-Mart finds the CIO of Campbell’s Soup and the chairman of Smucker’s to support RFID value prop. Meanwhile, CIO of Sara Lee says at the same time that RFID isn’t making sense at the current level of cost and performance. October 2007: Wal-Mart announces a major change in its RFID strategy, largely abandoning the initial pallet/case focus on shipments going to Wal-Mart stores in favor of three focus areas: (1) shipments going to Sam’s Club; (2) promotional displays and products going to Wal-Mart stores; (3) tests to see RFID’s impact in improving category management in select areas. "We're coming at RFID from a different angle," Wal-Mart's VP of Information Technology, Carolyn Walton, says at the EPC Global conference. January 2008: Wal-Mart announces its first real compliances “penalties” for failure to tag products, specifically for shipments to its Sam’s Club chain. Wal-Mart says in letter to suppliers that a failure to tag pallets sent to its distribution center in DeSoto, Texas, or directly to one of its stores served by that DC after January 31 will be charged a service fee, starting at $2 per untagged pallet on Feb. 1, and capping at $3 per pallet on Jan. 1, 2009. Wal-Mart also announced its plans for the Sam’s Club rollout (which was later changed). January 2009: Sam’s Club dramatically lowers penalties for failure to tag pallets from $2-3 dollars per pallet to just 12 cents – what Wal-Mart estimates it will cost Sam’s to do the tagging itself. It also pushes back the rollout schedule announced the previous January, saying the tagging requirement will apply only to pallets sent to the DeSoto DC or stores served by that DC in 2009. DC. Pallet-level tagging is expected to be rolled out chain-wide in 2010, while the deadline for tagging sellable units is "under review." February 2009: Procter & Gamble says that after “validating” the benefits of RFID in merchandising and promotional displays, it is ending its pilot program with Wal-Mart for those displays, implying Wal-Mart is not acting on the information to improve store execution. The retail store RFID Ecosystem CPG’s RFID Tags RFID Readers RFID and ERP connection RFID Integrators Logistics, distribution Other Retailers RFID Tags manufacturers: They can be integrated or not, in the sense they produce only the chip, or they produce the whole tag. They expertise lies in mass production of semiconductor technology. Tags can be passive, active, only reading or write and read. RFID readers manufacturers: They can be integrated with the antenna manufacturers or not. They expertise lies in designing circuits and electronics. They readers vary by range, precision, resistance to interference, wavelength at type of frequency (UHF, RHF) RFID and ERP connection: They designed the software and middle ware that handles the RFID readers, and also the connection between that system and the ERP system most companies use. RIFD integrators: Some are vertically integrated and manufacture tags, readers and software or a combination of some of them. But there are also some that only offer the integration and consulting services to join all these different pieces into an application the different participants in the retail industry can use. CPG: Consumer product companies are the first link in the retail value chain, and are the most likely candidate to attach the RFID tags. They sell to Wal-Mart, other big retailers and also to big distributors that then reach smaller retailers. Distributors and logistics: This category could include big distributors, logistics operators, trucking companies, warehouse companies, and distribution center companies. Other retailers: This category includes big retailers that compete with Wal-Mart, like target, supermarket chains, wholesale chains like Costco and BJ’s, pharmacy chains like Walgreen’s and CVS, and all other smaller retailers. Wal-Mart: For the ecosystem we consider Wal-Mart to depending of the level of RFID implementation, the Wal-Mart stores, their Sam’s Club stores, and their distribution centers. Wal-Mart RFID Initiative Ecosystem Analysis In this section we are going to analyze the ecosystem that Wal-Mart was facing at the time of the first RFID deployment. To that purpose, we are going to frame our analysis utilizing the ecosystem diagrams we learned in class and define what went wrong under each of the components that resulted in a failed a) Innovation Strategy Back in 2003, Wal-Mart communicated under the leadership of its then CIO, Linda Dillman, a mandate for its top 137 suppliers to start shipping RFID-tagged pallets and cases to three selected distribution centers beginning in January 2005. When Wal-Mart communicated this mandate, it had already defined an innovation strategy and the steps it needed to make to get it started. Wal-Mart dreamt of achieving a fool proof, error free, transparent supply chain utilizing RFID technology as the key enabler. Long before the mandate was announced, Wal-Mart had established their own RFID Lab in Rogers, AR and funded research conducted by the University of Arkansas’s RFID Research Center in order to understand the benefits the company could realize by implementing the technology in their operations. From our perspective, Wal-Mart’s RFID innovation strategy was rooted on: Establishing a competitive advantage by discovering the benefits of using RFID in the retail industry earlier than its competitors. Influence the nascent global standards for RFID data exchange However, what they really lacked was an understanding on how this technology adoption in the ecosystem was going to benefit is trading partners. b) Co-Innovation Risk The ecosystem at the time of Wal-Mart’s announcement had many risks related to innovations that technology providers need to make in order to make the viability of the initiative a success. Here is a list of some of the innovations that were required: - Develop a tag / reader configuration that could guarantee 100% read accuracy (HIGH): The performance of the tags before the initiative was to go live varied depending on the business process to be performed. For example, a key read point for the business case was the move from the back room of the store to the front. At this location, reads were taken at conveyors and box crushers that were only achieving between 50-90% accuracy. - Lack of widely adopted Electronic Product Code (EPC) standards (MEDIUM): The standards for RFID tag serialization and labeling had not yet been defined by the time of the announcement. GS1, the entity that controlled the supply chain management standards for barcodes would not define a final standard (EPCGlobal) for at least a few more months after the Wal-Mart announcement and even then it took many years to gain mass adoption - Need for RFID Middleware and Application to process read data (HIGH): Companies like Microsoft, IBM and SAP all jumped to the opportunity of developing the infrastructure necessary to enable the conversion of RFID data into actionable information. However, no application gained wide acceptance in the market. As a consequence, system integrators were bringing various software platforms, readers and tags that created confusion in the market - 5 cent RFID tags (HIGH): Finally, the biggest risk of all. For the implementation to be sustainable over the long term, RFID tags needed to reach a cost of $0.05 / case. This was not the case in 2003 and has not happened yet c) Adoption Chain Risk The key players in Wal-Mart’s RFID deployment ecosystem are: - Tag manufacturers Reader and hardware providers Software analytic companies System Integrators Wal-Mart’s Suppliers The first four players were very eager to jump into the business opportunities that the RFID mandate was creating. This was exemplified in the various startups that occurred from 20032005 while Wal-Mart was defining the details of the mandate. Therefore, adoption by these players was not a risk The real risk in the adoption chain was Wal-Mart’s suppliers. In a way, Wal-Mart unilaterally established the mandate to its top 100 suppliers by using its purchasing power as leverage. Suppliers did not have a clear picture on what benefits they were going to realize on the RFID rollout and as such were very cautious and slow in implementing the technology. As we could see from the RFID timeline, the number of tagged pallets and cases shipped to Wal-Mart’s DCs did not keep with the initial rollout timeline and many delays took place. “Compliance” became a new word that was frequently used among suppliers to gauge the level of engagement with the initiative and some suppliers opted for a tag “slap and ship approach” without any real RFID infrastructure investment in their operations. What we can learn from this is that Wal-Mart underestimated the adoption risks of this initiative. In retrospect, what Wal-Mart could have done to mitigate this risk is to include its key suppliers on the quantification of supply chain savings and its corresponding division. Moreover, education seminars on how to reap the benefits of the technology could have mitigated the confusion in the space. In reality, system integrators were the ones educating suppliers on the potential benefits of RFID in their operations. d) Execution Risk The execution risk of the mandate was greatly underestimated by Wal-Mart. The original timeline established for compliance with the mandate (January 2005) was very aggressive and did not take into account the co-innovation risks that needed to take place in regards to tags and systems to make it a reality. It also underestimated the knowledge curve that needed to take place for its suppliers to understand the value to be realized upon a RFID implementation. This was critical considering the large capital outlays associated with the initiative. Even within its own facilities, Wal-Mart was unable to meet the original timeline proposed internally for deploying RFID infrastructure in its distribution centers and stores. Is RFID an incremental or destructive innovation? Let’s consider the two key dimensions of process and user knowledge. Process In general RFID is not destructive to the participant’s processes and is basically and incremental innovation, by making it easier to identify and follow products, boxes and pallets during logistic, handling, shelving, and checkout. Let’s see it from the perspective of each participant. - CPG manufacturers: RFID could add features (ie. more data) but does not change the fundamental process of distribution of their products, they still have to put a tag on boxes and they still have to keep track of pallets. RFID would only change that they won’t have to directly scan any bar code in their processes. - Distributors, logistics operators: RFID does not change fundamentally how they run their process; it would mostly make it easier in an incremental way. Retailers: In terms of process RFID at least the first implementation are not destructive to the process of retailers. They still receive the merchandize in almost the same way, restock in the same way, the only process that could eventually change with RFID implemented at SKU level would be checkout, and even then it won’t be such a big change since self-checkout has been around for a while now. Knowledge Here is where the issue is more complicated. RFID technology does not imply a destruction of user’s knowledge per se. It is not like the ability of knowing how to scan a bar code will become useless, or had any value in the first place. But the deployment of RFID changes considerably the IT support and infrastructure companies need to have in place. To really reap the benefits of RFID supply chains participants will have to share information at level never seen before. Deciding what to share and what to keep will imply the development of new knowledge. System compatibility issues, and standardization of information will also force companies to develop new expertize. Today many databases of these companies have several issues in terms of reliability of information, which will need to be solved first. At the end it will force companies to hire new employees, and force some current ones to develop new skills. The advantage of having full, real-time visibility on the supply chain for a product from manufacturing to shelve will not yield the expected fruits unless accompanied by new data analysis, fast decision making, instant promotions, and new database marketing tools and skills. For each participant the degree of new knowledge to be developed will vary, but the main conclusion remains the same: On paper RFID sound great, but to make it work companies need knowledge that they do not possess today. Table : RFID disruption matrix for CPG, logistics, and retailers Knowledge Destructive RFID Incremental Incremental Destructive Process The Leadership Prism on Wal-Mart’s RFID Mandate To evaluate the leadership prism on Wal-Mart’s RFID mandate and identify who was better positioned to drive the initiative we put a side by side comparison on the benefits, costs and surpluses of the various players in the ecosystem. It was not a surprise that Wal-Mart emerged as the player that was to benefit the most from this engagement. However, Wal-Mart failed in its approach to have its suppliers, the biggest losers in this initiative, benefit from the introduction of the technology and mitigate their adoption risk in the rollout. Thus, we can conclude that Wal-Mart should have being more strategic in its approach to driving development activity for the initiative. As we studied in the Pixtech case, sometimes the player that will benefit the most from the implementation of an innovative strategy needs to postpone the realization of its own business benefits in lieu of securing development and adoption by the members of its ecosystem. In retrospective, Wal-Mart should have focused its first efforts on: - Building an environment for suppliers to learn about the benefits of RFID Developing alliances with relevant system integrators and hardware providers to seek standardization of technology Create a clear benefit delivery roadmap for Wal-Mart and its suppliers Find below a table that shows the estimated benefits and cost for each of the players in the ecosystem: (These figures were estimated on just the volumes of the initial 2003 mandate only) Benefits Wal-Mart 1. Prevent stock-outs 2. Optimize shelf space usage 3. Improve customer shopping experience 4. Save handling time in receiving and stocking orders in stores 5. Save handling time and labor in distribution centers 6. Reduce theft, both from employees and customers 7. Gather better data on promotion and placement effectiveness of different locations in the store 8. Boost sales It was estimated that Wal-Mart can see increased sales of $300 million per year, by having the inventory visibility and not incur on stock outs (Figures based on a full scale rollout with 100% compliance by all global suppliers) For the purposes of the 3 DC's originally targetted, we could reduce the benefit to 5% of the total opportunity size, which give an opportunity of $15 million 1. Better visibility on the raw materials needed to carry out their production, effectively reducing working capital Suppliers 2. Monitor products with low fill rates at Wal-mart to prevent lost sales However, the exact delivery process for the benefits were unclear and hard to quantify Potential of large tag sales based on the mandate adoption Tag Manufacturers The estimated sales per year on tags in average for each of the top 100 suppliers was approximated to be: $7.6 million (19 million shipments X $0.40 per tag) Estimated Cost Surplus Benefit of reduced sales on The cost for rolling out RFID the 3 DC's infrastructure and systems across their selected distribution centers can $15 million increased sales be estimated to be $3 million for the $3 million investment = $12 three initial DC's million gain for Walmart Forrester estimated that the approximated cost, each of the top 100 Wal-Mart suppliers will incur on the initiative will reach the $10 million No surplus, in reality the initiative was mostly a cost of doing business with WalMart No surplus, losses of $10 million We estimated the cost of sales (inclusive of delivery of the tags) to be 80% of the sell price, Thus costs were $608M Margin opportunity of $152 Million We estimated the cost of sales (inclusive of delivery of the hardware) to be 70% of the sell price. Thus overall costs are $23 million Margin opportunity of $10 million We estimate the costs of sales for hardware (just licensing right for simplification) to be 50%. Thus overall software production costs are $9 million Margin opportunity of $9 million Thus, market opportunity for this mandate alone of $760 million in tag sales Reader and Hardware Providers Software analytic companies System Intregators New business based on Wal-Mart and suppliers buying RFID readers and other associated hardware Approximated hardware and infrastructure investment by supplier of $330,000 Market opportunity for new hardware sales over $33 million Opportunity to sell systems across the supply chain partners to enable the RFID data capture and create meaningful analytics. Opportunity per supplier of $180,000 Thus, market opportunity of $18 million Opportunity to service players in this ecosystem by selling solutions from We estimate the costs of sales for the hardware, software and tags integration perspective, as well as to hardware (just licensing right for provide consulting services for a nascent industry. Opportunity per supplier Margin opportunity of $7.2 simplification) to be 40%. Thus overall $127,500 million software production costs are $5.2 million Thus, market opportunity approx $13 million Premium for Performance Bar Codes vs RFID Although bar codes have become the standard for identifying and tracking objects in the supply chain, RFID seems to have appeared to substitute this technology, by offering some key benefits that increase transparency across the product handling lifecycle. One of the benefits of RFID, is that there is no need for line of sight back to a reader whereas bar codes require a scanner to pass over each product. RFID enables pallets of products to pass through a stationary portal reader and the information is automatically captured. RFID can also read multiple tags simultaneously and they often have a longer life span than bar codes. Data capabilities of RFID are also superior. Product maintenance instructions, shipping histories, manufacturing and expiry dates are just a few examples of the types of information that can be programmed onto an RFID tag. This information can help track specific products as they move through the supply chain giving a detailed snapshot of how a product was handled from the moment it enters the warehouse to when it is purchased by a consumer. However, although RFID is offering interesting benefits compared to Bar Codes, it seems that the new technology doesn’t provide yet an appropriate performance/price balance, in terms of the price consumers are willing to pay for the expected performance of the new technology. The chart below is useful to represent the current status of both technologies given the current demand curve. Bar Code (point A) is right on the demand curve, providing a certain level of performance for a price that consumers are willing to pay. However, given the current performance that RFID (point B) is delivering, consumers find the respective price too high to think about a possible conversion. At this moment, we think that RFID technology must be following one of the possible paths represented in the chart, in order to find a good position over the demand curve. One option would be to decrease the total cost of the technology, considering not only hardware costs but also all other costs associated with the implementation of the technology (training, systems and risks; product vs. total costs framework). Another option would be to find improvements for the technology. In this sense, we believe RFID still has some room to prove that it can considerably impact one of the most important indicators in the retail industry, product sales. Preventing stock-out, one of the main benefits, doesn’t seem to be enough. To exemplify this situation, it is interesting to present a simple model we developed to simulate and compare the relative benefits and costs of RFID from the perspective of a supplier (Consumer Goods Company - CPG). Premium for Performance - Supplier’s Perspective – Minimum tag cost needed The relationship presented below shows a very straightforward set up to compare benefits and costs of implementing RFID in a CGP company. It only addresses the cost of incorporating tags in products, and it does not consider all the costs commented previously. However the exercise is valid, since if the technology doesn’t prove to be profitable considering just one cost category, it won’t work when other costs are included. Total profit = (quantity) . (profit margin – tag cost) + (incremental quantity sold) . (profit margin – tag cost) Since bar codes have proven to be a good solution for handling materials in an efficient way, we believe that RFID will be considered when it can have a considerable impact in sales (by the reducing stock outs, improving targeted promotions or the customer experience). Therefore, we are using the variable incremental quantity sold to measure the main benefit of the implementation of RFID. Let assume that we have an average CPG company with annual revenues of 12 billion dollars. Let’s say that given expensive and cheap products, the average price of each unit sold is 6 dollars. This implies that the company is selling 2 billion products annually. Based on industry standards, we can assume that on average, product profits are 20%, which implies in this case that the company is getting 1.2 dollars every time a product is sold. Let’s now start playing with costs and benefits. The benefits are represented by the incremental sales for a CPG. The costs are represented by the decrease of margins given the cost of tags. Supplier - CPG Basic Set Up Revenues Avg Price Units Margins Unit Margin Cost per tag in dollars Estimated incresed in sales 12,000,000,000 6 2,000,000,000 20% 1.2 0.15 5% No Tags Total Profit 2,400,000,000 Tags Profit with tags Extra sales Total Profit 2,100,000,000 105,000,000 2,205,000,000 Profit Increase -195,000,000 For a 5% increase of sales, and a 15 cents cost of tags, the situation doesn’t seem to be profitable (loss of 195M). Let see other scenarios (table below) by doing a sensitivity analysis using tag cost and sales increase as variables. Sales Increase 5% 10% 15% 20% 0.05 15 130 245 360 Tag Cost 0.1 0.15 -90 -195 20 -90 130 15 240 120 0.2 -300 -200 -100 0 A 20% increase in sales would be great scenario, however, it is difficult to justify that RFID can achieve a sales increase of 20%. Usually, stock-outs do not represent 20% of sales, and it is difficult to think that targeted promotions or customer satisfaction will have a contribution to achieve a 20% increase. Let say that it is reasonable to think that a sales increase between 5 and 10% can be achieved with today’s technology. With this base, the cost of tags needs to go down to 5 cents per tag to make the implementation feasible. However, it is important to remember that we are just considering the cost of tags, and therefore the situation can be even worse if we consider all the other associated with the implementation of RFID1. It is important to mention, that these numbers are aligned with many researchers and literatures that have also stated numbers below 5 cents as a minimum cost to enable CPGS to start thinking about RFID. 1. Total Implementation Costs - Infrastructure costs ( Readers at DC and Stores - Shelves, Doors, Forklifts, Registers), Software systems (Middleware, Applications), Processes (Organization change management, Training, Store layout adaption), Installation (System set-up, Labeling and encoding of items), Supplier goodwill, Public Relations risk In summary, although Wal-Mart is pushing hard to implement the technology, the analysis of relative benefit vs total cost analysis from a supplier perspective introduces some insights that may explain why the technology has not been approved by Consumer Goods Companies. 3. Conclusion Why did EZ pass succeed and Wal-Mart failed? Ecosystem issues: EZ pass was the correct leader of the ecosystem; they were bearers of most of initial costs of starting the ecosystem, but also most of the later benefits. Wal-Mart completely disregarded ecosystem issues in their successive attempts to use RFID technology. Failed to recognize that CPG’s where the key adopter and RFID did not necessarily made sense to them, they forced them to do it. Wal-Mart also forgot that CPg serve a number of other retailers and that a partial implementation of RFID only for Wal-Mart might never be economically viable for them. Failed to compensate important ecosystem players for their initial loses. Wal-Mart only saw their benefits never cared about other cost benefit equation for the RFID implementation. Technology and Knowledge issues: In both EZ pass and Wal-Mart case the technology implicated some kind of destruction either to knowledge, processes of both. But the difference is EZ seemed have been aware of this and at instead of running pilots to improve the technology and educate the participants, they started with a just a couple of highways. In a way they started with a minimum commercially viable option and grew from there, this proved the right choice since the first years where difficult and many issues had to be solved before being able to fully expand. Wal-Mart disregarded this effect and tried to by only market share power impose a standardization of the technology and failed to facilitate the training of ecosystem players so they could see the benefits of the technology in their processes. They did not actively engaged and associate with technology providers to figure and reach a standardization of RFID that was suited for all the players in the ecosystem. Price benefits issues: RFID tag prices are just too expensive for a SKU or box level implementation yet. The fundamental difference between EZ pass and Wal-Mart or in general retail implementations is that EZ pass needed only one tag per customer and many readers to work, rendering the price of the tags insignificant compared to other costs. The retail supply chain instead needs a huge number of tags and also a big number of readers to make it work, so adoption is very sensitive to the price of tags, and therefore to the current number of users. Prices won’t drop until mass production process are developed, something that will not happen until producers can envision mass adoption.