Validation - reveiw and summary

advertisement

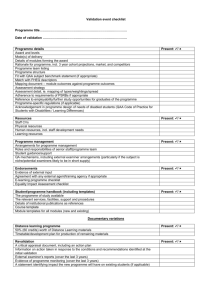

Supplementary Training modules on Good Manufacturing Practices Validations –part 2 Pharmaceutical Quality, Good manufacturing Practice & Bioequivalence Kiev, Ukraine 3 - 7 October 2005 Maija Hietava M.Sci.Pharm Quality Assurance and Safety: Medicines, Medicines Policy and Standards, Health Technology and Pharmaceuticals Cluster Tel: +41.22.791.3598 Fax: +41.22.791.4730 World Health Organization E-mail: hietavam@who.int © WHO – PSM Validation principles Objectives To review: WHO validation definition Philosophy of validation Personnel requirements Protocol requirements DQ IQ OQ and PQ summary Checklist for validation © WHO – PSM Validation WHO validation definition The documented act of proving that any procedure, process, equipment, material, activity or system actually leads to the expected results. © WHO – PSM Validation The VMP The VMP provides a summary of the company’s philosophy, policy, intentions and approach to validation. © WHO – PSM Validation The WHO GMP Guidelines state: Validation studies are an essential part of good manufacturing practice and should be conducted in accordance with predefined protocols. written report and conclusion process and procedures processing testing cleaning procedures © WHO – PSM Validation Quality is designed and built into the process/method/premises Functionality, consistency and repeatability is confirmed by validation © WHO – PSM Validation Validation as such does not improve the process but it confirms and assures that the process Has It It been well developed is well maintained operates as it should © WHO – PSM Validation Advantages of validation: During the process the knowledge of process increases Assures the repeatability of the process Assures Assures the fluency of production that the product is continuously according to the marketing authorisation Decreases Decreases the risk of the manufacturing problems the expenses caused by the failures in production Decreases the risks of failing in GMP Decreases the expenses of the every day production even though the validation itself will create expenses © WHO – PSM Validation Personnel - Validation team members Quality Assurance Engineering Manufacturing Other disciplines may be involved depending on the product and process: laboratory, technical services research and development, regulatory affairs clinical chemical engineering purchasing/planning © WHO – PSM Validation Protocol development (1) Identification of process Objective and measurable criteria Length and duration of the validation Shifts, equipment Identification and quality of utilities Identification of operators and operator training and qualification © WHO – PSM WBS/Validation of clean area VALIDATION Clean area Premises - HVAC System - LAF Units - Cold Storage - Env. Monitoring - Facility Cleaning - Transfer hatches - Verifi. of classific. Aseptic Processing - Media Fills Utility Systems Manufacturing Support Syst. - Water systems - Plant Steam - Pure/Clean Steam - Process Gases - Sterilizers - Depyrogenators - SIP Systems - CIP Systems - Washing - Waste Systems - Fermentors - Scales - Incubators - Filtration Units - Filling Equipment - Computerised systems In-Process Control Personnel Training Packaging & Labeling - Packaging - Labeling - Process Measurem. - Visual Inspection - Label Control - Sampling Equipment - GMP - Gpwning valid.. - SOPs - Equipment - Processes © WHO – PSM Manufacturing Processes - Fermentation - Separation - Purification - Filtration - Filling Analytical Methods - Chemical - Cleaning valid - Physical - Sterility tests - Biological - Stability Validation Protocol development (2) Complete description of the process Relevant specifications and tests Samples and sampling methods Special controls or conditions Process parameters to be monitored Methods for controlling and monitoring © WHO – PSM Validation Protocol development (3) Objective and subjective criteria used to evaluate the product Definition of non-conformance Statistical methods Maintenance and repairs Criteria for revalidation Criteria for change control © WHO – PSM Validation © WHO – PSM Validation GMP Inspector’s check list for validation (1) Check that the manufacturer has: A VMP and multi-functional team for validation Planned approach , defined requirements Identified and described processes Analyse the amount of validation work to perform © WHO – PSM Validation GMP Inspector’s check list for validation (2) Check that the manufacturer has: Selected methods and tools for validation Created protocols Performed DQ, IQ, OQ, PQ and documented results Exerted change control, set revalidation time © WHO – PSM Validation Summary Validation A quality tool that makes lot of sense A prevention-based activity= important part of quality building process Expensive in the beginning later will "save the money back" In danger of becoming overwhelming Risk-based assessment of what needs to be validated or verified The process must be under control/validation as such does not improve the process Logical entity: protocol + procedure + report © WHO – PSM Validation Summary cont… Validation - Logical entity: protocol + procedure + report © WHO – PSM