View/Open - Daffodil International University

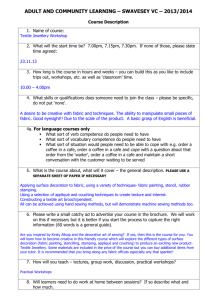

advertisement