Victoria: Providing Complete Capability

advertisement

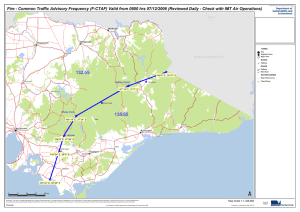

Victoria: Providing Complete Capability Land Message from the Premier Victoria has shared a long and proud association with defence and civil aviation in Australia. In fact, the RAAF Williams base at Point Cook is the birthplace of the Australian Flying Corps - the precursor to the Royal Australian Air Force. The tradition continues to this day as Victoria underpins the Australian Defence Force's ability to plan, train and defend our nation. Victorian-based companies are leading the world in innovation and new technologies to produce world -class defence and aviation-related equipment in the areas of aerospace design and materials, avionic and electronic systems integration, simulation and airspace management. Victoria’s defence-based capabilities incorporate the sky, land and sea. Our state leads in military vehicle design, manufacture, assembly and systems integration. Our complex system design, world -class testing facilities and naval shipbuilding has highlighted us on a global scale. We lead the Joint Strike Fighter global supply chain, with our companies supplying 70 per cent of Australia’s contribution to the world’s most advanced strike fighter program. The Victorian Government is nurturing an environment which will maximise industry participation in collaborative networks to access global aviation and aerospace supply chains. We believe access to global opportunities will help energise the economic future of the defence industry and our state. The defence industry is central to the Victorian Government’s plans for the future of the Victorian economy and is one of six future growth areas the Government is targeting through the $200 million Future Industries Fund. Victoria is a leader in aviation and aerospace, including the state’s renowned airports and airline services, and we are known as a global hub for training within this sector. Furthermore, the civil aviation and aerospace industry is a major contributor to the state’s economy as it facilitates tourism activity and inbound investment. Our aviation and aerospace industry is known to be highly innovative, competitive and capable. The Victorian Government is geared to assist businesses in grasping the opportunities to participate in the defence industry, na tionally and globally. Specialist Victorian aerospace and aviation companies are ideal for forming joint ventures and business partnerships to undertake complex projects. The Victorian Government welcomes new business and is here to help defence, aerospa ce and aviation companies to thrive. The Hon Daniel Andrews MP, Premier Message from the Minister for Industry The Andrews Labor Government is proud of Victoria’s innovative, globally competitive, highly skilled and adaptive defence industry. The Government supports the highly capable defence and aerospace sector through dedicated trade missions, business development, investment attraction and export facilitation activities for companies based in this state. Support from the Andrews Labor Government will ensure that Victoria remains at the forefront of the defence industry. Victoria is home to a highly trained and skilled workforce, coupled with world -class innovation, research and development institutes that focus on high-performance and specialised products. The combined factors of manufacturing and design capability, a skilled workforce and our strategic location with a sought after lifestyle have attracted international companies to base operations in Victoria — Australia’s innovation, knowledge and technology powerhouse. The Andrews Labor Government will continue to support Victoria’s defence industry to ensure it continues to grow as the leading-edge provider, serving the Australian Defence Force and global aviation and aerospace supply chains. Victoria is renowned as a centre for advanced manufacturing, and with more than 300 companies involved, the defence industry plays a major role. The success achieved from Victorian defence companies in global supply chain programs, such as the Joint Strike Fighter, demonstrates the abilities of Victorian-based companies to deliver leading-edge military technology. Together, Victoria’s advantages provide a positive and sustainable capability advantage for the future of Australia’s defence force. The Hon Lily D’Ambrosio MP, Minister for Industry Why Victoria, Australia Victoria designs, manufactures and delivers world-class, innovative capabilities to the Australian Defence Force and global customers. The State’s protected geographic location on the south-eastern edge of the Australian continent and historical strength at the centre of Australia’s advanced manufacturing industry have complemented the ADF’s strategic need to design, manufacture and deliver world-class, innovative capabilities to competitively equip and train the nation’s military forces. Twenty percent of the national APS defence workforce is based in Victoria, attracted by the State’s internationally competitive defence industry, highly skilled workforce, and world-class research and development (R&D) institutes, focussed on developing high-performance and specialised products to create and sustain capability advantage for the ADF. A commitment to innovation and active collaboration through networks and global supply chains has delivered competitive and diverse industry capabilities to equip and sustain the ADF domains of Land and Vehicles, Maritime, Aerospace, Electronic Systems, and Weapons and Munitions. Victoria is recognised as a: lead Australian state for the Joint Strike Fighter (JSF) global supply-chain work national hub for R&D of emerging defence-related technologies, including advanced composites, simulation, autonomous systems, and ICT lead Australian state for military vehicle design, manufacture, assembly and integration centre for naval shipbuilding, systems design, engineering and through-life-support lead national manufacturer of ballistic munitions and explosives major centre for ballistic protection for personnel, vehicles, aircraft and naval vessels leader in complex system design, development, integration and support provider of world-class testing facilities for new defence technologies prime location for training of ADF personnel and military trade skills Victorian industry also provides garrison support services to significant defence facilities and bases for the Army, Navy and Air Force, including: RAAF Base Williams RAAF Base East Sale Victoria Barracks, Melbourne Simpson Barracks, Watsonia Bandiana Joint Logistics Unit HMAS Cerberus DSTO, Fishermans Bend Victoria offers world-class, dedicated military training and testing areas at: Puckapunyal Training Area Albury-Wodonga Military Area Proof and Experimental Establishment (P&EE), Graytown Monegeetta Proving Grounds This significant defence presence, strong military design, development and manufacturing capacity, combined with the state’s stable economy, skilled workforce and desirable lifestyle has attracted international companies with defence capabilities to base either headquarters or significant operations within Victoria. These global capabilities, integrated with Victoria’s strong design, technology and manufacturing skills, position the state as Australia’s innovation, knowledge and technology powerhouse, equipped to sustain competitive ADF operations in complex, changing environments. INFOGRAPHIC VICTORIA’S DEFENCE AIRSPACE Centre of excellence for military training Home to the International Airshow – One of the premier Airshows of the Asia-Pacific World leaders in aviation and aerospace research, development and innovation; and education and training, including: o Swinburne University - Australian Advanced Manufacturing Research Centre o Royal Melbourne Institute of Technology - Sir Lawrence Wackett Aerospace Research Centre o Monash University - Monash Centre for Additive Manufacturing o Defence Materials Technology Centre o Deakin University - Australian Future Fibre Research and Innovation Centre o World class military training and testing areas o Puckapunyal Training Area o Albury-Wodonga Military Area o Proof and Experimental Establishment (P&EE), Graytown DEFENCE Science Institute Significant defence facilities and bases for Army, Navy and Airforce o Victoria Barracks, Melbourne o Simpson Barracks, Watsonia o Bandiana Joint Logistics Unit Victoria o RAAF Base Williams o RAAF Base East Sale o HMAS Cerberus o DSTO, Fishermans Bend Victorian companies have won 70% of the supply chain contracts for the Joint Strike Fighter (JSF) Program Providing complete capability – aviation and aerospace Right here in Victoria our companies are developing world-class defence equipment and leading the world in new innovations and technologies. Our dynamic and thriving industry supplies a range of vital AVIATION and AEROSPACE capabilities including: aerospace component manufacture, test, processing and certification design, manufacturing and testing of unmanned aerial vehicles and systems systems integration and engineering services maintenance, repair and overhaul advanced composite materials R&D and production simulation and modelling precision machining and tooling ground equipment, design and manufacture air traffic management systems military pilot training aerospace education Examples of the diverse range of globally competitive companies located in Victoria with aerospace and aviation defence capabilities include: AAI Aerosonde Able Engineering Industries Adacel Technologies Aerospace Materials Aerostructures Technologies Agent Orientated Software APV Safety Products AW Bell BAE Systems Beak Engineering Boeing Aerostructures Australia Cablex Cambridge Technologies Chemring Australia EDAG Australia Electromold GippsAero Hofmann Engineering Invenio Keech 3D Lovitt Technologies Lockheed Martin Marand Precision Engineering MEMKO Metaltec Precision International Ocean Software Pennant Australasia PHM Technology QinetiQ QuEST Global Engineering Ronson Gears Rosebank Engineering Australia (A RUAG Group Company) SYPAQ Thales Australia Transfield Services Trimcast Vipac YTEK PILLAR ONE: Competitive & experienced industry PILLAR TWO: Highly skilled workforce PILLAR THREE: Strategic facilities & infrastructure PILLAR FOUR: Research & development Pillar one: Competitive and experienced industry Victoria has a competitive and dynamic business environment. Our defence industry, comprised of more than 300 proven businesses, has an annual turnover of approximately $1.5 billion and directly employs around 6,000 people in the manufacture of equipment and provision of services to support national and international defence a ctivities. Victoria’s expertise extends across the state from Melbourne’s suburbs including Port Melbourne, Bayswater, Montmorency and Moorabbin, to regional centres of Geelong and the Latrobe Valley. This industry capability spans the state and is intertwined with the leading global defence primes. For example, Victorian industry, primes and SMEs currently support a range of active and emerging aerospace projects within the state: Thales Australia’s Centre for Advanced Studies in Air Traffic Management (CASIA) located in Melbourne, develops air traffic management solutions for civil and military customers Aerosonde designs, manufactures and services a range of unmanned aircraft systems BAE Systems Australia, located in Melbourne, conducts large scale aerospace platform support and systems engineering on behalf of the RAAF and RAN aircraft and helicopter fleets. BAE Systems is also an international centre of excellence for autonomous missions systems, utilising West Sale Airport for autonomous systems te sts and trials Boeing Aerostructures Australia (BAA) is Boeing’s largest manufacturing footprint outside North America and is Australia’s only designer and manufacturer of high-end composite aerostructure components for commercial aircraft Electromold Australia provides specialised surface coating and processing of commercial and defence components that go into Boeing and Lockheed Martin military aircraft such as the F/A-18 Super Hornet and the JSF Beak Engineering designs and manufactures bespoke ground support equipment including specialised ground power units (GPUs) for both military and commercial markets, and supports the RAST helicopter landing systems and other military aviation systems on board Royal Australian Navy (RAN) ships Marand Precision Engineering is the largest Australian supplier to the JSF program, manufacturing and delivering the vertical tails to Lockheed Martin’s JSF production plant in Fort Worth, Texas. Marand is also the sole global supplier of the JSF engine removal and installation trailer YTEK provides software engineering, modelling and simulation and associated specialist aerospace engineering services with a focus on the defence sector. Working closely with DSTO, YTEK develops new concepts and products for individual and command team training in the aerospace battle-management environment The Nulka missile system, an Australian innovation derived from a DSTO concept and engineered through a collaborative program between Australia and the US remains one of Australia’s largest and most successful defence exports. With three facilities in Victoria, BAE Systems is the prime contractor for the DSTO -developed Nulka system and remains responsible for the design, development and integration of the Nulka system Lovitt Technologies, located in Montmorency, manufactures highly complex airframe components for companies such as Boeing (F/A-18 and Chinook) and Lockheed Martin’s JSF program Victoria’s industry experience in aerospace engineering for both military and commercial application leads the nation. Victorian-based companies have demonstrated outstanding successes in delivering state -of-the-art solutions for national and global projects. The Victorian Government welcomes and helps enable investment in a diverse range of military and civil aviation and aerospace projects. Case study: Marand Marand is a prime example of Victorian ingenuity and enterprising spirit, adapting to the age of manufacturers relying on innovation and quality rather than scale for success: ideal traits for serving th e defence sector. This ingenuity has resulted in Marand becoming the largest Australian provider to the JSF program which includes exporting tooling to countries around the world. Primarily a machine-tooling specialist, Marand has spent the last 20 years transitioning its operations away from Victoria’s traditional automotive manufacturing sector to diversify into a number of key sectors, including aviation, defence, rail and mining. Operating two manufacturing and assembly sites in Victoria, one in south -east Melbourne and one in the nearby regional city of Geelong, Marand now dedicates around 60 per cent of its capacity to aerospace engineering projects, and is the largest Australian supplier to the Royal Australian Air Force’s new flagship fighter aircraft program, the F -35 Lightning II Joint Strike Fighter. Marand Chief Executive Officer, Rohan Stocker, said the company’s Victorian location offers a positive platform to partner with businesses internationally, and to thrive in the local economy. “A lot of our clients are from Europe, Asia and the United States. Melbourne is an attractive destination for our customers we don’t have many customers who aren’t happy to travel to Melbourne,” Mr Stocker said. “We find there’s a lot of international links into Melbourne: many companies have offices in Melbourne and there’s a lot of cross-cultural and personal links back into Melbourne, particularly throughout Asia. “Over the last 10 to 15 years the Victorian Government has provided support in our transition from automotive to aerospace, and we’ve certainly seen positive outcomes from government trade missions, grant programs and various business improvement programs.” As well as finding Victoria a place to do business globally, it has also provided a ready source of talent. With 270 employees across the business, including around 120 specialist manufacturing tradespeople and another 80 engineers, Marand has attracted a range of high-quality tradespeople and professionals from Victoria. “We find the general skills base in Victoria is strong,” Mr Stocker said. “We’re an engineering and innovation-based business, more-so than a straight manufacturer. We design the majority of our products ourselves, bringing something new to our customers. We solve problems for our customers, and can tie that back to being based in Victoria, where we have a ready supply of skilled workers with good education and strong industry experience. “The breadth of our capabilities is reflected in our aerospace and aviation work, particularly for defence projects. As Australia’s largest supplier to the F-35 manufacturing program, we will manufacture around 30 per cent of the vertical tails. “We also supply the engine installation removal trailer, which is the highest value piece of support equipment, and we’re one of the most distributed aerostructure tooling suppliers on the F-35 program, given we export tooling all around the world, including Canada, Norway, Denmark, the UK, the United States and to plants in Australia.” Pillar two: Highly skilled workforce The availability of a highly skilled, dynamic workforce is vital to generating and sustaining a competitive capability edge f or the defence industry. Victoria boasts leading world-class universities, research expertise and infrastructure. Victorian universities produce highly educated graduates through collaboration with industry. This ensures graduates have the skills businesses need. This is complemented by an industry-focused and responsive Vocational Education Training (VET) and skills sector to meet the needs of the defence industry – now and into the future. Victorians are highly educated. We have nurtured four Nobel Prize winners and Victoria is home to Australia’s largest share of university graduates. Two out of three Victorians hold a post-secondary qualification. One in three hold a university degree. The depth and breadth of Victoria’s workforce includes Australia’s largest share of science, engineering and IT graduates, along with one of the nation’s highest VET participation rates. An extensive range of professional and technical training relevant to the defence industry is on offer at universities and VET campuses throughout Victoria. Melbourne is consistently named the ‘most liveable’ city in the world, with high international rankings for stability, infrastructure, healthcare, culture and environment. Melbourne is culturally diverse and globally connected. In fact, out of five million Melbourne residents - 30 per cent speak a language other than English at home. Victoria’s outstanding quality of life, AAA-rated economy and international community assists in recruiting and retaining talented professionals. Case study: Sir Lawrence Wackett Aerospace Centre For more than 20 years, the Sir Lawrence Wackett Aerospace Centre has been making significant contributions to the Australian aviation industry, through its substantial and excellent research in aviation and aerospace. The Centre is internationally recognised for research into composite materials and more recently, advanced manufacturing. Other major research areas include avionics and air traffic control systems, unmanned aircraft, power energy and propulsion systems; and design certification and manufacturing processes. A number of Multinational corporations and local small to medium enterprises, including Boeing Research and Technology Australia, Defence Science and Technology Organisation (DSTO), Carbon Revolutions, United States Air Force Research Laboratory, Northrop Grumman Corporation, Thales, Airbus, Defence Materials Technology Centre, CRC -ACS, and CRCAuto have all benefited from a strong partnership with the Sir Lawrence Wackett Aerospace Centre. Professor Chun Wang, Director of the Sir Lawrence Wackett Aerospace Research Centre has led several collaborative research projects co-funded by the Australia Research Council and Boeing Research and Technology – Australia and Carbon Revolutions. Dr Reece Clothier, Deputy Director of the Sir Lawrence Wackett Aerospace Research Centre said the Centre has a long standing reputation in the industry for research excellence and capacity to solve c omplex industry problems. “The combination of world-leading researchers with world-class facilities provides a unique capability; one that is renowned for delivering research outcomes to the aerospace and defence sectors,” Dr Clothier said. “The recent Excellence in Research for Australia national assessment round ranked our research capability as above world standard. Global recognition of this excellence has helped us establish strategic partnerships with institutions and industry on almost every continent. “The Victorian State Government’s unwavering support has played a pivotal role in allowing businesses to engage with our research capability and ultimately nurture innovation and efficiency.” Pillar three: Facilities and infrastructure Victoria’s exceptional aviation and transport infrastructure network provides straightforward access to domestic and global markets. Melbourne Airport is Australia’s largest curfew-free freight and passenger airport, open for business 24 hours a day, seven days a week. This contributes to Melbourne’s position as one of Australia’s major transport, distribution and service industry hubs. The Port of Melbourne is Australia’s largest and busiest container sea -port, handling nearly 40 per cent of the nation’s container trade. It is an intermodal port, with excellent road and rail connections linking to the CBD, regional centres and interstate. Victoria hosts the RAAF’s major training facilities. RAAF Base East Sale, in Victoria’s Gippsland region, is home to several specialist training schools and is the base of the Victoria hosts the RAAF’s major training facilities. RAAF Base East Sale, in Victoria’s Gippsland region, is home to several specialist training schools and is the base of the renowned Roulettes aerobatic display team from the Central Flying School. Sale houses the RAAF’s: Air Training Wing Officers’ Training School No 453 East Sale Flight – air traffic control No 32 Squadron – King Air multi-role aircraft No 30 Squadron – Airbase Operations Central Flying School – flying instructor training School of Air Traffic Control School of Air Warfare Photographic Training Flight No 1 Expeditionary Health Squadron Detachment RAAF Base Williams was established in 1999 as a primary training facility f ollowing the merger of two of Australia’s longestestablished flying bases: Laverton and Point Cook. Point Cook was the birthplace of the Air Force and is credited as the oldest continually operating military airfield in the world. Laverton was the Air For ce’s third base, established in 1925. The Air Force Training Group assets at the Williams base include: ADF School of Languages Defence International Training Centre (cultural and military familiarisation training for foreign military personnel training in Australia) No 21 Squadron – Airbase Operations No 1 Security Force Squadron Detachment Williams Pillar four: Research and development Victoria is home to 10 universities including Australia’s leading university, ranked in the world’s top 40 - the University of Melbourne. Victoria’s intellectual capital is advanced by globally connected research institutes and a number of technology parks and innovation precincts. Victoria’s defence industry is a significant contributor to global innovation because of its strong focus on driving, developing and collaborating on R&D, including the adoption of emerging technologies from commercial markets. This enables Victoria to sustain its competitive military capability edge. This advantage, coupled with Victoria’s long and rich tradition of world class R&D makes Victoria Australia’s knowledge, innovation and technology heartland. As a result, world -leading technology and manufacturing enterprises have established R&D operations in Victoria. Nationally significant defence industry institutions are also based in Victoria. For example, the Defence Materials Technology Centre (DMTC), the Defence Science and Technology Organisation (DSTO), the Defence Science Institute (DSI), the Commonwealth Scientific and Research Organisation (CSIRO), and the Cooperative Research Centre for Advanced Composite Structures (CRC-ACS) all offer world-class R&D capabilities and reside in Melbourne. The DSI is a leading example of acclaimed researchers joining forces to create outstanding results. It is a joint initiative of the DSTO and the University of Melbourne, supported by the Victorian Government. The DSI’s cross -disciplinary research solves complex and long-term challenges for the Australian Defence Force. The DSI is a gateway to Victoria’s broader research ecosystem through formal partnerships with other universities and research institutes. Victoria is home to specialist aerospace education and research facilities, including the Sir L awrence Wackett Aerospace Centre in RMIT University. The Sir Lawrence Wackett Aerospace Research Centre partners with industry to lead fundamental and applied research into key research areas including: aerospace materials and structures avionics systems and through-life-support autonomous systems design, certification and manufacturing processes power, energy and propulsion systems The CRC-ACS at Monash University unites researchers, international companies and SMEs to develop advanced composites technology for markets within Australian and around the world. The Advanced Manufacturing Cooperative Research Centre (AMCRC) links into Monash, Swinburne and Deakin universities in Victoria to develop the next-generation technology, processes and human capabilities necessary for a competitive, knowledge-based industry of the future. The Australian Advanced Manufacturing Research Centre (AusAMRC) is a collaborative venture between Swinburne University and Boeing which undertakes projects designed to improve Austr alia’s global competitiveness in aerospace and advanced manufacturing. The Victorian Centre for Advanced Materials Manufacturing (VCAMM) partners with leading R&D organisations including Latrobe University, Deakin University, Monash University, Swinburne University and the DMTC to develop Australia’s effectiveness in the advanced materials and manufacturing industries. The development of Carbon Nexus and the Australian Future Fibre Research and Innovation Centre in Geelong are exampl es of initiatives for new advanced carbon fibre capabilities in Australia. Access to a workforce capable of driving innovation and R&D is essential for economic growth. It also increases the competitiveness of the Australian defence industry. Victoria is pushing technological boundaries through collaboration across industry, education and research. Partnerships between Victorian industry, research organisations and universities are developing and commercialising high-performance, specialised military products. By harnessing the talents of our academics and researchers, we are accelerating innovations for real-world application. Case study: Thales – Air Traffic Management Thales is recognised across the world for its market leading defence and civil systems , including leading air traffic management (ATM) systems, and its Victorian operations are playing a leading role in the global scope of the company’s success. In addition to its defence manufacturing sites at Bendigo and Benalla in regional Victoria, Tha les Australia has a 400-strong workforce at its Air Traffic Management division in the heart of Melbourne, providing leading software and hardware engineering that is a crucial part of Thales’s global ATM offering. After 20 years in Victoria, Thales’s ATM business has grown its capabilities to not only capitalise on healthy domestic demand, but penetrate the Asia-Pacific region and push into markets beyond. One example of the Melbourne division’s quality design and production is its ongoing contribution to Thales’s leading ATM system offering, which is a by-word for cutting-edge ATM around the globe. Thales Australia’s Vice President of Air Traffic Management, Adam Burford, said the Melbourne unit’s ability to integrate seamlessly with global operations has played a fundamental role in bringing Thales ATM technology to the world. “Within the global ATM domain for Thales, there are two key sites; one being France and the other being Melbourne. We share the technology, competency and responsibility for parts of the system through the transfer of technology,” Mr Burford said. “There were two different ATM systems developed in France and in Melbourne. In the European region, the specific requirement differed to that of the rest of the world in terms of how air traffic is managed. The system developed here in Melbourne, under the old EUROCAT-X name and now the TopSky name, has been developed to suit the needs of regions outside Europe.” Victoria’s ready supply of well-educated, keen minds and its strategic position as a launchpad into the Asia-Pacific region have proved invaluable for Thales’s ATM business. Future-proofing Thales’s ATM output at Melbourne is crucial, and the business maintains formal relationships with well regarded educators, including the Royal Melbourne Institute of Technology (RMIT), Monash University and Swinburne University, which all offer a competitive pool of high-quality engineering graduates. It is this home-grown Victorian talent, combined with knowledge and capabilities that fil ter seamlessly from Thales’s French operations, that has seen Thales Australia invest in a cutting-edge ATM research laboratory in Melbourne, which will continue to underpin the local division’s commercial success. Mr Burford said Australia’s integration into the Asia-Pacific region and its strong domestic market means the business is well placed to take advantage of its location, while using its superior knowledge and resources to continually drive commercial success. “In terms of ATM capabilities, Thales here in Melbourne is the only development-capable ATM manufacturer in the southern hemisphere,” he said. “We’ve grown our local capability to not only service the Australian ATM market, but also approximately 80 per cent of ATM systems sold into the Asia-Pacific region, which come from Thales in Melbourne. We have also sold into a number of countries outside of the Asia-Pacific region, including Lithuania, Mexico, various countries in Africa and more around the world. “In addition, the solid base of domestic Australian customers and the capabilities we develop jointly with them are big factors in our success. “Because of Australia’s location, we do see ourselves as part of the Asia -Pacific in terms of both adapting to the cultural needs of nations within the region, our time zone and our working style, all of which put us in a good position to leverage into the market. “On top of that, our ATM system is adapted for this region and our technology really is quite different. “We’ve enjoyed a good relationship with the Victorian Government over the years. Specifically, we received a supportive grant from the Victorian Government, which allowed us to establish our Centre for Advanced Studies in Air Traffic Management (CASIA) in Melbourne. Over the next 20 years air traffic growth across the region is likely to double, so the CASIA facility is working to develop the next generation of technology to make air traffic more efficient, to cope with the demands that increased air travel places on air traffic management. “We’re very thankful to have the support of the Victorian Government. It’s certainly helped us to leverage and sustain our position in the Asia-Pacific region, which commercially is a very tough market. But we’ve got the right product offering, and with the continued support of our Victorian capabilities, particularly our CASIA lab in Melbourne, we’re certainly in a good position.” Aviation and aerospace With a proud history as the birthplace of Australian aviation and recognised as Australia ’s powerhouse for advanced manufacturing, Victoria is positioned as the premier state to design, create and deliver highly sophisticated aerospace products and services. Competitive strengths include: strategic proximity to infrastructure and facilities for aeronautical uses, including curfew-free airports and sea ports a critical mass of Victorian-based global prime contractors with advanced technology and systems integration capabilities an internationally competitive, innovative industry supply chain with demonstrated capacity to design, assemble, integrate and deliver aerospace products to global export markets capacity to transition advanced design, prototype development, component production and engineering skills from Victoria’s advanced automotive manufacturing industry to defence and aerospace applications collaborative partnerships between Victorian industry, research organisations and universities focussed on developing and commercialising high performance, specialised products for defence and aerospace a world-class education system complete with training facilities to support future technologies and skills development a demonstrated commitment to R&D, technology diffusion and commercialisation an attractive lifestyle, supporting the recruitment and retention of talented professionals a supportive Victorian Government, focused on growing and sustaining an innovative, globally competitive defence and aerospace industry Victorian government’s active support The Victorian Government values the contribution the defence business makes to the Victorian economy and the role industry plays in delivering competitive capabilities to the ADF and global supply chains. The Victorian Government’s vision is for an innovative, globally competitive, highly skilled and adaptive defence industry that enhances its position at the leading edge of providers serving the ADF and global supply chains. The Victorian Government actively supports the state’s defence industry through: targeted investment advocacy, promoting Victoria as a competitive location for major defence prime contractors and projects facilitation of global collaboration by linking Victorian industry into international defence supply chains promotion of Victorian industry capabilities within domestic and international defence trade shows and missions provision of information to industry on defence market opportunities and procurement processes encouraging R&D through support for innovation and facilitation of infrastructure and new technologi es developing a highly skilled workforce facilitating effective stakeholder engagement across the Victorian defence industry to develop teams of SMEs with the capacity and agility to target defence market opportunities industry support to help companies improve productivity and competitiveness in global markets A key part of our commitment to the state’s defence industry is the vital strategic guidance and advocacy provided by the Government-appointed Defence Council Victoria. The Council plays an important role advising on defence industry issues and is a great asset for both the Government and industry for identifying and capitalising on opportunities for defence businesses. The Victorian Government, through the Department of Economic Development, Jobs, Transport and Resources (DEDJTR), will continue to work closely with the Commonwealth Department of Defence and the defence industry to identify and support strategic industry capability requirements, including domestic and i nternational aerospace projects. Back page Defence Industry Unit Department of State Development, Business and Innovation Phone: 03 9651 9311 Email: defence@dsdbi.vic.gov.au Web: www.dsdbi.vic.gov.au/defence