CARBOHYDRATES

advertisement

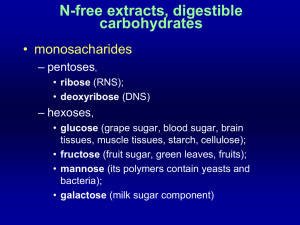

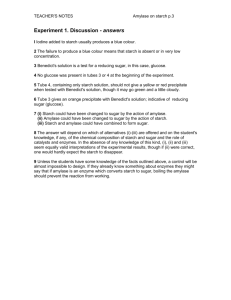

CARBOHYDRATES SUGARS, STARCHES, PECTINS, AND OTHER CARBOHYDRATES CHARACTERISTICS Organic compounds Carbon, Hydrogen, Oxygen Simple or complex Source of energy or fiber Important food CHOs - Sugars, dextrins, starches, celluloses, hemicellulose, pectins, gums FUNCTIONS SWEETENERS THICKENERS STABILIZERS GELLING AGENTS FAT REPLACERS MONOSACCHARIDES SIMPLE SUGARS MOST COMMON - 5 OR 6 CARBON GLUCOSE Dextrose Naturally present in fruit Basic unit for starches Less sweet than fructose Used in food industry because of water holding properties and ability to control crystals Food for yeast FRUCTOSE Levulose Part of sucrose Sweetest of all sugars In many fruits Very soluble Not easily crystallized Glucose isomerase to change glucose to fructose GALACTOSE Part of lactose – milk sugar Basic unit of pectic substances Building block of many vegetable gums COMMON MONOSACCHARIDES DISACCHARIDES Two monosaccharides Glycosidic bonds-readily hydrolyzed by heat, acid, enzymes SUCROSE Table sugar From sugar cane or sugar beet Glucose + fructose Invert sugar important in controlling crystallization Most common disaccharide MALTOSE Glucose + glucose Product of starch breakdown Corn syrup Flavoring and coloring agent in beer, candies, shakes LACTOSE Glucose + galactose Milk sugar Extracted from solutions of whey Not broken down or fermented by yeast Does not react in batter leavened with baking soda or baking powder Available for Maillard reaction so added to bakery products for browning DISACCHARIDES PROPERTIES OF SUGAR SOLUBILITY Solution in foods Varying degrees of solubility for monosaccharides and disaccahrides As temperature increases greater the amount of sugar that dissolves Slow heating increases the solubility As concentration increases boiling point increases Each gram molecular weight of sucrose increases boiling point 0.940F (0.520C) Can use temperature to determine sucrose concentration SATURATION Unsaturated – small amount of sugar in water, can hold more sugar Saturated – no more sugar can be dissolved Supersaturated – holds more than what is usually soluble at a certain temperature Supersaturation – heat to high temperature and cool slowly CRYSTALLIZATION Cool supersaturated solution Formation of closely packed molecules from the solidification of dispersed elements in a precise orderly structure Arranged around a nuclei Size of crystal depends on rate of formation of nuclei and rate of growth Crystals form too soon only a few crystals too large, continue to grow, candy grainy MELTING POINT/HEAT DECOMPOSITION Apply dry heat sugars melt to liquid state Sucrose melts and forms liquid that turns brown Carmelization – nonenzymatic browning, flavors food Noncrystalline HYGROSCOPICITY Ability to absorb moisture Responsible for lumpiness (sugar) Decreases staling in bread Gives stickiness for high moisture characteristics to foods Fructose most hygroscopic INVERT SUGAR Acid hydrolysis of disaccharide sucrose Heat increases hydrolysis Glucose and fructose in equal amounts (equimolar) Resists cyrstallization and retains moisture Add cream of tartar, vinegar, molasses (acids) Enzyme hydrolysis with invertase TYPES OF SUGARS CRYSTALLINE AND NONCRYSTALLINE GRANULATED SUGAR Crystalline – table sugar Sugar cane or sugar beet Affects texture of baked goods Improves body and texture of ice cream Fermented by yeast Retards growth of microorganisms Raw sugar banned by FDA Turbinado –raw sugar separated in centrifuge, washed with steam Retailed as fine or extra fine POWDERED SUGAR Pulverized granulated sugar Add cornstarch to prevent caking X designates fineness BROWN SUGARS From cane sugar – late stages of refining Crystals of sugar coated with molasses Contains invert sugar Sold in grades More refined lighter color, less flavor, lower grade – for baking – less flavor Higher, darker grades more flavorful and suitable for cooking strong flavored foods CORN SYRUP Acid and high temperatures to hydrolyze corn starch Varying degrees of sugars High fructose corn syrup (HFCS) from high glucose corn syrup – use enzyme glucose isomerase Significant use in food industry MOLASSES AND SORGHUM By-product of sugar production from sugar cane Mineral content varies Bitterness increases as refinement continues – blackstrap molasses Treacle – dark fluid left after sugar cane is processed Sorghum – from cane sorghum, similar to molasses MAPLE SYRUP AND HONEY Maple syrup from sap of mature maple trees Water evaporated, organic acids cause flavor Honey flavors according to flower nectars USDA has standards for grades of honey ALTERNATIVE SWEETENERS Non-nutritive – high intensity sweeteners Approved saccharin, aspartame, acesulfame-K, sucralose, neotame Except for sucralose not enough bulk to substitute in recipes Cyclamates – banned Sugar alcohols - polyols– improve bulk, mouthfeel, and texture SUGAR COOKERY CANDIES CRYSTALLINE CANDIES Generally soft Smooth, creamy with tiny crystals that cannot be detected with the tongue Fondant and fudge Use interfering agent to prevent early crystallization Must concentrate solution-test temperature to determine concentration Complete solution of crystalline sugar INTERFERING AGENT Interfere with size or rate of crystal growth Contribute to viscosity of syrup and elevate the boiling point Examples – milk, butter, cream, eggs, chocolate, cocoa, proteins, fats, dextrins, invert sugar, corn syrup NON-CRYSTALLINE CANDIES Amorphous No definite crystalline pattern Cook to very high temperature Adding large amounts of interfering agent Combination of methods Hard – brittles, high temperature, low moisture Chewy – caramels, high interfering agent Aerated – marshmallows, air trapped in protein foams and interfering agent POLYSACCHARIDES Complex carbohydrate polymers Properties depend on sugar units, glycosidic linkage and degree of branching Starches, Pectins, Gums most important Hydrocolloids – water loving colloidal substances STARCH Plant polysaccharide - linked glucose monomers GRANULES - formed in cells, grow by adding on layers Long-chain glucose polymers Insoluble in water Form temporary suspension SOURCES Characteristic of finished food depends on starch source Seeds, roots and tubers Cereal grains - wheat, corn, rice, oats Roots and tubers - potatoes, arrowroot, cassava STRUCTURE AMYLOSE AND AMYLOPECTIN AMYLOSE Straight chain or linear fraction 1/4 of all starch Thousands of glucose units Forms thick gels-hold shape when molded, rigid AMYLOPECTIN Highly branched 3/4 of starches Thickens but does not gel Proportion of amylose:amylopectin influences cooking qualities and keeping characteristics of finished food product AMYLOPECTIN STARCH CHARACTERISTICS Ability to absorb water limited In uncooked stage is insoluble in cold water - forms temporary suspension because polymer is too large Doesn’t change boiling point or freezing point of liquid Reversible EFFECTS OF HEAT DRY HEAT Heating - increases uptake of water Dextrinization Color and flavor changes Reduced thickening power Nonenzymatic browning Dry flour browned MOIST HEAT Complete absorption as heat increases - permanent swelling, irreversible Sol - as starch continues to come out of granules Viscosity-thickness, thinness of liquid Translucency increases during heating GELATINIZATION Sum of changes in first stages of moist heating of starch granules Gelatinized granules = opaque, fragile, ordered structure disrupted Temperature of gelatinization differs for each starch Short chains of amylose come out of the granules Irreversible changes CONTINUED HEATING Gelatinization requires addition of heat Cooking develops flavor Pasting occurs Granules swell Granules of starch swell independently PASTE CHARACTERISTICS Concentration of starch affects consistency Clear thickened gel made from root starches or waxy versions of starches Cloudy gels from cereal starches FACTORS AFFECTING GELATINIZATION ACID Fragments (hydrolyzes) starch molecule = thinner hot paste and less firm product Hydrolysis = less hydration of starch Add acid after gelatinization and after starch has cooked Applicable - lemon juice, vinegar, tomatoes AGITATION Over-stirring causes granules to burst, empty bound water = gel will thin Creates more uniform mixture OTHER FACTORS FAT AND PROTEIN- coats (adsorbs) to surface of granule = delays hydration Fat in pie crust to prevent clumping SUGAR - competes for liquid = delays absorption by granule = thinner mixture Elevates temperature for gelatinization ENZYMES - hydrolyze starch molecules TIME AND TEMPERATURE Lengthen heating time = causes granules to rupture - thins product More rapid heating = smoother paste Bring to boil over direct heat GELATION Formation of a gel when gelatinized starch is cooled Strong amylose bonds Elastic solid Retrogradation-reverting to crystalline state Syneresis - water loss during retrogradation, “weeping”-as water evaporates dried out rubbery matrix of starch Non-pourable, highly viscous SEPARATING AGENTS DEFINED - ingredients or additives which physically separate starch granules during hydration, allowing maximum hydration Prevents lump formation FAT -ROUX- forms film around granule = each granule swells independently of others COLD WATER- SLURRY-physically separates granules (hot water causes partial gelatinization) SUGAR-LIAISON - physically separates MODIFIED STARCHES Defined-starches which have been chemically altered to produce physical changes Will improve stability, convenience, performance during food processing Use acids or oxidizing agents FDA-regulations governing modification EXAMPLES PREGELATINIZED STARCH - gelatinized, dried, can reconstitute without heat (instant potatoes, hot cereal) Acid-modified starch - treated with acid slurry, forms strong gel upon cooling Cross-linked starches - acid resistant, resists rupture Cold water-swelling - instant starch that remains intact FUNCTIONS OF MODIFIED STARCHES Increase acceptability of product flavor and consistency Prevent retrogradation Stabilizers in conjunction with emulsifiers Improve freeze-thaw stability Prolong shelf life of frozen food by preventing oxidation WAXY STARCHES Commonly used in pie fillings Made from natural starches Practically no amlyose Thicken at lower temperature but no gelling Less retrogradation Barley, corn, rice, sorghum HIGH AMLYOSE STARCHES Genetic manipulation Form films and bind other ingredients PECTINS AND GUMS Polysaccharides Plant tissue Used as gelling agents, thickeners, stabilizers PECTIC SUBSTANCES Part of primary cell wall Hold cells together, hold skin on fruit Protopectin - immature fruits Pectinic acid- mature fruit, includes pectins Pectic acid - over ripe fruit PECTIN Dispersible in water Forms a sol Can be converted to a gel in the presence of water with addition of sugar or acid Attraction to water is decreased Pectin under skin of fruits melts with heat application (peel tomatoes, etc) PECTINS Commercially extracted from apple cores and skins; form white inner skin of citrus fruits Boiling too long - depolymerization occurs, gel may not set Boiling too short - insufficient invert sugar formed, sucrose may crystallize GUMS All are colloidal polymers (too large to dissolve) All are very hydrophilic All are thickeners in water dispersions Galactose most common sugar All are polysaccharides – EXCEPT for gelatin Examples: Guar gum, gum arabic, carob bean gum, carageenan, agar, xanthan gum USES Thickening agents replacing starch Stabilizers of emulsions Maintain smooth texture of products like ice cream All do not form gels