1 - Fusion Energy Research Program

advertisement

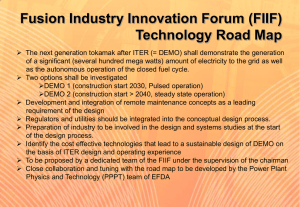

Preliminary Conceptual Design Study of K-DEMO Japan-US Workshop February 26th, 2013 Advanced Project Division National Fusion Research Institute kkeeman@nfri.re.kr Introduction Advanced Project Division Mid-Entry Strategy in 1995 Conventional Device (Cu) Superconducting Device ITER DEMO 1GW JET 1MW Fusion Power KSTAR TFTR JT-60U JET TFTR 1KW PDX JET/TFTR DIII-D DIII SC Device PLT ALCATOR C 1W 1965 T-3 (1968) 1970 ATC ALCATOR A 1975 1980 KAIST-T KT-1 SNUT-79 1985 1990 1995 2000 2005 2010 2015 2020 2040 Year 3 Advanced Project Division KSTAR Superconducting Tokamak Advanced Project Division KSTAR Device for 2012 Campaign 2* ECE-I + MIR (POSTECH, UCD) VUV (ITER KO) FIR Thomson, 5 J, 100 Hz (JAEA, NIFS) Reflectometer BES (8X8) (RMKI) Image Bolometer (NIFS) Div. IRTV NBI-1 2nd 100 keV, 2 MW, 10 s NBI-1 1st 100 keV, 1.5 MW, 10 s (KAERI, JAEA) 5 MD, Probes Da, VS, Filterscope (ORNL) XICS, CES (NIFS), ECE (KAERI, NIFS) BES (RMKI), CI/2D MSE (ANU), Interferometer, Bolometer (NIFS) SXR (KAIST), XPH (KAIST) Fast ion loss, Neutron (Hanyang U, ITER KO) ECH 84 GHz / 110 GHz 0.3 MW, 2 s ICRF 30-60 MHz, 1 MW, 1 s (POSTECH, GA) (KAERI) LHCD 5 GHz, 0.5 MW, 1 s RMP PS 4 kA/t (n=1, 2) ECH (170 GHz) 0.7 MW, cw (JAEA, PPPL) Advanced Project Division KSTAR In-vessel Control Coil System (3-D) Modular 3D field coils (3 poloidal x 4 toroidal) - all internal and segmented with saddle loop configurations - 8 conductors in each coil - Control capability : vertical control, radial control, error correction, RMP, RWM Wide spectra of Resonance Magnetic Perturbations (RMP) are possible - n=1 RMP (phase angles : +90, -90, 180, 0) and n=2 RMP (even or odd parity) n=1, +90 phase + + - + - - n=2, even parity - - top + - + - top + - mid - + - + mid + + bot + - + - bot - top BP n=1, 0 phase Schematics of IVCC and its conductor n=2, odd parity + + - - top + + - - mid + + - - bot + - + mid - + - + bot Advanced Project Division βN-limit and ELM Suppression KSTAR reached βN〉2.5 and βN/li〉 4.0 “no-wall limit” in H-mode Operation ELM suppressed by n=1 RMP (Ip = 600 kA, BT=1.6~2.3T) # 6123 Hα/ RMP 2012 New Data 2.7s 3.4s 4.3s Advanced Project Division Fusion Energy Development Promotion Law (FEDPL) To establish a long-term and sustainable legal framework for fusion energy development phases. To promote industries and institutes which participating the fusion energy development by supports and benefit. The first country in the world prepared a legal foundation in fusion energy development. History of the FEDPL • 1995. 12 : National Fusion R&D Master Plan • 2005. 12 : National Fusion Energy Development Plan • 2007. • 2007. • 2007. • 2012. 8 3 : Fusion Energy Development Promotion Law 4 : Ratification of ITER Implementation Agreement 8 : Framework Plan of Fusion Energy Development (The first 5-Year Plan) 1 : The 2nd 5-year plan has begun Advanced Project Division Vision and Goal of Fusion Energy Development Policy Vision Secure sustainable new energy source by technological development and the commercialization of fusion energy Phase Phase 1 (’07~’11) Phase 2 (’12~’21) Phase 3 (’22~’36) Policy Goal Establishment of a foundation for fusion energy development Development of core technology for DEMO Construction of DEMO by acquiring construction capability of fusion power plants Acquisition of operating technology for the KSTAR Basic Directions Basic Promotion Plan Policy Goal for Plan-2 Primary Strategy for Plan-2 Participation in the international joint construction of ITER Establishment of a system for the development of fusion reactor engineering technology Basic Promotion Plan 1 (’07~‘11) High-performance plasma operation in KSTAR for preparations for the ITER Completion of ITER and acquisition of core technology Developmentof core technology for the design of DEMO Basic Promotion Plan 2 (‘12~‘16) Basic Promotion Plan 3 (‘17~‘21) DEMO design, construction, and demonstration of electricity production Undertaking of a key role in ITER operations Completion of reactor core and system design of the fusion power reactor Commercialization of fusion technology Basic promotion plan 4 (‘22~‘26) Basic promotion plan 5 (‘27~‘31) Basic promotion plan 6 (‘32~‘36) R&D for DEMO Technology based on KSTAR and ITER Attainment of KSTAR high-performance plasma and development of DEMO basic technology Basic research in fusion and cultivation of man power International cooperation and improvement of status in ITER operations Commercialization of fusion/plasma technology and promotion of social acceptance Advanced Project Division Korean Fusion Energy Development Roadmap “Key Milestones” Pre-Conceptual DEMO R&D Launch & Design Study CDA DEMO Phase-1 DEMO EDA DEMO Final 10 Start Design & Constr. Construction Finish Start Advanced Project Division K-DEMO Tokamak Design Advanced Project Division General Requirement (Two Phase Operation) K-DEMO has two operation phases, Phase I and Phase II. Though the operation phase I K-DEMO does not need to demonstrate the competitiveness in COE(Cost of Electricity), the operation phase II KDEMO need to demonstrate the competitiveness in COE. All power core and plant subsystems in K-DEMO plant must be representative of those in the commercial plant. Extrapolation of technologies from K-DEMO to a commercial reactor should be straight forward. Practically all technologies to be used in commercial reactors should be demonstrated in the K-DEMO. Also, extrapolation of performance parameters between K-DEMO and commercial reactors should be minimized. K-DEMO shall be operated and maintained with remote handling equipment. This is an absolute prerequisite as the neutron level during operation and radioactive activation during maintenance periods will be excessive for human intervention inside the power core building and hot cell bioshields at all times The operation phase II K-DEMO plant need to achieve an overall all plant availability larger than 70%. The operation phase I K-DEMO is not considered as the final DEMO. It is a kind of test facility for a commercial reactor. But the operation phase II K-DEMO will require a major up-grade by replacing the blanket & divertor system and others if required. Construction cost for K-DEMO should be minimized and the size of the K-DEMO Tokamak is expected to be smaller or similar size of ITER Tokamak. The operation phase I K-DEMO • • • At initial stage, many of ports will be used for diagnostics for the operation and burning plasma physics study, but many of them will be transformed to the CTF (Component Test Facility). At least more than one port will be designated for the CTF including blanket test facility. It should demonstrate the net electricity generation (Qeng > 1) and the self-sufficient Tritium cycle (TBR > 1.05). The operation phase II K-DEMO • • Though there will be a major upgrade of In-Vessel-Components, at least one port will be designated for CTF for future studies. It is expected to demonstrate the net electricity generation larger than 450 MWe and the self-sufficient Tritium cycle . Advanced Project Division Optimization Concept of K-DEMO Demonstrate a reasonable net-electricity (> 300 MW) generation with a minimum cost Provide a maximum flexibility 8 βN 6 ARIES-AT CREST 4 ARIES-RS K-DEMO (Stage II) PPCS-D SSTR K-DEMO (Stage I) ITER 2 0 4 6 8 10 12 BT(T) Advanced Project Division K-DEMO Design Parameters Basic Parameter Option I Option II Option III Major Radius 6.0 m 6.65 m 7.15 m Minor Radius 1.8 m 2.0 m 2.2 m Elongation (k95) 1.8 Magnetic Field (Bo)/Peak Field 7.5 Tesla / ~ 16 Tesla Divertor Type Double Null (or Single Null) Bootstrap Current Fraction ~ 0.6 Normalized beta ~ 4.0 Safety Factor (q95) 3.5~5.0 Plasma Current > 10 MA > 12 MA > 13 MA Total Fusion Power (Neutron) 1700 MW 2130 MW 2721 MW Q-value 24 27 30 Total H&CD Power 70 MW 80 MW 90 MW Thermodynamic Efficiency 0.35 Gross Electric Power 767 MW 958 MW 1220 MW Recirculating Fraction 0.7 0.6 0.55 Recirculating Electric Power 537 MW 575 MW 671 MW Net Electric Power 230 MW 383 MW 549 MW Advanced Project Division DEMO TF CICC Parameter(Helical Spiral) Cable Pattern: (3SC)x4x6x6x(5+Spiral)[2160 SC strand] Void Fraction : 28.85% Strand : High Jc (> 2600A/mm2) Nb3Sn Strand Cu/Non-Cu = 1.0 R3 Helical Spiral : ID = 8 mm OD = 12 mm Insulation : 1.6 mm (with Voltage Tap) 0.1 mm Kapton 400% 0.3 mm S-glass 400% Jacket Thickness : 5.0 mm Twist Pitch • • • • • 1st Stage 45 ± 5 mm 2nd Stage 85 ± 10 mm 3rd Stage 125 ± 15 mm 4th Stage 245 ± 20 mm 5th Stage 435 ± 20 mm Wrapping Tape Thickness • • • • 5.0 Insulation Jacket 70.8 74.0 • • 1.6 60.8 • • 30.8 40.8 44.0 Sub-cable : 0.08 m 40% Sub-cable wrap width : 15 mm Cable : 0.08 mm 140% Final wrap width : 40 mm SC Strand Weight : ~600 ton DEMO TF CICC Cross-section Advanced Project Division DEMO Small TF CICC Parameter Cable Pattern: (3SC)x4x5x(6+Central Spiral)[360 SC strand] Void Fraction : 31.03% Strand : High Jc (> 2600A/mm2) Nb3Sn Strand Cu/Non-Cu = 1.0 Central Spiral : ID = 7 mm OD = 10 mm Insulation : 1.6 mm (with Voltage Tap) 0.1 mm Kapton 400% 0.3 mm S-glass 400% Jacket Thickness : 5.0 mm Twist Pitch • • • • 1st Stage 45 ± 5 mm 2nd Stage 85 ± 10 mm 3rd Stage 125 ± 15 mm 4th Stage 335 ± 20 mm Wrapping Tape Thickness • • • • Sub-cable : 0.08 m 40% Sub-cable wrap width : 15 mm Cable : 0.08 mm 200% Final wrap width : 40 mm 1.6 5.0 R3 Insulation 34.0 • • 20.8 30.8 • • Jacket 20.8 30.8 34.0 DEMO TF CICC Cross-section Advanced Project Division Inboard Cross-Section of TF Coil (Option I) R = 6.0 m, a = 1.8 m Small CICC Coil : 16 x 8 turns Large CICC Coil : 12 x 5 turns (Total : 188 turns) Magnetic Field at Plasma Center : ~7.72 Tesla (Bpeak ~ 16 Tesla, T-margin > 1 K) Nominal Current : 77.0 kA Conductor Length : • • LQP = ~777 m (Quadruple Pancake) Total : ~445 tons SDP = ~634 m (Double Pancake) Total : ~163 tons Clearance Filled with Glass Fiber (5 mm) Ground Wrap (5 mm) 2050 mm 2388 mm 2660 mm 2890 mm 2970 mm Advanced Project Division Outboard Cross-Section of TF Coil (Option I) Ground Wrap (5 mm) Space (Filled with 316) for Turn Transition and Feed Through (90 mm) 550 mm 106 mm Clearance Filled with Glass Fiber (5 mm) 278 mm 870mm 10910 mm 10990 mm 11210 mm 112310 mm 198 mm 11582 mm 11780 mm Advanced Project Division Inboard Cross-Section of TF Coil (Option II) R = 6.5 m, a = 2.0 m Small CICC Coil : 18 x 8 turns Large CICC Coil : 12 x 5 turns (Total : 204 turns) Magnetic Field at Plasma Center : ~7.72 Tesla (Bpeak ~ 16 Tesla, T-margin > 1 K) Nominal Current : 76.9kA Conductor Length : • • LQP = ~825 m (Quadruple Pancake) (Total : ~480 ton) SDP = ~680 m (Double Pancake) (Total : ~200 ton) Clearance Filled with Glass Fiber (5 mm) Ground Wrap (5 mm) 2150 mm 2633 mm 2905 mm 3135 mm 3220 mm Advanced Project Division Outboard Cross-Section of TF Coil (Option II) 106 mm Clearance Filled with Glass Fiber (5 mm) Space (Filled with 316) for Turn Transition and Feed Through (90 mm) 11810 mm 550 mm Ground Wrap (5 mm) 244 mm 880 mm 11895 mm 12115 mm 12215 mm 203 mm 12487 mm 12690 mm Advanced Project Division DEMO TF CICC Parameter(Option II-A) Cable Pattern: (3SC)x4x5x6x(5 + Helical Spiral) [1800 SC strand] Void Fraction : 28.1% Strand : • • High Jc (> 2600A/mm2) Nb3Sn Strand Cu/Non-Cu = 1.0 R3 Helical Spiral : ID = 8 mm OD = 12 mm 1.6 Insulation : 1.6 mm (including Voltage Tap) Jacket Thickness : 5.0 mm Twist Pitch • • • • • 1st Stage 45 ± 5 mm 2nd Stage 85 ± 10 mm 3rd Stage 125 ± 15 mm 4th Stage 245 ± 20 mm 5th Stage 435 ± 20 mm Wrapping Tape Thickness • • • • Insulation 68.8 72.0 0.1 mm Kapton 400% 0.3 mm S-glass 400% 58.8 • • 5.0 Jacket 26.8 36.8 40.0 Sub-cable : 0.08 m 40% Sub-cable wrap width : 15 mm Cable : 0.08 mm 140% Final wrap width : 40 mm DEMO TF CICC Cross-section Advanced Project Division Inboard Cross-Section of TF Coil (Option II-A) Selected for Detailed Study R = 6.8 m, a = 2.1 m Small CICC Coil : 20 x 9 turns Large CICC Coil : 12 x 5 turns (Total : 240 turns) Magnetic Field at Plasma Center : ~7.4 Tesla (Bpeak ~ 16 Tesla, T-margin > 1 K) Nominal Current : 65.52 kA Conductor Length : • • LQP = ~872 m (Quadruple Pancake) (Total : ~418 ton) SDP = ~810 m (Double Pancake) (Total : ~258 ton) Clearance Filled with Glass Fiber (5 mm) Ground Wrap (5 mm) 2150 mm 2619 mm 2925 mm 3135 mm 3220 mm Advanced Project Division Outboard Cross-Section of TF Coil (Option II-A) 118 mm Clearance Filled with Glass Fiber (5 mm) Space (Filled with 316) for Turn Transition and Feed Through (120 mm) 12210 mm 550 mm Ground Wrap (5 mm) 210 mm 925 mm 12295 mm 12525 mm 12655 mm 204 mm 12961 mm 13165 mm Advanced Project Division Inboard Cross-Section of TF Coil (Option III) R = 7.15 m, a = 2.2 m Small CICC Coil : 18 x 8 turns, Large CICC Coil : 12 x 6 turns (Total : 216 turns) Magnetic Field at Plasma Center : ~7.5 Tesla (Bpeak ~ 16 Tesla, T-margin > 1 K) Nominal Current : 77.6 kA Conductor Length : • • LQP = ~ 1102 m (Quadruple Pancake) (~643 ton) SDP = ~ 763 m (Double Pancake) (~218 ton) Clearance Filled with Glass Fiber (5 mm) Ground Wrap (5 mm) 2385 mm 2849 mm 3121 mm 3395 mm 3480 mm Advanced Project Division Outboard Cross-Section of TF Coil (Option III) 955 mm 550 mm Ground Wrap (5 mm) Space (Filled with 316) for Turn Transition and Feed Through (120 mm) 244 mm 106 mm Clearance Filled with Glass Fiber (5 mm) 13025 mm 13110 mm 13374 mm 13504 mm 204 mm 13776 mm 13980 mm Advanced Project Division Joint Scheme of Inner Magnet From PS (or Inner Magnet Lead) Inter Coil Joint Helium Feed Through Inter Coil Joint Layer Transition Layer Transition Layer Transition To Neighboring Inner Magnet Lead Advanced Project Division Joint Scheme of Outer Magnet From Outer (or Last Inner) Magnet Lead To Neighboring Outer Magnet Lead Advanced Project Division 3D Modeling of TF Magnet Advanced Project Division 3D Modeling of TF Assembly Advanced Project Division TF Coil Structure Advanced Project Division DEMO CS CICC Parameter (Corner Channel) Cable Pattern: (3SC)x3x4x4x6 [864 SC strand] Void Fraction : 37.19% Strand : ITER Type (Jc ~ 1050A/mm2) Nb3Sn Strand Cu/Non-Cu = 1.2 NO COOLING SPIRAL Corner Channel Jacket Thickness : 5 mm Insulation : 2.0 mm (with Voltage Tap) • • • • • • • 1st Stage 45 ± 5 mm 2nd Stage 85 ± 10 mm 3rd Stage 145 ± 10 mm 4th Stage 250 ± 15 mm 5th Stage 420 ± 20 mm Wrapping Tape Thickness • • • • 2 0.1 mm Kapton 400% 0.4 mm S-glass 400% Twist Pitch Sub-cable : 0.08 mm 40% Sub-cable wrap width : 15 mm Cable : 0.5 mm 60% Final wrap width : 7 mm R3 Insulation Jacket 5 40 50 54 • • 34 30 20 DEMO CS CICC Cross-section Advanced Project Division Cross-Section of CS Coils (Option I) 1296 mm Number of Turns : 14 (Total SC strand weight : ~120 tons) Number of Layers : CS1 & CS2 : 30 layers, CS3 : 24 layers Magnetic Field at Center : ~12.52 Tesla (Bpeak < 12.774 Tesla) Conductor Unit Length : 895 m (CS1 & CS2 : UL x 5, CS3 : UL x 4) Gap Between Coils : 50 mm 1620 mm 1420 mm 1420 mm CS1 & CS2 Coil 1896 mm 1896 mm CS3 Coils Advanced Project Division Magnetic Field of CS Coils (Option I) Magnetic Field • Field at Center : ~12.835 Tesla • Peak Field : ~ 13.086 Tesla • Maximum Flux Swing : ~81 V·sec Nominal Current : 44 kA (Current can be increased) Temperature Margin ~ 1.4 K Advanced Project Division Cross-Section of CS Coils (Option II) Number of Turns : 14 (Total SC strand weight : ~145 tons) Number of Layers : CS1, CS2 & CS2 : 30 layers Magnetic Field at Center : ~13.12 Tesla (Bpeak < 13.37 Tesla) Conductor Unit Length : 950 m (CS1, CS2 & CS3 : UL x 5) Gap Between Coils : 50 mm 1620 mm 1500 mm CS1 & CS2 & CS3 Coil 1976 mm CS3 Coils Advanced Project Division Magnetic Field of CS Coils (Option II) Magnetic Field • Field at Center : ~13.12 Tesla • Peak Field : ~ 13.37 Tesla • Maximum Flux Swing : ~93 V·sec Nominal Current : 45 kA (Current can be increased) Temperature Margin ~ 1.1 K Advanced Project Division Cross-Section of CS Coils (Option III) Number of Turns : 14 (Total SC strand weight : ~165 tons) Number of Layers : CS1, CS2 & CS2 : 30 layers Magnetic Field at Center : ~13.1 Tesla (Bpeak < 13.35 Tesla) Conductor Unit Length : 1070 m (CS1, CS2 & CS3 : UL x 5) Gap Between Coils : 50 mm 1620 mm 1730 mm CS1 & CS2 & CS3 Coil 2206 mm CS3 Coils Advanced Project Division Magnetic Field of CS Coils (Option III) Magnetic Field • Field at Center : ~13.12 Tesla • Peak Field : ~ 13.41 Tesla • Maximum Flux Swing : ~123 V·sec Nominal Current : 46 kA (Current can be increased) Temperature Margin ~ 1.1 K Advanced Project Division Test Samples of Conductors DEMO CS CICC(corner channel) & Large TF CICC (helical spiral) Thanks to Antonio della Corte & his colleagues (ENEA/ICAS) !! Advanced Project Division Concept of Vertical Maintenance (Pilot Plant) Vertical maintenance of all in-vessel components for Pilot Plant (PPPL) Case Enlarged TF VV (~150° C) Semi-permanent Inboard Shield structure (~350° C) Internal VV maintenance space expanded Horizontal assisted maintenance Horizontal assisted maintenance DCLL PbLi/He Base Blanket (350/450° C) Gravity support / coolant supply plenum Coolant supply from below Advanced Project Division 3D Modeling of Blanket System Advanced Project Division 3D Modeling of Blanket System Advanced Project Division 3D Modeling of Blanket System Advanced Project Division 3D Modeling of Blanket System Advanced Project Division 3D Modeling of Blanket System Advanced Project Division 3D Modeling of Blanket System Advanced Project Division 3D Modeling of Blanket System Advanced Project Division Assumption for the Thickness of Blanket Inboard-Side Blanket [Thickness = 1000 mm] FW 38 Blanket 150 50 85 200 70 240 Be Be 167 Manifold & Structures Shield W FW 40 Structural Material Li4SiO4 Cooling channel Be B4C Outboard-Side Blanket [Thickness = 1225 mm] Blanket 50 150 Be 85 200 Be 100 100 20 200 Shield 280 Manifold & Structures Advanced Project Division Radial Build of K-DEMO [unit : mm] (Option I) CS 1420 1896 2050 TF BlanVV ket SOL TS 3000 3170 3300 Plasma Blanket VV SOL Space for Vertical Maintenance 4100 4200 6000 7800 7900 9100 TF TS 10100 10480 10910 11780 Advanced Project Division Radial Build of K-DEMO [unit : mm] (Option II) CS 1500 1976 2150 TF BlanVV ket TS 3220 3420 3550 4550 4650 Plasma SOL Blanket SOL 6650 8650 8750 VV Space for Vertical Maintenance 9975 11175 11555 11985 TF TS 12895 Advanced Project Division Radial Build of K-DEMO [unit : mm] (Option II-A) CS 1500 1976 2150 TF BlanVV ket TS 3220 3420 3550 4600 4700 Plasma SOL Blanket SOL 6800 8900 9000 VV Space for Vertical Maintenance 10200 11400 11780 12210 TF TS 13135 Advanced Project Division Radial Build of K-DEMO [unit : mm] (Option III) CS 1730 2206 2385 TF BlanVV ket TS 3480 3680 3850 4850 4950 Plasma Blanket SOL SOL 7650 9350 9450 VV Space for Vertical Maintenance 10675 12175 12575 13025 TF TS 13980 Advanced Project Division K-DEMO Conceptual Study & CDA Schedule 2012.1~2012.12 2013.1~2013.12 2014.1~2014.12 2015.1~2017.12 2018.1~2021.12 Pre-study Pre-study Report Design Parameter Options Physics & Backup Study (Phase I) Physics & Backup Study (Phase II) Pre-Conceptual Design Study Report ★ Improvement of Report CDA Phase I ★ CDA Phase II + CDR Target Date for K-DEMO Construction : End of 2037 Advanced Project Division SUCCEX Facility Advanced Project Division Requirement Split pair solenoid magnet system Inner bore size : ~1 m Maximum magnetic field : ~16.39 Tesla Magnetic field at center : ~ 15.33 Tesla Maximum Helium flow channel length : < 100 m • One magnet of the split pair consists of three coil (IC, MC, OC) and the maximum of Helium channel length should be maintained below 100 m • Every double pancake of each coil will have Helium inlet and outlet • Each coil have a number of inter magnet joints because of the maximum fabrication capability in the length of CICC Test Mode • Semi-circle type conductor sample test mode U-shape sample with the bottom radius of 0.5 m DEMO TF conductor will have a rectangular cross-section to reduce the strain effect & will have capability of a minimum bending radius of 0.5 m No joint : no question regarding voltage arising from the joint There are enough distance for the voltage relaxation from the sample terminal to voltage taps • Sultan like sample test mode For the case of CS conductor, the size of the is expected to be a range of 50 mm. And it is not easy to make the U-shape sample because of the minimum bending radius Also the facility could support the joint technology development Advanced Project Division Coil Parameters Gap Between Upper and Lower Coil : 140 mm Operating Current : 18 kA Peak Field : 16.39 Tesla Center Field : 15.33 Tesla Number of Strand per CICC • IC : 360 strands • MC : 244 strands • OC : 72 strands Conductor Size (Including 1.0 mm insulation) • IC : 18 x 37 mm • MC : 16 x 30 mm • OC : 15 x 29 mm Jacket Thickness • IC : 3 mm • MC : 3 mm • OC : 2.5 mm Insulation : 1.0 mm Thick • 0.1 mm Kaption (400%) 0.4 mm • 0.15 mm S-Grass Fiber Tape (400%) 0.6 mm (include voltage tap) Advanced Project Division Conductor Parameter IC (Inner Coil) CICC : (3SC)x4x5x6[360 SC strand], VF = 27.62% MC (Middle Coil) CICC : (2SC+1Cu)x3x4x6[144 SC strand], VF = 26.96% OC (Outer Coil) CICC : (1SC+2Cu)x3x4x6[72 SC strand], VF = 26.96% Strand : High Jc (> 2600A/mm2) Nb3Sn (total ~ 6.5 ton) Twist Pitch : 50 mm – 110 mm – 170 mm – 290 mm No Sub-Cable Wrapping 18.0 16.0 1.0 3.0 IC CICC Cross-section 30.0 37.0 R3 1.0 16.0 14.0 15.0 13.0 R3 R3 3.0 MC CICC Cross-section 29.0 1.0 2.5 OC CICC Cross-section Advanced Project Division Coil Parameters Peak Field in Each Coil • IC : 16.39 Tesla, MC : 13.6 Tesla, OC : 7.9 Tesla Number of Turns per Layer • IC : 6 turns, MC : 16 turns, OC : 13 turns Number of Layers • IC : 20 layers, MC : 24 layers, OC : 24 layers Geometry (Excluding Ground Wrapping) • IC : ID = 500 mm, OD = 608 mm, Height = 740 mm • MC : ID = 648 mm, OD = 904 mm, Height = 720 mm • OC : ID = 944 mm, OD = 1139 mm, Height = 696 mm Helium Channel Length • IC : 42 m, MC : 78 m, OC : 85 m Required SC Strand Mass : total 5,615 kg in Coil • Strand Diameter : 0.82 mm including 0.002 mm Cr Plating • IC : 1.51 ton (437 m x 2), MC : 2.66 ton (644 m x 3 x 2), OC : 1.45 ton (700 m x 3 x 2) • Strand Required including Cabling Loss : ~6.5 ton Advanced Project Division 766 mm 500 mm 608 mm 648 mm 904 mm 944 mm 1139 mm 70 mm 790 mm 810 mm SUCCEX Magnet Cross-Section (Upper Coil) Advanced Project Division Magnetic Field Profile Advanced Project Division