Proposal Final Draft - College of Engineering | SIU

advertisement

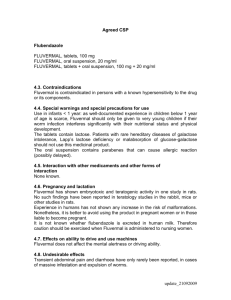

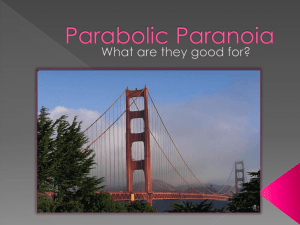

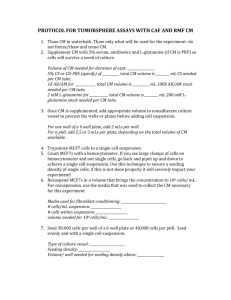

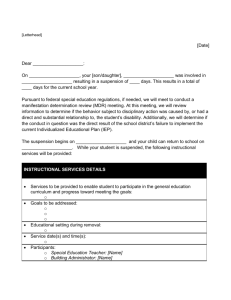

1 2013 F13-62-FSAE Proposal Southern Illinois University Carbondale 12/5/2013 2 Contents Transmittal letter .........................................................................................................................................................4 Executive Summary (Mi) ............................................................................................................................................5 Non-Disclosure Statement ..........................................................................................................................................6 Introduction (Mi) ..........................................................................................................................................................7 Validity statement .......................................................................................................................................................8 Literature Survey ........................................................................................................................................................9 Introduction .............................................................................................................................................................9 Chassis and Suspension Design Overview (Br) .................................................................................................. 10 Past FSAE (Br) ..................................................................................................................................................... 10 Upright (Ni) ........................................................................................................................................................... 10 Front Suspension (Mi) .......................................................................................................................................... 11 Rear Suspension (Ma) ......................................................................................................................................... 11 Control Arm Design (Na) ...................................................................................................................................... 12 Chassis (Br) ......................................................................................................................................................... 13 Brake System (J).................................................................................................................................................. 13 Disc brake assembly (Az) .................................................................................................................................... 14 Project Description (Ma) .......................................................................................................................................... 15 Project Organization (Ma) ........................................................................................................................................ 15 Chassis (Br) ......................................................................................................................................................... 16 Front Suspension (Mi) .......................................................................................................................................... 16 Rear Suspension (Ma) ......................................................................................................................................... 16 Brake rotors (Az) .................................................................................................................................................. 16 Brake system (J) .................................................................................................................................................. 17 Upright Design (Ni)............................................................................................................................................... 17 Block Diagrams (Ma) ............................................................................................................................................... 18 House of Quality (Ma) .............................................................................................................................................. 20 Design Basis (Mi) ..................................................................................................................................................... 21 Project Deliverables ................................................................................................................................................. 21 Action Item List ........................................................................................................................................................ 21 Timeline (Ni) ............................................................................................................................................................ 22 Resources (Br) ......................................................................................................................................................... 23 Appendix A: Resumes ............................................................................................................................................. 24 Abdul Azim bin Abdul Nasser .............................................................................................................................. 24 Nickolas J. Twombly ............................................................................................................................................ 26 Ng Kay Chong ...................................................................................................................................................... 30 Matthew D. Haeuber ............................................................................................................................................ 32 Michael D Haeuber .............................................................................................................................................. 33 Brian Watters ....................................................................................................................................................... 34 Nathaniel Tyler ..................................................................................................................................................... 36 Appendix B: References (Ma) ................................................................................................................................. 37 3 Appendix C: Project Specifications (Ni) ................................................................................................................... 38 4 Transmittal letter November 11, 2013 Saluki Engineering Company Southern Illinois University Carbondale College of Engineering - Mail code 6603 Carbondale, IL 62901-6604 Dr. Vidya Singh-Gupta Assistant Manager of ECE Projects Southern Illinois University Carbondale Carbondale, IL 62901-6603 (618)- 453-7641 Dear Dr. Vidya Singh-Gupta, On September 11, 2013 we received your request for proposal for the FSAE chassis, suspension, and brake system of SIU Carbondale’s 2013-2014 Formula SAE race car. We would like to take this opportunity to thank you for your consideration of our bid on this project. Formula SAE is a student design competition annually organized by SAE International (Society of Automotive Engineers) at the Michigan International Speedway in Brooklyn, Michigan. The concept behind Formula SAE is that a fictional manufacturing company has contracted a student design team to develop a small Formula-style race car. The prototype race car is to be evaluated for its potential as a production item. Each student team designs, builds and tests a prototype based on a series of rules, whose purpose is both ensuring ontrack safety (the cars are driven by the students themselves) and promoting clever problem solving The competition challenges teams from engineering universities around the world to compare their race cars in numerous areas including fastest lap time, stopping distance, and many other categories. This event attracts approximately one hundred participants from around the world each year in addition to representatives of large automotive companies such as General Motors, Ford, and Chrysler, affording the engineering students the opportunity to interact with them. The proposed chassis, suspension, and brake system will be implemented to the car for the 2014 competition in accordance with the competition rules. Implementation of our design will be undertaken by the FSAE design team (SEC reference number: F13-62-FSAE) in conjunction with the SIU Carbondale Formula SAE Race Team. Improvements over last year’s design include increasing efficiency and effectiveness of an open wheel race car through material selection and design. The resulting effects of these optimizations are further discussed in the Literature Review Section of the Proposal. Thank for your consideration of the FSAE design. We look forward to working with you. Sincerely, Brian Watters _______________________ Project Manager, F13-FSAE-62 design team Saluki Engineering Company (708)-712-6512 pontiackid73@gmail.com 5 Executive Summary (Mi) The Society of Automotive Engineers (SAE) organizes Formula SAE (FSAE), a student design competition in which a group of student engineers design single seat open wheel vehicles capable of enduring rigorous racing events. In addition to the finished product technical drawings, specifications and explanatory text will all be provided near project completion. The chassis and suspension design as well as the braking system and upright design, as requested, will be considered carefully in all aspects. The goal of the project is to redesign the subsystems in order to simplify the existing design and decrease manufacturing time. These design modifications will, in turn, decrease overall weight of the finished vehicle, while improving its performance. Additionally, lightening the load will improve the fuel economy. The project will be completed near the end of spring semester 2014, leaving ample time for testing of all subsystems. The expected cost of the project, including all of the materials and components, will be no more than $5944.50. 6 Non-Disclosure Statement RESTRICTION ON DISCLOSURE OF INFORMATION The information provided in for this proposal is the intimate, proprietary property of the Saluki Engineering Company of Carbondale, Illinois, USA. Such information may be used solely by the party to whom this proposal has been submitted by Saluki Engineering Company and solely for the purpose of evaluating this proposal. The submittal of this proposal confers no right in, or license to use, or right to disclose to others for any purpose, the subject matter, or such information and data, nor confers the right to reproduce, or offer such information for sale. All drawings, specifications, and other writings supplied with this proposal are to be returned to Saluki Engineering Company promptly upon request. The use of this information, other than for the purpose of evaluating this proposal, is subject to the terms of an agreement under which services are to be performed pursuant to this proposal. 7 Introduction (Mi) The design competition held by The Formula Society of Automotive Engineers allows for student engineers to, as a team, design and manufacture a Formula SAE Racing Car. Engineering Schools from all over the world come together to compete against each other’s designs. The main goal of creating a simplified FSAE race car design is to drastically reduce the time required to build the vehicle. Keeping this in mind, the testing and tuning time of the post build process is maximized. With the complexity of existing designs it is nearly impossible to tune a race car to perform to its full potential. With a much simpler design, the cost of manufacture will be decreased due to reduced building materials and will minimize the weight of the finished product which is an underestimated attribute of a race car. The most weight will be shed from the chassis all while making sure not to compromise the rigidity of the frame and ultimately the safety of the driver. The goals listed above will be completed in the final product all while conforming to the updated Society of Automotive Engineers Rules and Guidelines for the year of 2014. 8 Validity statement This proposal is valid for a period of 30 days from the date of the proposal. After this time, Saluki Engineering Company reserves the right to review it and determine if any modification is needed. 9 Literature Survey Introduction Every year the Society of Automotive Engineers (SAE) sponsors many vehicle based competitions open to collegiate universities across the globe. One of the competitions is called Formula SAE (FSAE). In this competition a group of student engineers design single seat open-wheel vehicles capable of enduring rigorous racing events. These events include a timed autocross race, endurance race, skid pad test, and acceleration test all of which will be explained in more detail later in this report. The Society of Automotive Engineers requires a very strict technical set of rules that the vehicle must adhere to. These rules are put in place to control the specifications to which the vehicle can be built, and to ensure the safety of everyone participating in the competitions. A very thorough inspection is conducted on all vehicles before they are allowed to compete in any event. The safety inspection is performed first to ensure the chassis and components of the vehicle are built to the minimum requirements and will protect the driver in the event of a collision. The safety gear and harness are also inspected to ensure driver protection. Several other inspections are performed before the vehicle is allowed to do the dynamic technical inspections which include sound test, braking test, and tilt test. Once the vehicle is deemed safe for competition the dynamic racing events commence. These aforementioned events are conducted with the goal of completing them with the quickest time. The quicker the time that is taken to complete the event the more points are given to your team and the higher you will place. The dynamic events accumulate about 1/3 of the overall competition points, the endurance race being the most influential out of all of them. The overall design objectives of the competition according to the 2014 FSAE rulebook are as follows: A1.2 Vehicle Design Objectives For the purpose of the Formula SAE competition, teams are to assume that they work for a design firm that is designing, fabricating, testing and demonstrating a prototype vehicle for the nonprofessional, weekend, competition market. A1.2.1 The vehicle should have very high performance in terms of acceleration, braking and handling and be sufficiently durable to successfully complete all the events described in the Formula SAE Rules and held at the Formula SAE competitions. A1.2.2 The vehicle must accommodate drivers whose stature ranges from 5th percentile female to 95th percentile male and must satisfy the requirements of the Formula SAE Rules. A1.2.3 Additional design factors to be considered include: aesthetics, cost, ergonomics, maintainability, manufacturability, and reliability. A1.2.4 Once the vehicle has been completed and tested, your design firm will attempt to “sell” the design to a “corporation” that is considering the production of a competition vehicle. The challenge to the design team is to develop a prototype car that best meets the FSAE vehicle design goals and which can be profitably marketed. A1.2.5 Each design will be judged and evaluated against other competing designs to determine the best overall car [12]. 10 Chassis and Suspension Design Overview (Br) The chassis and suspension are critical components needed for proper vehicle operation in both passenger type and racing vehicles. Racing vehicles require much stiffer and stronger chassis and suspension as driver comfort is not a concern and vehicle performance is the main goals. The chassis has two main purposes. One is to maintain fixed rigid points for the suspension to bolt to and withstand all of the forces associated with vehicle racing, the other is to protect the driver in the event of a collision. The suspension in a racing vehicle has one purpose and that is to keep the largest contact patch of the tire connected to the road surface as best as is possible. Past FSAE (Br) Previous teams have done a variety of suspension and chassis configurations. Most recent was a doubleunequal length wishbone geometry, pushrod activated suspension, and a space frame type tubular steel chassis. This has been a common theme for teams in the past and has been successful Upright (Ni) The upright serves as the mounting point for the brake rotor, caliper, the wheel assembly, the steering, and control arm connections (see figure 1). This part of the car must provide the rigid platform needed to accommodate the forces encountered during cornering, acceleration and braking. Design of the upright is constrained to the inner dimension of the wheel. The upright will work in conjunction with the control arms to constrain the wheel to its set degrees of freedom [1]. An important design parameter of the upright is the orientation of the steering axis or kingpin angle. The kingpin angle is the imaginary line of rotation, about which the wheel and upright assembly rotate when the steering wheel is turned. There are a number of attributes that the kingpin position will determine, one of which is the caster angle. Looking at the car from a side view, the vertical orientation of the pivoting joints is known as the caster angle [2]. The caster angle is responsible for generating an aligning torque, the force responsible for turning the steering wheel back to the neutral position after completing a turn. The torque tells the driver when the wheel is nearing the maximum lateral force. The driver must input a force to overcome the Figure 1: Upright aligning torque in order to turn the car’s wheels. The input force required from the driver increases as the lateral force generated by the tire increases. There is a point at which the lateral force and aligning force reach a maximum, after which they both begin to decline. When the lateral force of the tire begins to decrease, the drag force of the tire becomes larger, effectively slowing the car down. Since the aligning torque begins to decline slightly before the lateral force reaches its maximum, a properly designed upright can tell the driver that the additional steering angle will only decrease the speed of the car without aiding in cornering [1]. Further consideration must be given to the type of material used in constructing the upright, since this component is part of the unsprung weight that is not supported by the suspension of the car [3]. Unsprung weight is detrimental to the car’s performance as the added moment of inertia associated with rotating the assembly reduces handling performance of the vehicle. Another negative aspect of unsprung weight is the effect of the weight’s inertia on the geometry of the suspension. A heavier unsprung weight will create a larger force during bumps and cornering, requiring the need for larger or stronger control arms. Considering that the upright is most often the largest contributor to unsprung weight (next to the wheel) the importance of optimized material selection becomes apparent. 11 Front Suspension (Mi) The primary goal of the front suspension in racing applications is to keep the largest contact patch of both steering tires on the ground in order to maintain the most traction possible. In the world of racing particularly in Formula SAE there are a few different front suspension design types. The first design type is known as the short long arm (SLA) suspension whereas the second design type is known as the MacPherson strut suspension [4]. Variations of the SLA suspension include those with parallel control arms or non-parallel control arms. The final front suspension type resembles the SLA suspension but instead of having different length control arms this type has equal length control arms. This suspension design is known as the equal length wishbone suspension and can be configured to have parallel or non-parallel control arms [2]. Each suspension type has several variations. The formula race cars are not limited to these types of front suspension designs; they are most widely used for this particular application [4]. As the name indicates the control arms of an SLA suspension are of different lengths and can be parallel or non-parallel in relation to each other [2]. In general, this type of suspension is widely used that there is much more freedom of upright design choice [4]. This suspension type is popular due to the fact that during the suspension travel there is a camber change. This camber change can be used to maintain traction between the wheels and the ground during a tight corner. In the SLA, suspension traction is maintained because the upper control arm, which is shorter, will move toward the center of the car sooner than the lower control arm will when the car corners [5]. The MacPherson strut front suspension was used in earlier racing cars and has since then become less popular [2]. This strut type suspension is a variation in some ways of the SLA system. There is a lower control arm paired with a strut which replaces the upper control arm [4]. With this particular type of suspension brings many drawbacks to racing cars. One drawback is the packaging parameters is that it is not well suited for race cars that sit very low to the ground [2]. Another drawback is the camber gain when the suspension cycles [5]. Difficulty of camber adjustment is another reason that this type of suspension is not practical for racing cars [2]. The final suspension type is equal length wishbone suspension which can also be called equal length double A-arm. This design type uses control arms of equal length, and can be parallel or non-parallel in nature (see figure 2). A good advantage of this design type is that the roll center is located at ground level; however, there is no camber gain when the car goes into a corner ultimately results in a loss of traction [2]. Rear Suspension (Ma) An independent rear suspension is a Figure 2: Equal Length Double-A-Arms suspension with each tire of the car free of the others. For the purposes of Formula SAE racing, independent suspensions the best designs. One of the advantages to independent suspension systems is its superb ability to maintain contact with the road [5]. There are four main types of independent rear suspension designs that race car engineers consider when 12 choosing the right design. Some designs are meant to cushion the driver from bumps and bad road conditions using significant suspension travel while others are designed to maximize the tires contact area with the driving surface. Formula car engineers are focused on maintaining high tire contact patch area [6]. The four types of suspension designs are as follows; Trailing arms, swing axel, Macpherson struts, and SLA. Each of these designs have slightly modified sub-designs [4]. The first design for discussion is trailing arms. A trailing arm suspension design is pivots on a line perpendicular to the center line of the car. This design has problems with toeing out of the tires during cornering and producing bending and deflection of links [4]. The design also produces problems with camber angle and loss of tire contact patch. One positive aspect of this design is that it is relatively compact as a whole [7]. A swing axle is a suspension design that pivots near the center of the chassis [5]. Other than being a relatively easy design, the swing axle has several negative attributes. The design typically produces a geometry with a high roll center, and as a result of that, the design will produce large jacking forces [7]. Jacking is the tendency for the car to lift a tire on the inside of the car during cornering [2]. With this said, it is important to reiterate that with these disadvantages, camber angle is reduced producing decreased cornering power. This is caused by the loss of tire contact patch area. Herb Adams says; “Since the jacking only happens during hard cornering, the loss of cornering power happens when it’s needed most” [5]. The Macpherson strut design is based on a lower-A-arm or H arm connected to the chassis along with a spring which connects at the knuckle (upright). This design is different in the way that the axis of rotation acts as a structural link [4]. This begs the need to design the axis link to resist bending and shear. A disadvantage to the design as a whole is that with the strut in the way, there isn’t much room for a wide wheel and tire combination, which racing vehicles most often need [5]. For this reason, this suspension design is not a very common design in formula car engineering The Short Long Arm designs is widely used by many formula race car teams for the reason that its geometry through motion controls the camber angle. This geometry is the best design for keeping a large tire contact patch throughout the travel of the suspension. SLA suspension design consists of a double-A-arm with the top link shorter than the bottom [4]. This design produces a negative camber angle as the suspension is compressed, keeping the tires perpendicular to the ground which helps with higher cornering speeds [5]. One important type of dependent suspension systems is live axels. Live axles are relatively easy to design and to manufacture. Additionally, this design has been known to perform well in formula competitions. According to Adams, “On smooth roads, it is usually difficult to see any advantage for an independent rear suspension.” [5: 60] This means that live axle systems should not be overlooked for designing a formula car rear suspension. For a live axle suspension, the roll center of the car will be in the very center of the differential, meaning that it is higher than other designs mentioned above [2]. In live axles, there are methods of controlling side to side motion suspension such as panhard and watts linkages [5]. Control Arm Design (Na) The control arms connect the chassis to the uprights. The control arm has two sub-components: ‘upper’ and ‘lower’ control arm, There are many ways to design a control arm. Note that even though a variety of shapes exist, the control arm’s geometric orientation is dependent upon the suspension design. Consequently, the arm’s design is mainly a subject matter of static force calculations and Finite Element Analysis FEA. Consequently, both subcomponents play different roles in the overall design of the car. If an appropriate arm design is created 13 then one can expect satisfying results during racing competitions. The arm’s overall performance will be seriously impacted in the categories of strength, stiffness, and durability. Chassis (Br) The chassis of the FSAE vehicle is a critical component of a safe well-functioning car. Many of race vehicle chassis are built in a space frame or tubular frame construction. A space frame chassis is constructed with a series of tubular steel members welded together at nodes (see figure 3). This space frame chassis is the preferred style for FSAE as it is a simple conceptual design and can become a very rigid chassis with proper engineering. As a chassis rigidiy increses, the car’s overall preformace increses. Consquently, the more flexible the chassis is, the worse the car’s handeling will be. “The basic shape for cunstructing rigid structures is the triangle” [5: 55]. Triangulation, as it is known, is the basic fundamental Figure 3: Chassis design component of space frame design. It is a critical geometric component of chassis design that provides the required rigidity of a race chassis. There must be a balance met in chassis design between rigidity and weight. A very rigid chassis can become too heavy for the application, and consequently become a disadvantage in competition. To accommodate all compononents of a vehicle which are crucial to the chassis design, thorough planning and a carefully prepared geometry design is required. Brake System (J) An experiment conducted by a pilot of FSAE, reveals that an everyday driver can stop a car with 45.36 𝑘𝑔 of pedal effect. The material choice for brake pedals must be strong and tough in order to prevent failure under the applied forces. Titanium, carbon fiber, steel, and aluminum are common choices. The pedal ratio is the ratio distance from the brake pedal pivot point to the point of pedal input force application over the point of master cylinder attachment to the brake pedal to the pivot point. The higher the ratio the less input force required for the same resulting braking force.A ratio of about 6/1 is ideal for most racing car. Master cylinder is a large cylinder in a hydraulic system in which the working fluid is compressed by a piston. Pressure produced by master cylinder by assuming incompressible liquids and infinitely rigid Figure 4 - Brake System 14 hydraulic vessels is equal to: 𝑃𝑚𝑐 = 𝐹𝑏𝑝 𝐴𝑚𝑐 (Equation 1) 𝑃𝑚𝑐 = hydraulic pressure generated by master cylinder 𝐴𝑚𝑐 = effective area of the master cylinder hydraulic piston The total hydraulic system pressure act on braking system determine by master cylinder bore size and petal ratio. The master cylinder is connected to the brake pedal to create brake to the fluid movement and pressure. The material use to build master cylinder must be high boiling point, stainless steel to prevent corrosion, chemical property and affect the performance [8]. Figure 5: Brake Lines Brake lines are the pipes that connect the master cylinder and the wheel cylinders in a hydraulic brake system (see figure 5). Brake line must made by double wall steel tubing to make sure that it did not swell due to high pressure and not easily to be cut off. Disc brake assembly (Az) The disc brake assemblies used in modern day vehicles are fairly efficient and perform consistently. The disc brake assembly consists of brake caliper, brake pads, and brake rotor. Using hydraulic pressure through the caliper, brake pads are forced into the spinning rotor clamping down on it. The resulting frictional forces cause the wheel to decelerate [9]. The brake-pad/disc-brakes require applied pressure forces which generate friction forces that consequently halt or dampen the motion of the rotors. This is made possible by positioning of the brake pads where the friction surfaces face the rotors [10]. There is no comparison between the performance of the brake pads and the drum brakes. Both of them perform quite well in decelerating a vehicle. Brake pads function better compared to the drum brakes because they dry faster in wet conditions and they have a longer duration before they wear out. Brake pads are categorized according to their intended purpose. They have greatly improved the new braking systems to increase efficiency. Conventionally Cast iron and steel are the main elements used in making the rotors. In racing applications carbon composite materials are also used. Slotting and drilling rotors was introduced in the 1960’s and is still used today as a method of dissipating heat. Floated and vented disc designs operate within a certain temperature range in order to optimize brake performance [11]. 15 Project Description (Ma) The main part of the project is the chassis space frame design. From this, all other subsystems are connected. The sub-systems directly in contact with the chassis are the front suspension system and the rear suspension system. The front suspension will have a total of six chassis pick up points and the rear suspension will have four chassis pick up points. The front suspension sub-system gives way to the upright assembly sub-system. This sub-system is only implemented on the front suspension of the car due to the fact that the rear suspension does not require the involved components. The rear suspension system has two sub-systems in direct contact, the brake rotor sub-system and the braking sub-system. The brake rotor sub-system and the braking sub-system will also work in conjunction with the front suspension sub-systems and the upright assembly sub-system. The overall project including sub-system interactions is illustrated in the below project organizational chart. Project Organization (Ma) 16 Chassis (Br) The vehicle chassis will be constructed of 4130 chromoly steel tubing. This style of chassis is known as a space frame design. The chassis will be joined together with a process called TIG welding. The goal of the chassis design is to simplify the manufacturing processes and shorten the time required to construct it. The rules of Formula SAE dictate several minimum and maximum design sizes which must be met in order to qualify for the competition. Careful concern must be taken to ensure safety of the driver and structural integrity of the vehicle. Several of the chassis tube dimensions are specified by the rule book so the variety of design parameters is somewhat limited. The chassis is designed to accommodate all of the components of the vehicle such as steering components, engine, and driver. The chassis has also been designed with simple tube dimensions and easy to fabricate bended sections. It is predicted that the chassis would only take a few weeks to construct once the money and materials have been gathered to do so. Overall a simple approach has been taken to ensure completion of the chassis by the 2014-2015 racing team. Front Suspension (Mi) The front suspension design will follow a swing arm style. This type of suspension will consist of two main chassis pick up points and an additional point for the shock absorber. The sub-system will be a rigidly welded piece consisting of two V-shaped components meeting at the location where the upright will be mounted. The V-shaped linkages will be steel round tubing and will be mended with plates of various angles. The plates will be made of steel as well and will all be joined together by welding. The mounting locations on the swing arm will be on the steel plates mentioned previously. It is on these plates were there will be a press fit spherical bearings. With this, the swing arm will be mounted to the chassis and freely move in the vertical direction. At the opposite side of the swing arm there will be two more of the steel mounting plates, one at the top and one at the bottom. The upright will then be connected to this side of the swing arm with the same type of press fit spherical bearings. The shock absorber will be connected from the lower part of the swing arm to the chassis and it will run between the V-shaped tubes. Rear Suspension (Ma) The rear suspension design is a solid live axle system. This design will be split up into four main components. The first component is the upper assembly. This assembly will consist of two tie rods with spherical rod ends which will connect the chassis to the top portion of the rear suspension. The second component involved in the design is the lower assembly. The lower assembly will comprise two longer tie rods with a two crossing tie rods in the middle. These components will all be welded together and will create rigidity and strength within the lower assembly. The third component is the bearing carrier, and each side of the car’s rear suspension will have one. The role of the bearing carrier is to house the bearings that the axle will rotate on. The fourth and final component of the rear suspension is the spring and damper. This will be directly mounted off of the top of the bearing carrier and connected to chassis. The rear suspension design is essentially a four bar mechanism with the chassis acting as two of the fixed points. Brake rotors (Az) The material that will be used for the brake rotors is maraging steel. Maraging steel has a better heat dissipation, and gives less deformation and stresses when loads are applied compared to other materials such as carbon-carbon composites, and cast iron. Maraging steel also prevents brake fade to occur and has longer life span than the previously used carbon-carbon composite brake rotors. This will 17 allow the vehicle to stay longer on the track and requires less time at pit stops caused by overheated brakes. Brake system (J) The brake system focuses on the converting driver input in the form of depressing the brake pedal to the force applied to the brake rotor. Material and design for the brake sub-system must be considered. The material for brake pedal design must be steel. Steel is strong and a good candidate for the design. The steel offers strength to make sure that the brake pedal is able to sustain the brake force. The ratio for the brake pedal is 4:1, so the driver does not have to use excessive amounts of energy to the brake pedal. Upright Design (Ni) The front upright design consists of a central bearing holder coupled to two mounting brackets. The bearing holder will connect to the mounting brackets through the use of 0.25 inch thick steel plates. The plates will be cut to shape using a water jet. The individual sheet metal pieces will be welded to the bearing carrier. The use of a welding jig will aid in part dimension accuracy and reproducibility. The upright will connect to the control arm assembly using a mounting block made of aluminum. This mounting block will be interchangeable in order to adjust the caster and camber angles. The bearing carrier is designed to house a sealed bearing assembly. The bearing assembly will be held in place through the use of a lip and snap ring. 18 Block Diagrams (Ma) 19 20 House of Quality (Ma) 21 Design Basis (Mi) The basis of design for work on the F13-62-FSAE project can be found in the documents listed below. Document Request for Proposal Formula SAE Rules 2014 Project Specifications Date Created September 10 2013 August 19 2013 October 8 2013 Project Deliverables CAD renderings of all items FEA analysis (mechanical characteristics) Validations for all design changes to be implemented Testing to show design outcomes Actual implementation on Spring 2014 or 2015 FSAE vehicle Action Item List Research: Azim Nasser Brian Watters Matt Haeuber Michael Haeuber Nathaniel Tyler Nick Twombly Jerry Persons: Az Br Ma Mi Na Ni J # Action 1 Design Chassis 2 Design Front Suspension 3 Design Rear Suspension 4 Design Control Arms 5 Design Uprights 6 Design Brake System 7 Design Brake Rotor 8 Order Chassis Parts 9 Order Front Suspension Parts 10 Order Rear Suspension Parts 11 Order Control Arms 12 Order Upright Parts 13 Order Brake System Parts 14 Order Brake Rotor Material Field: ME ME ME ME ME ME ME Persons Br MI Ma Na Ni J Az Br MI Ma Na Ni J Az Assigned Date 13-Jan 13-Jan 13-Jan 13-Jan 13-Jan 13-Jan 13-Jan 20-Jan 20-Jan 20-Jan 20-Jan 20-Jan 20-Jan 20-Jan Due Date 27-Jan 27-Jan 27-Jan 27-Jan 27-Jan 27-Jan 27-Jan 3-Feb 3-Feb 3-Feb 3-Feb 3-Feb 3-Feb 3-Feb New Due Date Status 0% 0% 0% 0% 0% 0% 0% 0% 0% 0% 0% 0% 0% 0% Comments 22 Timeline (Ni) 23 Resources (Br) As the Formula SAE team has its own shop, the manufacture of the final product will not require many more resources. Welding, Cutting, and all other fabrication processes with exception of milling of some parts will be done in house. It is also notable that the arrangements have been made for anything that will need to be manufactured at another location. Item # Item Description 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Tires Wheels Wheel Studs Wheel lug nuts Upright spindle Wheel bearings Upright housing material Control arm material Control arm Spherical bearing Brake calipers Rotors Brake pedal materials Brake Pads Master Cylinders Brake lines Brake fluid Suspension dampers Suspension springs Suspension mount material Fasteners Chassis Tubing Rear Axle Material Drive sprocket Rear hub materials Bearing carrier materials Rear axle bearings Rear suspension link materials Rear suspension Spherical bearings Computers Solidworks Modeling Software Matlab Formula SAE shop TOTAL Quantity 4 4 16 16 2 4 2 10 8 4 4 1 8 2 2 2 4 4 4 TBA 120 4 1 2 2 4 10 12 On hand On hand On hand On hand Price per component ($) 220.00 80.00 4.00 4.00 50.00 65.00 30.00 1.75 37.00 120.00 60.00 20.00 30.00 170.00 45.00 5.00 160.00 90.00 10.00 TBA 3.50 12.00 20.00 40.00 50.00 65.00 1.50 40.00 0 0 0 0 Total ($) 880.00 320.00 64.00 64.00 100.00 260.00 60.00 17.50 296.00 480.00 240.00 20.00 240.00 340.00 90.00 10.00 640.00 360.00 40.00 0.00 420.00 48.00 20.00 80.00 100.00 260.00 15.00 480.00 0.00 0.00 0.00 0.00 5944.50 24 Appendix A: Resumes Abdul Azim bin Abdul Nasser aazimban@gmail.com Permanent Address: University Address: No. 5 Lrg AU 1C/3F, Tmn Keramat Permai, 54200 Kuala Lumpur, Malaysia +60342573685 2511 S Illinois Ave Lot 2, Carbondale, IL 62903 (618) 303-6326 Objective: To obtain an entry-level mechanical engineering position and develop occupational experience towards a career. Professional Summary Achieved Dean’s list status on a semester while working 20 hours per week Education Southern Illinois University, Carbondale, IL 62901 Bachelor of Science in Mechanical Engineering, Minor in Mathematics Graduate: May 2014 GPA: 3.17/4.0 Relevant Coursework Dynamics Statics Thermodynamics I & II Auto CAD Measurement and Controls Fluid Mechanics Manufacturing Processes Heat Transfer 25 Experience Barista, Coffee Bean & Tea Leaf. Kuala Lumpur, Malaysia Skills AutoCAD Proficient in MS Excel/Word Honors/Awards SIUC College of Engineering Dean’s List, Fall 2011 Language Malay English Volunteer Work Midwest Games International 2012 – volunteered as helper January 2009 to April 2009 26 Nickolas J. Twombly Carbondale, IL 62903 ntwombly@siu.edu (708) 441-7233 EDUCATION Southern Illinois University, Carbondale, IL Bachelor’s of Science in Mechanical Engineering Minor in Physics GPA: 3.8 May 2014 (projected) Kishwaukee College, Malta, IL Associate’s of Science Summa cum Laude GPA: 3.8 May 2010 Universal Technical Institute, Glendale Heights, IL Certificate of Completion Automotive Service and Repair August 2008 RELEVANT EXPERIENCE Undergraduate Research Assistant May 2013- Current Southern Illinois University, Carbondale, IL Faculty Advisor: Vik Malhotra, Ph.D. Used various machining devices to produce coal samples in different forms including powders, cores, and sheets. Designed and implemented an impulse testing apparatus, complete with an electromagnetic triggering device, used to simulate seismic activity. Undergraduate Research Assistant August 2012- December 2012 Southern Illinois University, Carbondale, IL Faculty Advisor: Samir Aouadi, Ph. D. Participated in a novel research project in which friction reducing nano coatings were applied to substrates using the sol-gel method. Performed various maintenance activities on laboratory equipment, including a magnetron sputtering machine, wear testing apparatus, and roughing and turbo vacuum pumps. Team Captain May 2012- Current Formula SAE (Saluki Racing) Southern Illinois University, Carbondale, IL Managed the design, fabrication and testing of a Formula style race car. Oversaw the recruitment and expansion efforts in order secure the progress of the team in future years. Facilitated a comfortable learning environment for underclassmen, while simultaneously promoting a high level of design by upperclassmen team leaders. Worked with local and national companies on parts and monetary sponsorships. 27 Undergraduate Research Assistant August 2011- May 2012 Southern Illinois University, Carbondale, IL Faculty Advisor: Asghar Esmaeeli, Ph. D. Used visualization applications to generate 3D images of fluid data. Solved higher order linear equations related to fluid dynamics research using Mathematica and Matlab software. ADDITIONAL EXPERIENCE_____________________________________________________ Mathematics Tutor 2011-2012 Southern Illinois University, Carbondale, IL Faculty Advisor: Kathleen Pericak-Spector, Ph. D. Tutored SIU students in college level mathematics classes including Algebra, Trigonometry, Calculus, and Differential Equations. General Science Tutor 2010 – 2011 Kishwaukee College Tutored college students in Algebra, Trigonometry, Calculus, Biology, Physics, and Chemistry. Automotive Technician European Cars of Evergreen Park, Evergreen Park, IL 2008 - 2011 Diagnosed and repaired various automotive systems, including A/C pressure systems, fuel injection components, and emission regulation requirements. IT Systems Administrator 2007-2011 Alliance Lighting LTD Supervisor: Tim Preihs Set up and maintained office computer network, including desktop laptop interfaces, wireless networking, virus protection, and troubleshooting WORKS IN PROGRESS S. Harbin, N. Twombly, V. Malhotra, R. West, Effects of seismic activities on carbon dioxide sequestered in bituminous coal. Fuel. (being written) AFFILIATIONS Tau Beta Pi Engineering Honors Society, Member, May 2013 Formula SAE (Saluki Racing), Member, August 2011 Society of Automotive Engineers, Student Member, May 2013 Phi Theta Kappa Honors Society, Member, August 2010 Delta Chi International Fraternity, Member, March 2005 Automotive Service Excellence, Master Certified Member, September 2009 HONORS 28 Dean’s List, Southern Illinois University, Spring 2012, Fall 2012, Spring 2013 Dean’s List, Kishwaukee College, Spring 2011, Fall 2010, Spring 2010, Fall 2009 Perfect Attendance Award, Universal Technical Institute, 2008 VOLUNTEER SERVICE IJAS Region 8 Science Fair at Southern Illinois University (Judge) CTM conference at Carbondale Community H.S. (Exam Proctor) 2012 Math Field Day at Southern Illinois University (Assistant) Honor Flight Chicago silent charity auction (Security) SKILLS Computer Programming Languages: C/C++, Java, Python Computer Programs: SolidWorks, MS Excel, MS Word, MS PowerPoint, Xilinx, Autodesk Inventor, AutoCAD Operating Systems: MS Windows 2000/XP/Vista/7, Linux/Unix (Ubuntu) Networking Skills: Static/Dynamic IP configuration, small office/home network communications, remote desktop connections, remote printing/faxing Miscellaneous Computer Skills: hard drive backup and recovery (ghosting), hardware configurations, CPU/RAM overclocking, virus protection/prevention/recovery Nickolas J. Twombly Carbondale, IL 62903 ntwombly@siu.edu (708) 441-7233 REFERENCES Vik Malhotra, Ph.D Professor Emeritus Department of Physics Southern Illinois University Carbondale, Illinois (618) 453-2643 Samir Aouadi, Ph. D. Associate Professor Department of Materials Science and Engineering University of North Texas Dallas, TX (940) 565-4759 Steve Dunn Physics and Engineering Instructor, Coordinator Kishwaukee College, Malta, IL (815) 825-2086 ext. 2470 29 Timothy Preihs President, CEO Alliance Lighting, LTD Rolling Meadows, IL (815) 378-5626 30 Ng Kay Chong J09051493@siu.edu Permanent Address: 711 S Wall, Apt304 Carbondale, IL 62901 (573) 846-0412 University Address: Southern Illinois University Carbondale Carbondale, IL 62901 (618) 453-1111 Objective: To gain entry-level mechanical engineering position and to develop skills toward carrier Professional Summary Achieved Dean’s list status last semester while working 20 hours per week Education Sunway University, Kuala Lumpur, Malaysia December 2011 Southern Illinois University, Carbondale, IL 62901 GPA: 3.0/4.0 Relevant Coursework Auto-CAD C++ Calculus Economic Experience Intern, Epsilon, Malaysia. May –August 2013 Learn the skills to repair some simple machines like air conditional Redesigned and improved some medical tube Assembling all the parts into big machine Skills Drawing Assembling 31 Honors/Awards Dean List, Southern University Illinois Carbondale, Summer 2012 Vice president: Calculus, Sunway University, November 2010 Activities Financial Chair, Sunway University , September 2010 Represent Southern Illinois University Carbondale play for Midwest International Games Language Mandarin English Malay Cantonese 32 Matthew D. Haeuber 501 N. Washington St. McLeansboro, IL (618) 895-6505 haeuberma@siu.edu Summary Highly motivated, hard working engineering student seeking entry level position in the field of mechanical engineering. Work / Engineering Experience Intern for Black and Sons Construction for summer of 2013. All work was at Continental Tire North America in Mt. Vernon, Illinois. Tasks included design and assembly of two electrical access points, assisting in design of mobile cleaning platform, reading and analysis of technical drawings in preparation of assembly of conveyor belts, as well as other odd jobs. McLeansboro Golf Club, 2009-2012. Job description: front desk, open/close, cleaning, maintenance of property/equipment. Lawn care 2008-present. Mowing, trimming, raking, clean-up, repair and maintenance of equipment, and other maintenance jobs. Education Southern Illinois University Carbondale, 2012-present. Rend Lake College Ina, IL Major: Associate in engineering science, 2010-2012. Currently working on Associate in Science degree from Rend Lake College. Hamilton County Sr. High School, McLeansboro, IL, 2007-2010. Phi Theta Kappa Academic Society – inducted Feb. 2011. Member Crossroads Bible Church, Norris City, IL. Formula SAE Team Member. Memberships Special Skills/ Achievements Skilled in Microsoft Excel and displaying data graphically. Rend Lake College President’s List Spring 2012. SIUC College of Engineering Dean’s List, Fall 2012, Spring 2013. GPA 3.619/4.0 Credentials Transcripts and References available upon request. 33 Michael D Haeuber 501 North Washington St. McLeansboro, Illinois 62859 Tel: (618) 643-7016 Cell: (618) 895-6506 haeubermi@siu.edu OBJECTIVE Seeking an entry-level position in mechanical engineering EDUCATION Southern Illinois University Carbondale, Illinois Mechanical Engineering, May 2014 GPA: 3.374/4.0 Rend Lake College Ina, Illinois Associate in Engineering, GPA: 3.329/4.0 WORK EXPERIENCE Quality Engineering Internship, North American Lighting, Salem IL Dimensioning of parts Shipping of pre-production parts 5/2013-8/2013 Grounds Crew McLeansboro Golf Club, McLeansboro, Illinois Mowed tee boxes, collars, aprons, and rough Maintained putting greens Maintained mowing equipment 5/2012-8/2012 Weed Eater Operator, Mike Kerans Lawn Mowing, McLeansboro, IL Weed Eater operator of 25+ yards a week 5/2011-8/2011 Honors/Awards/Memberships Member of SIUC Formula SAE Dean’s List SIUC fall 2012 and spring 2013 34 Brian Watters 709 S. Wall Street appt. 204 Carbondale, IL 62901 Cell: (708) 712-6512 Pontiackid73@gmail.com EDUCATION Perusing bachelors in Mechanical Engineering at Southern Illinois University Carbondale Graduation date estimated December 2014 GPA: 3.4 with 25 Hour per Week Working schedule PROFESSIONAL EXPERIENCE HVAC Service Technician Apprentice Industrial Heating, Ventilation, and Air Conditioning repair and maintenance Fleet Vehicle Service Mechanic Vehicle Maintenance and repair Equipment Maintenance Technician Serviced Fork Lifts, Welders, service equipment, power tools, and Industrial sheet metal forming tools High performance vehicle Technician Assembled engines and transmissions on Drag Racing and Road Racing vehicles mostly domestic V-8 ( Pontiac, chevy, ford, GM). Performed maintenance and assembly on vehicle subsystems such as Drive-train, electrical, and suspension. Performance Component Fabrication Specialist Design and fabrication of Components such as Chassis, fuel cells, forced induction packaging, and suspension. High Performance Vehicle Design and Fabrication Design, assembly, and fabrication of most vehicle subsystems such as chassis, suspensions, engine, Intake systems, exhaust systems, fueling, and drive-train. Vehicle Engine Tuning Tuning engines for maximum power output throughout operating range using aftermarket control systems. AMS Mechanical Systems Inc. 2012-2013 AMS Mechanical Systems Inc. 2010-2013 AMS Mechanical Systems Inc. 2009-2013 High Speed Performance Inc. 2009-2011 High Speed Performance Inc. 2010-2012 Self Employed 2012-present Self Employed 2012-present TECHNICAL EXPERIENCE o o o Proficient In Auto CAD, Inventor, and Solidworks 3D Modeling software including Design, FEA, and CFD Welding in MIG, TIG, STICK, and Oxy-Acetylene gas welding. Metal Fabrication o o o o Composite materials fabrication such as carbon fiber, fiberglass, and Kevlar. Wide array and experience of maintaining and improving motorized vehicles ( cars, trucks, motorcycles, watercraft, off-road vehicles, heavy equipment) Proficient in Manual machining practices such as Vertical Mill, Horizontal Lathe, hydraulic pressing. Electrical and wiring experience in vehicles and personal residences. Nathaniel Tyler Nathaniel Tyler 3208 Clairbridge Drive Bloomington, Illinois 61704 – 309-660-1210 (H) - 309-660-6603 (C) – ntylerbert@gmail.com Looking for Engineering Internship for summer of 2013. Highlights Analytical Thinking Works well in diverse team environment Complex problem solving Expert at using Microsoft Word, Excel, &PowerPoint. Good at using Microsoft OneNote, Outlook, &Publisher. Autodesk Inventor – experienced Diligent worker Education Southern Illinois University Carbondale, Carbondale, IL Junior Mechanical Engineering Student @ SIUC – Currently Targeted B.S. Degree in May 2014 Heartland Community College, Normal, IL Mechanical Engineering Associates in Engineering – May 2012 Accomplishments Created and followed through on a Calculus 3 petition at Heartland Community College. Hosted study groups for engineering students. Normal Community High School, Normal, IL Diploma - 2010 Accomplishments Participated in track and cross county 2 years in high school and basketball 1 year Project Lead The Way – Reverse engineered a hose nozzle Learned Autodesk inventor – part of a team—team simulating exercises Web design --- Created 2 to 3 YouTube clips using Autodesk 3D Max software Experience Dwight Rentals Seasonal 2006 – 2011 Bloomington, Illinois Trouble shooting and repair of faulty equipment Take care of duties independent of direct supervision Appendix B: References (Ma) [1] Edmondson, C. (2011). Fast car physics / Chuck Edmondson. Baltimore, Md. : Johns Hopkins University Press, 2011. [2] Staniforth, A. (1999). Competition car suspension : design, construction, tuning / Allan Staniforth. Newbury Park, CA : Haynes North America, 1999. [3] REDUCING UNSPRUNG WEIGHT IS KEY TO FORGED ALUMINUM CONTROL ARM INTEREST. (2006). Forging, 17(4), 18. [4] Milliken, William F., and Douglas L. Milliken. Race Car Vehicle Dynamics. Warrendale: SAE, 1995. Print. [5] Adams, Herb. Chassis Engineering. New York: The Berkley Publishing Group, 1993. Print. [6] Bolles, Bob. Advanced Race Car Chassis Technology. New York: The Penguin Group, 2010. Print. [7] Isaac-Lowry, Jacob. "Suspension Design: Types of Suspensions." AutomotiveArticles. N.p., n.d. Web. 5 Oct 2013. <file:///H:/Suspension Design Types of Suspensions.htm (Source1).htm>. [8] Wagh, Nikhil, Pratap, “Design and Analsis of Modern Caliper Assembly,” Witchita State University Master’s Theses, pp. 85, Dec 2005 [9] J.E. Duffy, ‘Brake System Fundamentals.” In Modern Automotive Technology, GoodheartWillcox Company, Inc, 1998. pp. 1331-1344 [10] Henderson, B. (2011). "Disc brakes". The Haynes automotive brake manual. Haynes North America. [11] Domond, K. (2012). Brake rotor design and comparison using finite element analysis: an investigation in topology optimization. University of California. Pp.1- 81. [12] 2014 formula sae rules. (n.d.). Retrieved from http://students.sae.org/cds/formulaseries/rules/2014_fsae_rules.pdf Appendix C: Project Specifications (Ni) Weight Chassis Type Material Engine Type Displacement Horsepower Torque Redline Suspension Front Rear Brakes Rotor Pad Caliper Steering Wheel Tire Compound Size 475 lbs Space frame 4130 Chrome-Moly Steel 4 cylinders, DOHC, gasoline (E85) 600 cc 68 bhp 50 ft*lbs @ 10,000 RPM 12,500 RPM Unequal length wishbone, pushrod Unequal length wishbone, pushrod Steel Ceramic composite Wilwood PS-1 Rack and pinion Aluminum drum with magnesium hub Hoosier R252 13 x 7.5 in.