bridges - Mount Pleasant Area School District

advertisement

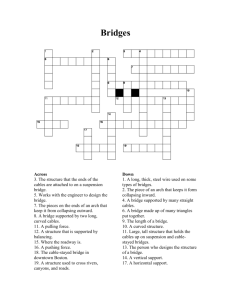

BRIDGES Bridge Basics Bridge is a structure built to span a valley, road, river, body of water, or any other physical obstacle. Designed to carry their own weight, (dead load) and to carry people and traffic, (live load) and to resist natural forces, such as wind and earthquakes. Must consider effects of contraction and/or Expansion due to temperature changes Designs of bridges will vary depending on the function of the bridge and the nature of the area where the bridge is to be constructed. Bridge Basics Bridges have been used since the dawn of humankind Bridges are based on one or more of three basic structures that are derived from forms found in nature. Beam: a log fallen across a stream Arch: natural rock formations Suspension: from a hanging vine Though traditionally constructed from wood, stone, concrete, or steel, new bridges made from high-performance composite materials such has reinforced plastic are emerging Bridge Terminology Abutment- A substructure element supporting each end of a single span or the extreme ends of a multi-span superstructure and, in general, retaining or supporting the approach embankment. Deck- The roadway portion of a bridge that directly supports vehicular and pedestrian traffic. Span- The distance between the main supports of a bridge. The length normally measured when describing the size of the bridge Simple Span- a plank across a stream Continuous Span- supported along its length by piers and abutments Cofferdam- A watertight structure allowing underwater foundations to be built in the dry. Bridge Terminology Bridge Forces Four types of forces act on a bridge, either separately or in combination. Tension Compression Torsion Shear http://www.pbs.org/wgbh/buildingbig/lab/forces.html Bridges Beam Bridge (Girder) The simplest form of a bridge A rigid horizontal structure that is resting on two piers, one at each end. The weight of the bridge and any traffic on it is directly supported by the piers. The weight is traveling directly downward. Mostly built from steel and concrete beams, or girders. The size of the beam, and in particular the height of the beam, controls the distance that the beam can span. Truss Bridges Truss bridges are a type of beam bridge made up of many small beams attached together in triangular configuration to support a large amount of weight and span great distances. They function by compression and tension forces and not by bending forces. They are identified according to the way the chords are arranged. How Truss Bridges Work A truss is an Trusses must be stable, interconnected framework of beams designed to hold something up. Trusses don’t bend, they get pulled apart and pushed together. However once the weight is increased the bridge will stag in the middle. This is due to the individual beams expanding and contracting due to the weight. and not able freely in any direction in order for them to work. The beams have to be placed carefully in the right angles and in equal distances away from each other so they can distribute the weight equally. They are usually supported at the ends by abutments and sometimes in the middle by piers. Arch Bridges Arch bridges are one of the oldest types of bridges and have great natural strength. The load on the roadway of this bridge is carried by the arch. The arch is supported at each end by a support called an abutment The arch is held together by the main piece in the middle which is called the “keystone” The roadway can be placed above or below the arch. Arch Bridges Arch Bridges consist of compression and tension. Compression Arch bridges are continuously under compression. The force of compression is pushed along the curve of the arch toward abutments. Tension The greater the degree of curvature (the larger the semicircle of the arch), the greater the effects of tension on the underside. The natural curve of the arch and its ability to dissipate the force outward greatly reduces the effects of tension on the underside of the arch. Suspension Bridges Suspension Bridge Tall towers on both sides of the roadway support the main cables. The cables run the entire length of the suspension bridge and are anchored in the concrete abutments at each end. Smaller cables are suspended from the main cables and these cables support the roadway. Almost all suspension bridges have, in addition to the cables, a supporting truss system beneath the bridge deck (This helps to stiffen the deck and reduce the tendency of the roadway to sway and ripple. Suspension Bridges Light, and strong, suspension bridges can span distances from 2,000 to 7,000 feet far longer than any other kind of bridge. They are ideal for covering busy waterways. This type of bridge is the only practical type suitable for very long spans or when it would be hazardous to maritime traffic to add central supports. Cable-Stayed Bridges Similar to the suspension bridge but the difference lies in how the cables are connected to the towers This bridge supports the roadway by cables that run from towers to the actual roadway Cable-stayed require less cable, can be constructed out of identical pre-cast concrete sections, and are faster to build. Cost-effective bridge that is undeniably beautiful. Cable-Stayed Bridges A cable stayed bridge is a bridge with one or more pillars. The two types of cablestayed bridges are parallel attachment design and radial attachment design. In a parallel attachment design the cables are attached at different heights along the tower and are parallel to one another in a radial attachment design the cables are attached at a single point at the top of the tower and on several places on the road. Parallel Attachment Design Radial Attachment Design Cantilever Bridges A structure or beam that is unsupported at one end but supported at the other, like diving boards A cantilever does not reach all the way across the bridge so they are connected in the middle by a part called the suspension span The suspended span may be built off-site and lifted into place, or constructed in place using special traveling supports. Cantilever Bridge Forth Railway Bridge The Forth Railway Bridge (or Firth of Forth Bridge) is made of a pair of cantilever arms that extend out from two main towers. The beams are supported by diagonal steel tubes projecting from the top and bottom of the towers. These spans support a central suspended span. Some structural members of the bridge are as large as 12 feet in diameter. Cantilever Bridges Movable Bridges •This bridge is usually used to span canals and rivers that carry heavy boat traffic •Usually powered by electric motors •In the past they were powered by steam engines •original movable bridges were the drawbridges of medieval times, raised by ropes and pulleys • There are three main types: 1.Bascule 2.Vertical lift 3. Swing Bascule Bridge or Drawbridge •Used for short distances •Have two movable spans the rise upward, opening in the middle •When open the weight is supported by the stationary section of the bridge Vertical-lift Bridge Used for longer distances Straight bridge, held between two towers Lifted by steel ropes, attached to counterweights -as the counterweights go down the bridge goes up and vise-versa. Operate in an elevator like fashion Swing Bridges Mounted on a central pier The central pier allows the bridge to rotate to the side Uncommonly used because the central pier is located in the area where boats like to travel Moveable Bridges Bascule Bridge Swing Bridge Lift Bridge Understanding Bridges Video http://videos.howstuffworks.com/hsw/20829understanding-bridges-video.htm