Questions? Contact Dan Fitch with IEA at 763-315

advertisement

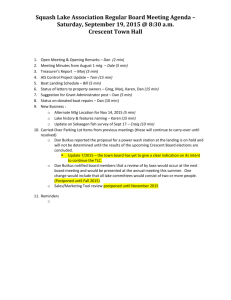

St. Louis Park Public Schools QUESTIONS? If you have questions about this training contact: Tom Bravo, Facilities Manager St. Louis Park Public Schools 952-928-6004 Bravo.thomas@slpschools.org TRAINING INSTRUCTIONS • Read the information on each slide • Click on the link on the last slide to complete the quiz • Answer all of the question on the quiz • Please note, you will NOT receive a training certificate or other notification. If you read the slides and finish the quiz, then you have successfully completed this training. • Answers to the quiz questions will be sent out at a later date. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com PURPOSE OF THIS TRAINING • Overview of OSHA’s Employee Right-to-Know (ERK) Standard and the district’s ERK Safety Program • Learn how to identify chemical hazards and other harmful physical agents in your workplace. • Understand the safe work practices and protocols that are expected in order to prevent injury and illness. • Satisfy OSHA requirement for annual training Question: Who’s responsible for your safety? Answer: You Are! Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com EMPLOYEE RIGHT-TO-KNOW (ERK) OVERVIEW ERK is a MNOSHA standard that requires employers to make employees aware of hazardous substances and/or harmful physical agents that may be encountered at work ERK standard is also know as the Hazard Communications standard, or HazCom The ERK Coordinator for St. Louis Park Public Schools is Tom Bravo, Facilities Manager. WHAT’S NEEDED FOR AN ERK PROGRAM? • Written Program that includes: • List of hazardous substances/agents • Identification of employees exposed to those hazards • Safety Data Sheets (a.k.a. MSDS) • Training • Labeling/warnings Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com LIST OF HAZARDOUS SUBSTANCES & AGENTS • Must consider the following: Hazardous Substances/Chemicals Infectious Agents (e.g. bloodborne pathogens) Harmful Physical Agents Noise Heat Ionizing and non-ionizing radiation (not typically a hazard in schools) Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com CHEMICALS IN THE WORKPLACE • District employees are NOT allowed to bring their own cleaning chemicals into the workplace. • Must use cleaners/chemicals purchased through the district. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com LABELING • All Chemical Containers Must be Labeled: – Shipping Containers (from vendors/distributors) – Secondary Containers (e.g. plastic spray bottles) • Name of product • Appropriate hazard warnings (e.g. flammable, toxic, corrosive) Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com CHEMICAL LABELING SYSTEMS • Used for labeling secondary containers and chemical storage areas in maintenance areas, kitchens, science labs, etc. NFPA LABEL • Blue = Health/Toxicity Hazard • Red = Fire Hazard • Yellow = Reactivity Hazard • White = Specific Hazard Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com HMIS LABEL • 4 = Deadly • 3 = Severe • 2 = Moderate • 1 = Slight • 0 = No Hazard Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com SAFETY DATA SHEETS (SDS) • Formerly known as Material Safety Data Sheets (MSDS) • Created by chemical manufacturers • Intended to provide employees and emergency personnel with recommendations for safe handling and use of a chemical or substance. • Includes information such as hazardous ingredients, first aid, personal protective equipment, storage and safe handling procedures Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com HOW CAN I ACCESS SAFETY DATA SHEETS? • Option 1: MSDSonline for electronic access • Option 2: Hard copy SDS binders are also maintained in the following areas: – Art, Food Service, Custodial/Maintenance, Grounds, Health Services, Industrial Tech, Science Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com MSDSonline • SDSs can be viewed on MSDSonline: – Web-based storage of district’s Safety Data Sheets – Can be accessed by all employees – No username or password required! – Search by product name or manufacturer – Employees can request a SDS for new products – Link is located on the district’s website under: Departments/Buildings and Grounds/Safety Data Sheets Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com INFECTIOUS AGENTS • Infectious agents are organisms capable of producing infection or infectious disease (e.g. virus, bacteria, pathogens) including influenza and MRSA, and colds. • Infectious diseases account for millions of school days lost each year for K-12 students and staff. • Schools inherently foster transmission of infections from person to person because they are a group setting in which people are in close contact and share supplies and equipment. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com INFECTIOUS AGENTS • According to the CDC, schools can be instrumental in keeping their communities healthy by: – Encouraging sick students and staff to stay home and seek medical attention for severe illness. – Facilitating hand hygiene by supplying soap and paper towels and teaching good hand washing practices. – Being vigilant about cleaning and disinfecting classroom materials and surfaces. – Providing messages in daily announcements about preventing spread of infectious disease. – Adopting healthy practices such as safe handling of food and use of standard precautions when handling body fluids. – Encouraging students and staff to get annual influenza vaccinations. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com BLOODBORNE PATHOGENS • Bloodborne pathogens (BBPs) are a type of infectious agent. Examples include HIV, Hepatitis B, and Hepatitis C. • BBPs can be present in human blood and other potentially infectious materials (OPIMs). • Modes of transmission include exposure to another person’s blood through: – Blood contact with non-intact skin – Blood contact with mucous membranes (i.e. eyes, nose, mouth) – Skin pierced by used sharp or needle Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com UNIVERSAL PRECAUTIONS FOR BBPS • Most effective means for preventing spread of BBPs: – Treat all blood and bodily fluids as potentially infectious – Avoid skin exposure to blood and bodily fluids – Use gloves or other impervious barrier to prevent contact with skin – Wash hands with soap and water after handling blood or bodily fluids, even when gloves are used. – Dispose of needles and other contaminated sharps in Sharps Container located in school health offices. – Contact your building custodian for any blood/bodily fluid cleanup. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com HARMFUL PHYSICAL AGENTS - HEAT • Working in a hot environment can alter the body's natural defenses against heat. • Heat stress is rarely a hazard within a school district; however staff with outside duties (e.g. grounds and maintenance) are informed of the potential for heat stress during summer months and are instructed to take frequent breaks in a cooler environment and increase liquid intake to help guard against heat stress and heat stroke. • If you suspect you or a coworker are suffering from heat stress, make sure to get cooled off immediately and call for help if needed. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com HARMFUL PHYSICAL AGENTS - NOISE • Federal OSHA sets specific standards for noise exposure. • Hearing protection is provided by the district when employee noise exposure exceeds OSHA’s Action Level of 85 decibels (dB) based on an eight-hour time-weighted average. Employees exposed to this level of noise would be covered in the district's Hearing Conservation Program. • Grounds employees, and band teachers are currently on the district’s Hearing Conservation Program. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com SYMPTOMS OF OVEREXPOSURE TO NOISE • Temporary Hearing Loss – Everything sounds muffled after exposure to loud noise (e.g. going to concert) – Repeated exposure could result in permanent hearing loss • Chronic Hearing Loss – Higher pitches are not discernible – Human speech sounds garbled – Tinnitus (constant ringing in your ears) Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com PERMISSIBLE NOISE EXPOSURES Duration Per Day (Hours) Sound Level Ave. 8 6 4 3 90 92 95 97 2 1½ 1 ½ ¼ or less 100 102 105 110 115 Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com (decibels) RECOGNIZING OCCUPATIONAL HAZARDOUS NOISE Task Avg. Noise Level (dBA) Tools Avg. Noise Level (dBA) Operating forklift 87 Lathe 81 Cutting Wood 93 Welding Equipment 94.9 Cutting lawn 94 97.2 Installing trench conduit 95.8 Hand Power Saw Screw Gun, Drill 97.7 Welding 98.4 Rotohammer 97.8 Grinding 99.7 Chop saw 98.4 Chipping Concrete 102.9 Stationary Power tool 101.8 Working near Generator 116 Chipping Gun 103.0 Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com NON-OCCUPATIONAL NOISE SOURCES Sound Source Sporting Events Lawn Mower Motorcycle Riding Concerts Shooting Range Fireworks Chain Saw Snow Blower Snowmobile Sound Level (dBA) 100-125 90-100 95-120 95-125 130-165 130-190 105-125 100-105 85-100 Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com TYPES OF HEARING PROTECTION Earplugs Hearing Bands Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com Earmuffs PROPER USE To be effective, hearing protectors must: Fit properly Be used per manufacturer instructions Have the appropriate Noise Reduction Rating (NRR) Be kept clean to prevent ear infection Be visually inspected prior to use Be replaced as needed Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com PERSONAL PROTECTIVE EQUIPMENT • Protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury • Provided to employees who are exposed to hazards in the workplace at NO COST • Required in certain areas within schools: – Art rooms (e.g. gloves, safety glasses, dust mask) – Band rooms (e.g. hearing protection) – Custodial and maintenance areas (e.g. gloves, goggles, face shield, hearing protection, respirator) – Health offices (e.g. gloves) – Industrial technology shops (e.g. gloves, safety glasses, hearing protection) – Kitchens (e.g. gloves, goggles) – Science labs (e.g. gloves, goggles, aprons/lab coats) Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com PERSONAL PROTECTIVE EQUIPMENT • Chemical Splash Goggles – Provides eye protection from chemicals. – Tighter fit than safety glasses for max protection – Required in the work place when handling corrosive chemicals (e.g. bleach) – Make sure to purchase Indirect vent or non-vented goggles. Never purchase vented goggles for protection from chemical splash hazard Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com PERSONAL PROTECTIVE EQUIPMENT • Safety Glasses – Provides eye protection from impact of flying particles and objects (e.g. sawing, grinding, sanding) – Should NOT be used for protection against chemical splash or vapor hazards. Use tight fitting goggles instead. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com PERSONAL PROTECTIVE EQUIPMENT • Cut Resistant Gloves – For using knives, graters, slicers, other sharp objects • Thermal Gloves – For handling hot items in kitchens/science labs • Chemical Gloves – For mixing/diluting/handling chemicals – Nitrile, vinyl, rubber Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com PERSONAL PROTECTIVE EQUIPMENT • First Aid Gloves (Disposable) – For use when providing first aid or cleaning up blood/OPIM – Kept in first aid kit - make sure to check supply annually • Serving Gloves (Disposable) – For serving food to prevent spread of germs – Typically polyethylene or vinyl Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com PERSONAL PROTECTIVE EQUIPMENT Air Purifying Respirator N95 Respirator – You must be on the district’s Respirator Program before you are authorized to wear an air purifying respirator at work. – If using N95 Dust Mask (two strap dust mask), you must review and sign “OSHA Appendix D - Voluntary User” Form – Contact Tom Bravo, Facilities Manager, if you’d like to wear aN95 mask at work. Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com CHANGES TO THE OSHA EMPLOYEE RIGHT-TO-KNOW STANDARD WHAT IS GHS? • United Nations Globally Harmonized System of Classification and Labeling of Chemicals (GHS) 1. Document created by United Nations; 2. It is NOT a global law or regulation – it is a SYSTEM for ensuring the safe production, transport, handling, use and disposal of hazardous materials. 3. Establishes objective criteria for classifying & ID chemical hazards; 4. Defines health, physical and environmental hazards; 5. Standardized system for classifying, & communicating hazards that has been adopted by over 65 countries 6. Adopted by the USA on March 26, 2012 and enforced by OSHA CHANGES: 1. 2. 3. 4. 5. Hazard Classifications Hazard Categories Pictograms Labels Safety Data Sheets (SDS) GHS CHANGE #1 - CLASSIFICATIONS • Health Hazards – Acute Toxicity – Skin Corrosion/Irritation – Serious Eye Damage/Eye Irritation – Respiratory or Skin Sensitization – Germ Cell Mutagenicity – Carcinogenicity – Reproductive Toxicity – Target Organ Systemic Toxicity – Single and Repeated Dose Chemical manufacturers must reclassify their chemicals using criteria established by the GHS Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com GHS CHANGE #1 - CLASSIFICATIONS • Physical Hazards – – – – – – – – – – Explosives Flammability – gases, aerosols, liquids, solids Oxidizers – liquid, solid, gases Self-Reactive Pyrophoric – liquids, solids Self-Heating Organic Peroxides Corrosive to Metals Gases Under Pressure Water activated flammable gases Chemical manufacturers must reclassify their chemicals using criteria established by the GHS Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com CHANGE #2 – HAZARD CATEGORIES • Hazard category will tell you how severe the hazard is. • GHS System – 1 to 4 scale with 1 indicating most significant hazard and 4 as least significant • HMIS and NFPA Labeling System (opposite of GHS) – NFPA Diamond: 0-4 scale with 4 indicating most significant hazard and 0 least significant – HMIS Label: same as NFPA diamond GHS Change #3 - Pictograms • Will be located on all GHS labels and safety data sheets • Tells you what the chemical classifications are Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com EXPLODING BOMB • Explosives • Self-Reactives • Organic Peroxides FLAME • Flammables • Pyrophorics • Self-Heating • Emits Flammable Gas • Self-Reactives • Organic Peroxides FLAME OVER CIRCLE • Oxidizers GAS CYLINDER • Gases Under Pressure SKULL & CROSSBONES • Acute Toxicity (fatal or toxic if swallowed) EXCLAMATION POINT • Irritant • Dermal Sensitizer • Acute Toxicity (harmful or maybe harmful if swallowed) • Narcotic effects • Respiratory Sensitizer • Irritation CORROSION • Corrosive HEALTH HAZARD • Carcinogen • Respiratory Sensitizer • Reproductive Toxicity • Target Organ Toxicity • Mutagenicity • Aspiration Toxicity GHS CHANGE #4 – LABELING • GHS container labels will provide the following six sections of information: 1. Name of Hazardous Substance 2. Manufacturers Information 3. Signal Words (i.e. “Danger” and “Warning”) 4. Hazard Statement (e.g. “fatal if swallowed”) 5. Precautionary Statement (e.g. “wear splash protection for face”) 6. Pictogram Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com GHS SAMPLE LABEL Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com GHS CHANGE #5 – SAFETY DATA SHEETS • Material Safety Data Sheets (MSDS) are now referred to as Safety Data Sheets (SDS) – 16 section, standardized format Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com SAFETY DATA SHEET STANDARDIZED FORMAT 1. 2. 3. 4. 5. 6. 7. 8. Identification of the substance or mixture and of the supplier Hazards identification Composition/information on ingredients First-aid measures Fire-fighting measures Accidental release measures Handling and storage Exposure controls/personal protection 9. Physical and chemical properties 10. Stability and reactivity 11. Toxicological information 12. Ecological information 13. Disposal considerations 14. Transport information 15. Regulatory information 16. Other information, including date of preparation or last revision Questions? Contact Dan Fitch with IEA at 763-315-7900 or dan.fitch@ieasafety.com QUIZ AND QUESTIONS • Please click on the link below for the ERK Quiz or copy and paste this address into your browser. That will be your documentation of training for this year. • https://www.surveymonkey.com/r/XKWS3QF • If you have any questions throughout the quiz, please contact Tom Bravo, Facilities Manager at 952-9286004 or email bravo.thomas@slpschools.org