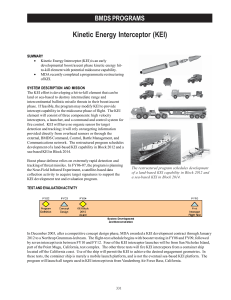

KEI Sentinel Architecture

advertisement

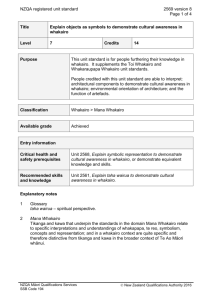

Kesler Engineering Component Software: Using ActiveX Object Modeling with PI PI System User’s Conference March 1999 Introduction to KEI • KEI Established 1979 by Michael Kesler – Co-Author of Lee-Kesler Correlation for Thermodynamic Properties of Mixtures – Developed First Industry General Process Simulator (MW Kellogg -1958) • Main Business – Process Engineering – Software Products • Sophisticated highly focused models that work on-line with PI and ProcessBook • KEI is Partly Owned by OSI Software Real-Time and Relational Databases • All data is accessible to everybody - all the time – Configuration – Results – No proprietary application file formats • Application data is scripted, reported, and manipulated using real, existing, well-established, robust tools Specialized GUIs • KEI ActiveX controls provide specialized view of process operations for operators, engineers, and management • Configuration Wizards provide ‘notraining’ views of configuration data • Administrative control panel allows monitoring and administration of KEI engine on a per model basis Embed Application GUI in PB • Allow end user to customize view of data • Use ProcessBook to provide customizable navigation to data views • Use ProcessBook trends and other widgets KEI Component Software • KEI ActiveX controls embedded in ProcessBook • KEI models are COM objects that are instantiated when needed • KEI engine uses KEI models to generate results The KEI Sentinel Engine Creates and Uses KEI Models Open-Equation modeling system, calculated and known parameters are specified in the RDB by the engineer. Component Based Modeling Models implement the IKEIModel COM interface Parameters are the ‘knowns’ and the ‘unknowns’ of the model Parameters and Models • Parameter values come from different sources... – Specified constant • Value is stored in RDB – PI Tag • Live (conditioned) value from PI tag; PI tag specification is stored in RDB – Calculated Value • Value is calculated by the KEI engine Models: COM Objects Fired Heater Model • Parameters: Stack Temperature, Stack O2, Thermal Efficiency, Process Duty,… • Equations: Overall mass balance, Reaction stoichiometry, Overall energy balance,… • Submodels: FuelGas, Pass 1, Pass 2,... Process Pass Model • Parameters: Tube length, Mean Metal Temperature, Mean Flux, Duty… • Equations: Equations of radiant heat transfer,… Models: COM Objects • When a model is created, its parameters and submodels are read from the RDB. • All model configurations are stored in the RDB. Models: COM Objects • Use the same model for off-line what-if analysis – Excel spreadsheets, VB applications • Open equation model format permits flexible case studies – “How much fuel would be required if stack temperature was 550ºF?” • On-line case studies KEI ActiveX Controls Also Create and Use KEI Models KEI Model Explorer • Developed to persistently store COM objects used in PB applications • Containment hierarchy (Company Refinery Crude Unit Fired Heater Pass Duty) • Possible to trend or get a pump’s inlet and outlet pressure, vibration, etc., with one click • Call methods on a heater pass to calculate its duty KEI Software Philosophy Products are sophisticated highly focused models that work on-line • Software must be robust! • All data, including configuration and results, must be accessible to everyone, all the time • Software must be easy-to-install and maintain Fired Heater Sentinel - Value • Correct Fired Heater Operation of a 200 MM Btu/hr Heater Results in an 2% Increase in Efficiency, Saving US$70,000/yr • If Fired Heater Is the Plant Constraint, 1% Increase in Heat Transfer (by Preventing Coking) Will Increase Throughput by 1% – Up to US$1 Million/yr in Refining Margins for a 100,000 BPD Refinery • Pass Balancing Can Increase Plant Throughput If Plant Is Heater Constrained Inferential Fractionator Sentinel - Value • Estimate $2-5 Million Increased Profit * Due to Improved Crude Switch Operations – Allows Control System to Shorten Crude Switch Time – Reduce Product Give-away • Eliminates 1+ Hour Analyzer Lag Time • Reduces Number of On-line Analyzers ~$100,000 Per Stream Per Property (~5 Analyzers) *“Mining Gold From Black Oil Using Virtual Picks and Shovels”, P. Nick, Process Systems Engineering; W. Cheng TOSCO Los Angeles Refinery, NPRA Computer Conference Nov. 1997.