Inlets and Nozzles

advertisement

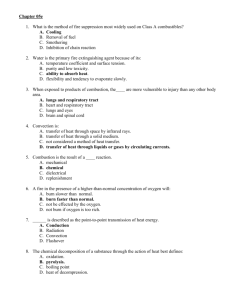

Combustion Design Considerations EGR 4347 Analysis and Design of Propulsion Systems PROPERTIES OF COMBUSTION CHAMBERS • • • • • • • • Complete combustion Low total pressure loss Stability of combustion process Proper temperature distribution at the exit with no “hot spots” Short length and small cross section Freedom from flameout Relightability Operation over a wide range of mass flow rates, pressure and temperatures COMBUSTOR DESIGN GOALS ARE DEFINED BY THE ENGINE OPERATING REQUIREMENTS • • • • • • • • LEAN BLOW OUT FUEL-AIR RATIO IGNITION FUEL-AIR RATIO PATTERN FACTOR RADIAL PROFILE FACTOR PRESSURE DROP (SYSTEM AND LINER) COMBUSTION EFFICIENCY MAXIMUM WALL TEMPERATURE SMOKE AND GASEOUS EMISSIONS CRITICAL DESIGN PARAMETERS • • • • • • • • • • Equivalence ratio, Combustor loading parameter, CLP Space heat release rate, SR Reference velocity, Vref Main burner dome height, Hd Main burner length/dome height ratio, Lmb/Hd Passage velocity, Vpass Number and spacing of fuel injectors Pattern factor correlation parameters, PF Profile factor correlation parameter, Pf DEFINITION OF TERMS • PATTERN FACTOR (TEXIT)MAX - (TEXIT)AVE PF = (TEXIT)AVE - (TINLET)AVE • SYSTEM PRESSURE DROP (PINLET)TOTAL - (PEXIT)TOTAL DPS = (PINLET)TOTAL • LINER PRESSURE DROP (PINLET)STATIC - (PEXIT)STATIC DP = (PINLET)STATIC COMBUSTION PROCESS • REACTION RATE - f(Temp, Press) – T & P high fast reaction rate – limited by rate at which fuel is vaporized • FUEL/AIR RATIO (OCTANE e.g.) – 2C8H18 + 25(O2 + 79/21 N2) – fstoich = 16 CO2 + 18H2O + 25(79/21)N2 2(96 18) 0.0664 25(32 79 21 28) • EQUIVALENCE RATIO, ff stoich ENGINE OPERATION AFFECTS INGNITION AND LEAN STABILITY IGNITION ENVELOPE FUEL FLOW ALTITUDE OPERATIONAL ENVELOPE DECELERATION SCHEDULE STABLE FLAMEOUT MACH NO. ENGINE SPEED COMBUSTION PROCESS 10 Equivalence Ratio, 6 4 2 Rich flammability limit Flammable mist Flammable vapor 1.0 0.6 0.4 Spontaneous ignition Lean flamm abilit y lim it Flash point 0.2 0.1 50 100 150 200 250 T (C) • PROBLEM: want low (<1); can easily by 0.5 SOLUTION: locally rich mixture that’s burned then diluted and cooled to acceptable Tt4 • PROBLEM: want stationary flame within a moving flow SOLUTION: Recirculating region at front of combustor, or “flame holders” in AB COMBUSTION PROCESS (Ignition) • Requires fuel/air mixture be within flammability limits • Sufficient residence time • Ignition source in vicinity of combustible mixture – If mixture is below Spontaneous Ignition Temperature (SIT), an ignition source is required to bring temp up to SIT (Spark Plug) – Ignition energy - fig 10-68 const 1 – Ignition Delay tign exp , T P COMBUSTION PROCESS (Stability) • Ability of the combustion process to sustain itself • PROBLEMS: Too lean or too rich – Temp & reaction rates drop below that required to heat and vaporize the fuel/air mixture • CLP (Combustion Loading Parameter) – Indication of stability based on mass flow, pressure (n = 1.8 for typical fuels), and combustor volume CLP m P n Vol Unstable Stable Unstable CLP COMBUSTION PROCESS (Stability - CLP) • Gives an estimate of combustor length L Vref t res t 3A ref t res m L Aref 2" Vave = Vref m L: distance required for combustion to be completed Aref: cross-sectional area normal to airflow 1 t3: approximate density of air entering combustor t 3 Pt 3 t res Pt3 n c COMBUSTION PROCESS (Stability - CLP) Eq. 10-31: L c 1 Pt 3 c Tt 4 A4 t res A ref Note: this equation needs to be corrected in your book Design of “new” combustor based on “old” designs (Table 10-5) Known Similar Reference F100: L = 18.5 in D = 25 in Pt3 = 366 psia Tt4max = 3025 R c 1 L const c Pt 3 Tt 4 Pt3n New Design Pt3r L Const Tt 4 1 where r n c c Thus: the length of main burners varies with pressure and temperature COMBUSTION PROCESS (Total Pressure Loss) • Heat interaction (Rayleigh Loss) + Friction/Drag (Fanno Loss) 1 Drag i Vi2 C D A q = cpeTte - cpiTti 2 Vi Tti D Ve Tte e i q Cont: Vi i Vee i Vi2 eVe2 1 Mom: Pi Pe i Vi2CD gc gc 2 Energy: q = c peTte - c pi Tti COMBUSTION PROCESS (Total Pressure Loss) • Solution to these 3 equations: exit, e 4 inlet, i 3 • Equations 10-35 thru 10-38 on page 823 Tt4 q c p3Tt3 1. Tt3 c p4 Tt3 1 2 3 M 32 1 3 M3 2 Tt4 2. = 2 4 1 + 3 M 32 1 CD Tt3 3. M 42 P 4. 4 P3 2 1 - 2 4 1 - 2 4 1 1 + 3 M 32 1 CD 2 1 4 M 42 4 4 1 2 4 1 M4 1 Pt4 P4 2 5. 3 1 Pt3 P3 1 3 1 M 2 3 1 3 2 COMBUSTION PROCESS (Total Pressure Loss) Pte / Pti or Pt4 / Pt3 1.00 1.0 0.95 0.80 0.90 0.6 Me or M4 0.85 0.4 0.80 0.2 0.75 0.0 0.3 0 0.05 0.1 0.15 0.2 Mi or M3 0.25 COMBUSTOR DIFFUSER (Total Pressure Loss) 3 Set by Compressor Blade Height 2 1 A2 A1 A3 smooth-wall diffuser step (dump) diffuser Smooth-Wall 2 2 A1 M1 1 1 A 2 Pt 2 2 1 Pt1 1 1 M 2 1 1 2 Dump 2 6 Pt 3 A A 2 2 2 exp M 2 1 1 Pt 2 2 A A 3 3 COMBUSTOR DESIGN ITERATION • Estimate the combustor geometry – Check Combustion Stability (at all flight conditions) – Determine Combustion Efficiency (at all flight conditions) – Calculate Space Rate Heat Release (at all flight conditions) – Determine Combustor Reference Velocity (at all flight conditions) • NEXT: Modify design based on the above calculations and typical/target values Main Burner Areas, Heights, and Velocities rm Vref Aref Acomb Vcomb~ 30 ft/s ro Apass Vpass~ 150 ft/s ri Main Burner Height, H Aref = Apass + Acomb m 3a Vref t 3 Aref H = ro - ri Aref H 2 rm COMBUSTOR DESIGN ITERATION • Assume the following “typical” combustor geometry – Primary Combustor Volume, 3.5 ft3 ( Acomb*Lcomb) – Combustor Reference Area, Aref = (rt2 - rh2) = 5 ft2 – Dome Height, H = rt - rh = 7 in – Total Combustor Volume, Vol = 7.0 ft3 rt Vref H = rt-rh Acomb Aref Primary Volume Combustor Volume (includes Primary) rh Lmb = Ldiff + Lcomb COMBUSTOR DESIGN ITERATION • Can calculate from performance data the following: – Combustor Efficiency, b – Check Stability by plotting CLP vs – Calculate Space Rate or Space Heat Release Rate -- measure of intensity of energy release – Calculate the Reference Velocity, Vref • Review literature to determine acceptable values for the above parameters then adjust the design choices such as Volumes, Areas, and Height. COMBUSTOR EFFICIENCY (reaction rate parameter) 1.75 t3 P Tt 3 b Aref e H . x 10 5 m3 "" when 1.03 where b 382 2 ln / 1.03 "" when 1.03 COMBUSTOR STABILITY (CLP) CLP m P Vol n SPACE HEAT RELASE (SR) and REFERENCE VELOCITY (Vref) f AB hPR 3600 m SR Pt (Vol ) AB . Vref m3 t 3 Aref Main Burner Lengths and Mass Flow Rates Lcomb Ldiff = Lsm +Ldump Ldiff local = /50% m3a*50% Primary Comb Zone 3b 3c m3a Passage m3a*50% 3a Lmb Lmb = Ldiff + Lcomb Pt3r Lmb const Tt 4 Volmb = 0.8Lmb*Aref Volcomb = Lcomb*Acomb Afterburner Design Requirements *Large temperature rise *Low dry loss (non-AB thrust) *Wide temperature modulation (throttle) *High combustion efficiency *Short length; light weight *Altitude light-off capability *No acoustic combustion instabilities *Long life, low cost, easy repair Afterburners Components: • Diffuser • Spray Ring • Flame Holder • Cooling Liner • Screech Liner • Variable Throat Nozzle Afterburners - Components Diffuser Combustion Section Zone 4 fuel spray ring Zone 3 fuel spray ring Zone 2 fuel spray ring Fan flow Splitter cone Flame holder Cooling Liner Core flow Zone 2 fuel Zone 1 fuel spray ring spray ring Diffuser cone Linear perforated Linear louvered Station 6 Station 7 Afterburners - Components Spray Ring Diffuser Flame Holder V2 d Recirculating Zone H W L Mixing Zone Diffuser • Balance between low total pressure loss during combustion (loss Mach no) and AB cross-sectional area (no larger than largest diameter upstream) • Short diffuser to reduce AB length with low total pressure loss • Analysis - same as combustor diffuser Spray Ring - Injection, Atomization, Vaporization, & Ignition • Injection: core stream first (high temp) spray ring Fuel is injected perpendicular to air stream & ripped into micron-sized droplets (atomized). Fuel is vaporized then ignited prior to being trapped in downstream flameholder • Ignition: spark or arc igniter pilot burner Flame Holder - Flame Stabilization • Two main types – V-gutter Flame Holders – Pilot burners V2 d Recirculating Zone W L Flame Holder Mixing Zone • Bluff body that generates a low-speed mixing region just downstream of fuel injection – high local equivalence ratio (~ 1) – 2 zones: 1) Mixing - turbulent flow with very high shear sharp temp gradients and vigorous chemical reactions; 2) Recirculating - strong recirculation, low reaction rates and temps very near stoiciometric Cooling and Screech Liner • Cooling – Isolates the very high temperatures from outer casing. In F119 all the fan air is used to cool the AB and Nozzle during AB operation. • Screech – Attenuates high frequency oscillations associated with combustion instability (high heat release rates) – 200-20000 Hz,high heat loading & vibratory stresses Rumble Alt Screech Regime M Variable Nozzle • MFP - applied at Nozzle throat, M8 = 1 m 8 Tt 8 A8 Pt 8MFP(M8 ) Single Flameholder Design Dmax= 35 in V1 d V2 L 1, i Inlet Conditions (Typical) Pt1 = 40 psia Tt1 =1750 R m = 200 lbm/s 1 = 1.33 Exit Conditions (Typical) Tte = 3800 R 2 = 1.3 fAB = 0.035 W H e Flameholder Geometry (Choice) half angle, a = 30 deg d = 3.5 in local = 0.8 Design Calculations 1. Find M1 m 1 Tt1 MFP ( M1 ) Pt1A1 2. Check for flame stability for local = 0.8 Tt1 T1 1 1 2 M1 1 2 P1 Pt1 1 1 2 M1 1 2 Eq. 10-53 and Fig 10-89 Characteristic ignition time, tc tc k ( ) PT 2.5 t c ref 2.5 t c ref Pref Tref PT 2.5 1 ( 1 1) k () 2.5 Pref Tref Design Calculations (cont’d) 2. Flame stability (cont’d) eq 10-51: tc L V2c want something in terms of V1c, H, and tc, where V1c is the maximum entrance velocity for a stable flame V1c L W V1 L W V1ctc eq 10 54 H Blowout H V2c W V2 W H V1 W , V2 H are functions of flameholder blockage ratio, B = d/H - see Table 10-7 L 4 W Solve for V1c above and compare to V1 M1 1RT1gc If V1c > V1, the flame will not blow out Design Calculations (cont’d) 3. Total Pressure Drop (AB) - Target Values: Fig 10-90 Diffuser: combination of smooth wall & dump - same approach as main combustor diffuser using equations 10-42a&b and 10-43 Rayleigh + Fanno: CD & Tte/Tti - Tte/Tti is given from calculations (Perf) - CD is estimated using equation 10-57 V C D B 2 V1 2 - Use equations 10-35 thru 10-38 to determine pressure ratio due to Rayleigh & Fanno losses Design Calculations (cont’d) 4. Total Afterburner Length - Based on Fig 10-92 5. Space Heat Release Rate, SR f AB hPR 3600 m SR Pt (Vol ) AB Vol = (total length x AB cross-sectional area) Desired value near 8 x 106 Btu/(hr ft3 atm) Combustion Chemistry - General Fuel-to-Air Stoichiometric Equation y z y z y y z C x H y Oz x O2 3.76 x N 2 xCO2 H 2O 3.76 x N 2 4 2 4 2 2 4 2 f stoich m fuel mair 12 x 1y 16 z y z x 32 3.76 28.16 4 2 - Simple Approximation for Heating Value of the Fuel (Hill and Peterson, p. 221) H hPR 15,900 15,800 in BTU lb m C H 1.008 m where for Hydrocarbo n C n H m C 12.01 n Combustion Chemistry Fuel Heating Value (Btu/lbm) Estimate (Btu/lbm) JP4 (CH2.02) Propane (C3H8) Methane (CH4) Liquid Hydrogen 1 18,4001 19,9442 21,5182 18,579 19,436 21,203 51,5932 (Equation not Valid) EGTP, pg 827 2 Standard Handbook for Mechanical Engineers, pg 4-29, table 4.1.6 Combustion Chemistry - Non-Reacting MixturesBasic Equations Applied Equations k mass: m m mi i 1 R k Mole Number : N m N i C p A0 A1T A2T 2 A3T 3 A4T 4 i 1 k Mass Fraction: mf i mf i , i 1 Mole Fraction: i Ni , Nm 1.9857117 (Btu/lb mole R) 28.97 - f 0.946186lb m /lb mole k mf i 1 i 1 k i 1 i 1 A5T 5 A6T 6 A7T 7 C pm C pair f C pprod 1 f R 1 m C pm 1 k Mass: mi N i M i ; m m i M i i 1 Gas Constant: R m Ru Mm -Coefficients for Cp equation given in Table 2-4 (pg 106) Mattingly -Variation in properties given in Figures 6-1 and 6-2 Combustion Chemistry - Variation with Temp- versus Temp for JP-4 Cp versus Temp for JP-4 1.42 0.36 f=0 f = 0.02 1.4 0.34 f = 0.04 f = 0.06 1.38 f = 0.0676 0.32 0.3 1.34 Cp (Btu/lb mR) 1.36 1.32 0.28 1.3 f=0 0.26 f = 0.02 1.28 f = 0.04 0.24 f = 0.06 1.26 f = 0.0676 0.22 1.24 0 500 1000 1500 2000 2500 Temp (R) 3000 3500 4000 4500 0 500 1000 1500 2000 2500 Temp (R) 3000 3500 4000 4500 Design Example For the information given on the 1st slide, find the following: 1. M1 and V1 2. V1c (check stability) 3. Pressure ratio due to Rayleigh and Fanno losses 4. AB length 5. SR COMBUSTION PROCESS (Total Pressure Loss) Example: What is the pressure ratio across the burner for the following conditions: Pt4/Pt3 1. Tt4/Tt3 = 3.0 and CD = 0 (No Drag) 2. Tt4/Tt3 = 1 and CD = 2.0 (No q) 3. Tt4/Tt3 = 3.0 and CD = 2.0 (Both Drag and q) COMBUSTOR DIFFUSER (Total Pressure Loss) Set by Compressor Blade Height Station 1 to 2 (smooth-wall, sm) Given: = 0.9, A1/A3 = 0.20 M1 = 0.5 Pick: A1/A2 = ________ Find: Pt2/Pt1 = __________ (Use Eq 9.17b) 2 1 Hsm Lsm M2 = _______ (Use MFP) Lsm/Hsm = ___________ (Use Fig 9.8) 3 Station 2 to 3 (Dump) Calc: A2/A3 = ________ Find: Pt3/Pt2 = __________ (Use Eq 9.18) 2 HD M3 = ___________ (Use MFP) Overall Pressure Ratio of Diffuser, Pt3/Pt1: _________ L D HD