Industry

advertisement

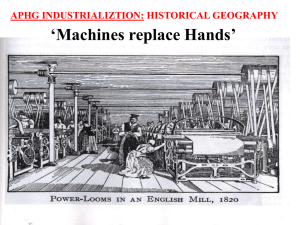

Industry Industrial Revolution • • • • Began in England in late 1700’s 1800’s reached the US and Europe invention of machines Iron was a leader and was followed by: – Coal, engineering(making of machines), Transportation(shipping, canals, railway), textiles, chemicals, food processing From Britain to Europe • France, Germany and Belgium had followed Britain into the Industrial Revolution • Unrest (wars) in Europe during this time delayed new technology for some countries. • This forced cooperation of countries who had been separated after “nationalism” I.R in the U.S • Took longer to begin but once it did it developed very quickly. Industry Goal: Make $$$ • Maximize Profit while Minimizing Production Cost. Why There? • Situation and Site Factors • Situation: transportation of materials to and from factory • Site: what is going on in that location?—Land, Labor and $$---depends on location. Situation • Goal is to have as little cost to the producer of the good as possible. • Place Industry in an area that is inexpensive to get to the plant but also inexpensive to get to the customer. • Best location: If raw materials are expensive to get to the plant----put plant near raw materials. If shipment from the plant to the customers is expensive----put the plant near the customers. Bulk-Reducing Industry • These are products (inputs) that are physically heavy or expensive to move from the earth (or original location) to the processing plant. • Products that are Bulk-Reducing have plants located near the material. • Examples include: – Copper and Steel Bulk-Gaining Industry • These are products (goods) that after produced they become heavier, bulkier, or more expensive to transport. – Soda (comes in as a number of small, light, ingredients and goes out as heavy bottled material) – Automobiles (tend to be centrally located or near large market areas) Put plants near populations that will buy cars. Single-Market • Force the people to come to you. • Manufactures make a single product and are located in one place. • Clothing-high end are clustered in N.Y because of the quick demand and concentration of customers. • Car Parts-only a few customers (large car companies) located near manufactures. Perishable Products • Stuff that goes bad. • Fresh food producers must get their product to customers quickly. • Newpapers- news gets old so people must locate their printing offices near big market areas so people can get quick information. Shipment • Ship, Rail, Truck or Air? • Which one is cheaper depends on how far it must go. • The further the distance the cheaper (per mile) because 10miles or 1000miles you still must pay people to load and unload your goods. • Trucks-cheapest for short distances • Ships-if water is available and your going far this is cost effective. • Air-Most expensive but if customers are requesting fast service this is the best. • However, with many stops the price increases. • Break-Of-Bulk Point—transfer mode of transportation _sea ports or air ports. Site Factors • Land • Labor • Capital Land • manufactures need a large space to build their factories. • Most factories will be built in suburban and rural areas where land is less expensive. • Also, available resources to help run the company influence its land area. – Coal: near coal fields – Electricity: depends on cost Labor • Labor prices (what you must pay your employees) vary from country to country and also state to state. • Labor-Intensive Industry- where a company spends a large amount of their cost on workers. – Two forms: Highly Skilled and Expensive and Low Skilled and Inexpensive. Unskilled/Low-wage • Textile and Clothing Industries. • LDC’S perform these jobs. • In MDC’S factories are located in areas where people might be less educated and are forced to settle for a lower wage. • Southeast US Skilled/High Wages • Electronics and Computer Manufactures. • Primarily done in MDC’s where people are educated in this specialized field. • Factories are located near Universities, large Urban areas and regionally in the NE and West Coast Capital= $$$$ • In order to build factories manufactures must borrow money. • Factories will be built in areas where money is more easily attainable (where they can get it) • If an area is known for supporting industry by providing loans people will put their business there. Ex: Silicon Valley • This is a huge factor that separates LDC’s and MDC’s • Communities want business! More Jobs! Agglomeration • Centralization of features of an industry for the mutual benefit of the industry as a whole. • Think Mall—each store is benefitted by the concentration of all of the other stores. • Draws consumers to one location each benefitting through proximity. • Detroit for example had multiple competing auto manufactures in the same city. Alfred Weber • Created the classical model of industrial location theory in 1909 Least-Cost Theory • Explains the optimum location of a manufacturing establishment in terms of minimizing three basic expenses – Transportation cost, labor, agglomeration Least Cost Theory 1) Transportation: the site chosen must entail the lowest possible cost of A) moving raw materials to the factory B) finished products to the market. This, according to Weber, is the most important. Least Cost Theory 2) Labor: higher labor costs reduce profits, so a factory might do better farther from raw materials and markets if cheap labor is available -ex: China – today Least Cost Theory 3) Agglomeration: when a large number of enterprises cluster in the same area, they can provide assistance to each other through shared talents, services, and facilities -ex: manufacturing plants need office furniture 5 Controlling Assumptions 1. Area is uniform physically, culturally, and technologically 2. Manufacturing involves a single product to be shipped to a single market whose location is known 3. Inputs involve raw materials from more than one known source location 5 Controlling Assumptions 4. Labor is infinitely available but immobile in location 5. Transportation routes connect origin and destination by the shortest path and directly reflect the weight of the items shipped and distance moved Situation and Site isn’t everything • With the global community that exists today not all businesses need to be in a place that is best for bulk-gaining or bulk-reducing nor does Land, Labor and Capital mean as much. • Corporations look at many factors when choosing a location for their business, profit is a major driving force in location of industry.