Personal and Occupational Safety in the Workplace

advertisement

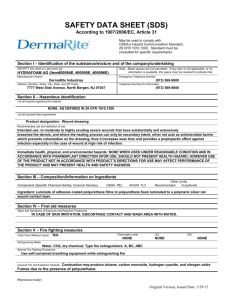

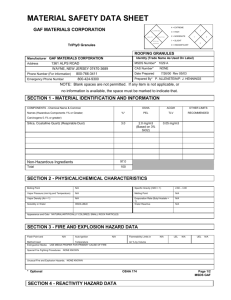

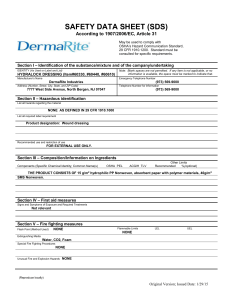

Personal and Occupational Safety in the Workplace Instructional Materials Service IMS #8000G Objectives Locate sources of information regarding relevant safety policies and regulations. Identify proper safety procedures. Apply safe working practices to all training/working situations. Introduction Everyone shares the responsibility of safety, whether at home, in school, or in the workplace. The responsibility for safety is shared between children, parents, students, employees, and employers. Safety benefits everyone! Introduction Webster defines safety as “protection against accidents and breakage.” Safety has also been defined as a “state of being relatively free from harm, danger, injury, or damage.” Prevention is one key to safety. Introduction Prevention is stopping an injury before it occurs. Safety is knowing what to do once the accident has occurred. It may not be possible to prevent all accidents from happening, but it is possible to decrease the number of serious injuries. Introduction Each year, nearly 6,000 people die from workplace injuries. Another 4 million suffer non-fatal injury or illness. In the agriculture industry alone, over 700 workers die in work-related accidents yearly. Another 120,000 suffer disabling injuries. Introduction These figures are an improvement from the 1,200 deaths and 140,000 disabling injuries in 1992. However, these figures are still much too high when considered in proportion to the total American population. Only about 2% of the workforce is engaged in fulltime agricultural production. Common Hazards Associated with Agricultural Occupations Mechanical Electrical Chemical Livestock Environmental Mechanical Hazards Leading cause of fatal injury in the industry between 1996 and 2001. Over 4,000 died due to accidents involving tractors, trucks, fishing boats, harvesting machines, mowing machines, and other agricultural machines. Machinery is also the leading cause of non-fatal injury in the industry. Mechanical Hazards Tractors are responsible for 350-450 fatalities each year. Common tractor-related accidents include: overturns; runovers; entanglements highway in power drivelines; and collisions. General Safety Tips for Tractor Operation Set parking brake when tractor is stopped. Ensure tractor is equipped with a bypass starter. This prevents jump-starting and reduces the likelihood that someone could be run over if tractor lurches forward when jump-started. General Safety Tips for Tractor Operation Be sure all people are clear of the machine before moving. When driving at a mere 5 mph, it still takes 1.6 seconds and 12 feet to stop a tractor. Relationship Between Tractor Speed and Stopping Tractor Speed (mph) Time Tractor Covers 6 ft. Stopping Time Stopping Distance (seconds) (feet) (seconds) 5 0.82 1.6 12 10 0.41 3.2 30 15 0.27 4.8 48 20 0.20 6.4 64 25 0.16 8.0 84 30 0.14 9.6 111 General Safety Tips for Tractor Operations Farm equipment should be hitched properly. At the drawbar and recommended hitch points. Drawbar Failure to properly hitch equipment results in instability and may cause a rear overturn. Rollover Protective Structures Tractors should be equipped with rollover protective structures (ROPS). These devices, in conjunction with wearing a seatbelt, prevent the driver from being crushed in the event of an overturn. ROPS Rollover Protective Structures Since 1976, ROPS have been designed into the cabs of new tractors. ROPS can also be purchased to fit older models. When used appropriately, it is estimated that ROPS and seat belts are 99% effective in preventing death or serious injury in the event of an overturn and would save 350 lives annually. Avoiding Tractor Overturns Photo Courtesy of USDA CREES Tractors should not be operated on slopes greater than 20 to 25 degrees. Avoiding Tractor Overturns Embankments, ditches, and holes should be avoided when possible. Reduce driving speed when turning, crossing slopes, or driving on rough, slick, or muddy surfaces. Preventing Runovers Each year many people die when run over by a tractor. In almost all instances, the person was a passenger while someone else was operating the tractor. Extra riders can be thrown from a tractor in the event of an overturn, when the tractor hits a bump, during a sudden stop or sharp turn, or when leaning against the door of an enclosed cab. Preventing Runovers Passengers can also distract the operator, blocking access to controls, or obstructing the operator’s view. The best way to avoid such dangers is to adopt a “No Riders” policy. Preventing Entanglements in Power Take Off Drivelines PTOs involve a rotating bar that attaches implements such as augers, mowers, and choppers to the tractor and transfers power from the tractor to the implement. This energy transfer is achieved by turning at speeds of 9-16 rotations per second. PTO Preventing Entanglements in Power Take Off Drivelines PTO Master Shield If used incorrectly, PTOs can maim or kill a person before the person even has a chance to react. PTOs should have a machine shield or guard covering the moving parts. Tips for Preventing Entanglements in Power Take Off Drivelines Wear close fitting clothes. Avoid clothes with a drawstring. Make sure clothes are not torn. Remove jewelry. Tie back long hair. Never step over a rotating PTO. Never start or stop the PTO unless seated in the tractor. Transporting Agricultural Machinery Transport of agricultural machinery can be dangerous to the operator as well as those sharing the road. Thousands of accidents occur each year involving farm machinery and other vehicles. Tips for Safely Transporting Agricultural Machinery Equipment should be equipped with clean, bright slow moving vehicle (SMV) emblems. This helps warn approaching drivers and is required by state law on all equipment moving at less than 25 miles per hour on roadways. Slow Moving Vehicle Emblem Tips for Safely Transporting Agricultural Machinery Hazard Lights Functional headlights, hazard warning lights, and turn signals will provide advance notice to approaching vehicles. Avoid transport of farm equipment at dawn or dusk. Tips for Safely Transporting Agricultural Machinery Safety Chain When towing a trailer or other piece of equipment, do not tow more than one at a time. Always use at least one safety chain in addition to the hitch bar. All-Terrain Vehicles Commonly used in agricultural work. Often treated as a form or recreation and not given proper respect, especially by youth. Between 1982 and 2002, one-third of all ATV accidents occurred in youth under age 16. 2005 National FFA Convention ATV Survey At the 2005 National FFA Convention, youth were asked to participate in a survey regarding ATV use and safety. Participants ranged in age from 12-20 and included both males and females. 2005 National FFA Convention ATV Survey Results 37% of boys and 20% of girls had been hurt in an ATV accident. Only 22% of survey participants had received any safety training. 25% never wear a helmet. Only 12% never allow a passenger. Most participants operate larger ATVs than recommended for their age. Tips for Safe Operation of All-Terrain Vehicles Wear a helmet. Operate a machine appropriate for your size and age. Avoid paved roads. Be free from the influence of alcohol or drugs. Tips for Safe Operation of All-Terrain Vehicles Cease operation in adverse weather conditions. Receive proper training. Avoid unnecessary risks and inappropriate behavior. Electrical Hazards Electrical shock results from accidents involving electricity. Possible outcomes of electrical shock: Burned flesh. Respiratory Cardiac arrest. Permanent Death. failure. disfigurement. Electrical Hazards The following can be responsible for electrical accidents: Contact with overhead electrical lines. Electrical Contact shorts in buildings and work areas. with electrical wiring. Malfunction tools. of or inappropriate use of power Overhead Electrical Lines Contact can occur when driving under the line with machinery, erecting poles or structures, or using tall ladders. Be aware of the location of overhead lines and make certain adequate clearance exists before working or traveling below them. Buildings and Work Areas Electrical panels should be covered. Work areas should be equipped with Ground Fault Circuit Interrupters (GFCI) and three-prong grounding plugs. All switches and outlets should be covered with face plates. Power Tools Power tools should always be properly functioning and not be used if damaged. Insulation around the cord should be fully intact and without cuts or tears. When repairing or cleaning tools, be sure to switch off and unplug the tool. Power Tools When unplugging a tool, grip it by the plug, not the cord. When carrying a power tool, do not carry it by the cord. If a tool is equipped with safety guards or shields, never remove them, and always keep them in good shape. Power Tools In the event of a tool starting to smoke or burn, or the endangerment of an operator or bystander, shut off the tool and unplug it, or use an emergency cutoff switch. Never use electrical tools around water. Chemical Hazards Chemical exposure can be a result of: ingestion by swallowing or eating; contact with the skin; contact with the eyes, or inhaling or breathing it into the lungs. Tips for Safely Handling Chemicals Use appropriate protective clothing or gear. Photo Courtesy of USDA Natural Resources Conservation Service Protective gear may include rubber gloves, mask, eye goggles, longsleeved shirt, long pants, or close-toed shoes. Wash clothes exposed to chemicals separately from the rest of the laundry. Chemical Labeling A chemical label provides information regarding potential hazards associated with the chemical product. Hazard level categories include: Caution Warning Danger Caution Lowest level of potential harm. Exposure isn’t likely to produce permanent damage if appropriate first-aid is rendered. Common ailments upon exposure include eye or skin inflammation, dizziness, or upset stomach. Warning Indicates the potential for serious illness or harm. Danger Highest level of potential harm. Exposure may result in tissue damage to the eyes or skin. If swallowed, the result could be damage to the mouth, throat, and stomach; or even death. Proper Chemical Storage Chemicals should be kept in locked storage, out of reach of children. Chemicals should be stored in their original, labeled container. Storing chemicals in unapproved containers, especially containers formerly containing foodstuff, is dangerous because it can easily be mistaken for something else that poses no danger. Empty chemical containers should be disposed of properly and not reused for storing something else. Livestock Hazards Livestock is a leading cause of nonfatal occupational farming injuries. This is rivaled only by machinery. Additionally, countless visitors and family members that are not employed by the farm are injured by livestock each year. Instincts and Characteristics Making Livestock Dangerous Difficulty judging distances. Easily spooked by sudden or loud noises, changes in lighting or shadows, and swift or sudden movements. Highly territorial and extremely protective of their young. Tendency to become unpredictable and aggressive when separated from the group. Tips for Safely Handling and Working With Livestock Photo Courtesy of USDA Agricultural Research Service Remain calm, move slowly, and avoid making loud noises. Avoid animals with newborns and bulls, boars, rams, or stallions. Tips for Safely Handling and Working With Livestock Approach animals, particularly cattle and horses, at the shoulder, and avoid their hind legs. Photo Courtesy of USDA Natural Resources Conservation Service Tips for Safely Handling and Working With Livestock Always have an escape route, especially in enclosed spaces. Consistently and properly use available restraining equipment. Photo Courtesy of USDA Agricultural Research Service Tips for Safely Handling and Working with Livestock Photo Courtesy of USDA Natural Resources Conservation Service Facilities should be designed for easy access to and exit from animals. Bystanders and children should be banned from handling areas. Tips for Safely Handling and Working With Livestock Wear a helmet when riding horses. Wear close-toed or steel-toed shoes when working with any type of large animal. Environmental Hazards Sun Damage Hearing Loss Respiratory Ailments Sun Damage According to the National Safety Council, there has been an increase in skin cancer among farmers and ranchers. This can be attributed to prolonged sun exposure. Tips for Preventing Sun Damage Wear hats with wide brims that cover most of the face, neck, and ears. Tips for Preventing Sun Damage Cover other areas of the body by wearing lightweight clothing. Apply sunscreen with a sun protection factor (SPF) of 15 or higher. Protect your eyes by wearing sunglasses that block 99% or 100% of UV light. Hearing Loss Hearing loss can result from frequent exposure to loud, damaging sounds and noises such as running machinery. According to the National Safety Council, farmers and ranchers have increased levels of hearing loss when compared to other occupations. Damaging Sounds Noise Noise Level (decibels) Sounds are considered to be hazardous if more than 85 decibels. Jet Airplane 140 Pig Squeals 130 Chain Saw 115 Loud Rock Music 115 Chickens (inside building) 105 Table Saw 100 Shop Vacuum 98 Tractor (wearing protective gear) 85-95 Electric Drill 88 Lawnmower 85 Quiet Whisper 20 Damaging Sounds An easy test for determining if a sound has reached this proportion is to see if you can be heard shouting at three feet away. If not, the sound is probably greater than 85 decibels. Tips for Preventing Hearing Loss Utilize hearing protection devices such as muffs or ear plugs. Increase the distance between you and the source of the noise. Respiratory Hazards Grain Dust Animal Dander Molds Pollen Soil Fumes Exhaust Respiratory Hazards If not kept from entering the lungs, air contaminants can cause lung damage and long-term respiratory problems. Exposure to toxic gases, particularly those resulting from manure or crop storage, could result in asphyxiation, irreversible lung damage, lingering respiratory problems, and perhaps even death. Respiratory Hazards The best way to prevent lung damage is to wear appropriate respiratory equipment. Other Hazards Lifting Repetitive Motion Injury Falls and Slips Lifting More than 30% of all workers’ compensation cases are related to back injury. Lifting If possible, avoid lifting heavy objects by pushing, pulling, rolling, or sliding the object. Use mechanical assistance, carts, or dollies when possible. Tips for Preventing Injury During Lifting Do not attempt to lift a load of more than one-third, or 35%, of your body weight. If possible, ask other workers for help. A signal should be given to lift when two or more workers are lifting to equalize the load. Tips for Preventing Injury During Lifting Feet should be kept close to the object being lifted. One foot should be closer to the object than the other, to maintain balance. Feet should be 8 to 12 inches apart. Knees should be bent, and hips should be kept lower than the shoulders when lifting. Tips for Preventing Injury During Lifting Heavy loads should be lifted with the legs and not the back. Assume a squatting position with back erect. Straighten the legs to raise the weight. Repetitive Motion Injury Commonly referred to as RMI. Can include the following: Carpal Tunnel Syndrome Muscle Strain Tendonitis Chronic Neck and Back Pain Approximately 60% of lost-time at work due to muscle and skeletal complaints are due to RMIs. Occupations that Commonly Suffer from Repetitive Motion Injury Assembly Line Work Meat Cutting and Packaging Product Testing Cabinet Making Loading/Unloading Situations Tips for Preventing Repetitive Motion Injuries Find a comfortable and efficient work posture. Maintain a balance of movements. Use ergonomic chairs. Correct monitor height. Falls and Slips Falls from ladders are particularly dangerous. Other falls and slips are generally caused by work areas or walkways that are dirty, cluttered, or wet. Tips for Preventing Falls from Ladders Prior to use, inspect it for problems with its structure. Ensure ladder chosen is appropriate for the task at hand. Metal ladders should not be used in electrical settings. If possible, a ladder with “safety feet” that stays stable on most surfaces should be selected. Tips for Preventing Falls from Ladders While in use, the ladder should be placed at the proper angle when propped against the wall or object of support. The distance from the base of the ladder to the wall should be one-fourth of the height of the ladder. Tips for Preventing Falls from Ladders The ladder should be long enough to safely accomplish the job. If one is working at a higher surface, the ladder should extend three feet above the upper surface. Tips for Preventing Falls and Slips Ensure that work areas and walkways are clean and dry. Do not leave objects lying on the ground. Wear footwear with slip-resistant soles and heels. Personal Safety Practices Show consideration for others. Do not leave drawers or cabinets open that may cause others to stumble. Clean up after yourself. Return Clear equipment to the proper location. walkways. Correct safety hazards and make others aware of hazardous situations. Personal Safety Practices Avoid inappropriate behavior. Do not run around hazardous materials, machinery, or equipment. Be aware of one’s own personal state and how it affects others. If one is tired or fatigued, driving or other complex tasks may be difficult and dangerous to the individual and others in the workplace. Personal Safety Practices Be aware of one’s own personal emotional state. An individual who is depressed, nervous, angry, or overly excited may forget things or become agitated. The lack of attention caused by the person’s emotional state may lead to safety hazards. Avoid use of alcohol or drugs. These can inhibit one’s ability to drive, operate machinery, or carry out other difficult procedures, endangering not only one’s self, but also others. Universal Safety Color Coding Familiarity with the meaning of safety colors can help an employee avoid hazards and locate safety equipment. Colors generally serve as the background for safety signs and notices. Safety Colors Red Danger or Emergency o Code for stop controls, safety switches, containers for combustible materials, and fire equipment. Orange Warning Indicates machine hazards such as edges and openings. Also used as background for electrical switches, levers, and controls. Yellow Caution Indicates adjusting wheels, levers, and controls that should be checked before turning on power. Yellow and Black Stripes Marks stairs, protruding objects, and other stationary equipment. Blue Information Provides warning or caution when machines or equipment is “Out-of-Order” or under repair. Green Safety Indicates the location of medical equipment, first aid, safety areas, and medical services. Yellow and Black Diagonal Stripes Radiation Hazards Aluminum Waste Containers Flammable waste when container has an orange band. Inflammable waste when container has a black band. Personal Protective Equipment (PPE) Eye Protection Hearing Protection Respiratory Protection Headgear Gloves Footwear Protective Eyewear Protects an individual from foreign matter flying into the eyes. Common types include: Safety Glasses Goggles Face Shields Safety Glasses Worn like regular prescription glasses, but made to standards that are much stricter than personal eyewear. May be worn in conjunction with personal eyewear. Generally offers no side protection, but may be available with either permanent or detachable side shields. Safety Goggles Photo Courtesy of USDA CREES Should be used when working with chemicals or chainsaws, or when chipping, riveting or grinding. Made to fit snugly around the eyes. Provide protection from all angles. Most can be worn with prescription glasses. Face Shields Designed to cover the entire face. Protects from heat, glare, and flying objects. Generally offers only secondary protection. May require use in conjunction with another form of protective eyewear. Photo Courtesy of USDA Agricultural Research Service Protective Eyewear for Welding Welding requires specialized protection due to the nature of the strong ultraviolet and infrared rays. Welding helmets and goggles are equipped with special filtering lenses that can protect the eyes against the powerful rays. Hearing Protection Acoustic Earmuffs Hearing Plugs Acoustic Earmuffs Worn over the ears. May be more comfortable than plugs when used over an extended period. Hearing Plugs Plugged into the ear. Can be either reusable or disposable. If they will be used infrequently or for a short period of time, disposable plugs may be preferable. Respiratory Protection Equipment should cover the mouth and nose and effectively filter the hazardous particles. Simple dust mask is generally sufficient. Respiratory Protection Tasks involving chemicals or fumes may require a respirator. Device purifies existing air and filters out damaging particles. Involves a mask worn over the nose and mouth and a filter or cartridge. Photo Courtesy of USDA Agricultural Research Service Headgear Hard Hats Bump Caps Hard Hats Consist of a hard shell made of aluminum, fiberglass, or plastic, and a suspension system. Should be worn when the possibility exists of falling objects such as building materials or tools. Bump Caps Meant to be worn in areas with little headroom or low-hanging machinery. Provide no impact protection but can protect against bumps and minor head injury. Gloves Provide valuable protection for hands and forearms. Can prevent cuts, abrasions, burns, contact with hazardous chemicals, and some electrical shocks. Gloves worn should always be appropriate for the task at hand. Types of Gloves Leather Protects the hand against rough objects, chips, sparks, and moderate heat. Cotton Can protect against abrasions, splinters, and dirt. Helpful in gripping slippery objects. Types of Gloves Rubber, neoprene, or vinyl Used when working with chemicals. Metal Mesh and Kevlar Knit Prevents cuts from sharp objects. Footwear Steel-toe cap protects the toes. Steel shanks help more evenly distribute weight. Metatarsal guards protect the top of the foot. Steel mid-soles protect against punctures. Slip-resistant soles help prevent slips and falls. Hazardous Communications (HazCOM) Program The Hazardous Communications Standard is administered by OSHA. Standard strives to ensure the following: Employers and employees are aware of hazards posed by chemicals. Workers know how to protect themselves from such hazards. Reduce the incidence of illnesses and injuries caused by chemical hazards. Parts of HazCOM 1. 2. Labeling Material Safety Data Sheets 3. Training Labeling Chemical manufacturers convey hazard information on the product’s container label. Label must identify the following: Chemical Hazard Name Warnings and Address of Manufacturer Labeling Hazard warnings can consist of any message, word, picture, or symbol that provides information regarding the hazards of the chemical and organs that may be affected by exposure. Employers are responsible for ensuring that containers remain labeled, tagged, or marked once in the workplace. Material Safety Data Sheets (MSDS) Chemical manufacturers prepare Material Safety Data Sheets (MSDS) that are supplied when the chemical is purchased or distributed. Material Safety Data Sheets (MSDS) The MSDS is an information bulletin describing the following: Physical and chemical properties of the chemical. Physical and health hazards chemical may pose. Routes of exposure. Precautions for safe handling and use. Emergency and first-aid procedures. Control Contact measures. information of the organization that prepared the sheet. Material Safety Data Sheets (MSDS) Employers are responsible for preparing a list of all hazardous materials in the workplace and collecting MSDS forms on each of those chemicals. Copies of MSDS forms must be available to all employees. Training Training or information programs should be conducted when: An employee is initially assigned a task involving hazardous chemicals. A new hazard is introduced. Information To Be Discussed in Training or Information Programs HazCOM standard and its requirements. Components of the workplace’s hazard communication program. Operations in work areas where hazardous chemicals are present. Location of hazard evaluation procedures, communications program, lists of hazardous chemicals, and MSDS forms. Information To Be Discussed In Training or Information Programs How to read and interpret labels and the MSDS. Hazards of chemicals in the work area. Measures employees can take to protect themselves. Methods and observations that can be used to detect the presence of a hazardous chemical. Lockout/Tagout Programs Designed to disable machinery and prevent unexpected energization or startup while performing repairs or maintenance. Involves applying an energy-isolating device or lock to a piece of machinery or equipment. Lockout/Tagout Programs Require that a designated individual perform the following steps before repair or maintenance: 1. Disconnect the machinery or equipment from its power source. 2. Lock or tag the piece of equipment using the appropriate energy-isolating device. 3. Verify that energy has been isolated effectively. Responding to Injury and Accidents The response of individuals on the scene and medical professionals can often determine the severity of the outcome. Many agricultural workers die, or suffer from aggravated injuries, each year when the first individuals on the scene are not prepared to offer appropriate assistance. Responding to Injury Remember the “three C’s” of responding to injury. Check Call for the safety of the victim. 911. Care for the conditions you find. Responding to Injury Remain calm! Failure to do so will inhibit your ability to offer assistance and could ultimately be devastating to the victim. Check the victim for consciousness, breathing status, bleeding, broken bones, and the cause of the accident or injury. If necessary, render first-aid needed to stabilize the victim. Responding to Injury After assessing the health and condition of the victim, promptly call 911. When speaking with the dispatcher, remain calm and listen carefully. Be prepared to answer questions regarding the victim’s condition. You may be asked to follow instructions on how to care for the victim. First-Aid for Bleeding Stop or control the bleeding. A clean cloth should be placed over the wound and pressure applied with the palm of the hand until the bleeding stops. If possible, elevate the wound above the victim’s heart to slow the bleeding. First Aid for Bleeding A tourniquet should only be used if blood loss may result in death. Tourniquet can damage tissue, nerves, and blood vessels, potentially causing the victim to lose his/her arm or leg. First Aid for Shock Victims Shock occurs when vital body functions are threatened by not getting enough blood or oxygen to major organs and tissues. Shock generally occurs following severe injury or emotional upset. Symptoms may include pale or bluish skin, skin that is cold to the touch, dull or sunken eyes, nausea or vomiting, unusual thirst, shallow breathing, or confusion. First Aid for Shock Victims Shock victims should be kept lying flat on their back with their legs elevated. Covering the victim with blankets will prevent the loss of body heat. Try not to give the victim something to eat or drink, as this may cause vomiting. First Aid for Potential Spinal Injury If possible, avoid moving an injured person, especially if a spinal injury is a possibility. Moving an individual with a spinal injury could make the injury worse. These injuries can not be repaired, and often result in paralysis or death. First Aid for Potential Spinal Injury If a victim must be moved, keep the neck and torso as straight as possible. If possible, drag the person on a blanket or by the clothing around the neck or shoulder area. The next best alternative would be to pull the person by his/her feet. Regardless of the method used, move the person using both arms or feet and pull in a straight line, not sideways. First Aid for Burn Victims For most burns, immerse the burned area in cool water, or run cold water over the burned area for 30 minutes. If clothing is stuck to the burn, do not remove it. Once the burn has been flushed, cover it with clean, cotton material. Do not scrub the burn, use soap, or apply ointments. First Aid for Heat Exhaustion Heat exhaustion can occur when an individual has difficulty adjusting to warm temperatures or is in an area with poor air circulation. Cause is generally loss of body fluids and salts. Signs of heat exhaustion include excessive fatigue, dizziness, disorientation, or clammy skin. Move the victim to a cool area and encourage the individual to drink cool water and rest. First Aid for Heat Stroke Heat stroke is a grave condition in which the body’s sweat glands shut down. Symptoms include confusion, collapse, unconsciousness, or fever with dry, mottled skin. If not treated immediately, a victim could die. First Aid for Heat Stroke The victim should be moved to a cool place and cool water poured over him/her until help arrives. First Aid for Poisoning Call the Poison Control Center at: 1-800-222-1222. Keep the poison container or label available when you call for medical assistance, whether the Poison Control Center or 911. First Aid for Poisoning If the poison is corrosive to the skin, remove clothing from the affected area and flush the area with water for 30 minutes. If poison comes into contact with the eyes, flush the eyes for at least 15 minutes with clean water. Rescue Breathing Necessary when breathing has stopped or the lips, tongue and fingernails become blue. Steps for Administering Rescue Breathing 1. Determine if the person can respond. 2. Ask someone to phone for help. 3. Roll the person onto their back. 4. Open the airway by tilting the head back, and lifting the chin. 5. Clear the mouth and throat of any obstructions with your fingers. Steps for Administering Rescue Breathing 6. Check for breathing by looking, listening, and feeling for breathing for 3-5 seconds. 7. Give the person two full breaths by tilting their head back, pinching the nose shut, sealing your lips around their mouth, and breathing two 1-1 ½ second breaths into their mouth. 8. Check for pulse at the side of the neck for 5-10 seconds. Steps for Administering Rescue Breathing 9. Phone emergency staff for help. 10. Continue rescue breathing, giving one full breath every 5 seconds. 11. Re-check the pulse every minute. 12. Continue rescue breathing until the person has a pulse or until medical help arrives. Cardiopulmonary Resuscitation (CPR) Combination of rescue breathing and chest compressions used when a victim is thought to be in cardiac arrest. Requires specialized training. Highly recommended to have one or many employees trained in CPR. Responding to Accidents Quick action and response helps prevent further injury and/or loss. In the event of an electrical problem, electrical fire, or employee entanglement in a piece of electrical-powered equipment, the electrical service disconnect should be promptly activated. Responding to Accidents All employees should know the location of emergency exits and be familiar with proper fire evacuation procedures. Everyone should know where to locate and how to properly operate a fire extinguisher. Fire Extinguishers Fire extinguishers should be appropriate for the class of fire that is most probable in a particular workplace. Classes of fires are determined by the material on fire and the surroundings. Classes of Fires Class A Ordinary combustibles such as wood, paper, or cloth, excluding any type of liquid or the presence of electricity. Class B Flammable liquids such as grease, fuels, and paints not in the presence of electricity. Classes of Fires Class C Electrical equipment such as motors and switches. Class D Combustible titanium. metals such as magnesium and Fire Extinguishers May be labeled using a combination of letters or symbols showing the type of fires it can be used to extinguish. Fire Extinguishers The most comprehensive type of fire extinguisher is a multipurpose dry chemical extinguisher which can be used for Class A, B, or C fires. Dry powder special compound extinguishers can be used to extinguish Class D fires. Operating a Fire Extinguisher 1. P – Pull the pin, thus unlocking the operating handle. 2. A – Aim the extinguisher at the base of the fire. 3. S – Squeeze the operating handle. 4. S – Sweep from side to side until the fire is out. Safety Organizations and Laws Safety laws and programs are aimed at reducing injury, death, and monetary costs. There are many state, federal, and public agencies dedicated to the prevention of injuries. Safety organizations or programs are typically dedicated to regulation, enforcement, and/or education. Federal Entities Concerned with Occupational Safety Department of Labor Occupational Safety and Health Administration National Institute of Occupational Safety and Health Environmental Protection Agency State Entities Concerned with Occupational Safety Workers’ Compensation Public Entities Concerned with Occupational Safety National Safety Council Partners for a Safer Community Department of Labor Mission or Purpose Foster and promote the welfare of American workers by improving their working conditions and administering various Federal labor laws aimed at guaranteeing safe and healthful working conditions. Major Law or Program Administered Fair Labor Standards Act (FLSA) Fair Labor Standards Act (FLSA) Sets youth employment standards and minimum age requirements. Includes some provisions relating specifically to agriculture. Minimum Age Requirements Hazardous Occupations Orders for Agricultural Employment Minimum Age Requirements Must be 16 years of age to engage in agricultural employment during school hours. Must be 14 years of age to engage in agricultural employment outside school hours. Minimum Age Requirements Young people age 12 or older may be employed at a farm where their parent is employed, or with written consent from their parents. A child of any age may be employed on a farm owned or operated by their parent. Hazardous Occupations Orders for Agricultural Employment Includes 11 on-farm occupations involving equipment that have been declared hazardous and prohibited for minors under 16 years of age. Hazardous Occupations Orders for Agricultural Employment 1. Operating a tractor of over 20 powertake-off (PTO) horsepower, or connecting or disconnecting an implement or any of its parts to or from such a tractor. Hazardous Occupations Orders for Agricultural Employment 2. Operating or assisting to operate (including starting, stopping, adjusting, feeding or any other activity involving physical contact associated with the operation) any of the following machines: a) b) c) corn picker, cotton picker, grain combine, hay mower, forage harvester, hay baler, potato digger, mobile pea viner; feed grinder, crop dryer, forage blower, auger conveyer, or the unloading mechanism of a nongravity-type self-unloading wagon or trailer; or power post hole diggers, power post driver, or nonwalking type rotary tiller. Hazardous Occupations Orders for Agricultural Employment 3. Operating or assisting to operate (including starting, stopping, adjusting, feeding, or any other activity involving physical contact associated with the operation) any of the following machines: a) trencher or earthmoving equipment; b) forklift; c) potato combine; or d) power-driven circular, band, or chain saw. Hazardous Occupations Orders for Agricultural Employment 4. Working on a farm in a yard, pen, or stall occupied by a) bull, boar, or stud horse maintained for breeding purposes; b) a sow with suckling pigs, or a cow with a newborn calf (with umbilical cord present). Hazardous Occupations Orders for Agricultural Employment 5. Felling, bucking, skidding, loading, or unloading timber with butt diameter of more than 6 inches. 6. Working from a ladder or scaffold (painting, repairing, or building structures, pruning trees, picking fruit, etc.) at a height of over 20 feet. Hazardous Occupations Orders for Agricultural Employment 7. Driving a bus, truck, or automobile when transporting passengers or riding on a tractor as a passenger or helper. Hazardous Occupations Orders for Agricultural Employment 8. Working inside: a) a fruit, forage, or grain storage designed to retain an oxygen deficient or toxic atmosphere; b) an upright silo within 2 weeks after silage has been added or when a top unloading device is in operating position; c) a manure pit; or d) a horizontal silo while operating a tractor for packing purposes. Hazardous Occupations Orders for Agricultural Employment 9. Handling or applying toxic agricultural chemicals (including cleaning or decontaminating equipment, disposal or return of empty containers, or serving as a flagman for aircraft applying such chemicals). Such toxic chemicals are identified by the word “poison,” or “warning,” or are identified by a “skull and crossbones” on the label. Hazardous Occupations Orders for Agricultural Employment 10. Handling or using a blasting agent, including but not limited to, dynamite, black powder, sensitized ammonium nitrate, blasting caps, and primer cord; or 11. Transporting, transferring, or applying anhydrous ammonia. Occupational Safety and Health Administration (OSHA) Established under the Williams-Steiger Occupational Safety and Health Act (OSH Act) enacted in 1971. OSHA Mission “To assure the safety and health of America’s workers by setting and enforcing standards; providing training outreach, and education; establishing partnerships; and encouraging continual improvement in workplace safety and health.” Entities Subject to OSHA Regulation Private sector employers and their employees. The OSH Act does not cover the following: the self-employed; members of the immediate family of farm employers that do not employ outside workers; worker conditions that are regulated under worker safety or health requirements of other federal agencies; and employees of state and local governments. State Programs States have the option to take over safety regulation if they adopt a program that is: approved and monitored by the Secretary of Labor and OSHA; and at least as strong as the Federal program. Texas does not have its own program. Texas gives jurisdiction to OSHA and current federal regulations. Employer Responsibilities Under OSHA Provide a workplace free from serious recognized hazards and comply with standards, rules, and regulations issued under the OSH Act. Examine workplace conditions to make sure they conform to applicable OSHA standards. Make sure employees have and use safe tools and equipment and properly maintain this equipment. Employer Responsibilities Under OSHA Use color codes, posters, labels, or signs to warn employees of potential hazards. Establish or update operating procedures and communicate them so that employees follow safety and health requirements. Provide medical examinations and training when required by OSHA standards. Employer Responsibilities Under OSHA Post, at a prominent location within the workplace, the OSHA poster (or the stateplan equivalent) informing employees of their rights and responsibilities. Report to the nearest OSHA office within 8 hours any fatal accident, or one that results in the hospitalization of three or more employees. Employer Responsibilities Under OSHA Keep records of work-related injuries and illnesses. Employers with 10 or fewer employees and employers in certain low-hazard industries are exempt from this requirement. Provide employees, former employees, and their representatives access to the Log of Work-Related Injuries and Illnesses. Employer Responsibilities Under OSHA Provide access to employee medical records and exposure records to employees or their authorized representatives. Provide to the OSHA compliance officer the names of authorized employee representatives who may be asked to accompany the compliance officer during an inspection. Employer Responsibilities Under OSHA Not discriminate against employees who exercise their rights under the Act. Post OSHA citations at or near the work area involved. Each citation must remain posted until the violation has been corrected, or for three working days, whichever is longer. Post tags. abatement verification documents or Employer Responsibilities Under OSHA Correct cited violations by the deadline set in the OSHA citation and submit required abatement verification documentation. OSHA Standards OSHA standards require that employers: maintain conditions or adopt practices reasonably necessary and appropriate to protect workers on the job; be familiar with and comply with standards applicable to their establishments; and ensure that employees have and use personal protective equipments when required for safety and health. Hazards Addressed by OSHA Standards Toxic Substances Infectious Diseases Harmful Physical Agents Fire and Explosion Hazards Electrical Hazards Fall Hazards Dangerous Atmospheres Machine Hazards Confined Spaces Trenching Hazards Hazardous Waste General Duty Clause Employers must comply with the “generally duty clause” when no specific OSHA standards are in place. The clause requires that each employer furnish a place of employment that is free from recognized hazards that are causing, or could cause, death or serious harm to employees. OSHA Enforcement OSHA’s primary method of enforcing safety standards is through worksite inspections. OSHA is unable to inspect all 7 million worksites under its jurisdiction. Therefore the agency focuses on the most hazardous workplaces. OSHA Inspection Priorities 1. Imminent Danger Situations 2. Hazards exist that could cause death or serious physical harm. Fatalities and Catastrophes Incidents have occurred involving an employee death or hospitalization of three or more employees. OSHA Inspection Priorities 3. Complaints 4. Employee allegation has been made regarding hazards or violations. Referrals Another federal, state, or local agency, individual, organization, or the media has provided hazard information to the agency. OSHA Inspection Priorities 5. Follow-Ups 6. Inspection to ensure correction of violations cited during a previous inspection. Planned or Programmed Investigations Aimed at specific high-hazard industries or individual workplaces that have experienced high rates of injuries and illnesses. OSHA Inspection Procedures 1. OSHA compliance officer arrives during work hours, but generally without advance notice. 2. Compliance officer presents identifying credentials. 3. During an opening conference, officer explains why the workplace has been selected for inspection and explains the inspection process. OSHA Inspection Procedures 4. The compliance officer, along with an employer representative and possibly an employee representative, will conduct a “walkaround”. 5. Compliance officer walks through portions of the workplace, identifies hazards, reviews worksite injury and illness records, and notes whether or not the official OSHA poster is displayed. OSHA Inspection Procedures 6. If violations are identified, the employer may be given a chance to correct the hazard immediately and avoid citation. 7. Compliance officer consults privately with a number of employees. 8. Compliance officer holds a closing conference in which he/she discusses findings and offers possible courses of action by the employer. OSHA Inspection Procedures 9. Within six months, OSHA may issue a citation based on violations identified during the inspection. Violations may be categorized as otherthan-serious, serious, willful, repeated, and failure to abate. Depending on the severity of the violation, an employer could be fined up to $7,000 for each serious violation and up to $70,000 for each willful or repeated violation. OSHA Inspection Procedures 10. In the event of a citation, an employer may appeal the decision in an informal conference with, or written notice to, the OSHA Area Director. Employee Rights Under OSHA Get training from your employer as required by OSHA standards. Request information from your employer about OSHA standards, worker injuries and illnesses, job hazards, and workers’ rights. Request action from your employer to correct hazards or violations. Employee Rights Under OSHA File a complaint with OSHA if you believe that there are either violations of OSHA standards or serious workplace hazards. Be involved in OSHA’s inspection of your workplace. Find out the results of an OSHA inspection. Employee Rights Under OSHA Get involved in any meetings or hearings to discuss any objections your employer has to OSHA’s citations or to changes in abatement deadlines. File a formal appeal of deadlines for correction of hazards. File a discrimination complaint. Employee Rights Under OSHA Request a research investigation on possible workplace health hazards. Provide comments and testimony to OSHA during rulemaking on new standards. Employee Responsibilities Under OSHA Read the OSHA Poster at the jobsite. Comply with all applicable OSHA standards. Follow all lawful employer safety and health rules and regulations, and wear or use prescribed protective equipment while working. Employee Responsibilities Under OSHA Report hazardous conditions to the supervisor. Report any job-related injury or illness to the employer, and seek treatment promptly. Exercise rights under the Act in a responsible manner. National Institute of Occupational Safety and Health Also known as NIOSH. Established under the Williams-Steiger Occupational Safety and Health Act (OSH Act) enacted in 1971. NIOSH Responsibilities Conducts research relating to safety and health problems. Provides technical assistance. Makes recommendations to OSHA regarding standard setting. Environmental Protection Agency Also known as EPA. Regulates the application and use of pesticides. Responsible for administering and enforcing the Worker Protection Standard (WPS). Worker Protection Standard Protects workers on farms or in forests, nurseries, and greenhouses from exposure to agricultural pesticides. Covers both pesticide handlers and agricultural workers. Pesticide handlers are “those who mix, load, or apply agricultural pesticides; clean or repair pesticide application equipment; or assist with the application of pesticides in any way.” Agricultural workers are “those who perform tasks related to the cultivation and harvesting of plants on farms or in greenhouses, nurseries, or forests.” Safety Requirements under Worker Protection Standard Applicators are prohibited from applying a pesticide in a way that could endanger or expose workers or other persons. Workers must be excluded from the area when pesticides are being applied. Safety Requirements under Worker Protection Standard Workers must be excluded from a pesticide-treated area during the restricted-entry interval specified on the pesticide product label. Personal protective equipment must be provided and maintained for handlers. Workers must be notified about treated areas so that they may avoid exposure. Safety Requirements Under Worker Protection Standard Water, soap, and towels must be provided for both handlers and workers for routine washing and emergency decontamination. In the event of injury or poisoning, transportation must be made available to a medical care facility and information must be provided about the pesticide to which the person may have been exposed. Safety Requirements Under Worker Protection Standard Pesticide safety training is required for all workers and handlers. A pesticide safety poster must be displayed in the workplace. Employees must be informed of pesticide label requirements. Recent pesticide applications must be posted in a central location. Workers’ Compensation A state-regulated insurance program. Texas Department of Insurance, Division of Workers’ Compensation (Division) regulates the delivery of workers’ compensation benefits in Texas. Employer participation is voluntary, with the exception of public entities. Workers’ Compensation Participating employers may choose to self-insure or purchase a workers’ compensation insurance policy through a private insurance company. In the event that an employee is injured on the job or suffers from a work-related illness, workers’ compensation will provide employees, or their families, with income and medical benefits. Benefits of Workers’ Compensation for Employees In the event that you are injured on the job or suffer from a work-related illness, workers’ compensation will: Pay your medical bills if your employer has workers’ compensation insurance. Replace a portion of your lost wages if the work-related injury or illness causes you to lose all or some of your wages for more than seven days. Employee Rights Under Texas Workers’ Compensation Receive benefits based on work-related injuries or illness. Receive medical care. Choose the treating doctor. Hire an attorney to help you with your claim or to resolve disputes. Employee Rights Under Texas Workers’ Compensation Receive information and assistance from the Office of Injured Employee Counsel. Receive ombudsman assistance if you do not have an attorney and a dispute resolution has been scheduled. Confidentiality of claim information. Exceptions to Eligibility for Benefits Employee was intoxicated at the time of injury. Injury was self-inflicted or a result of attempts to injure someone else. Employee was injured by another person for personal reasons. Exceptions to Eligibility for Benefits Injury was the result of an act of God. Injury occurred during horseplay. Injury occurred while voluntarily participating in an off-duty recreational, social, or athletic activity. Employee Responsibilities Under Texas Workers’ Compensation Inform your employer that you have been injured at work or in the scope of your employment. Follow guidelines for treatment based on the type of insurance network of which your employer is a part. Tell your doctor how you were injured and whether the injury is work-related. Employee Responsibilities Under Texas Workers’ Compensation Complete and submit a claim form. Provide your current contact information to the Division of Workers’ compensation and the insurance carrier. Inform the Division and insurance carrier any time there is a change in your employment status or wages. Time Requirements for Filing a Claim Employee must inform their employer of the injury or illness, and the date of its occurrence or learning of it, within 30 days. Workers’ compensation claims must be filed with the Division within one year of the date of the injury. Drawbacks to Filing a Claim In most cases, the employee gives up the right to sue the employer. However, the employee can sue a third party (i.e. manufacturers or inspectors). Workers’ compensation does not pay a full salary. Benefits of Workers’ Compensation for Employers Ensures that employees will receive benefits if they suffer from a work-related injury or illness. Limits their liability. Employer Rights Under Texas Workers’ Compensation Contest a claim. Be informed of dispute resolution proceedings and outcomes. Attend any dispute resolution proceedings. Employer Rights Under Texas Workers’ Compensation Present relevant evidence at dispute resolution hearings. Report suspected fraud to the Division or the insurance carrier. Contest the failure of the insurance carrier to provide acceptable accident prevention services. Employer Responsibilities Under Texas Workers’ Compensation Report the following to the insurance carrier within eight days: work-related injuries causing employees to miss more than one day of work; occupational illnesses that may or may not cause lost-time; or employee death resulting from work-related injury or illness. Employer Responsibilities Under Texas Workers’ Compensation Provide a copy of the completed Employer’s First Report of Injury or Illness to the injured employee at the time the injury is reported to the insurance carrier. Provide a copy of “Notice of Injured Employee Rights and Responsibilities in the Texas Workers’ Compensation System” to the injured employee. Employer Responsibilities Under Texas Workers’ Compensation Report any changes in an injured employee’s pay or employment status to insurance carrier. Keep records of work-related injuries, illnesses, and fatalities. Post all appropriate workplace notices regarding workers’ compensation in plain view in both English and Spanish. Employer Responsibilities Under Texas Workers’ Compensation Provide written notice of coverage to new employees. Provide all employees written notice if there is a change in coverage. Failure to meet these requirements may result in fines due to noncompliance. Fines range between $500 and $1,000 per occurrence. National Safety Council Also known as NSC. Not-for-profit, non-governmental public service organization. Source of injury prevention information. Deals with key issues in safety, health, and environmental concerns. National Safety Council Encourages society to adopt safety, health, and environmental policies, practices, and procedures that prevent injury and economic losses arising from preventable causes. Has over 18,500 members from business, labor, government, community groups, trade and professional associations, and schools. Partners for a Safer Community™ A special project of the National FFA Organization. Collaborative effort to promote safety and health to agricultural youth. Utilizes a multi-disciplinary approach -incorporating education, community needs identification and development, and youth leadership. Partners for a Safer Community™ Features an instructional package available for youth-teaching-youth activities. Allows concepts to be incorporated into your FFA chapter’s Program of Activities and National Chapter Rating application. Goals of Partners for a Safer Community™ Increase student knowledge of safety and health-promoting behaviors. Provide teachers and community leaders with necessary tools for teaching youth safety successfully. Goals of Partners for a Safer Community™ Provide leadership development opportunities for students through active community participation. Expand the use of existing safety resources. Foster ongoing community collaboration for youth safety issues and programs. Sponsors of Partners for a Safer Community™ John Deere New Holland Lorsban* 15G Farm Safety 4 Just Kids Pioneer Hi-Bred International, Inc. National Farm Medicine Center Kellogg Foundation National Safety Council Equipment Manufacturers Institute Cooperative Extension Service National Food and Energy Council National FFA Agricultural Education Related Organizations NIOSH Summary Although the rate of occupational related accidents, injuries, and illnesses is on the decline, more can always be done to improve the situation. Preserving the health and lives of American workers is the ultimate goal of safety efforts. Summary Saving money is an additional benefit of safety efforts. According to OSHA and the U.S. Bureau of Labor Statistics, workplace injuries and illnesses cost U.S. businesses more than $125 billion each year. Increased safety and prevention efforts can reduce expenses associated with workers’ compensation insurance premiums, medical expenses, lost production, and safety violation fines. Summary Money saved by successful safety programs can also be passed on to consumers in the form of lower prices. Improved safety programs also give consumers comfort in knowing that the goods and services they enjoy do not come at the price of American workers’ lives. Summary Everyone shares the responsibility for safety and prevention. Employers must make every effort to provide a safe work environment and educate their employees regarding workplace hazards and safety practices. Employees must recognize workplace hazards and adhere to safety guidelines. Government entities and public organizations must remain diligent in their efforts to enforce safety laws and standards and to educate both employers and employees on matters regarding safety.