Life Cycle of a Pencil

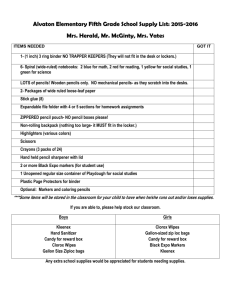

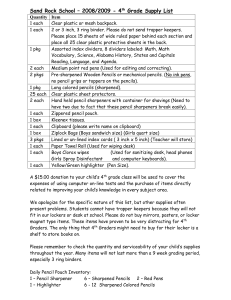

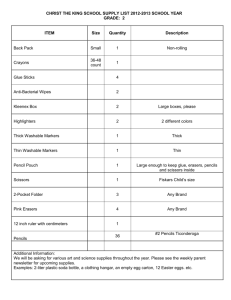

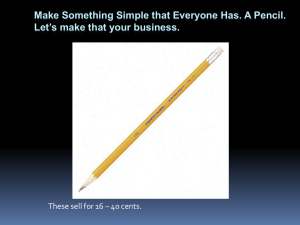

advertisement

The Life Cycle of a Pencil Harry and Dominic Design • The pencil is a small wooden writing utensil with an rubber eraser at one end and a stick of graphite in the center. The materials used to make it are wood, aluminum or brass, glue, rubber, and graphite, and usually paint. The graphite may be mixed with clay to soften it. It was most likely not expected to last long, since they are sold in packages of about 12. Materials Acquisition • For a pencil, first the wood is from timber, or trees. Secondly, the graphite is mined from places like Finland and Italy. If needed to soften the graphite, clay is mined all around the world, even some places in the United States of America. Rubber comes from a milky white liquid that some trees excrete instead of sap as usual. The metal, aluminum, is mined usually in Australia. Pencil Materials Processing/Manufacturing Graphite Graphite can be made into the stick in the middle in two different ways. The first is when the graphite and a waxy mixture are forced through a mold, creating a spaghetti-like string. The string is then cut into precise measurements, then dried in ovens. In the second method, the graphite and a clay mixture is poured into a machine, a billet press. There is then a ram placed just over the press. The ram comes down, and out comes a hard cylinder, called a billet. Wood Casing The cedar will usually arrive at the factory already pre-dried, stained, and waxed to avoid warping. Next, logs are sawed into thin strips, called slats. They are all about 7.25 inches long, and about .25 inches thick. They are then put on a feeder, then dropped one at a time onto a conveyor belt which is always moving along at a constant rate. After that, the slats are planed to give them a flat surface. Next, they pass under a cutting head that makes parallel circular grooves in the wood-one half as deep as the graphite is thick-along the length of each wooden slat. Continuing their journey along the conveyor belt, half the slats are covered in a layer of glue, and cut graphite is laid in the clue-covered slats. The slats with neither glue nor graphite on them are continued down another conveyor belt, where they will be picked up and turned over so that the grooves are facing down. When the two belts meet, the slats without glue drop on the ones without, and they form a sandwich. When the sandwiches have been removed from the conveyor belt, they are clamped together, and will stay that way until the glue dries. When the glue has dried, the ends are trimmed of excess glue. Materials Processing/Manufacturing Cont. Shaping the pencil Next comes shaping, the step in which those 'Sandwiches' become pencils. The sandwiches are then placed on a conveyor belt with cutters coming from the top and the bottom of the belt. The cutters above cut the top half, while the ones on the bottom cut the bottom half and separates the pencils when they are completely cut. The majoraty of all pencils is hexagonal to keep them from rolling off the conveyor. A single sandwich will hold enough for six to nine pencils. Finishing Steps After pencils have been cut, they are moved to sanders that will make them smooth, like the ones you get fresh out of a box. Varnish is then applied to their surface, then dried. This is done with varnishing machines, that dip the pencils in a pot of varnish, then feed them through a felt disc to remove excess varnish. This process is done many times until the wanted color is achieved. The pencil will then receive a final coat. The pencils are then sent on yet another conveyor belt, this time another shaping one. It will ensure not only that no excess varnish has accumulated on the end of the pencil, but also that they are all the same length. Finally, the erasers are attached. They are held in place by a thin metal binding called a ferrule. The ferrule is either attached by a coating of glue of small metal prongs. The ferrule is first attached on to the pencil, then the eraser is clamped inside. The final step is when the company logo is stamped on. The pencil is complete! Packaging • The hexagonal shape of the pencils allows them to be tightly packed together to reduce packaging demand and empty space. The packaging is made of cardboard. Cardboard is made from wood from pine trees. The wood is then shredded to a pulp and sent to a paper machine where the pulp is pressed and rolled until it is sent to corrugating plants to be made into cardboard. Corn starch glue is used to bond the flattened pulp to liner sheets. After a few more steps, bold designs are applied then it is shaped into a thin container to hold the pencils. Distribution • Pencils are not distributed individually, but instead in packs of 12, give or take a bit. They are often made in China or Vietnam, as quite a few products are, but that probability is actually about the same for every continent, with the obvious exception of Antarctica. Penguins don't make pencils. Use • A pencil is used by writing on a piece of paper, or drawing on paper, along with hundreds and hundreds of other ways, both practical and impractical, including but not limited to darts. A pencil is slowly becoming obsolete because of our rapidly increasing technology. However, millions of people still use both technology and pencils, like the creators of this presentation. Reuse/Recycling • The greatest thing about pencils is that they have uses for everybody, artists, authors, and even office workers alike. Also, pencils can be sharpened until they're roughly the size of your thumbnail, so they can last years if used wisely! And another bonus is that when you buy a whole pack of pencils, if one breaks, who cares? You have 11 more at your disposal to do whatever you please. There are also many decorative uses for a broken pencil. For example, you can get some colorful duct tape and then even the least artistic of people could create a pencil-flower! Unfortunately, nothing is forever, so even the most scarcely used pencil has to be disposed of, as seen in the next slide. Disposal • The most heartbreaking part of owning a pencil is the deathAKA the disposal. Fortunately if they're sharpened to the last tiny bit, they will have served a good purpose. Pencils, like all items don't last forever, and eventually end up in a landfill. Unfortunately from this point, there is nothing you can do about it. Pencils cannot be recycled, so buying a mechanical pencil or a pen is a smart decision. Bibliography http://www.madehow.com/Volume-1/Pencil.html