I, Pencil PowerPoints - Worth Publishers Blogs

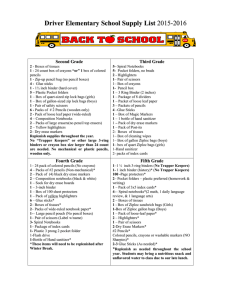

advertisement

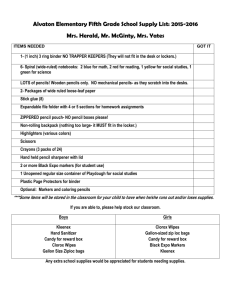

Make Something Simple that Everyone Has. A Pencil. Let’s make that your business. These sell for 16 – 40 cents. If you are really clever, you could make this! 72 needed – but this is just “art” – someone must make the pencils. But: Nobody Can Make a Pencil ! No one knows how to make a pencil. Here is a description of contents of “Mirado” brand pencils: Material: California Incense Cedar. Finish: Glossy black with gold lettering. Ferrule: Red-banded brass. Eraser: Genuine Pink Pearl. Core: Waxed-ceramic/graphite composite. Available in #1/B, #2/HB, #2.5/F, #3/H. Markings: “USA/Mirado Black Warrior/HB/[two hearts].” Packaging: Varies from open-stock, to packs of eight or ten, to boxes of a dozen. Origin: Made in Lewisburg, Tennessee, United States by the Sanford Corporation. Availability: Widely available in office supply stores, art supply stores, university bookstores, department stores and online. Step One: “California Incense Cedar” Here one is. You paid the owner for the right to cut it down to get the wood you will need. You will need: Big chain saw, big truck, a saw mill, and other equipment. But wait—who makes all those things? They require steel, machinery, buildings, trained workers. And the workers need food, clothing, housing, transportation, etc. We need the wood for the pencil … Your tree is one of these! Now get it milled down a bit. And start sawing. Of course— precision is required if you don’t want to waste valuable wood and want to keep costs under control. Keep cutting the wood smaller and smaller—but remember to kiln dry it. If the wood is not dried, quality of the pencil will be bad & you lose customers. So the wood get put in a kiln drying machine. This one claims to be good. So you get little pieces of wood. Also consider: poplar - Turkey, pine – Russia & basswood – China. Next: Glossy black (or classic yellow) finish. The color is a lacquer applied to the pencil. Lacquer came from China and India originally— made from resin from the Rhus tree or squeezed from a bug (insect lac). Now, of course, we have factories to make this complex chemical. Previously it was quite toxic, now it has been made fast drying and safe. Colors come from many sources of dyes or pigments added to the lacquer (another industry). Side Note: Why yellow? In late 1800s—a Frenchman exploring Siberia near the China border found the highest quality deposits of graphite ever. Hence, the pencils made with that graphite were the best. Yellow in China is associated with royalty, so the pencils were colored yellow as a signal of the highest quality in the market. Put your name on the pencil. Then the company name or your logo must be embossed on the side. Here is one machine that will do that. But anyone can make this machine, so lets get to the more technical stuff about pencil making. Lead pencils… There is no lead in pencils. The inner stuff is a mix of clay that comes from many places and graphite. Sri Lanka and China are the leaders. The number on the pencil (hardness) depends on the clay/graphite mix. First good quality pencil factory in the U.S. was the Thoreau factory—founded by brother-in-law of Henry David Thoreau. Side Note: Colored Pencils You can get pencils that draw in red, green or whatever. That stuff in the pencil is a mix of clay (called china clay because it dries hard), pigments, and wax. There are other specialty pencils—charcoal pencils for drawing; eye-liner pencils for makeup, etc. But back to the main product…… Erasers Get your vocabulary right—plugs, not erasers. First patented in 1858. Standard in the U.S., but not Europe (go figure). Today—synthetic rubber or vinyl is used—get the right consistency and an extruder machine squirts out long ribbons of plugs. When cool, cut to size. And then, because we like soft edges, hundreds of pounds of them are tumbled in a tumbler to get softer edges. New word for the day: Ferrule That is the little band, made of zinc and copper (and mixes of other metals) that hold the plug to the end of the pencil (too complicated for Europeans). Traditionally— the ferrule put on first, then plug shoved in after some glue put inside the ferrule. Thermoplastics now commonly used. Put on by “ultrasonic welding.” So you need to figure out how to get all those machines and parts. Ready to go! Now we have the simple pencil made—so put them in boxes you get from somewhere and then get the boxes into cartons and on to trucks to get them to distributors and stores.