GCSE Mathematics

advertisement

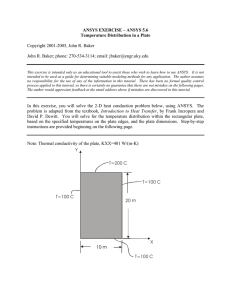

Fluid Analysis A simulated response in ANSYS By Terence James Haydock 1 Overview • Introduction • Background o Density and pressure o Example and Problem • ANSYS Tutorial • Summary • References 2 Introduction Aim: To calculate a fluid analysis problem via analytical methods and compare such results with a numerical analysis with ANSYS 3 Background A fluid is a material that offers no permanent resistance to change of shape i.e. its flow matches the shape of the vessel to which its found. The general laws of mechanics for solids apply equally to fluids. Acting force, equilibrium, momentum and energy all have the same meaning, hence, Newton’s law are just as valid for solids and fluids. 4 Density and Pressure Density (ƿ) is found by dividing mass by volume and its SI units are kg/m^3. For example, water has a density of 1000kg/m^3. The density of other liquids are defined as a ratio of water (relative density or specific gravity) e.g. oil has a relative density of 0.9. When a fluids is not in motion is exerts pressure in all directions. The unit of pressure is N/m^2, though it is usually quoted in bar e.g. 100kN/m^2 which equals 10^5N/m^2 or 10^5Pa. Consider a vertical tube of water, at a height h, if the density of a liquid is ƿ and the cross sectional area is A, then the volume of liquid is Ah and its mass is ƿAh. The weight of the liquid is ƿgAh. The pressure at any cross section due to liquid is: P = force / area = ƿgAh / A = ƿgh 5 Cont. The height h is also known as the pressure head, thus, pressure maybe given in terms of head. All liquids have the same pressure at the same level (2 & 3) and as such, the required pressure is given by the column of liquid above 2. If the column is sealed (vacuum above liquid) the value is known as absolute pressure, if open, then the liquid gives a gauge value, both are related by: Absolute pressure = gauge pressure + atmospheric pressure 6 The stresses in the walls of a pressure vessel rely on the difference between external and internal pressures, with external pressure been atmospheric, thus, gauge pressure must also be used. In fluid mechanics the change in pressure is required whether the separate values are gauge or absolute. Example The pressure at the top of a mountain is found to be 0.7bar. Express this in metres of water. What would be the reading of a mercury barometer at this point? Relative density of mercury, 13.6 Solution: The density of water maybe taken as 1000kg/m^3. Working in SI units, the equivalent head h is given by: pgh = 0.7 x 10^5 or h= 0.7 𝑥 10^5 𝑝𝑔 = 0.7 𝑥 10^5 = 1000 𝑥 9.81 7.14m The corresponding head for mercury is thus: 7.14 / 13.6 = 0.525m or525mm 7 Problem The cross section of a circular pipe is occupied by a constant flow of water. The water gradually expands due to varied diameters at either end, with one end been 0.2m diameter and the other with a 0.3m diameter. If the velocity at the first section is 5m/s, find: a) The volume flow rate, b) The velocity at the second section, 8 Area A1 Area A2 v2 v1 Use subscripts for the two sections a) The volume flow rate Q is: Q v1 A1 5 * 4 * 0.2 2 0.1571m3 / s b) The equation of continuity is: Q v1 A1 v2 A2 So the second velocity, after transposition is: A1 ( / 4) * 0.2 2 v2 v1 * 5* 2.222m / s 2 A2 ( / 4) * 0.3 9 Area A2 v2 Area A1 z2 v1 If the question was further expanded and we were to describe the second area of 0.3m as been 2m above the first area of 0.2m, then what would the pressure head be? z1 2 Tip: Bernoulli's equation would be used, as follows: 10 2 v1 p1 v2 p2 z1 z2 2 g pg 2 g pg Transpose the equation and note the level difference ( z2 – z1 ), is 2m pressure difference and expressed as the head is as follows: p1 p2 v2 v1 2.222 2 52 z2 z1 2 0.977m pg pg 2g 2g 2 * 9.81 2 2 The pressure difference is 0.977m of water greater at the first section. In N/m^2 this becomes: p1 p2 pg * 0.977 1000 * 9.81* 0.977 9.5 *10^3N / m 2 or 11 9.5kN / m 2 ANSYS Tutorial Geometry We start of with our first sketch, apply the correct dimensions of 0.2m and 0.3m, to represent the inlet and outlet. The distance in-between is set at 0.5m 12 Mesh As shown, the mesh has been applied using the advanced size function, on: proximity and curvature, with the rest of the options left at default. The result can be seen in a well structured mesh. 13 Right-click on Default Domain in the Outline tree Select Rename The domain name can now be edited. Change the domain name to Pipe Set the Material to Water. The available materials can be found in the drop-down menu 14 Our next aim is to define the inlet an outlet of the pipe. By right clicking on pipe, going to inset and then boundary, we are given the options to do so. There are other variables to choose from however, this options are for more complicated examples. Click the Boundary Details tab. Enter a value of 5 for Normal Speed. The default units are [m s^-1] 15 Set Relative Pressure to 0 [Pa]. This is relative to the domain Reference Pressure, which is 1 [atm] Click Start Run to begin the solution process. 45 iterations are required to reduce the RMS residuals to below the target of 1.0x10-4. The pressure monitor points approach steady values The Solver Control options set various parameters that are used by the solver and can affect the accuracy of the results. The default settings are reasonable, but will not be correct for all simulations. In this case the default settings will be used, but you will still look at what those defaults are. 16 An expression will be used to define the monitor point. 7. Set Option to Expression Enter the expression: areaAve(Pressure) @inlety in the Expression Value field The expression calculates the area weighted average of pressure at the boundary inlet. When the results are loaded, CFD-Post displays the outline (wireframe) of the model. The icons on the viewer toolbar control how the mouse manipulates the view You can create many different objects in CFDPost. The Insert menu shows a full list, but there are toolbar shortcuts for all items. Such as: Location: Points, Lines, Planes, Surfaces, Volumes 17 Summary The results shown in ANSYS are very accurate when compared to the analytical method we applied earlier. As such, we have proved the correct results for both analytical and numerical application. Learning objectives covered in this workshop relate to fluid analysis, with knowledge gained in density and pressure when applied to real world application, furthermore the use of ANSYS for verification has also proven to be a small example its potential. 18 References Norman. E. et al. Advanced Design and Technology. 1995 Longman Group UK Limited, ISBN 0 582 014638 ANSYS 13.0 Help files 19