Shook_Presentation

advertisement

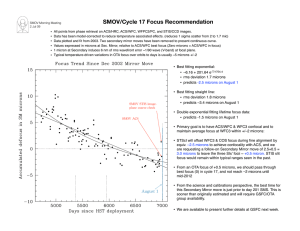

By: Richard Shook Computer-Aided Design Sample Design Design Process (SLAC) ST-O And Filters Background Analysis Results Design Solid Edge 3D Digital Model Finite Element Analysis (FEA) Robust Editing 2D Drafting (Geometric Dimensioning and Tolerancing) AutoCAD 2D Model Beam line Layout Purpose Visualization Prototyping Legal Basic Shape Protrusion Feature Able to make extended features on coincident planes Cutout Feature Removing material from selected bodies Round Feature Giving a selected edge, face or curve a radial feature. Organization Clarity Cooperation 1. Project 3. Data Sheets 2. Base Drawings 3. Vendor Documents Approvals 2. Checker 3. Document Control 1. 2. Design Processing/Releasing 1. 4. Modeling 2. Official Drawings Fabrication Manufacturer 2. Machinist 1. 1. 5. Implementation (Final Assembly) Function Parameters Beam Energy 800 eV to 9000 eV Absorption Length: 10 microns to 100 microns Attenuation factor: 10 microns to 100 microns 0.01 e x / 0.10 Geometry What is attenuation length/coefficient? What is a k-edge and how can that help? Intensity: I I 0 e x where I is the intensity of the photon beam, α is the linear attenuation coefficient, x is the path length Transmission: T I e I0 T e x / Beer-Lambert Law Element K-Edge (keV) Absorption Coefficient (1/cm2) 1/μ (microns) Hydrogen 0.014 --- 735.6 E+04 Helium 0.025 --- 41.6 E+04 Lithium 0.054 200.269 49.932 Beryllium 0.112 1951.20 5.125 Boron 0.188 4985.80 2.006 Carbon 0.284 9011.27 1.108 Sodium 1.072 1247.55 8.016 Magnesium 1.305 3335.04 2.998 Used mat’l Acceptable mat’l Rejected mat’l Transmission Graph Beam Transmission vs. Photon energy at 20 microns for Beryllium Photon Beam Transmission For Beryllium and Boron Carbide 0.11 0.1 Be: 20 Microns Be:40 Microns 0.09 Be: 80 Microns 0.08 Be: 160 Microns Transmission 0.07 Be: 320 Microns Be: 640 Microns 0.06 Be: 1280 Microns 0.05 Be: 2560 Microns Be: 5120 Microns 0.04 B4C: 2000 Microns 0.03 B4C: 4000 Microns B4C: 6000 Microns 0.02 0.01 0 0 1000 2000 3000 4000 5000 6000 Photon Beam Energy (eV) 7000 8000 9000 10000 Geometric Parameters: Thicknesses (determined by analysis) Filter Cross-Sectional Area Vacuum Other Experiments Materials Acquired Parts/Vendor Parts Dept. of Energy, Office of Science, SULI SLAC Rick Tankersley Paul Stephens Steve Score Josef Frisch http://mdweb.slac.stanford.edu/index.php http://www.plm.automation.siemens.com/en_us/products/velocit y/solidedge/index.shtml Materials Handbook, 14th ed. Brady, Clauser, Vaccari. McGraw-Hill 1997 http://henke.lbl.gov/optical_constants/ http://www.ct.infn.it/~rivel/Glossario/node30.html#29 http://www.chemguide.co.uk/analysis/uvvisible/beerlambert.html http://www.files.chem.vt.edu/chem-ed/spec/beerslaw.html http://physics.nist.gov/PhysRefData/XrayMassCoef/cover.html http://www.csrri.iit.edu/periodic-table.html