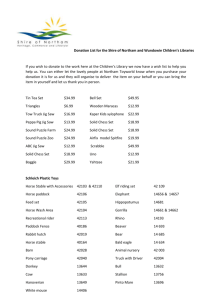

FWR's TS Multi

advertisement

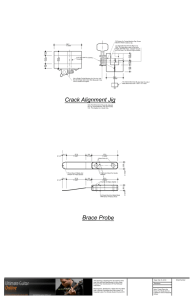

FLWoodRat's Multi-Use TS Jig “Consider the Possibilities” The Base Unit • This JIG can be built to any size and out of any materials you have sitting around the shop. Be creative and personalize it with some special wood. I used some scrap TEAK for the right hand push block. The Base Unit • The face of my jig is approximately 10” tall and 19” long. The Base Unit • The back risers and base are ~ 6” wide. The Base Unit • The gap between the base and the runner is sized to span my TS Fence with “0” clearance. • You can ‘wax’ your fence to help things glide smoothly The Base Unit • The TEAK push block has a short riser block (7/8” tall) attached. • Chamfering the edges makes it easier on the hands The Base Unit •When using the jig: – Place your LEFT hand here. – Place your RIGHT hand here At no time will your hands be in harms way! The Base Unit • The rear risers are spaced to allow for clamping at the ends of your work. • OR in the center. The Base Unit • When using the jig for cutting tenons: – Attach a sacrificial vertical stop rail somewhere around here – Drill pilot holes and screw it on from the back The Base Unit • Using the jig to cut a Tenon • After flipping and then cross cutting the cheeks, this is what you get The Base Unit • You can use the same set-up for cutting raised panels. • Obviously, you need a LEFT Tilting arbor to do that with this jig. Some Raised Panels • Just a little clean up left.. Some Raised Panels • Profile View • I also cut a rabbet on the back side Is that all we can do? Not at all. By adding the “Auxiliary Spline-SlotCutter”Accessory Face You can do even more exciting things…. The “Spline-Cutter” Attachment • So, you want to cut some “slots” for “splines” in your box corners…. • All you have to do is attach this “accessory V-Face.” The “Spline-Cutter” Attachment •I used a “Splined-Butt” technique and glue for the “V” joint. •Then I screwed the “V” to the aux-face from behind…. MAKE SURE YOUR SCREWS ARE ABOVE THE CUTTING ZONE The “Spline-Cutter” Attachment 450 wedges were used to align the ‘V” at the center of the auxiliary face, then I screwed it from the back. One wedge was placed here to help with the alignment The “Spline-Cutter” Attachment •The “Spline Slot-Cutter Assembly” is screwed to the “base unit” from behind at “6” locations. •Drill “pilot holes” in the base unit and clamp the auxiliary face to it when attaching. Remove the clamps before cutting your slots. Build Your Own! •If you think of some other uses, share them. •If you have a better design idea, share it. In Closing •The next time you go into your shop, COUNT your fingers. •COUNT them again when you leave. •If the number is the same. COUNT YOUR BLESSINGS! Thanks for sharing your ideas! FLWoodRat Quic kT i me™ and a GIF dec ompres s or are needed t o s ee thi s pi c ture.