ptt307 Presentation8 bioenergy

advertisement

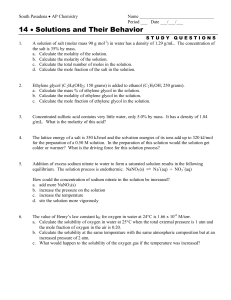

Bioenergy • Bioethanol • Biogas • Bio diesel ??? • Strategy in Perlis BIOETHANOL, BIOGAS and BIOHYDROGEN 10 May 2013 BIO ETHANOL 3 Raw materials Fermentation Fermentation product separation Microorganisms : Saccharomyces cerevisiae Zymomonas mobilis Raw material : Glucose containing materials Process : Aerobic and anaerobic ehanol 5 Saccharomyces cerevisiae Well studied, widely used commercially It growth is inhibited by ethanol (its own product) Zymomonas mobilis: can produce ethanol at much faster rates than S. cerevisiae high cell concentrations are not needed for high ethanol yield high ethanol tolerance, no requirements for aeration during the fermentation process 6 Raw materials (feedstocks) : Sugar Feedstocks 7 Starch Feedstocks : 8 Process Diagram 9 Calculation Prove that : 1 kg glucose will produce 0.511 kg ethanol 10 Extended question :Ethanol from starch n is the number of glucose residues in the starch The amount of glucose produced from 1 kg of starch is 180n/(162n + 18). When n is 2, as in maltose : the conversion factor is 1.053. When n becomes very large : The conversion factor approaches 1.111. Calculate theoretical ethanol yield from 1 kg of corn which has 15 percent moisture and contains 70 percent starch on a dry basis. Assume the conversion factor is 1.111. 12 Exampl e Determine ethanol fermentation efficiency for the corn with 70 percent starch on dry basis in laboratory. In this experiment, a mash having 30 percent total solids on dry basis and after 72 h of fermentation. Analysis of the final liquid sample by high pressure liquid chromatography (HPLC) showed an ethanol concentration of 13.1 g/L. 13 Basis: 1 kg of mash. One kg of mash contains 300 g total solids and 700 g water. Starch content: 300 g x 0.70 = 210 g Glucose production by starch hydrolysis: 210 g x 1.111 = 233.3 g Starch + water --------------->> glucose 210 233.3 Means that water consumption in starch hydrolysis:233.3 – 210 =23.3 gr or 23,3 ml Theoretical ethanol production: 233.3 x 0.511 = 119.0 g Volume of the ethanol produced: 119.0 g / 0.79 (g/mL) = 150.8 mL Total liquid volume: 700 mL – 23.3 mL + 150.8 mL = 827.5 mL Ethanol concentration expected: 119.0 / 827.5 mL = 0.144 g/mL or 14.4 g/L. Therefore, the fermentation efficiency is: (13.1 / 14.4) x 100% = 91.0%. 14 BIOGAS 15 Biogas is the CH4/CO2 gaseous mix evolved from digesters, including waste and sewage pits To utilise this gas, the digesters are constructed and controlled to favour methane production and extraction 16 Simple oil drum batch digester Indian ‘gobar gas’ digester 17 Chinese ‘dome’ for small-scale use 18 Accelerated rate farm digester with heating 19 During anaerobic digestion, glucose is transformed into methane through a series of steps. The overall reaction is : (CH2O)6 → 3CH4 + 3CO2. Calculate the percentage of methane (by both volume and mass) produced. 20 BIODIESEL April 2013 Methods of Biodiesel Production Raw material: waste vegetable oil (WVO) or straight vegetable oil (SVO). WVO is attractive to small producers , but large-scale plants may have difficulties with feedstock supplies because soap manufacturers use a lot of waste oils. Straight vegetable oil (SVO) Important Specifications : a. Cetane number. b. Viscosity. d. Freezing point / Cloud point. Mixed triglycerides do not have a clear freezing point—some componen Cetane number (C16H34), also called hexadecane, Cetane number is a measure of how quickly a fuel will ignite in a compression ignition engine. Cetane is very quickly ignited, and its number is set to 100. The cetane number of the fuel should be above 41. Most vegetable oils have an adequate cetane number, but, if necessary, additives can be mixed with the oil. Small amounts of acetone have been used. Straight vegetable oils (SVO): - Too viscous → can damage the fuel injection system of a normal diesel engine. Viscosity At 40C: Petrodiesel 4 to 5 mm2/s, vegetable oils 30 and 40 mm2/s. What to do ????? Solutions : a. Blend with Diesel oil or kerosene. b. Preheat (65 C) c. Transesterification --> biodiesel Transesterification Transesterification of triglycerides with alcohol Methanol or ethanol ? For biodiesel, methanol is currently popular, But ethanol is the better choice because it is produced from biomass Methanol is usually obtained from petroleum although it can be produced from biomass. Methanol is toxic You have 1000 kg of a vegetable oil that happens to consist of a single triglyceride (not a mixture of triglycerides). The three acids in each molecule are all palmitic acid (C16:0). What is the proper chemical name of this triglyceride? What is the molecular mass of the triglyceride? Estimate the number of kilograms of glycerine produced when the above vegetable oil is transesterified with ethanol. C16H32O2 Molar mass 256.42 g/mol This is a triple palmitate of glycerine hence it is glyceryl tri-palmitate. Molecular formula C16H32O2 Molar mass 256 When make a bond, loss 1 H → 255 Tri → 255 x 3 = 765 CH2-CH-CH2 = 41 Total = 806 Glycerol C 3H5(OH)3 Molar mass 92.09382 g/mol Each mole of triglyceride releases 1 mole of glycerine upon being esterified. 1000 kg of oil correspond to 1000/806 = 1.24 kilomoles. Hence glycerine produced : 1.24 kilomoles Weight of glycerine produced : 1.24 × 92 = 114 kg. Example 2: To produce biodiesel, ethyl or methyl esters from rapeseed oil, ethanol or methanol, and potassium hydroxide are used in the reaction: a. Determine the theoretical conversion efficiency of the biodiesel reaction b. Determine the amount of ethanol required to convert 1 L of rapeseed oil reacted with 1 percent potassium hydroxide. Base your calculations on triolein since this is often the predominant triglyceride in vegetable-based oils: C57H98O6, Oleic acid 18:1 cis-9 C18H34O2 C57H98O6, MW 878 g/gmol, density 0.88 kg/L Ethanol: C2H5OH, MW: 46 g/mol, density 0.794 kg/L Methanol: CH3OH, MW: 32 g/mol, density: 0.796 kg/L Potassium hydroxide in alcohol (1 wt %/vol): Fuel Density (kg/L Energy (MJ/ ) L) Biodiesel 0.88 36.6 Methanol 0.79 22.7 CH2-CH-CH2 = 41 3 Oxygen = 3 X 16 = 48 3 Carbonyl (CO) = 3 x 28 = 84 3 oleic = 3 [( 17x12 )+(33 x 1)] = 3[ 237]= 711 Total = 711+84+48+41 = 884 Molecular formula C57H104O6 57*12+104+6*16 = 884 3H5(OOCR)3 + 3 C2H5OH → 3 RCOOC2H5 + C3H5(OH) R= C17H33 237 + 12+32+24+5 36+5+(16+16+12+237)3 884 -->237 46 1000 gram = 1.13 mol 36+5+3(17) 310 92 3 x 1.13 =3.39 mol =1050 gram a. Conversion efficiency : 105 % b. The weight of 1 litre oil = volume x density , ------>0.88 kg = 0.995 mol ------> ethanol = 3 x 0.99 mol = 3 mol = 3 x 46 g = 138 gra Every 1 litre ( or 880 gram) oil needs 138 gram ethanol. Every 1 gram of ethanol will convert 880/138 = 6.4 gram 0f oil b. Molar ratio for alcohol to triglyceride molecule is 3 to 1; → 3 mol EtOH × 46 g/mol = 138 g of ethanol per gmol of triglyceride are needed. 1 gmol of triolean × 878 g/gmol = 878 g triolean; EtOH needed for compl conversion = 878 g triolean/138 g EtOH Fuel Density (kg/L Energy (MJ/ ) L) Biodiesel 0.88 36.6 Methanol 0.79 22.7 If methanol is used instead of ethanol : a. Stoichiometrically, how many kg of methanol are required for ea b. If the methanol, were used directly as fuel, how much energy w c. If 1 liter of biodiesel is used as fuel, how much energy is release d. What is the methanol-to-biodiesel energy ratio? C3H5(OOCR)3 + 3 CH3OH → 3 RCOOCH3 + C3H5(OH)3 a. 1 litre oil = 0.88 kg = 0.995 mol ------> Methanol = 3 x 0.99 mol = 3 mol = 3 x 32 g = 96 gram Every 1 litre ( or 880 gram) oil needs 96 gram Methanol. Every 1 gram of Methanol will convert 880/96 = 9.16 gram 0f oil (compare with that of ethanol) b. ref to table in question, methanol energy = 22.7 MJ / L Methanol density = 0.8 kg/L. Every 1 L methanol will produce 22.7 MJ energy Or, every 0.8 kg ( 800 gr) methanol will produce 22.7 MJ energy For every 96 gr methanol – > 96/800 x 22.7 = 2.72 MJ C3H5(OOCR)3 + 3 CH3OH → 3 RCOOCH3 + C3H5(OH)3 Fuel Density (kg/L Energy (MJ/ ) L) Biodiesel 0.88 36.6 Methanol 0.79 22.7 c. Mw biodiesel = 237+12+32+15 = 296 1 mol oil will produce 3 mol biodesel. 3 mol biodesel= 3 x 296 gr = 888 gr ref to table , biodiesel energy = 36.6 MJ / L Biodiesel density = 0.88 kg/L. Every 1 L methanol will produce 36.6 MJ energy Or, every 0.88 kg ( 880 gr) methanol will produce 36.6 MJ energy For every 888 gr biodiesel – > 888/880 x 36.6 = 37 MJ What is the main reason to prefer biodiesel to straight vegetable oils (SVO) as fuel for diesel engines? What should you do to make SVOs more acceptable as diesel fuel (other than making biodiesel out of them)?