History and Current Status of the Plastics Industry

advertisement

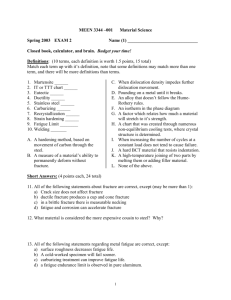

MFGT 104 Materials and Quality Chap 10: Kinetics Heat Treatment Professor Joe Greene CSU, CHICO MFGT 104 1 Chapter 10: Kinetics Heat Treatment • Objectives – Define heat treatment and the factors that influence its effectiveness. – Describe the phases of the quenching process and the various media used. – Explain the normalizing and annealing process for metals. – Describe the purposes and uses of the time-temperature transformation curve. – Describe the tempering process and its uses. – Define common terms and processes associated with the hardening of steels. – List the advantages and disadvantages of different hardening processes. 2 Introduction • Heat treatment refers to heating and cooling operations required to alter the properties of metals, plastics, and ceramics – Changes in a material’s properties result from changes made in microstructure of the material. • • • • Steel’s crystalline structure changes during heat treatment Most metal’s crystalline structure can not be changed. Room Temp steel is mixture of ferrite and pearlite. (BCC) At elevated temp (1333F), the structure changes to FCC austenite. – For slow cool, austenite returns to BCC – For fast cool, austenite turns to martensite, Body Centered tetragonal structure, the hardest form of steel. – The larger amount of martensite in steel, the harder – Martensite is formed from Pearlite which has an eutectoid composition of 0.77% Carbon – Steel that is 100% Pearlite, 1080 steel, will transform into 100% martensite if heated to austenite range and then cooled rapidly – Steel that is 50% Pearlite, 1040 steel, is hypoeutectoid and contains less Pearlite, will transform into 50% martensite. 3 Iron-Carbon Phase Diagram • Iron and Carbon are two main elements in steels. – Ferrite- alpha iron. BCC and magnetic. Alpha/delta = pure iron • Room temp dissolve only 0.008% C. • Delta iron if T is between 2552F and 2802F • Small amount of carbon dissolves interstitially (imperfection in the lattice) – Carbon steel of 0.77% carbon (eutectoid- lowest T a single phase can exist before becoming 2). All carbon dissolved into austenite. – Austenite- gamma iron. FCC and non-magnetic. – Steel must be taken into autenite region for all hardening and softening. When solution cools slowly steel separates into 2 distinct phases, ferrite and cementite. – Cementite- very hard and brittle compound, not alloy. – Iron is allotropic- can exist in more than one phase. 4 Iron-Carbon Phase Diagram • Iron is ferromagnetic- magnetism is dependent upon which crystalline structure is present due to Carbon content and temperature. • Curie Temperature- temperature at which magnetism changes • Ferrite holds between 0.006% Carbon at 392F and up to 0.04% at 1333F. • Austenite holds 0.77% at 1333F and up to 1.7% at 2066F • Pearlite is an eutectoid mixture of ferrite and cementite which form a lamellar structure. • Hypoeutectoid -less carbon and Hypereutectoid- more carbon than eutectoid composition for the steel. • Martensite- very hard and very brittle steel and forms when steel is rapidly cooled from the austenite state. Ferrite with highly saturated Carbon trapped in BC tetragonal structure. 5 Time-Temperature Transformation Curves • It takes time for crystalline structure of steel to change from one structure to another. – Quenching process traps structure. – Air cooled allows for slow transformation. – Note: the longer a piece of steel is allowed to cool below the austenite temperature, the softer the finished piece. – If piece is allowed to cool long enough the grain will all go to pearlite and no martensite will be formed. • TTT curve or C curve, Bain-S curve, isothermal transformation, I-T curve – Depicts the time the steel is allowed to cool versus the temperature. – Depicts the times and temperatures for the grain structure of steel to change from austenite to martensite or pearlite – Is the basis for all heat treatment of steels 6 Time-Temperature Transformation Curves • Temp on the y-axis and log time on the x- axis – Ps and Pf represent the start and finishing point for Pearlite – Microstructural development for eutectoid steel • C = 0.77% C, close to composition of 1080 steel. – – – – is called austenite range Course Pearlite is formed by slowest cooling. Remains at T room Fine Pearlite is formed by slower cooling. Remains at T room Banite is formed by slow cooling. Remains at T room C Austenite Temp Liquid, L 727C 800 600 400 Ps 50% Pf 1333C +Fe3C Fine pearlite Banite 200 0 Course pearlite 1 min 0.1 1 10 100 1 hour 1 day 1000 10000 100000 Time, seconds log scale Eutectic Temp + Fe3C + 727C + Fe3C 0.77 %C Eutectoid Composition 7 Time-Temperature Transformation Curves • Temp on the y-axis and log time on the x- axis – Banite microstructure involves extremely fine needles of -Fe and Fe3C in contrast to lamellar structure of pearlite Ms and Mf represent the start and finishing point for Martensite – A represents rapid cooling time and yields 100% Martensite, B is slower and yields some Pearlite and some Martensite, C is slowest and yields 100% Pearlite and is the softest. – Fig 10-11 and 10-12. Transformation from FCC to BCT – Fig 10-13. Microstructure of martensite C Austenite 727C 800 Temp Ps 600 Pf 400 200 0 A B 1 min 0.1 1 10 100 +Fe3C Course pearlite Fine pearlite C 1 hour Banite 1 day Ms Mf 1000 10000 100000 Time, seconds log scale 8 Time-Temperature Transformation Curves • Hypereutectic composition (1.13 wt % C) • – Position of transformation curves are shifted downward and toward 880C right of the martensitic reaction C Austenite 727C – Fig 10-15 800 Ps Course pearlite Hypoeutectic composition Temp 600 + +Fe C 3 +Fe3C Pf Fine pearlite • (0.5wt % C) Banite M 400 s – Position of transformation curves are200 1 day Mf 1 min 1 hour • shifted upward and toward left of the • martensitic reaction – Fig 10-16 • Martensitic forms at decreasing Temp – Temperatures with – Increasing C content – Around eutectoid composition range 0.1 0 1 10 100 1000 10000 100000 Time, seconds log scale 880C Austenite C 800 727C Ps 600 + +Fe3C Pf +Fe3C 400 1 min 200 0.1 0 1 10 100 1 hour Course pearlit Fine pearlite Banite M s 1 day Mf 1000 10000 100000 Time, seconds log scale 9 Alloying affects on TTT Curves • Alloying elements shift the TTT curve to the right – Allows for longer cooling times for martensitic transformation – Chromium and Nickel shift the curve and allow 5 more seconds. – Allows for transformation deeper into the product rather than hard surface and soft core. C Temp Austenite 800 727C 600 Ps Pf 400 200 0 Course pearlite A B 1 min 0.1 1 10 100 Fine pearlite C 1 hour Banite 1 day Ms Mf 1000 10000 100000 Time, seconds log scale 10 Tempering of Steels • Types of tempering (continued) – austempering: resembles martempering, except after leveling the temperature at 700F, it is held for a longer period of time while it passes through the Ps and Pf lines. • Bainite is formed which is the region of transformation between the rapid cooling curves for martensite and slower cooling pearlite. • Bainite has superior ductility and tougness but inferior hardness and strength versus martensite. • Once Bainite is formed, the steel is quenched to room temperature – isothermal quenching and tempering fits somewhere between martempering and austempering. • Steel is harder and stronger than austempering, yet more ductile and stress free than martempering. • Structure is combination of bainite and tempered martensite. • Metal is heated to autenite range then quenched to about 50% transformation from austenite to martensite. • Temperature of 300F is held for a few seconds while remaiing austenite transforms to bainite. 11 • Quenched to room temperature Heat Treatment of Steel • Martensite is a brittle phase. Formed by rapid quenching – 100% Martensite is impractical as a glass hammer. – Made less brittle by reheating and transforming to +Fe3C phase – Reheating to a moderate temperature and short time gives a high strength low ductility product. – Tempering process. Fig 10-17, Fig 10-18. • Microstructure has carbide forming isolated particles in matrix of ferrite. – Microstructure is different than pearlite and bainite. of part C Surface Center of part – Problem • Surface cools faster than center • Can crack Temp – Solution. Fig 10-19 • Martempering – Stop quenching above Ms, – then slow cool to martensite – Then tempering 727C Austenite 800 Ps 600 Pf 400 Tempering +Fe3C 200 0 1 min 0.1 1 10 100 1 hour 1 day Ms Mf 1000 10000 100000 Time, seconds log scale 12 Tempering of Steels • Rapid drops in temperature causes internal stresses in metals. • Tempering is the process of re-heating the metal immediatley after hardening to a temperature below the transformation temperature [700F and 800F] for 1 hour per inch of thickness then cooled to increase the ductility and toughness of steel. • Tempering is also called drawing because it “draws” the hardness from the metal • Types of tempering – martempering: part is quenched to a temperature just above the Ms line [between 500F and 600 F]for a few seconds to allow temperature throughout the part to stablilize. Then the part is quenched through the martensitic range to room temperature • Provides more uniform grain structure as it enters martensitic range • More stress free 13 Methods of Hardening Steels • Quenching is simply a controlled cooling process used during the heat treatment of metals. – Heat metal to high Temperature (above 1333F) to Austenite range – Quench in • water: Most common. Preferred for low carbon steels due to rapid temp change. Can cause internal stresses, cracks and distortions. Water is at room Temp. • brine (salt water): fastest of quenching. Contains 5% to 10% salt. Salt reduces the vapor film phases causing the outer surface of metal to explode off. • oil: slower than water as quenching medium due to thermal conductivity. Used for thinner parts and those with sharp edges, e.g., razor blades, knifes, and springs. Oil provides compromise in hardness and strength against cracking and distortion. Oil is heated to 100F to 150F (thins the oil)to provides better results. • air: less abrupt than either oil or water. Air is blown over heated part. The metal cools more slowly yielding less strength and hardness. Used in high alloy metals where alloys are used to harden metal. Produces least amount of internal stresses, cracks, and distortions. 14 Methods of Hardening Steels • Hardenability – Relative ability of steel to be hardened by quenching – Jominy end-quench test. Fig 10-22 • • • • • Standard-size steel bar (255 mm D and 100 mm L) Taken to Austenite temperature (727C) One end subject to water spray Produces common cooling rate gradient along the Jominy bar Fig 10-22 – Cooling rate along the Jominy bar. Cooling vs length is created. (Curve 1) – Greatest near water spray end. – Hardness varies along length.A hardness versus length is created. (Curve 2) • Information used in two ways – If quench rate is known for a steel to be hardened then curves 1 and 2 can be used to predict the hardness. – Hardness across several areas of a part that is quenched can be estimated. – Figs 10-23, 10-24 15 Heat Treatment of other Metals • Aluminum bronze Age-hardening – 10% Al – 90% Cu • Precipitation hardening – Small obstacles to dislocation motion can strengthen (harden) a metal. – Small second-phase precipitates are effective this way. • Chap 9 illustrated that cooling paths for certain alloy compositions lead to 2ndphase precipitation. – Al-Cu system. Fig 10-25 » Al-rich end (96% Al) starts in 100 phase and cools to + .with phase precipitating at the boundaries. – By quenching and reheating Al-Cu alloy (4.5%Cu). Fig 10-26 » A fine dispersion of precipitates forms within the boundaries » The precipitates are effective in hindering dislocation motion and increase alloy hardness and strength. » Known as precipitation hardeneing 16 Methods of Softening Steels • Ductility can be preferred rather than hardness and strength. – Annealing and normalizing are used to obtain a softer, more ductile, and less distorted metal that is easier to machine. – Normalizing involves heating the metal well into austenite range and then letting it air cool at room temperature. • Normalized metals have and even grain size that makes them easier to machine. • Normalizing is often used prior to other heat treatments for machinability. – Annealing is slow cooling from just above the austenite temperature range (50F to 100F above the range) to prevent excessively large grain • Temperature range is different for steels: 0.4% C = 1500F, 0.8% C = 1400F • Leaves the steel in its softest possible condition • Example, fully annealed – Steel with 0.4% Carbon requires 1500F for 1 hour per inch of thickness – Temperature is reduced slowly (20F per hour) until it passes the Pf line on the TTT Curve. Takes 2 to 3 days. – Softest possible steel with large, uniform grain structure 17 Methods of Softening Steels • Other Annealing processes – Box annealing • Place steel into an oven or box furnace and heated to just over the austenite range (50F to 100F) for 1 hour per inch thickness. • Oven is turned off and the steel is held in insulated box for 1 day • Resulting steel is not quite as soft as fully annealed steel but is cheaper & faster. – Process annealing • Metal is heated to 1050F to 1300F and then cooled. • Relieves internal stresses of the metal and gives good malleability. – Speroidizing • Similar to process annealing. • Parts are heated below the low transformation temperature (1333F) for 1 to 4 hours and then cooled slowly. • The cementite in the steel is speroidized, producing a tougher steel. • Used with high-carbon steel to make them machinable. • Tool steels are heated above the LTT (1333F) for 1 to 4 hours and cooled.` 18 Quenching of Steels • During quenching, there are four separate actions – vapor forming: vapor film forms next to metal as liquid boils. – vapor covering: bubbles around metal stick to metal and insulate it. – vapor discharge: vapor collapses and explodes off surface (max cool) – slow cooling: continues until the metal reaches room temperature. • Agitation of metal is used to reduce vapor effects – If bubbles are not removed the film of bubbles will form soft spots, warpage, and cracks in metal 19 Case Hardening of Steels • Case hardening involves four different methods – carburizing: crowing considerable amounts of carbon into the outer surface of the steel. Placing low-carbon steel in high carbon atmosphere and heating to 1400F. – Nitriding: same process as carburizing except that nitrogen is added to the outer shell of the part by plaicng the part in a nitrogen rich atmosphere. – Cyaniding: supply carbon and nitrogen to the steel. Hot steel is immersed in sodium cyanide for several hours while C and N disperse in steel. – Carbonitriding: same as Cyaniding • Case hardening is used on parts for gear teeeth, cutting wheels, and tools. • Flame hardening • Induction hardening 20