Introduction to Industrial Hygiene

advertisement

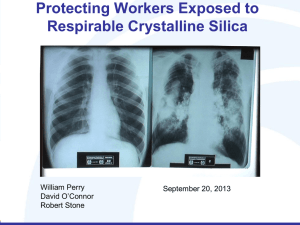

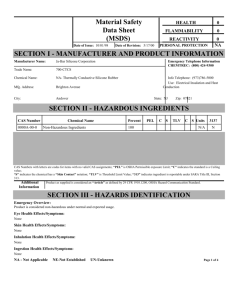

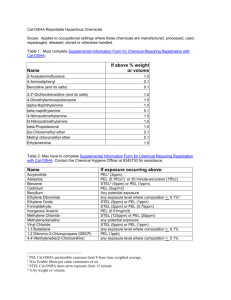

HEALTH HAZARDS OTI 500 Trainer Course in Occupational Safety and Health Hazards for Construction Industry 1 OSH Act of 1970 The purpose of the OSH Act is to “assure so far as possible every working, man and woman in the nation safe and healthful working conditions and to preserve our human resources.” 2 Routes of Entry Inhalation – airborne contaminants Absorption – penetration through the skin Ingestion – eating – drinking 3 OSHA Hierarchy of Control Engineering Work controls practice controls Administrative Personal controls protective equipment (PPE) 4 Types of Exposure Acute – Short term period between exposure and onset of symptoms Chronic – Long time period between exposure to an agent and the onset of symptoms 5 Exposure Limits Air Contaminants OSHA – Occupational Safety and Health Administration NIOSH – National Institute of Occupational Safety and Health ACGIH – American Conference of Governmental Industrial Hygienists 6 Exposure Limits Air Contaminants OSHA – PEL, STEL, Ceiling NIOSH – TWA, STEL, Ceiling ACGIH – TWA, STEL, Ceiling 7 Exposure Limits Air Contaminants TWA – takes into account variable exposure through a full shift, 8 hour work day STEL – limit of exposure during a short period, 15 minutes CEILING – absolute maximum level of exposure not to be exceeded 8 Exposure Limits Air Contaminants Legally enforceable – OSHA PEL – OSHA AL (action level) – OSHA EL (excursion limit) 9 Silica Special Emphasis Program (SEP) Special Emphasis Program--Silica OSHA’s Industrial Hygiene initiative Collaboration of OSHA Compliance and Consultation Programs SiO2 10 Why Target Crystalline Silica Exposure? Widespread occurrence and use Number of related deaths Number of exposed workers Health effects 11 Occurrence and Use of Silica SiO2 - basic component of sand, quartz & granite Quartz - 2nd most common mineral in the earth’s crust Airborne silica is produced by: 12 Occurrence and Use of Silica Airborne silica is produced by: – – – – – – sandblasting rock drilling foundry work stone cutting drilling quarrying – – – – tunneling jack hammering concrete manufacturing demolition asphalt pavement manufacturing 13 Construction Targeting jack hammering rock drilling abrasive blasting concrete mixing brick and concrete block or slab cutting 14 Permissible Exposure Limit (PEL) for Silica 10 mg/m3 = ? mg/m3 % Quartz +2 PEL for respirable dust containing a % silica. 15 Silicosis Prevention Program Medical surveillance program – baseline examination • medical and occupational history • prior to exposure – – – – – every 5 years if < 20 years of exposure every 2 years if > 20 years of exposure baseline chest x-ray pulmonary function tests (PFT) x-ray upon termination of employment Source: OSHA SEP16 Silicosis Prevention Program Personal air monitoring program Training and information on crystalline silica Availability of air and medical surveillance data to workers Respiratory protection program Source: OSHA SEP17 Silicosis Prevention Program Hygiene facilities and clothing change areas Recordkeeping Personal exposures below the PEL OR facility has an abatement program that provides interim worker protection Housekeeping program Regulated areas Source: OSHA SEP18 Health Effects Acute - intense crystalline silica exposure Accelerated - more intense exposure over 5 to 15 years Chronic - 20 to 45 years prolonged exposure to crystalline silica 19 Common Hazard Abrasive Paint blasting removal Renovation Road & demolition repair 20 Exposure Controls Substitution Coal slag (black beauty) Steel grit Aluminum oxide Wild stuff (frozen CO2, walnut shells, baking soda 21 Exposure Controls Wet Methods Water suppression of dust Very effective method May be less efficient Requires supply of water and clean up Power tools with HEPA exhaust 22 Silica Case Example 39 year old sandblaster diagnosed with silicosis and tuberculosis after 22 years of abrasive blasting – shortness of breath – wheezing – chest discomfort – lung tissue samples - extensive fibrosis (silicosis) 23 Silica Case Example 49 year old man diagnosed with silicosis, emphysema, and asthma after 21 years of work as a tile installer where he was exposed to dust from cutting, drilling, and working with grout. He was a nonsmoker 24 Cadmium 29 CFR 1926.1127 Blue-white metal Grayish-white powder Found in lead, copper, and zinc sulfide ores Compounds – highly colored from brown to yellow and red 25 Cadmium 29 CFR 1926.1127 Uses – electrode component in alkaline batteries – stabilizer in plastics – paints 26 Cadmium 29 CFR 1926.1127 Short term exposure – irritation of upper respiratory tract – constriction of the throat – metallic taste – cough – flu-like symptoms 27 Cadmium 29 CFR 1926.1127 Long term exposure – kidney damage – lung cancer – prostate cancer 28 Scope All occupational exposure to cadmium compounds – in all construction work • construction • alteration • repair 29 01/12/100 Covered Activities Wrecking Electrical grounding w/cadmium Salvage Installation of Use of cadmium cadmium products containing paints Emergencies cutting, brazing, burning, grinding Transportation, disposal, and or welding storage Demolition 30 01/12/100 Definitions Action level (AL) – 2.5 g/m3 Competent person (29 CFR 1926.32) – determines presents of cadmium – regulated areas – access – PPE – training 31 01/12/100 Permissible Exposure Limit PEL = 5 g/m3 32 01/12/100 Exposure Monitoring Prior to performance Exposure at or above the AL – relevant plans – reports – MSDSs – other records Frequency Additional ? monitoring 33 01/12/100 Initial Monitoring As soon as practicable Higher concentrations – monitor while conducting task Objective data Documentation – > 5 g/m3 – < 5 g/m3 34 01/12/100 Prohibited Activities Eating Drinking Smoking Chew tobacco Apply cosmetics OR carry such products into regulated areas 01/12/100 35 Methods of Compliance Intermittent exposure Exposure < 30 days per year Engineering and work practice controls are not feasible – reduce exposure to lowest level – PPE 36 01/12/100 Methods of Compliance Employee Rotation 37 Compliance Program Exposure > PEL Written program Review and update as necessary 38 01/12/100 Other Requirements Hygiene areas and practices Housekeeping Medical Surveillance – 30 or more days > action level – Communicating hazards – Recordkeeping 39 01/12/100 Lead in Construction Standard 29 CFR 1926.62 SCOPE AND APPLICATION – Applies to all construction work where an employee may be occupationally exposed to lead. – Excludes construction work covered in the general industry standard. 40 Lead in Construction Standard Applies to: – Demolition – Removal and Encapsulation – New construction, alteration, repair, or renovation – Installation of products containing lead – Lead contamination/ emergency cleanup – Transportation, disposal, storage – Maintenance operations associated with construction 41 Selected Definitions LEAD – Metallic lead – All inorganic lead compounds – Organic lead soaps ~ Excludes organic lead compounds. ~ 42 Selected Definitions COMPETENT ACTION PERSON LEVEL (AL) – 30 g/m3 PERMISSIBLE EXPOSURE LIMIT (PEL) – 50 g/m3 43 Selected Definitions ALLOWABLE (in g/m3) EXPOSURE 400 # hours worked 44 Selected Definitions INITIAL DETERMINATION – To determine whether employees are exposed at above the action level – May rely on historical data – May rely on objective data 45 Exposure Assessment Lead in Construction INITIAL DETERMINATION – TASK 1 TRIGGERS: • Exposure up to 500 g/m3 (10 x the PEL) • Activities include: – manual demolition of structures, hand scrapping or sanding, heat guns, power tool cleaning with dust collection systems, spray painting 46 Exposure Assessment Lead in Construction INITIAL DETERMINATION – TASK 2 TRIGGERS: • Exposure up to 2,500 g/m3 (>10 x the PEL, but less than 2,500 g/m3 ) • Activities include: – using lead containing mortar, cleanup where dry expendable abrasives are used, rivet busting, power tool cleaning without dust collection systems, movement/removal of enclosures 47 Exposure Assessment Lead in Construction INITIAL DETERMINATION – TASK 3 TRIGGERS: • Exposure > 2,500 g/m3 (>50 x the PEL) • Activities include: – abrasive blasting, welding, cutting, torch burning 48 Exposure Assessment Lead in Construction POSITIVE INITIAL DETERMINATION – Exposure at or above the action level and below the PEL • Conduct monitoring representative of each exposed employee – May use historical data – Additional monitoring - every 6 months – Document 49 Exposure Assessment Lead in Construction POSITIVE INITIAL DETERMINATION – Exposure at or above the PEL • Conduct monitoring representative of each exposed employee – May use historical data – Additional monitoring - quarterly – Document 50 Exposure Assessment Lead in Construction NEGATIVE INITIAL DETERMINATION – No exposure at or above the action level – Additional monitoring is not required unless there is a change in: – equipment, process, control, personnel or task resulting in levels at or above the action level – Document 51 Methods Of Compliance Lead in Construction Engineering Controls Respiratory protection Compliance program Mechanical ventilation Administrative Good controls work practices 52 Respiratory Protection Lead in Construction REQUIRED: While engineering and work practice controls are being installed or implemented During activities when engineering and work practice controls are not feasible Where engineering and work practice controls are not feasible to reduce exposures below PEL/AL In emergencies 53 Respiratory Protection Lead in Construction Must be provided whenever an employee requests a respirator. Must provide a PAPR whenever an employee requests one and it is protective against the level of exposure. 54 Exposure > PEL Lead in Construction Respiratory Personal Change protection protective equipment rooms Showers (where feasible in construction) Eating Hand facilities washing facilities 55 Housekeeping Lead in Construction Maintain surfaces as free as practicable of lead accumulation. 56 Medical Surveillance Lead in Construction INITIAL MEDICAL SURVEILLANCE – Exposure > AL one day MEDICAL SURVEILLANCE PROGRAM – Exposure > AL for more than 30 days per year 57 Medical Removal Lead in Construction Two blood lead levels > 50 g/dL Return - < 40 g/dL Benefits 58 Employee Training Lead in Construction EXPOSURE > AL ANNUALLY 59 Recordkeeping Lead in Construction EXPOSURE DATA – At least 30 years MEDICAL SURVEILLANCE – Duration of employment plus 30 years 60 Recordkeeping Lead in Construction MEDICAL REMOVAL – At least duration of employment OBJECTIVE DATA – 30 years 61