October 23, 2007 - University of Idaho

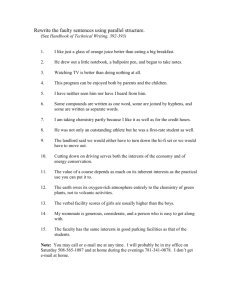

advertisement

Investigation on additives to improve positive active material utilization in lead-acid batteries Rubha Ponraj Research seminar October 23, 2007 Department of Chemistry Outline • • • • • • • • • Introduction to Electric vehicle (EV) Our choice of battery in EV Goal of our project Working principle Advantages and limitation How to overcome the limitation? Our effort Results Conclusion Department of Chemistry 2 Alternative fuel for vehicles • Gas emissions and its ecology impact • Electric vehicle • California Air Resources Board (CARB) –Zero emission vehicle – 1995 http://en.wikipedia.org/wiki/Electric_vehicle Department of Chemistry 3 Battery powered electric vehicles Batteries – Lead acid batteries, Nickel metal Hydride (Ni-MH) and Lithium-ion • Problem of recharging (7-10 hours) • Limited range – type and weight • Batteries are bulky • Safety issues • High initial cost http://www.naftc.wvu.edu/NAFTC/data/indepth/Electric/HybridElectric.HTML Department of Chemistry 4 Comparison between different batteries in electric vehicle Comparison between different batteries (++: very good, + : good, 0: satisfactory, : poor, : very poor) Safety Specific energy Specific power Specific cost Recycling Lead–acid Ni–MH + 0 + ++ + + ++ 0 Li-ion ++ + 0 0 Specific energy - Wh/kg Specific power - W/kg Specific cost - $/Wh Jürgen Garche, J. Phys. Chem. Chem. Phys., 3, (2001) 356-367 Department of Chemistry 5 Feasibility of lead acid batteries Can lead acid battery compete in modern times? Yes • Dominant position due to low cost - automobile applications • Cost efficient technologies – to improve the performance Department of Chemistry 6 Goal of our project Advanced lead-acid battery for military electric vehicle - high fuel economy - provides power at remote location - stealth operation Department of Chemistry 7 Lead-acid batteries Department of Chemistry History of lead-acid batteries Inventor of first rechargeable battery - 1859 Plante’s Lead–acid battery (1859) Gaston Plante (1834-1889) Department of Chemistry http://www.leadacidbatteryinfo.org/resources.htm http://www.geocities.com/bioelectrochemistry/plante.htm 9 Reaction mechanism • Reaction at positive electrode: Pb(IV)O2 + HSO4- + 3H+ + 2e- discharge charge Pb(II)SO4 + 2H2O Eo = 1.805 V • Reaction at negative electrode: Pb(0) + HSO4- discharge charge Pb(II)SO4 + H+ + 2e- Eo = -0.340 V • Total cell reaction: PbO2 + Pb + 2HSO4- + 4H+ discharge charge 2PbSO4 + 2H2O Eocell = 2.145 V E0 – in 1.3 specific gravity H2SO4 H. Bode, Lead-Acid Batteries, translated by R.J. Brodd and K.V. Kordesch, Wiley Interscience, New York, 1997, page 4. Department of Chemistry 10 Working principle LAB During discharge process: Link http://www.chem.iastate.edu/group/Greenbowe/sections/projectfolder/animations/PbbatteryV8web.html Department of Chemistry 11 Lead-acid battery construction Positive plate valve pack Negative cell Positive cell connection connector Microporous separator Grid plate casing terminal Positive plate pack Negative pole Negative plate Positive plate http://www.doitpoms.ac.uk/tlplib/batteries/batteries_lead_acid.php Department of Chemistry 12 Advantages • Low cost. • Reliable. • Indefinite shelf life – compared to modern batteries • Deliver high currents • Low self-discharge • Low maintenance requirements • Many suppliers world wide. • The world's most recycled product. http://en.wikipedia.org/wiki/Lead-acid_battery http://www.lead-battery-recycling.com/lead battery-recycling.html Department of Chemistry 13 Limitation • Low specific energy (energy to weight ratio) Department of Chemistry 14 Reasons for the reduction of the theoretical specific energy Specific energy of Plante’s battery- 9 Wh/kg Jürgen Garche, J. Phys. Chem. Chem. Phys., 3, (2001) 356-367 Department of Chemistry 15 What is active material utilization? • Positive electrode: lead dioxide • Negative electrode: lead - Ratio of ampere hours discharged to its stoichiometric capacity Department of Chemistry 16 Electrical conductivity • Positive electrode: PbO2 - 50 Ω-1cm-1 • Negative electrode: Pb - 5.3x104 Ω-1cm-1 • PbSO4 - Insulator Department of Chemistry 17 Positive electrode - reaction limiting Positive plate reaction Pb(IV)O2 + HSO4- + 3H+ + 2e- discharge charge Pb(II)SO4 + 2H2O Eo = 1.805 V Discharge capacity (Ah) depends on this reaction To sustain this reaction: • Supply of acid • Supply of electrons P.T. Moseley, J. of Power Sources 64 (1997) 47-50 Department of Chemistry 18 Methods to improve positive active material utilization • • • Increasing energy – weight ratio Increasing mass transport of H+ and HSO4ֿ inside active material Increasing electrical conductivity of active material H.Dietz, J.Garche, K.Weisner, J. Power Sources, 14 (1985) 305. D.B.Edwards, Song Zhang, J. Power Sources, 135 (2004) 297 Tokunaga, M. Tsubota, K. Yonezu, K. Ando, J. Electrochem. Soc., 13 (1987) 525-529 Department of Chemistry 19 Effect of discharge rates on active material utilization • During discharge – permanent layer of PbSO4 Grid • Fast discharge rate (50 mA/cm2) - Positive active material utilization – 30% - Not enough time (mass-transport limited) - Porous non-conductive additives • Slow discharge rate (10 mA/cm2) - Positive active material utilization – 60% (Electronic conduction limited) - higher electrical conductive materials Department of Chemistry PbSO4 eֿ Electrically isolated PbO2 HSO4¯ HSO4¯ PbO2 At positive electrode 20 Illustration on the effect of porous additive Grid PbSO4 HSO4ֿ eֿ HSO4¯ eֿ HSO4¯ PbO2 Active material without additive Department of Chemistry Active material with mass transport enhancing additive 21 Effect of electrically conductive additives Electronic conducting matrix in active mass Current collector (grid) Active material Electrically conductive material Jürgen Garche, J. Phys. Chem. Chem. Phys., 3, (2001) 356-367 Department of Chemistry 22 Survey on positive plate additives Carboxymethyl cellulose (0.2 wt.%) • 9.9% increase in utilization (at 1 h discharge rate) • Initial capacity was high • Not stable – carbon oxidized Carbon black (0.1 wt.%) • 3.3% increase in utilization (at 1 h discharge rate) • Not stable – carbon oxidized H.Dietz, J.Garche, K.Weisner, J. Power Sources, 14 (1985) 305. Department of Chemistry 23 Survey on positive plate additives Glass microspheres • Filler material • Utilization -11.4 % to 33.12% ( at 0.1 A/g discharge rate) • Optimum loading – 4.4 wt.% SEM image for glass microspheres (x 500) Silica gel • Particle size - 30 to 150 nm • 0.2 wt.% addition • Increases utilization by 10% (high discharge rate) D.B. Edwards, V.S.Srikanth, J. Power Sources, 34 (1991) 217 Wang Qing, J. of Wuhan University of Technology--Materials Science Edition, 22 (2007) 174 H.Dietz, J.Garche, K.Weisner, J. Power Sources, 14 (1985) 305 Department of Chemistry 24 Selection of additives • • • • • Stable Good adhesion to active material Improve positive active material utilization Cost effective Light weight Simon D. McAllister, Rubha Ponraj, I. Francis Cheng and Dean B. Edwards, J. of Power Sources 173, 2 (2007) Department of Chemistry 25 Our choice of additive Diatomaceous earth particles (SiO2) - Fossilized remains of diatoms, a type of hard-shelled algae 5µm - Uses: filtration aid, insecticide, cat litter - It is stable, light weight, porous and cost effective http://en.wikipedia.org/wiki/Diatomaceous_earth Department of Chemistry 26 EXPERIMENTAL Department of Chemistry Sorting of diatomaceous earth A - B Diatomaceous earth particles sorted using Nylon screen cloth 20-30 µm 30-53 µm 53-74 µm 74-90 µm C SEM of diatomites of different sizes: (A) 20–30 µm, (B) 53–74 µm, (C) >90 µm Department of Chemistry 28 Process of positive plate preparation Paste preparation Porosity test Zero valent Pb test Unsatisfactory Unsatisfactory Curing Satisfactory Formation Conditioning Department of Chemistry 29 Paste Composition • PbO-(11% Pb0), 0.5% Dynel fibers, additive - total 10 g Mixed with H2SO4 and H2O - paste • Density Paste inside Pb strip 3 2.5 – 3.5 g/cm teflon ring • Pasted into teflon rings (volume 0.24 ml) Department of Chemistry 30 Curing • • • • • 24 hrs hydroset – 250 °F pressure cooker Pb0→ PbO Some formation of PbSO4 Dried overnight Each plate - 0.6 to 0.8 g Department of Chemistry 31 Testing • Porosity by water absorption - >45% • Pb0 atomic absorption spectroscopy - <5wt.% • SO42- by ion-conduction chromatography If it passed the screen test…. Department of Chemistry 32 Formation PbO + H2SO4 PbSO4 oxidation PbSO4 + H2O PbO2 + 2e- • 1.1 sp. gr. H2SO4 • commercial negative plate with polyethylene separator • Theoretical capacity - 0.2241 Ah/g • Charge positive plates to 125% Calculation of theoretical capacity: 2F = 53.6 Ah Positive plate negative plate in between separators Glass mat with 90% porosity polyethylene separator b/w negative and positive plates Formation cell (side view) Formation cell (cross-sectional view) Berndt, D. Maintenance-Free Batteries. 2nd ed. 1997, p. 106 . Department of Chemistry 33 Conditioning and cycling Changed the electrolyte - 1.3 sp. gr. H2SO4 - Discharged at 10 mA/g - Charged to 125% discharge capacity - 4 to 5 cycles Counter Electrode 20-30 cm of Pt wire Working Electrode – Positive plate Department of Chemistry Reference Electrode – Ag/AgCl 34 Performance measurement • Capacity measurements are taken at a 50 mA cm-2 discharge and a 10 mA cm-2 discharge. • Diatomites - 20-30 µm, 30-53 µm, 53-74 µm and 74-90 µm, at 1 wt.%, 3 wt.% and 5 wt.% were tested. • Our control – without additive Department of Chemistry 35 RESULTS Department of Chemistry Discharge curve Voltage (V) PbO2 + HSO4- + 3H+ + 2e- discharge PbSO4 + H2O 1.80E+00 • Fast discharge rate (50 mA/cm2) 1.70E+00 • Discharge capacity (mAh) 1.60E+00 • Utilization = Calculated capacity Theoretical capacity 1.50E+00 • Theoretical capacity = 0.2241 Ah/g 1.40E+00 1.30E+00 1.20E+00 0 1000 2000 3000 4000 Tim e (s) Department of Chemistry 37 Utilization at fast discharge rate 14 % change in utilization 12 10 3% loadings 5% loadings 8 6 4 2 0 -2 -4 20-30 30-53 53-74 74-90 Size (µm) Department of Chemistry 38 Utilization at slow discharge rate % change in utilization 15 3% loadings 5% loadings 10 5 0 -5 -10 20-30 30-53 53-74 74-90 Size (µm) Department of Chemistry 39 Specific capacity Specific capacity – mAh/g At fast discharge rate (50 mA/cm2) At slow discharge rate (10 mA/cm2) 8 12 3% loadings 3% loadings 10 6 5% loadings 5% loadings 4 % change in specific capacity % change in specific capacity 8 6 4 2 0 -2 -4 2 0 -2 -4 -6 -6 -8 -8 -10 - 10 -12 20-30 3 0 - 53 53 - 74 Siz e (µm) Department of Chemistry 74 - 9 0 20-30 30-53 53-74 74-90 Size (µm) 40 Diatomites’ structure A • Diatomites are stable in the battery environment • Single diatomite elements did not perform as good as conglomerates B C Scanning electron micrograph of diatomites: A) recovered from active material after the performance tests, B) 20-30 µm C) 53–74 µm. Simon D. McAllister, Rubha Ponraj, I. Francis Cheng and Dean B. Edwards, J. of Power Sources 173, 2 (2007) Department of Chemistry 41 Conclusions Comparison of % utilization of best performed size of diatomites with control Fast discharge rate (50 mA/cm2) Slow discharge rate (10 mA/cm2) Control (without diatomites) 33.65 ± 2.52% 58.00 ± 2.01 % With diatomites particle size(53-74 µm) 38 .04 ± 2.09% 58.96 ± 2.42% • Statistically significant increase in performance • Specific energy – 12.69% increase relative to control Department of Chemistry 42 Summary • Diatomites are an inexpensive filler material • Utilization increases by 12.7% at a fast discharge rate. • Specific capacity increases by 9.3% at a fast discharge rate Department of Chemistry 43 The way forward • Test in Full sized plates 1cm2 • 3.65 x 3.365 x 0.050 in3 Use electrically conductive additives Department of Chemistry 44 Acknowledgements • • • • • • • • Dr. I. Francis Cheng Dr. Dean B. Edwards Simon D. McAllister Kenichi Shimizu Derek F. Laine Dr. Song Zhang Dr. and Mrs. Renfrew Office of Naval Research Award Number: N0001404-1-0612 Department of Chemistry 45