Design and Analysis of Experiments (3) Analysis of Variance (AVOVA)

advertisement

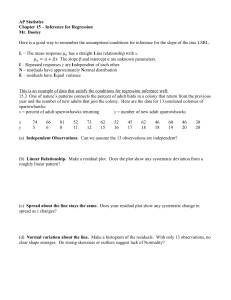

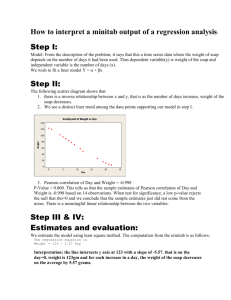

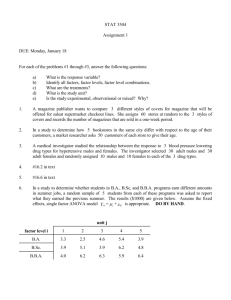

Design and Analysis of Experiments (3) Analysis of Variance (AVOVA) Kyung-Ho Park Experiments with a Single-Factor : The Analysis of Variance Factor : Simple (temperature) Level : 4 (140, 150, 160, 170℃) Treatment temperature Hardness (kg/cm2) 140℃ Y11 Y12 Y13 Y14 150℃ Y21 Y21 Y21 Y21 160℃ Y31 Y32 Y33 Y34 170℃ Y41 Y42 Y43 Y44 Table. Typical Data for a Single Factor Experiment yij ti ij , i 1,2, , a, j 1,2, , n yij: overall mean, μ: ith treatment effect, ε: a random error compound yij i ij , ij N (0, 2 ) Hypotheses H 0 : t1 t 2 t a 0 H1 : not H 0 Treatment temperature Hardness (kg/cm2) yi 140℃ 7 35.8 -0.175 1 36.9 +0.925 14 35.2 -0.775 2 36.0 +0.025 35.975 -3.375 150℃ 10 40.2 -0.15 11 40.4 +0.05 5 39.6 -0.75 9 41.2 +0.85 40.350 1.000 160℃ 13 42.0 -0.05 4 42.8 +0.75 3 41.5 -0.55 12 41.9 -0.15 42.050 2.7000 170℃ 15 39.8 +0.775 8 38.8 -0.225 6 38.5 -0.525 16 39.0 -0.025 39.025 -0.325 y=39.350 SST SSTreatment SS E a n SST ( yij y ) total sum of squares i 1 j 1 a SSTreatment n ( yi y ) 2 treatment of squares i 1 a n SS E ( yij yi ) 2 i 1 j 1 error of squares ANOVA Table Source Of Variation Sum of Squares Degree of Freedom Treatments SSTreatment a-1 Error SSE a(n-1) Total SST an-1 Mean Square F0 MSTreatments MSTreatments/ MSE =SSTreatment/(a-1) MSE =SSE/[a(n-1)] P 0.05 Factor : Simple (temperature) Level : 4 (140, 150, 160, 170℃) Randomization Order of test 1. Calc > Random data > Sample from Columns 2. Sample : 16 3. Enter: No, Temp 4. Store sample in: No, Temp No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Temp 140 140 140 140 150 150 150 150 160 160 160 160 170 170 170 170 No 2 4 11 10 7 15 1 14 8 5 6 12 9 3 13 16 Temp 140 140 160 160 150 170 140 170 150 150 150 160 160 140 170 170 Ex.3-1. Hardness of metal with quenching temperature [Step 1]: Input Data Order No Temp Hardness 1 2 140 36.9 2 4 140 36.0 3 11 160 41.5 4 10 160 42.8 5 7 150 39.6 6 15 170 38.5 7 1 140 35.8 8 14 170 38.8 9 8 150 41.2 10 5 150 40.2 11 6 150 40.4 12 12 160 41.9 13 9 160 42.0 14 3 140 35.2 15 13 170 39.8 16 16 170 39.0 Ex.3-1. Hardness of metal with quenching temperature [Step 2]: Stat > ANOVA > One-way 1. response : hardness 2. Factor : temp • Graph > click 1. individual value plot 2. Boxplots of data 3. Residual plots > Four in one Boxplot of Hardness by Temp 43 43 42 42 41 41 40 40 Hardness Hardness Individual Value Plot of Hardness vs Temp 39 38 39 38 37 37 36 36 35 35 140 150 160 Temp Individual Value Plot 170 140 150 160 Temp Boxplot 170 Residual Plots for Hardness Residuals Versus the Fitted Values 99 1.0 90 0.5 Residual Percent Normal Probability Plot of the Residuals 50 10 1 -1.0 -0.5 0.0 Residual 0.5 -0.5 -1.0 1.0 Histogram of the Residuals 4 1.0 3 0.5 2 1 0 -0.75 -0.50 -0.25 0.00 0.25 Residual 0.50 0.75 36.0 37.5 39.0 Fitted Value 40.5 42.0 Residuals Versus the Order of the Data Residual Frequency 0.0 1.00 0.0 -0.5 -1.0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Observation Order O rd er No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Tem p 2 4 11 10 7 15 1 14 8 5 6 12 9 3 13 16 140 140 160 160 150 170 140 170 150 150 150 160 160 140 170 170 H ard ness R E S I1 F ITS 1 36.9 0.925 35.975 36 0.025 35.975 41.5 -0.55 42.05 42.8 0.75 42.05 39.6 -0.75 40.35 38.5 -0.525 39.025 35.8 -0.175 35.975 38.8 -0.225 39.025 41.2 0.85 40.35 40.2 -0.15 40.35 40.4 0.05 40.35 41.9 -0.15 42.05 42 -0.05 42.05 35.2 -0.775 35.975 39.8 0.775 39.025 39 -0.025 39.025 [Step 2]: Results One-way ANOVA: Hardness versus Temp Source DF SS Temp 3 79.145 Error 12 4.615 Total 15 83.760 S = 0.6201 Level ---140 150 160 170 N 4 4 4 4 MS 26.382 0.385 R-Sq = 94.49% F P 68.60 0.000 R-Sq(adj) = 93.11% Individual 95% CIs For Mean Based on Pooled StDev Mean StDev ----+---------+---------+---------+- 35.975 40.350 42.050 39.025 0.704 (---*--) 0.661 (---*--) 0.545 (--*---) 0.556 (--*---) ----+---------+---------+---------+----36.0 38.0 40.0 42.0 Pooled StDev = 0.620 Regression Model [Step 4]: Stat > Regression > Fitted Line Plot 1. response : hardness 2. Factor : temp 3. Type of Regression Model : Quadratic • Graph > click 1. Standardized 2. Residual plots > Four in one 3. Residuals versus the variables : temp • Options >click 1. Display confidence interval 2. Display prediction interval 3. Confidence level : 95.0 Fitted Line Plot Hardness = - 419.6 + 5.844 Temp - 0.01850 Temp**2 Regression 95% CI 95% PI 43 42 S R-Sq R-Sq(adj) 40 39 38 37 36 35 34 140 145 150 155 Temp 160 165 170 Residuals Versus Temp (response is Hardness) 2 Standardized Residual Hardness 41 1 0 -1 -2 140 145 150 155 Temp 160 165 170 0.647807 93.5% 92.5% Residual Plots for Hardness Normal Probability Plot of the Residuals Standardized Residual 99 90 Percent Residuals Versus the Fitted Values 50 10 1 -2 -1 0 1 Standardized Residual 2 2 1 0 -1 -2 35.0 Histogram of the Residuals Standardized Residual Frequency 2 1 -2 -1 0 1 Standardized Residual 42.5 Residuals Versus the Order of the Data 3 0 37.5 40.0 Fitted Value 2 2 1 0 -1 -2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Observation Order Polynomial Regression Analysis: Hardness versus Temp The regression equation is Hardness = - 419.6 + 5.844 Temp - 0.01850 Temp**2 S = 0.647807 R-Sq = 93.5% R-Sq(adj) = 92.5% Analysis of Variance Source Regression Error Total DF 2 13 15 SS MS F P 78.3045 39.1522 93.30 0.000 5.4555 0.4197 83.7600 Sequential Analysis of Variance Source DF SS F P Linear 1 23.5445 5.47 0.035 Quadratic 1 54.7600 130.49 0.000 Experiments with Two Factors : The Analysis of Variance Factors : A, B No replication test No information on interaction between factors y = f(A, B) Replication test show the effect of interaction y = f(A, B, AB) Tests of the effect of reaction time and pressure on the strength of product time pressure 100 psi 110 psi 120 psi 130 psi 100 min 105 min 110 min 305 322 320 302 325 322 335 350 342 337 348 344 366 326 338 364 324 336 372 330 348 374 330 348 [Step 1]: Input Data tim e P ressure S trength 100 100 305 100 100 302 100 110 335 100 110 337 100 120 366 100 120 364 100 130 372 100 130 374 105 100 322 105 100 325 105 110 350 105 110 348 105 120 326 105 120 324 105 130 330 105 130 330 110 100 320 110 100 322 110 110 342 110 110 344 110 120 338 110 120 336 110 130 348 110 130 348 [Step 2]: Stat > ANOVA > Two - Way 1. Response : strength 2. Row factor: time √ Display means 3. Column factor : pressure √ Display means 4. Confidence level: 95.0 • Graph > click 1. √ Individual value plot 2. Residual plots: √ four in one Two-way ANOVA: Strength versus time, Pressure Source DF time 2 Pressure 3 Interaction 6 Error 12 Total 23 S = 1.443 SS 629.08 4059.33 3565.92 25.00 8279.33 R-Sq = 99.70% MS F P 314.54 150.98 0.000 1353.11 649.49 0.000 594.32 285.27 0.000 2.08 R-Sq(adj) = 99.42% Individual 95% CIs For Mean Based on Pooled StDev time Mean ---+---------+---------+---------+-----100 344.375 (--*--) 105 331.875 (--*-) 110 337.250 (--*--) ---+---------+---------+---------+-----332.0 336.0 340.0 344.0 Individual 95% CIs For Mean Based on Pooled StDev Pressure Mean -----+---------+---------+---------+---100 316.000 (*) 110 342.667 (-*) 120 342.333 (*-) 130 350.333 (*-) -----+---------+---------+---------+---320 330 340 350 Individual Value Plot of Strength vs time, Pressure 380 370 Strength 360 350 340 330 320 310 300 Pressure time 100 110 120 130 100 100 110 120 130 105 100 110 120 130 110 Residual Plots for Strength Normal Probability Plot of the Residuals Residuals Versus the Fitted Values 99 1 Residual Percent 90 50 10 1 0 -1 -2 -1 0 Residual 1 2 300 Histogram of the Residuals 320 340 Fitted Value 360 380 Residuals Versus the Order of the Data 1 6 Residual Frequency 8 4 2 0 0 -1 -1.6 -0.8 0.0 Residual 0.8 1.6 2 4 6 8 10 12 14 16 18 20 22 24 Observation Order [Step 2]: Stat > ANOVA > Analysis of Means 1. Response : strength 2. √ Normal - Factor 1: time - Factor 2: pressure Two-Way ANOM for Strength by time, Pressure Alpha = 0.05 Interaction Effects Effect 20 2.54 0 -2.54 0 -20 Pressure 100 time 100 110 120 130 100 105 110 120 Main Effects for time 110 120 130 Main Effects for Pressure 344 340 338.95 337.83 336.72 335 Mean Mean 100 110 356 345 330 130 339.28 337.83 336.38 332 320 100 105 time 110 100 110 120 Pressure 130 [Step 3]: Stat > ANOVA > Interval plot (Interval of mean) 1. √ Multiple Y’s (with group) 2. Graph variable: Strength 3. Categorical variable : C2-C2 Interval Plot of Strength vs time, Pressure 95% CI for the Mean 400 Strength 375 350 325 300 Pressure time 100 110 120 130 100 100 110 120 130 105 100 110 120 130 110 [Step 3]: Stat > ANOVA > Main effect plot 1. Response : strength 2. Factors : time, pressure Main Effects Plot (data means) for Strength time Pressure 350 Mean of Strength 345 340 335 330 325 320 315 100 105 110 100 110 120 130 [Step 3]: Stat > ANOVA > Interactions effect 1. Response : strength 2. Factors : time, pressure Interaction Plot (data means) for Strength 380 time 100 105 110 370 360 Mean 350 340 330 320 310 300 100 110 120 Pressure 130