The Creation of a Water Supply Design Tool

advertisement

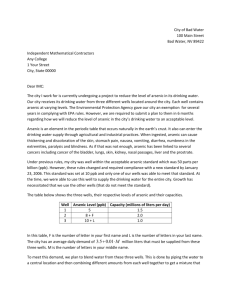

Image adapted from www.water4people.org Arsenic Remediation in Bangladesh/Nepal: The 3-kalshi Method vs. The Arsenic BioSand Filter vs. Well head removal Stephanie Arbelovsky Andrea Hektor Christina Hynes (team typhoidfun) Overview • Arsenic in Bangladesh • 3-kalshi Method • Arsenic Biosand Filter (ABF) • Well-head removal • Pteris vittata • Conclusion Contamination: Timeline • Pre-1970: Microbial contaminated surface water • 1970: 2.5 million tubewells drilled • 1990: 95% of population dependant on groundwater • 1993: Widespread arsenic contamination – 60% of wells above WHO guideline (10 ppb) – 30% of wells above Bangladesh guideline (50 ppb) THE 3-KALSHI METHOD Construction • • • • • • 3 kalshis Stand (steel or bamboo) Course/Fine sand Wood charcoal Iron filings Synthetic fabric Photo courtesy Susan Murcott Removal processes • Zero-valent iron – Arsenate (V) / Iron Oxides • Precipitation – Arsenite (III) / Fe (II) FeAsO4 , also AlAsO4 • Adsorption – Arsenate (V) / Fe(OH) 3 • Filtration Computer image courtesy Sandia National Laboratories Effectiveness • Khan’s Study: – As(III) removal from 800 ppb to less than 2 ppb – Final As(total) concentration less than 10 ppb • Hurd’s Study: – As(total) removal from 215 ppb to 4 ppb Flow rate • • • • 3 L water/day for adults recommended 3-kalshi provided 42-148 L/day (Khan) Efficiency decreases with increased flow rate Inconsistencies in the literature Flow Rate vs Final Arsenic Content Filtered Arsenic Content (ppb) Coal 754 gm Coal 606 gm Coal 757 gm 300 250 200 150 100 50 0 0 5 10 15 Flow Rate (L/hr) 20 25 Advantages • • • • Inexpensive, locally manufactured materials Point-of-use technology Uses existing tubewell infrastructure Easy to construct and operate ARSENIC BIOSAND FILTER Arsenic BioSand Filter (ABF) • A household-level drinking water filter developed at MIT to simultaneously remove arsenic & pathogens from tubewell water. • 3-month pilot study (Sep 2002 to Jan 2003) conducted in Nepal – Evaluated performance of filter under various conditions – Investigated long-term removal efficiencies – Improved filter design – Implemented filters in arsenicaffected villages http://ceemeng.mit.edu/~water/Docs/Other%20Documents/NgaiWa lewijk-%20ABF%20Report2003.pdf Integration of 2 Removal Units Arsenic Removal Unit • Metal Diffuser Box, Iron Nails, and Polyester Cloth Pathogen Removal Unit • Sand and Gravel Layers . . . So, Why Iron Nails?? • Ferrous hydroxide (iron rust) is an excellent absorbent for arsenic • Surface complexion reaction occurs when aqueous arsenic species come into contact with ferrous hydroxide How Does Arsenic Removal Work?? • Iron nails rust when exposed to air and water • Arsenic absorbed to ferrous hydroxide (FH) particles • Some arsenic loaded FH particles trapped by polyester cloth • Most settle on top of fine sand layer ABF Manufacturing •Can be entirely constructed with locally available materials and local labor Concrete ABF’s were constructed by International Buddhist Society Metal diffuser boxes manufactured in a metal shop in Kathmandu ABF Installation Materials needed: • A concrete ABF (including metal box and lid • 2 bottles of Piyush – A locally manufactured calcium hypochlorite solution used initially to disinfect the filter • 2.5 L gravel (above 6-15 mm grain size) – Can be collected from local river • 2.5 L sand (1-6 mm grain size) • ~30 L of fine sand (less than 1 mm grain size) • 1 piece of polyester cloth (30 by 30 cm) • 5 kg iron nails ABF Cleaning • Remove metal box • Scrape top 2 cm of fine sand layer by hand • Remove top layer of water with small container • Replace with arsenic-free water • Repeat process several times • Replace metal box and lid Results • AFB found to be effective removing: – – – – Arsenic: 85 – 96%, mean 93% Total Coliform: 0 - >99%, mean 58% E. coli: 0 - >99%, mean 64% Iron: >90 - >97%, mean >93% Users Liked. . . • • • • • High flow rates (~14 L/hr) Simple operation Minimal maintenance Clean-looking, good tasting water Think that the ABF is a durable, permanent solution to their drinking water problems!! WELL HEAD REMOVAL Larger Scale Treatment • Starting in 1998, Bengal Engineering College has installed in the Parganas and Nadia regions. • Initial installation costs Rs. 50,000 ($1250), but can provide water for two to three hundred households. • Utilizes activated alumina to adsorb arsenic. • Column lasts 10 to 15 years, but must be regenerated with caustic soda every 4 months. • Alumina found to be most effective, cost-efficient method of removing arsenic. • Arsenic sludge generated in a 4-month period amounts to less than 2 liters of sludge. • Requires no electricity. • Villagers understand basic operating principles of the units, and collectively help with day-to-day operations. • Tradition/routine of pumping water is not disturbed. • In all 8 locations, families pay approximately Rs. 50 per month for maintenance and operating costs. The poor are exempt. Pteris vittata: Plant Technology? • Fern native to Asia and Africa. Commonly called Chinese Brake Fern. • Can remove arsenic directly from water in a process called phytofiltration. • Also able to hyperaccumulate arsenic from the soil. Generally around 22,630 mg of arsenic per kilogram of dry fern shoots/fronds. • In phytofiltration, arsenic water concentrations of 200 micrograms/liter by 100-fold in 24 hours. • Squeezing sap from the plants in a press removes ¾ of the arsenic in the plant. This arsenic can then be used for industrial purposes. • Researchers determining feasibility/safety of burning plants for fuel. Further Research • Further study on flow rate / efficiency relationship • Lifetime of the system • Cheaper • Increased arsenic removal Final Thoughts • Tubewell investment • Perception of threat • Cost • Testing capability • Few researchers, extrapolated ideas • • • • • • • http://www.annieappleseedproject.org/ptervitfersu.html http://ceemeng.mit.edu/~water www.who.org www.undp.org www.unicef.org http://www.irc.nl/content/view/full/10354 http://www.pubmedcentral.nih.gov/articlerender.fcgi?artid =166674 • http://www.genomenewsnetwork.org/articles/2004/08/06/f ern.php • http://pubs.acs.org/subscribe/journals/esthagw/2001/may/science/kc_fern.html • http://www.science-writer.co.uk/award_winners/2028_years/2004/winner.html