Cell and Tissue Engineering Nanotechnology - Dr

advertisement

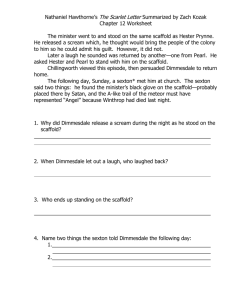

Liu Nanobionics Lab Micro and Nanotechnology Laboratory UNIVERSITY OF ILLINOIS AT URBANA - CHAMPAIGN Cell and Tissue Engineering Nanotechnology Yi Chen Outline • What is Tissue Engineering • What is Nanotechnology • Why we apply Nanotechnology to Tissue Engineering • How is Nanotechnology applied to Tissue Engineering – Different nanofabrication techniques – Applications Tissue Engineering Expand number in culture Remove cells from the body. Seed onto an appropriate scaffold with suitable growth factors and cytokines Re-implant engineered tissue repair damaged site Place into culture Tissue Engineering Hydrogels Nanofibrous scaffolds Self-assembling scaffolds Solid freeform fabricated scaffolds Differentiated cells Adult stem cells Embryonic stem cells Cells Scaffolds Tissue Engineering Biorectors Dynamic cell seeding Improved mass transfer Mechanical stimuli Signals Small molecules Growth factors/polypeptides Nucleic acids (DNA, siRNA, and antisense oligonucleotides) Nanotechnology and Tissue Engineering: The Scaffold, CRC Press; 1 edition (June 16, 2008) Nanotechnology Overview Nanotechnology is a branch of science and engineering which deals with structures and devices in nanometer scale. View & Characterize Optical Microscopy Electron Microscopy Atomic Force Microscopy Create & Manipulate Nanofabrication: (Top down & Bottom up) Lithography (Optical, E-beam, NIP, DPL) Etching (Wet Etching, Plasma Etching) Deposition (Evaporation, PECVD, Electrochemical Deposition, Sputtering, etc.) Epitaxial growth (MOCVD, MBE, etc.) Why we apply Nanotech in TE? Cells on microfibrous scaffolds have a polarized relationship, with one side of the cell attached to the scaffold, the other exposed to physiological media. In comparison, it is likely that cells are more naturally constrained by nanofibrous scaffolds. Nanofibrous Scaffold • Electrospinning • Self-Assembly Electrospinning • This process involves the ejection of a charged polymer fluid onto an oppositely charged surface. • Multiple polymers can be combined • Control over fiber diameter and scaffold architecture Research on Parameters of Electrospinning Process • Solution properties Viscosity Conductivity Surface tension Polymer molecular weight Dipole moment Dielectric constant • Controlled variables Flow rate Electric field strength Distance between tip and collector Needle tip design Collector composition and geometry • Ambient parameters Temperature Humidity Air velocity Tissue Engineering. May 2006, 12(5): 1197-1211. Research on Materials • Polyglycolic acid (PGA) – Highly crystalline, hydrophilic, byproduct is glycolic acid • Polylactic acid (PLA) – Hydrophobic, lower melting temperature, byproduct is lactic acid • Polydioxanone (PDO) – Highly crystalline • Polycaprolactone (PCL) – Semi-crystalline properties, easily co-polymerized, byproduct caproic acid • Blends – – – – PGA-PLA PGA-PCL PLA-PCL PDO-PCL • • • • • Elastin Gelatin collagen Fibrillar collagen Collagen blends Fibrinogen • Synthetic polymers PGA, PLA and PLGA most commonly used PDO most similar to Elastin collagen blend (limited by shape memory) PCL most elastic and mixed frequenlty with other material s Provide nanoscale physical features • Natural polymers Collagen Type I & III + PDO: best possible match for blood vessels Advanced Drug Delivery Reviews Volume 59, Issue 14, 10 December 2007, Pages 1413-1433 Self Assembly Figure 1: Fabrication of various peptide materials. Figure 2: Self-assembling peptides form a three-dimensional scaffold woven from nanofibers ~ 10 nm in diameter. (a) Representation of self-assembling peptide. (b) Electron micrograph of three-dimensional scaffold formed in vitro. (c) Rat hippocampal neurons form active nerve connections; each green dot represents a single synapsis. (d) Neural cells from a rat hippocampal tissue slide migrate on the three-dimensional peptide scaffold. Cells on the polymer membrane (left) and on the peptide scaffold (right) are shown. Both glial cells (green) and neural progenitors (red) migrate into the three-dimensional peptide scaffold. (e) Brain damage repair in hamster. The peptide scaffold was injected into the optic nerve, which was first severed with a knife. The cut was sealed by the migrating cells after 2 days. A great number of neurons form synapses. (f) Chondrocytes from young and adult bovine encapsulated in the peptide scaffold. These cells not only produce a large amount of glycosaminoglycans (purple) and type II collagen (yellow), characteristic materials found in cartilage, but also a cartilage-like tissue in vitro53. (g) Adult rat liver progenitor cells encapsulated in the peptide scaffold. The cells on the two-dimensional dish did not produce cytochrome P450–type enzymes (left). However, cells in three-dimensional scaffolds showed cytochrome P450 activity (right). Nature Biotechnology 21, 1171 - 1178 (2003) Self Assembly Figure 3: Lipid, peptide and protein scaffold nanowires. Figure 4: Microlenses and fiber-optics fabricated from protein scaffolds. Nature Biotechnology 21, 1171 - 1178 (2003) Self-Assembling Peptide Scaffolds for Regenerative Medicine SAPNS heals the brain in young animals. SAPNS allows axons to regenerate through the lesion site in brain. PNAS March 28, 2006 vol. 103 no. 13 5054-5059 Phase separation • • • This process involves dissolving of a polymer in a solvent at a high temperature followed by a liquid–liquid or solid–liquid phase separation induced by lowering the solution temperature Capable of wide range of geometry and dimensions include pits, islands, fibers, and irregular pore structures Simpler than self-assembly a) powder, b) scaffolds with continuous network, c) foam with closed pores SEM of nanofibrous scaffold with interconnected spherical macropores Advanced Drug Delivery Reviews Volume 59, Issue 14, 10 December 2007, Pages 1413-1433 Carbon Nanotube Cell tracking and labeling Sensing cellular behavior Augmenting cellular behavior Augmenting cellular behavior Cytotoxicity Murine myoblast stem cells incubated with DNA-encapsulated nanotubes neuron bridging an array of carbon nanotubes thereby creating neural networks. Biomaterials Volume 28, Issue 2, January 2007, Pages 344-353 Block Coploymer Synthetic scheme of block copolymers. In vitro release profile of FITClabelled dextran (Mr 20,000) from PEO–PLLA–PEO (Mr 5,000–2,040– 5,000) triblock copolymer. Injectable drug-delivery system Gel–sol transition curves. Science 30 May 1997: Vol. 276. no. 5317, pp. 1401 - 1404 Nature 388, 860-862 (28 August 1997) Printing Technology • Nanoimprinting Lithography • Organ Printing • Contact Printing Nanoimprinting Lithography Prof. Stephen Y. Chou Thermal-sensitive Polymer Optical-sensitive Polymer Nanopattern-induced changes in morphology and motility of smooth muscle cells Alignment and elongation characterization Wound healing assay for cell motility SMC morphology BrdU cell proliferation assay Biomaterials Volume 26, Issue 26, September 2005, Pages 5405-5413 Organ printing: computer-aided jet-based 3D tissue engineering Fig. 1. Fusion of embryonic myocardial ring. Myocardium rings were cut from Stage 15–16 HH chick ventricle, containing only myocardium, endocardium and some intervening matrix. Isolated rings beat steadily for several days; (a) adjacent apposed rings fused overnight and (b) beat as one. (c). Schematic representation of principle of organ printing technology: placing of cell aggregates layer by layer in solidifying thermo-reversible gel with sequential cell aggregate fusion and morphing into 3D tube. Fig. 2. Cell printer and images of printed cells and tissue constructs. Fig. 3. (a) Printed bagel-like ring that consists of several layers of sequentially (layer-by-layer) deposited collagen type 1 gel. (b) Manually printed living tube with radial branches from the chick 27stage HH embryonic heart cushion tissue placed in 3D collagen type 1 gel. Trends Biotechnol. 2003 Apr;21(4):157-61. Contact Printing J. Am. Chem. Soc., 2005, 127 (48), pp 16774–16775 Advanced Materials Volume 19 Issue 24, Pages 4338 - 4342 Summary • Nanofibrous Scaffold – Electrospinning – Self-Assembly • Nanoporous Scaffold – Phase Separation • Carbon Nanotube • Block Copolymer • Printing – Nanoimprinting Lithography – Organ Printing – Contact Printing Lab Chip, 2004, 4, 98 - 103 References Nanotechnology and Tissue Engineering: The Scaffold, CRC Press; 1 edition (June 16, 2008) Quynh P. Pham, Upma Sharma, Ph.D., Dr. Antonios G. Mikos, Electrospinning of Polymeric Nanofibers for Tissue Engineering Applications: A Review, Tissue Engineering. May 2006, 12(5): 1197-1211. Catherine P. Barnes, Scott A. Sell, Eugene D. Boland, David G. Simpson, Gary L. Bowlin, Nanofiber technology: Designing the next generation of tissue engineering scaffolds, Advanced Drug Delivery Reviews, Volume 59, Issue 14, Intersection of Nanoscience and Modern Surface Analytical Methodology, 10 December 2007, Pages 1413-1433, ISSN 0169-409X, DOI: 10.1016/j.addr.2007.04.022. Shuguang Zhang, Fabrication of novel biomaterials through molecular self-assembly, Nature Biotechnology 21, 1171 - 1178 (2003) Rutledge G. Ellis-Behnke, Yu-Xiang Liang, Si-Wei You, David K. C. Tay, Shuguang Zhang, Kwok-Fai So, and Gerald E. Schneider, Nano neuro knitting: Peptide nanofiber scaffold for brain repair and axon regeneration with functional return of vision PNAS 2006 103 (13) 5054-5059 Benjamin S. Harrison, Anthony Atala, Carbon nanotube applications for tissue engineering, Biomaterials, Volume 28, Issue 2, Cellular and Molecular Biology Techniques for Biomaterials Evaluation, January 2007, Pages 344-353, ISSN 0142-9612, DOI: 10.1016/j.biomaterials.2006.07.044. Miri Park, Christopher Harrison, Paul M. Chaikin, Richard A. Register, Douglas H. Adamson, Block Copolymer Lithography: Periodic Arrays of ~1011 Holes in 1 Square Centimeter, Science 30 May 1997: Vol. 276. no. 5317, pp. 1401 - 1404 Byeongmoon Jeong, You Han Bae, Doo Sung Lee and Sung Wan Kim, Biodegradable block copolymers as injectable drugdelivery systems, Nature 388, 860-862 (28 August 1997) Evelyn K.F. Yim, Ron M. Reano, Stella W. Pang, Albert F. Yee, Christopher S. Chen, Kam W. Leong, Nanopattern-induced changes in morphology and motility of smooth muscle cells, Biomaterials, Volume 26, Issue 26, September 2005, Pages 5405-5413, ISSN 0142-9612, DOI: 10.1016/j.biomaterials.2005.01.058. Mironov V, Boland T, Trusk T, Forgacs G, Markwald RR. Organ printing: computer-aided jet-based 3D tissue engineering. Trends Biotechnol. 2003 Apr;21(4):157-61. Yu, A. A.; Stellacci, F., Contact Printing beyond Surface Roughness: Liquid Supramolecular Nano-Stamping, Advanced Materials, 19, 4338-4342, 2007 Yu A.A., Savas T., Cabrini S., diFabrizio E., Smith H.I., Stellacci F., High resolution printing of DNA features on poly(methyl methacrylate) substrates using supramolecular nano-stamping, J. Am. Chem. Soc., 127, 16774-16775, 2005